ASTM F2826-14(2018)

(Test Method)Standard Test Method for Evaluating the Sustained Air Performance and Exhaust Emission Efficiencies of Central Vacuum Cleaning Units

Standard Test Method for Evaluating the Sustained Air Performance and Exhaust Emission Efficiencies of Central Vacuum Cleaning Units

SIGNIFICANCE AND USE

4.1 The test results allow comparison of sustained air performance of central vacuum cleaners that employ various methods of separating the dirt from the air used to convey the dirt to the central power unit. The results will be expressed as a percentage of the original vacuum performance after loading a prescribed weight of media.

4.2 The test results will allow a comparison of emissions by measuring the media emitted during the test and expressing this as an Exhaust Emissions.

SCOPE

1.1 This test method is a laboratory test for determining the sustained air performance and Exhaust Emissions of a central vacuum cleaner when tested under laboratory conditions.

1.2 This test method is applicable to all central vacuum cleaners with or without any type of internal filter. This test method is intended to help indicate how performance may be affected after multiple times of vacuuming over an extended period of time.

1.3 The inch-pound system of units is used in this standard except for weight measurements, which are measured in grams. The values stated in parentheses are given for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2826 − 14 (Reapproved 2018)

Standard Test Method for

Evaluating the Sustained Air Performance and Exhaust

1

Emission Efficiencies of Central Vacuum Cleaning Units

This standard is issued under the fixed designation F2826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F820Test Method for Measuring Air Performance Charac-

teristics of Central Vacuum Cleaning Systems

1.1 This test method is a laboratory test for determining the

3

2.2 ISO Standard:

sustained air performance and Exhaust Emissions of a central

ISO 5011Inlet Air Cleaning Equipment for Internal Com-

vacuum cleaner when tested under laboratory conditions.

bustion Engines and Compressors—Performance Testing

1.2 This test method is applicable to all central vacuum

3. Terminology

cleaners with or without any type of internal filter. This test

method is intended to help indicate how performance may be

3.1 Definitions:

affected after multiple times of vacuuming over an extended

3.1.1 exhaust emissions—measure of the efficiency of a unit

period of time.

to capture the loading media. Exhaust Emissions is (1 – (the

weight of the media exhausted into the exhaust emissions bag,

1.3 The inch-pound system of units is used in this standard

divided by the weight of the media introduced) × 100).

exceptforweightmeasurements,whicharemeasuredingrams.

Thevaluesstatedinparenthesesaregivenforinformationonly.

3.1.2 input power, W, n—the rate at which electrical energy

is absorbed by a vacuum cleaner motor/fan system.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.3 model, n—the designation of a group of vacuum

responsibility of the user of this standard to establish appro-

cleaner systems having the same mechanical and electrical

priate safety, health, and environmental practices and deter-

construction.

mine the applicability of regulatory limitations prior to use.

3.1.4 population, n—the total of all units of a particular

1.5 This international standard was developed in accor-

model vacuum cleaner system being tested.

dance with internationally recognized principles on standard-

3.1.5 sample, n—a group of vacuum cleaner systems taken

ization established in the Decision on Principles for the

from a large collection of vacuum cleaner systems of one

Development of International Standards, Guides and Recom-

particularmodel,whichservestoprovideinformationthatmay

mendations issued by the World Trade Organization Technical

be used as a basis for making a decision concerning the larger

Barriers to Trade (TBT) Committee.

collection.

2. Referenced Documents 3.1.6 seal vacuum—a water lift reading for a power unit

2 when the inlet is entirely closed or sealed.

2.1 ASTM Standards:

3

3.1.7 standard air density, ρ , lb/ft,n—atmospheric air

E1Specification for ASTM Liquid-in-Glass Thermometers

std

3 3

density of 0.075 lb/ft (1.2014 Kg/m ).

E177Practice for Use of the Terms Precision and Bias in

3.1.7.1 Discussion—Thisvalueofairdensitycorrespondsto

ASTM Test Methods

atmospheric air at a temperature of 68°F (20°C), 14.696 psi

E691Practice for Conducting an Interlaboratory Study to

(101.325 kPa), and approximately 30% relative humidity.

Determine the Precision of a Test Method

3.1.8 suction, inches of water, n—in a vacuum cleaner

system, the absolute difference between ambient and sub-

1

atmospheric pressure.

ThistestmethodisunderthejurisdictionofASTMCommitteeF11onVacuum

Cleaners and is the direct responsibility of Subcommittee F11.22 on Air Perfor-

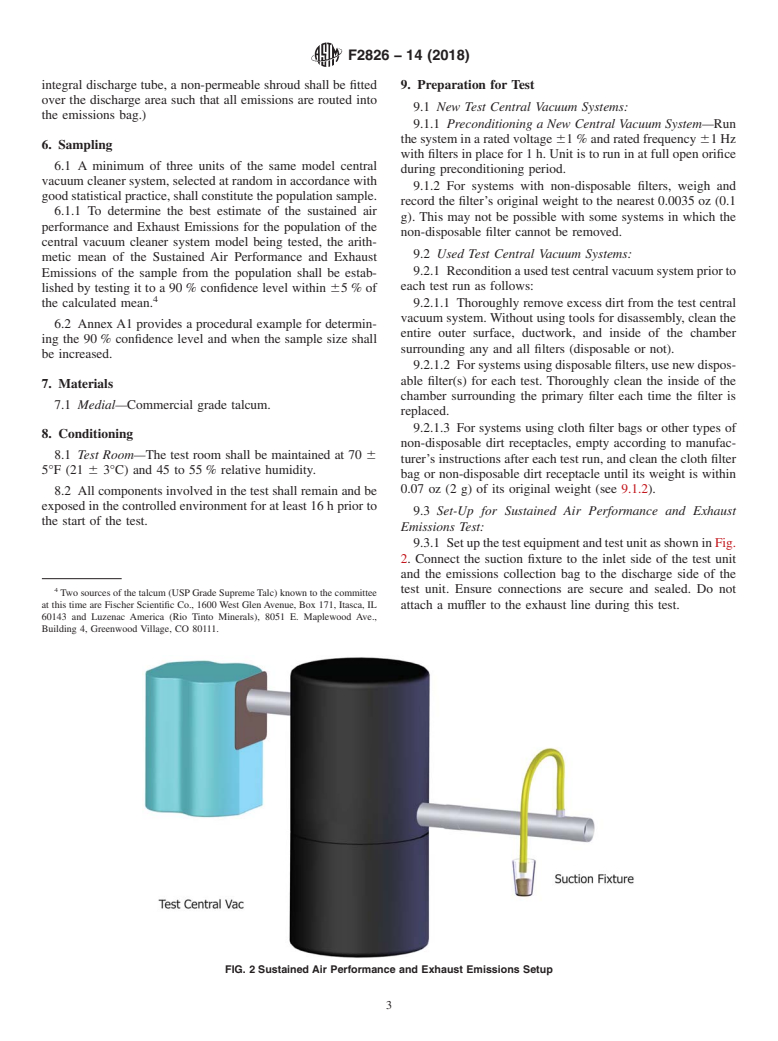

3.1.9 sustained air performance, n—the ability of a vacuum

mance.

cleaner to maintain air performance with a known quantity of

Current edition approved May 1, 2018. Published June 2018. Originally

approved in 2014. Last previous edition approved in 2014 as F2826–14. DOI: media aspirated into unit throughout a number of feeding

10.1520/F2826-14R18.

cycles.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from International Organization for Standardization (ISO), 1, ch. de

the ASTM website. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

--------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.