ASTM B924-02(2006)

(Specification)Standard Specification for Seamless and Welded Nickel Alloy Condenser and Heat Exchanger Tubes With Integral Fins

Standard Specification for Seamless and Welded Nickel Alloy Condenser and Heat Exchanger Tubes With Integral Fins

ABSTRACT

This specification covers seamless and welded nickel alloy tubing with either or both external and internal surfaces have been modified by cold forming. The cold forming process produces an enhanced surface for improved heat transfer in the tubing that makes these ideal for use in surface condensers, evaporators, heat exchangers and other similar heat transfer apparatus. The material properties and manufacturing conditions of the seamless and welded materials should conform accordingly.

SCOPE

1.1 This specification describes seamless and welded nickel alloy tubing on which the external or internal surface, or both, has been modified by a cold forming process to produce an integral enhanced surface, for improved heat transfer. The tubes are used in surface condensers, evaporators, heat exchangers and similar heat transfer apparatus in unfinned end diameters up to and including 1 in. (25.4 mm).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary statement pertains to the test method portion only: Section 10 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B924 – 02 (Reapproved 2006)

Standard Specification for

Seamless and Welded Nickel Alloy Condenser and Heat

Exchanger Tubes With Integral Fins

This standard is issued under the fixed designation B924; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope (UNS N06600, N06601, N06603, N06690, N06693,

2 N06025, N06045, and N06696), Nickel-Chromium-

1.1 This specification describes seamless and welded

Cobalt-Molybdenum Alloy (UNS N06617), and Nickel-

nickel alloy tubing on which the external or internal surface, or

Iron-Chromium-Tungsten Alloy (UNS N06674) Seamless

both, has been modified by a cold forming process to produce

Pipe and Tube

an integral enhanced surface, for improved heat transfer. The

B407 Specification for Nickel-Iron-ChromiumAlloy Seam-

tubes are used in surface condensers, evaporators, heat ex-

less Pipe and Tube

changers and similar heat transfer apparatus in unfinned end

B423 Specification for Nickel-Iron-Chromium-

diameters up to and including 1 in. (25.4 mm).

Molybdenum-Copper Alloy (UNS N08825, N08221, and

1.2 The values stated in inch-pound units are to be regarded

N06845) Seamless Pipe and Tube

as standard. The values given in parentheses are mathematical

B444 Specification for Nickel-Chromium-Molybdenum-

conversions to SI units that are provided for information only

Columbium Alloys (UNS N06625 and UNS N06852) and

and are not considered standard.

Nickel-Chromium-Molybdenum-Silicon Alloy (UNS

1.3 The following precautionary statement pertains to the

N06219) Pipe and Tube

test method portion only: Section 10 of this specification. This

B468 Specification for Welded UNS N08020 Alloy Tubes

standard does not purport to address all of the safety concerns,

B515 Specification for Welded UNS N08120, UNS

if any, associated with its use. It is the responsibility of the user

N08800, UNS N08810, and UNS N08811 Alloy Tubes

of this standard to become familiar with all hazards including

B516 Specification for Welded Nickel-Chromium-Iron Al-

those identified in the appropriate Material Safety Data Sheet

loy (UNS N06600, UNS N06603, UNS N06025, and UNS

(MSDS) for this product/material as provided by the manufac-

N06045) Tubes

turer, to establish appropriate safety and health practices, and

B622 Specification for Seamless Nickel and Nickel-Cobalt

determine the applicability of regulatory requirements prior to

Alloy Pipe and Tube

use.

B626 Specification for Welded Nickel and Nickel-Cobalt

2. Referenced Documents

Alloy Tube

B674 Specification for UNS N08925, UNS N08354, and

2.1 ASTM Standards:

UNS N08926 Welded Tube

A941 Terminology Relating to Steel, Stainless Steel, Re-

B676 Specification for UNS N08367 Welded Tube

lated Alloys, and Ferroalloys

B677 Specification for UNS N08925, UNS N08354, and

B163 Specification for Seamless Nickel and Nickel Alloy

UNS N08926 Seamless Pipe and Tube

(UNS N06845) Condenser and Heat-Exchanger Tubes

B690 Specification for Iron-Nickel-Chromium-

B167 Specification for Nickel-Chromium-Iron Alloys

Molybdenum Alloys (UNS N08366 and UNS N08367)

Seamless Pipe and Tube

B704 Specification forWelded UNS N06625, UNS N06219

This specification is under the jurisdiction of ASTM Committee B02 on

and UNS N08825 Alloy Tubes

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys. B729 Specification for Seamless UNS N08020, UNS

Current edition approved Dec. 1, 2006. Published December 2006. Originally

N08026, and UNS N08024 Nickel-Alloy Pipe and Tube

approved in 2002. Last previous edition approved in 2002 as B924 - 02. DOI:

B751 Specification for General Requirements for Nickel

10.1520/B0924-02R06.

and Nickel Alloy Welded Tube

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-924 in Section II of that Code.

