ASTM B579-73(2004)

(Specification)Standard Specification for Electrodeposited Coatings of Tin-Lead Alloy (Solder Plate)

Standard Specification for Electrodeposited Coatings of Tin-Lead Alloy (Solder Plate)

ABSTRACT

This specification establishes the requirements for mat, bright, and flow-brightened electrodeposited tin-lead alloy coatings on fabricated articles of iron, steel, copper, and copper alloys to protect them against corrosion, to improve and preserve solderability over long periods of storage, and to improve anti-galling characteristics. Sheets, strips, or wires in the unfabricated form, or threaded articles having a specified diameter, are not covered here. The classification notation shall include the type of basis metal, thickness of tin-lead coating required, service condition number indicating the severity of service required, and coating composition. Coatings shall be sampled, tested, and shall conform accordingly to specified requirements as to composition, appearance, thickness, adhesion (to be examined either by burnishing test, quenching test, reflow test, or bend test), and solderability (to be assessed either by non-automated or automated dip test, spread test, globule test, or artificial aging test).

SCOPE

1.1 This specification covers the requirements for electrodeposited tin-lead coatings on fabricated articles of iron, steel, copper, and copper alloys, to protect them against corrosion (Note 1), to improve and preserve solderability over long periods of storage, and to improve anti-galling characteristics. Note 1-Some corrosion of tin-lead coatings may be expected in outdoor exposure. In normal indoor exposure, tin-lead is protective on iron, copper, and copper alloys. Corrosion may be expected at discontinuities (pits or pores) in the coating. Porosity decreases as the thickness is increased. A primary use of the tin-lead coating (solder) is with the printed circuit industry as a solderable coating and as an etch mask material.

1.2 This specification applies to electrodeposited coatings containing a minimum of 50% and a maximum of 70% tin. The specification applies to mat, bright, and flow-brightened tin-lead coatings. Note 2-Tin-lead plating baths are composed of tin and lead fluoborates and of addition agents to promote stability. The final appearance may be influenced by the addition of proprietary brighteners. Without brighteners, the coatings are mat; with brighteners, they are semibright or bright. Flow-brightened coatings are obtained by heating mat coatings to above the melting point of tin-lead for a few seconds and then quenching; palm oil, hydrogenated oils, or fats are used as a heat-transfer medium at a temperature of 260 + 10°C (500 + 20°F), but other methods of heating are also in use. The maximum thickness for flow-brightening is about 7.5 [mu]m (0.3 mil); thicker coatings tend to reflow unevenly. The shape of the part is also a factor; flat surfaces tend to reflow more unevenly than wires or rounded shapes (Note 3). Note 3-Volatile impurities in tin-lead coatings will cause bubbling and foaming during flow-brightening resulting in voids and roughness. The impurities can arise from plating solution addition agents and from improper rinsing and processing.

1.3 This specification does not apply to sheet, strip, or wire in the unfabricated form or to threaded articles having basic major diameters up to and including 19 mm (0.75 in.).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B579 – 73 (Reapproved 2004)

Standard Specification for

Electrodeposited Coatings of Tin-Lead Alloy (Solder Plate)

This standard is issued under the fixed designation B579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This specification covers the requirements for electrode- 2.1 ASTM Standards:

posited tin-lead coatings on fabricated articles of iron, steel, B183 Practice for Preparation of Low-Carbon Steel for

copper, and copper alloys, to protect them against corrosion Electroplating

(Note 1), to improve and preserve solderability over long B242 Guide for Preparation of High-Carbon Steel for Elec-

periods of storage, and to improve anti-galling characteristics. troplating

B281 Practice for Preparation of Copper and Copper-Base

NOTE 1—Some corrosion of tin-lead coatings may be expected in

Alloys for Electroplating and Conversion Coatings

outdoor exposure. In normal indoor exposure, tin-lead is protective on

B322 Guide for Cleaning Metals Prior to Electroplating

iron, copper, and copper alloys. Corrosion may be expected at disconti-

B487 Test Method for Measurement of Metal and Oxide

nuities (pits or pores) in the coating. Porosity decreases as the thickness is

increased.Aprimaryuseofthetin-leadcoating(solder)iswiththeprinted

CoatingThicknessbyMicroscopicalExaminationofCross

circuit industry as a solderable coating and as an etch mask material.

Section

B499 Test Method for Measurement of Coating Thick-

1.2 This specification applies to electrodeposited coatings

nessesbytheMagneticMethod:NonmagneticCoatingson

containing a minimum of 50 % and a maximum of 70 % tin.

