ASTM D146-04

(Test Method)Standard Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing

Standard Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing

ABSTRACT

These test methods cover the sampling and examination of felts and woven fabrics, saturated or impregnated but not coated with asphaltic or coal-tar materials, for use in waterproofing or for the construction of built-up roof coverings. After appropriate sampling, representative specimens shall be examined for the mass of wrapping material and mandrel (core), net mass per unit area, appearance and dimension of rolls, detached comminuted surfacing, moisture, strength, pliability, and loss on heating. Consequently, desaturated felt or fabric shall be examined for weight, retained carbonaceous matter, total comminuted surfacing, bituminous saturant, thread count of fabrics, thickness of felts, and ash content.

SCOPE

1.1 These test methods cover the sampling and examination of felts or woven fabrics, saturated or impregnated but not coated with asphaltic or coal-tar materials, for use in waterproofing or for the construction of built-up roof coverings.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D146 – 04

Standard Test Methods for

Sampling and Testing Bitumen-Saturated Felts and Woven

1

Fabrics for Roofing and Waterproofing

This standard is issued under the fixed designation D146; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D4312 Test Method for Toluene-Insoluble (TI) Content of

Tar and Pitch (Short Method)

1.1 These test methods cover the sampling and examination

of felts or woven fabrics, saturated or impregnated but not

3. Sampling

coated with asphaltic or coal-tar materials, for use in water-

3.1 From each shipment of the specified saturated felt or

proofing or for the construction of built-up roof coverings.

fabric, select at random a number of rolls equal to one half the

1.2 The values stated in SI units are to be regarded as the

cube root of the total number of rolls in the lot. If the

standard. The values in parentheses are for information only.

specification requires sampling during manufacture, consider

1.3 This standard does not purport to address all of the

thelottobetheplannedproductionquantityandselecttherolls

safety concerns, if any, associated with its use. It is the

at uniformly spaced time intervals throughout the production

responsibility of the user of this standard to establish appro-

period. The minimum sample shall consist of five rolls. If the

priate safety and health practices and determine the applica-

calculated number is fractional, express it as the next highest

bility of regulatory limitations prior to use.

whole number. For convenience, the following table, showing

2. Referenced Documents the number of rolls to be selected from lots of various sizes, is

2

given:

2.1 ASTM Standards:

Number of Rolls in Shipment Number of Rolls in Sample

D95 Test Method for Water in Petroleum Products and

Bituminous Materials by Distillation

Up to 1 000 5

D645/D645M Test Method for Thickness of Paper and 1 001 to 1 728 6

3

1 729 to 2 744 7

Paperboard

2 745 to 4 096 8

D828 Test Method for Tensile Properties of Paper and

4 097 to 5 832 9

Paperboard Using Constant-Rate-of-Elongation Appara- 5 833 to 8 000 10

3

8 001 to 10 648 11

tus

10 649 to 13 842 12

D1079 Terminology Relating to Roofing andWaterproofing

13 843 to 17 576 13

D1682 Methods of Test for Breaking Load and Elongation

17 577 to 21 952 14

3

of Textile Fabrics

The rolls so selected constitute the representative sample

D1910 Methods of Test for Construction Characteristics of

used for all subsequent observations and tests pertaining to the

3

Woven Fabrics

lot of material being examined. Identify each individual roll.

D4072 Test Method for Toluene-Insoluble (TI) Content of

Tar and Pitch

EXAMINATION OF REPRESENTATIVE SAMPLE

4. Gross Mass per Roll

1

These test methods are under the jurisdiction of ASTM Committee D08 on

1

4.1 Weigh each roll, intact, to the nearest 100 g ( ⁄4 lb), and

Roofing and Waterproofing and are the direct responsibility of Subcommittee

D08.04 on Felts and Fabrics. record each weight as the gross mass of that roll.

Current edition approved Aug. 1, 2004. Published August 2004. Originally

approved in 1922. Last previous edition approved in 2003 as D146 – 03. DOI:

5. Mass of Wrapping Material and Mandrel (Core)

10.1520/D0146-04.