B829 Specification for General Requirements for Nickel

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Nickel Alloys Seamless Pipe and Tube

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B924 – 02 (2006)

B899 Terminology Relating to Non-ferrous Metals and

Alloys

E426 Practice for Electromagnetic (Eddy-Current) Exami-

nation of Seamless and Welded Tubular Products, Auste-

nitic Stainless Steel and Similar Alloys

E571 Practice for Electromagnetic (Eddy-Current) Exami-

nation of Nickel and Nickel Alloy Tubular Products

3. Terminology

3.1 For definition of general terms used in this specification,

FIG. 2 Outside and Inside Enhancement

refer to Terminologies A941 and B899.

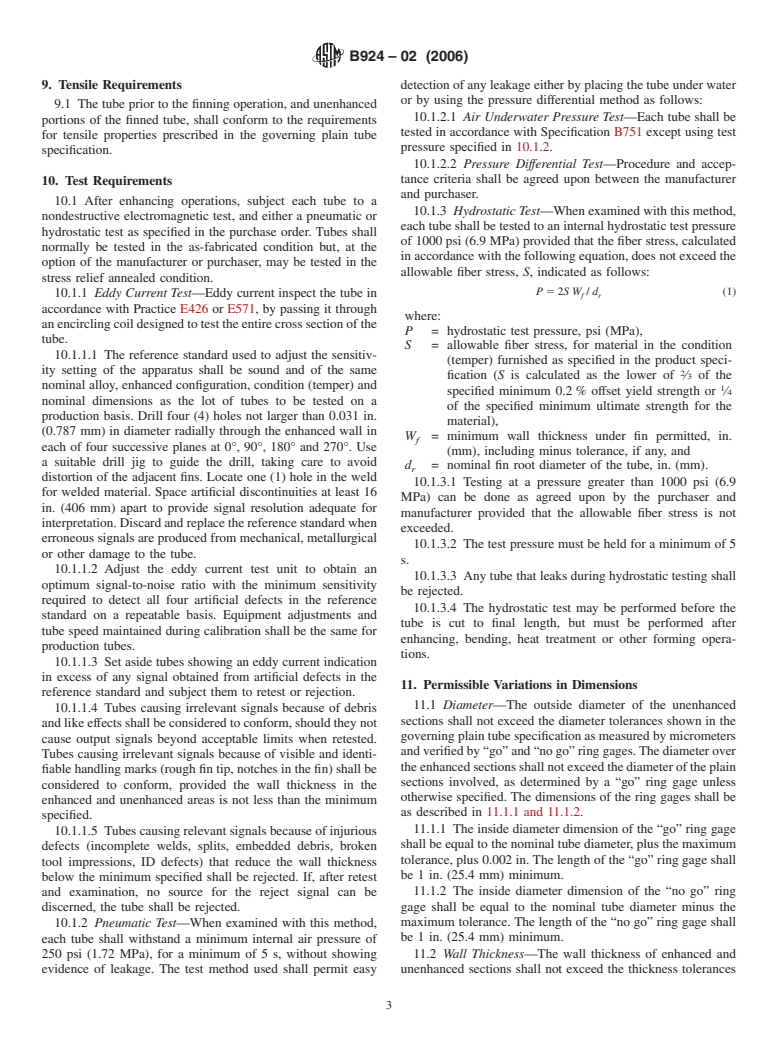

3.2 Definitions of Terms Specific to this Document (Integral

Fin Tube Nomenclature):

4.1.9 Nondestructive tests,

D = outside diameter of unenhanced section

4.1.10 Customer inspection,

D = inside diameter of unenhanced section

i

4.1.11 Mill test report, and

d = root diameter of enhanced section outside of tube

r

4.1.12 Certification.

d = outside diameter of enhanced section

o

d = inside diameter of enhanced section

i

5. General Requirements

W = wall thickness of unenhanced section

W = wall thickness of enhanced section 5.1 Seamless material furnished under this specification

f

F = height of fin—enhanced section outside of tube shall conform to the requirements of Specification B829,

h

F = mean fin thickness—enhanced section outside of tube unless otherwise provided herein.