Magnetic Basis Metals

The specification applies to mat, bright, and flow-brightened

B504 Test Method for Measurement of Thickness of Me-

tin-lead coatings.

tallic Coatings by the Coulometric Method

NOTE 2—Tin-lead plating baths are composed of tin and lead fluobo-

B567 Test Method for Measurement of Coating Thickness

ratesandofadditionagentstopromotestability.Thefinalappearancemay

by the Beta Backscatter Method

be influenced by the addition of proprietary brighteners. Without bright-

B568 Test Method for Measurement of Coating Thickness

eners,thecoatingsaremat;withbrighteners,theyaresemibrightorbright.

Flow-brightened coatings are obtained by heating mat coatings to above by X-Ray Spectrometry

the melting point of tin-lead for a few seconds and then quenching; palm

E105 Practice for Probability Sampling Of Materials

oil, hydrogenated oils, or fats are used as a heat-transfer medium at a

E122 Practice for Calculating Sample Size to Estimate,

temperature of 260 6 10°C (500 6 20°F), but other methods of heating

With Specified Precision, the Average for a Characteristic

are also in use. The maximum thickness for flow-brightening is about 7.5

of a Lot or Process

µm (0.3 mil); thicker coatings tend to reflow unevenly. The shape of the

2.2 Other Standards:

part is also a factor; flat surfaces tend to reflow more unevenly than wires

MIL-STD-105 Sampling Procedures and Tables for Inspec-

or rounded shapes (Note 3).

NOTE 3—Volatile impurities in tin-lead coatings will cause bubbling

tion by Attributes

and foaming during flow-brightening resulting in voids and roughness.

MIL-STD-414 Sampling Procedures and Tables for Inspec-

The impurities can arise from plating solution addition agents and from 3

tion by Variables for Percent Defective

improper rinsing and processing.

3. Classification and Service Condition

1.3 This specification does not apply to sheet, strip, or wire

in the unfabricated form or to threaded articles having basic

3.1 Orders for articles to be plated in accordance with this

major diameters up to and including 19 mm (0.75 in.).

specificationshallspecify,inadditiontotheASTMdesignation

1 2

This specification is under the jurisdiction of ASTM Committee B08 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

B08.08.04 on Soft Metals. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2004. Published April 2004. Originally the ASTM website.

approved in 1973. Last previous edition approved in 1999 as B579–73 (1999). DOI: AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

10.1520/B0579-73R04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B579 – 73 (2004)

number and year of issue, the classification notation indicating 5.2 Whenrequiredthebasismetalshallbesubjectedtosuch

the basis metal and thickness of tin-lead coating required, or polishing or buffing operations as are necessary to yield

the service condition number indicating the severity of service deposits with the desired final appearance (Section 6).

requiredforthecoating.Inaddition,whenspecifyingatin-lead 5.3 Proper preparatory procedures and thorough cleaning of

coating composition, the first number shall refer to the tin the basis metal surface are essential in order to assure satis-

content in percent. factory adhesion and corrosion performance of the coating.

3.1.1 Classification Notation: Accordingly, it is suggested that the following Practices for the

preparation of various basis metals for electroplating be

Symbol Classification

Fe/ Iron or steel basis metals

followed when appropriate: B183, B281, and B322 and Guide

Cu/ Copper or copper alloy basis metals

B242.

/Sn-Pb Tin-lead coating and its composition number, when re-

5.4 Whennecessary,preliminarysamplesshowingthefinish

quired; for example, Sn60-Pb40

Number Minimum coating thickness in micrometres

shallbesuppliedtoandapprovedbythepurchaser.Whererack

(5 to 50)

marks are inevitable, their location shall be the subject of

Suffix Letter agreement between supplier and purchaser.

f flow-brightened

b bright

6. Physical Composition

m mat

6.1 Composition—The tin-lead coating composition shall

An example of complete classification notation is as follows: Cu/Sn60-Pb40/5F

be as follows (Note 7):

Element Weight, %

3.1.2 Service Condition Number:

Tin (Sn) 50 to 70

No. Service Condition Lead (Pb) remainder

6.1.1 The tin percentage is calculated as follows:

4 very severe exposure

3 severe exposure

Tin, % 5 134.1 3 ~L/A 2 1! (1)

2 moderate exposure

1 mild exposure

NOTE 4—See Appendix X1 for additional description of exposure

where:

conditions and examples of typical end uses. The coating thicknesses

L = weight of lead coating, g, and

given for each service condition are guidelines and are not intended to be

A = weight of alloy coating, g.

absolute values.

NOTE 7—Only the tin content need be determined. Lead is usually

4. Significant Surfaces

determined by difference. A sample of the deposit can be obtained by

plating on a stainless steel panel from which the coating can be peeled or

4.1 Significant surfaces are defined as those surfaces nor-

by employing any recognized stripping method. The alloy composition of

mally visible (directly or by reflection) that are essential to the

the deposit can be determined by methods such as gravimetric or

appearance or serviceability of the article when assembled in

volumetricanalysis,densitymeasurements,atomicabsorptionspectropho-

normal position; or those surfaces that can be the source of

tometry, X-ray fluorescence, and beta backscatter.

corrosion products that will deface visible surfaces on the

In addition, the alloy composition produced by a plating solution may

assembled article. When necessary, the significant surfaces be obtained by comparing the weight of a tin-lead coating deposited by a

given number of ampere-hours to the weight of lead coating produced in

shall be indicated on the drawing of the part, or by the

a lead fluoborate coulometer in series with the plating bath.

provision of suitably marked samples.