2

5.1 Strip each roll of its wrappings and weigh it to the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nearest 100 g ( ⁄4 lb). If mandrels (cores) are used, collect them

Standards volume information, refer to the standard’s Document Summary page on

after the rolls are unwound and weigh them together, to the

the ASTM website.

1

3 nearest 100 g ( ⁄4 lb). Calculate the average mass of the

Withdrawn. The last approved version of this historical standard is referenced

wrappings and mandrels per roll and record.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

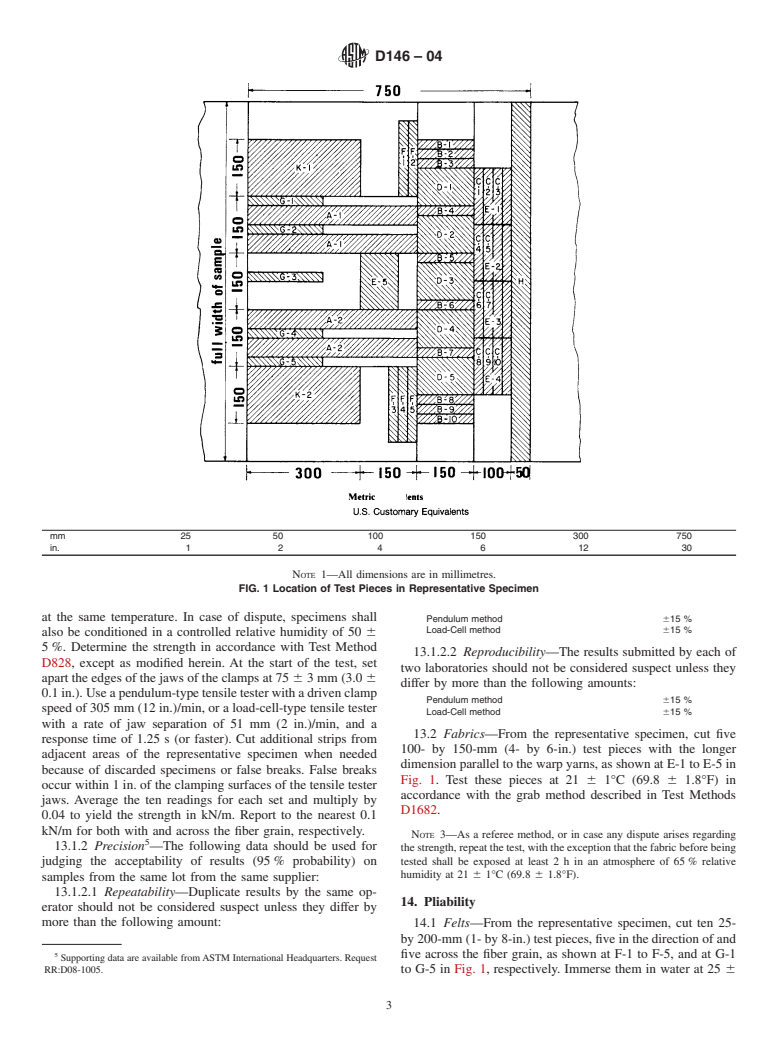

---------------------- Page: 1 ----------------------

D146 – 04

6. Mandrels (Cores) For Fabrics:

2 2

6.1 Determinetheshapeofthecrosssectionofthemandrels

g/m 5 1333.3 D/E ~ oz/yd 5 1.5238 D/E! (4)

(cores) and report. If circular, measure the outside diameter to

1

thenearest1mm( ⁄32in.).Ifsquare,measureeachoutsideedge

where:

1

to the nearest 1 mm ( ⁄32 in.). Measure and report the length of

D = mass of the specimen, g, and

the mandrel projecting beyond each end of each roll to the

E = width of the specimen, mm (in.).

3

nearest 5 mm ( ⁄16 in.).

Th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.