m

P = mean rib pitch—enhanced section inside of tube

5.2 Welded material furnished under this specification shall

R = height of rib—enhanced section inside of tube conform to the applicable requirements of Specification B751,

h

H = rib helix angle—enhanced section inside of tube

unless otherwise provided herein.

a

T = transition taper 5.3 Enhanced (integrally finned) sections of the tube shall

t

be produced by cold forming the tubing in such a manner that

4. Ordering Information

exterior fins, wall under the fin and inside ribs (when specified)

4.1 It is the responsibility of the purchaser to specify all are homogeneous.

requirements that are necessary for material ordered under this 5.4 Tubes described by this specification shall be furnished

specification. Such requirements may include, but are not with unenhanced (plain) ends.

limited to, the following: 5.5 Enhanced sections of the tube are normally supplied in

4.1.1 ASTM designation and year of issue (this specifica- the “as finned” temper (cold worked condition produced by the

tion), enhancing operation). The unenhanced sections of the tube

4.1.2 ASTM designation and year of issue (plain tube shall be in the annealed condition and shall be suitable for

specification), rolling-in operations.

4.1.3 Welded or seamless,

4.1.4 Alloy grade and UNS designation, 6. Materials and Manufacture

4.1.5 Dimensions; plain tube outside diameter, plain tube

6.1 The integrally enhanced (finned) tubes shall be manu-

wall thickness (ave. or min. specified), length and location of

factured from seamless, welded, or welded/cold worked plain

unenhancedsurfacesandthetotaltubelength.Configurationof

tubes that conform to one of the following ASTM specifica-

enhanced surfaces (fins per unit length, fin height, wall

tions: B163, B167, B407, B423, B444, B468, B515, B516,

thicknessunderfin,ribpitch,ribheight,etc.)shallbeasagreed

B622, B626, B674, B676, B677, B690, B704, and B729.

upon between the manufacturer and purchaser. (Refer to Figs.

1 and 2).

7. Temper

4.1.6 Temper (as-finned or stress relief annealed),

7.1 The tube after enhancing shall normally be supplied in

4.1.7 Quantity,

the as-finned temper. When specified by the purchaser, for

4.1.8 Packaging,

bending, coiling or other fabricating operations, enhanced

portions of the tube may be stress relief annealed or solution

annealed.

7.2 Heat treatment of enhanced sections and bend areas, or

both, shall be in accordance with the governing plain tube

specification.

8. Chemical Composition

8.1 The tubing specified shall conform to the chemical

requirements prescribed in the governing plain tube specifica-

FIG. 1 Outside Enhancement Only tion.

B924 – 02 (2006)

9. Tensile Requirements detection of any leakage either by placing the tube under water

or by using the pressure differential method as follows:

9.1 The tube prior to the finning operation, and unenhanced

10.1.2.1 Air Underwater Pressure Test—Each tube shall be

portions of the finned tube, shall conform to the requirements

tested in accordance with Specification B751 except using test

for tensile properties prescribed in the governing plain tube

pressure specified in 10.1.2.

specification.

10.1.2.2 Pressure Differential Test—Procedure and accep-

tance criteria shall be agreed upon between the manufacturer

10. Test Requirements

and purchaser.

10.1 After enhancing operations, subject each tube to a

10.1.3 Hydrostatic Test—When examined with this method,

nondestructive electromagnetic test, and either a pneumatic or

each tube shall be tested to an internal hydrostatic test pressure

hydrostatic test as specified in the purchase order. Tubes shall

of 1000 psi (6.9 MPa) provided that the fiber stress, calculated

normally be tested in the as-fabricated condition but, at the

in accordance with the following equation, does not exceed the

option of the manufacturer or purchaser, may be tested in the

allowable fiber stress, S, indicated as follows:

stress relief annealed condition.

P 5 2SW / d (1)

10.1.1 Eddy Current Test—Eddy current inspect the tube in f r

accordance with Practice E426 or E571, by passing it through

where:

anencirclingcoildesignedtotesttheentirecrosssectionofthe

P = hydrostatic test pressure, psi (MPa),

tube.

S = allowable fiber stress, for material in the condition

10.1.1.1 The reference standard used to adjust the sensitiv-

(temper) furnished as specified in the product speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.