6.2 Appearance—The tin-lead coating shall be smooth, fine

NOTE 5—When significant surfaces include areas on which the speci-

grained, continuous, adherent, and shall be free of visible

fied thickness of deposit cannot readily be controlled, such as threads,

blisters, pits, nodules, indications of burning, excessive build-

holes, deep recesses, bases of angles, and similar areas, the purchaser and

up, staining, and other defects. Flow-brightened coatings shall

themanufacturershouldrecognizethenecessityforeitherthickerdeposits

on the more accessible surfaces or for special racking. Special racks may

not have dewetted areas or beads, and shall be free of the oil

involve the use of conforming, auxiliary bipolar electrodes, or noncon-

used in the fusion process.

ducting shields.

6.3 Thickness—The thickness of the coating on significant

surfacesshallconformtotherequirementsinTable1andTable

5. Materials and Manufacture

5.1 Defects in the surface of the basis metal, such as

TABLE 1 Tin-Lead Alloy Coatings on Steel

scratches, porosity, nonconducting inclusions, roll and die

Minimum

marks, cold shuts, and cracks, may adversely affect the

Service Classification

Thickness

appearance and the performance of coatings applied thereto

Condition Number

µm mil

despite the observance of the best plating practices. Accord-

A

SC4 Fe/SnPb 30 30 1.2

ingly, the plater’s responsibility for defects in the coating

A

SC3 Fe/SnPb 20 20 0.8

resultingfromsuchconditionsshallbewaived,exceptwhenhe

SC2 Fe/SnPb 10 10 0.4

is also in the position of prime contractor supplying plated

SC1 Fe/SnPb 5 5 0.2

B

SC1 Fe/SnPb 5f 50.2

parts.

A

An undercoat of 2.5 µm (0.1 mil) copper is recommended for SC3 and SC4.

NOTE 6—In order to minimize problems of this sort, the specifications B

f = flow brightened or

covering the basis material or the item to be plated should contain

m = mat or

appropriate limitations on such basis metal conditions. b=bright

B579 – 73 (2004)

2. testing of lots of coated items. In order that the manufacturer

6.3.1 Thickness Measurements—Tin-lead alloy thickness (plater) may know the quality standard he is expected to meet,

measurements shall be made on those areas of the significant the plan selected should be made part of the purchase contract.

surfaces where the coating would be expected to be thinnest. 8.2 General information on sampling procedures is given in

The method of determining the thickness shall be agreed upon Recommended Practices E105 and E122. Standard sampling

by the manufacturer and purchaser. Several methods are plans are suggested in Military Standards MIL-STD-105 and

availabledependinguponthethicknessofcoating,theshapeof MIL-STD-414.

the article, and the basis metal. They include beta backscatter,

9. Test Methods

coulometric, magnetic, microscopical, and X-ray fluorescence

9.1 Thickness:

test methods. The methods are outlined in 9.1.

9.1.1 To meet the thickness specifications of the coatings,

NOTE 8—Thicknesses determined by beta backscatter, coulometry, and

the plater is advised to:

X-ray fluorescence are a function of the composition as well as the

9.1.1.1 Maintain regular control of all solutions,

thickness of the coating.

9.1.1.2 Inspect the equipment at regular intervals, and

6.4 Adhesion—The adhesion of the coating shall be ad-

9.1.1.3 Check thickness at periodic intervals.

equate to pass the tests described in 9.2.

9.1.2 The following ASTM methods are acceptable for

6.5 Solderability:

measuring local thickness of the coating: B487, B499, B504,

6.5.1 When specified by the purchaser, the coating shall be

B567, and B568.

tested by one of the methods described in 9.2.The results shall

9.2 Adhesion:

be evaluated in accordance with each procedure described in

9.2.1 Burnishing Test—Rub an area of not more than 630

that section. 2 2

mm (1 in. ) of the coated surface, selected at the discretion of

6.5.2 When specified by the purchaser, the coating on

the inspector, rapidly and firmly for 15 s with a smooth metal

copper and copper alloys shall, before solderability testing, be

implement. A suitable burnishing implement is a copper or

subjectedtothepreliminaryartificialagingtreatmentdescribed

steel disk used edgewise and broadside. Maintain a pressure

in 9.3.6 to determine if they may be expected to retain their

sufficienttoburnishthecoatingateverystroke,butnotsogreat

solderability during periods of storage.

as to cut it. Poor adhesion will be shown by the appearance of

a loose blister which grows as burnishing is continued. If the

NOTE 9—SeeAppendixX2fordesignconsiderationsthathaveaneffect

on the selection of thickness of the coating and, ultimately, on the qualityofthecoatingispooralso,theblistermaycrackandthe

solderability of the electrodeposits.

coating peel away from the basis metal.

9.2.2 Quenching Test—Heat the coating article in an oven

7. Hydrogen Embrittlement

for a sufficient time to reach 150 6 10°C (300 6 20°F) and

7.1 High-tensile strength steels, and severely cold-worked

quench in room-temperature water.The adhesion is inadequate

steels, are susceptible to embrittlement by hydrogen in both

if the coating blisters, cracks, or peels.

cleaning and plating operations. The embrittling hydrogen

9.2.3 Reflow Test—Parts may be evaluated by immersion in

shall be removed by heat treatment. Procedures for baking to

a bath of palm oil at a temperature of 205 – 260°C (400 –

minimize embrittlement before and after plating are covered in

500°F) until the deposit melts. A bright coating completely

Sections 2 and 7 of Guide B242.

covering the significant surfaces indicates adequate adhesion.

9.2.4 Bend Test—Bend a sample, with the coated surface

8. Sampling

away, over a mandrel until its two legs are parallel. The

8.1 Test methods are time consuming and often destructive;

mandrel shall have a diameter equal to the thickness of the

therefore 100 % inspection is usually impractical. The pur-

sample. Examination at 43 magnification should show no

chasershouldselectasuitablesamplingplanfortheacceptance

evidence of peeling or cracking.

9.3 Solderability:

A

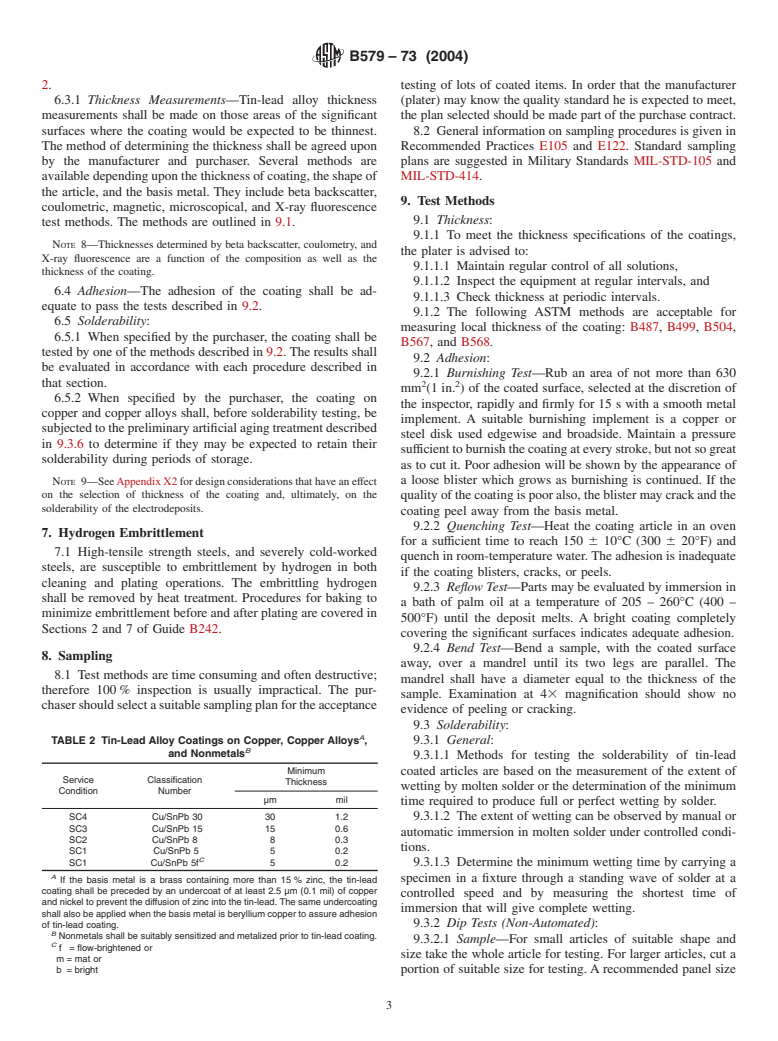

TABLE 2 Tin-Lead Alloy Coatings on Copper, Copper Alloys , 9.3.1 General:

B

and Nonmetals

9.3.1.1 Methods for testing the solderability of tin-lead

Minimum coated articles are based on the measurement of the extent of

Service Classification

Thickness

wetting by molten solder or the determination of the minimum

Condition Number

µm mil

time required to produce full or perfect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.