ASTM A523-96(2001)

(Specification)Standard Specification for Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

Standard Specification for Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

SCOPE

1.1 This specification covers seamless and electric-resistance-welded steel pipe used as conduit for the installation of high-pressure pipe-type electrical cables in NPS 4 to NPS 12, inclusive, with nominal (average) wall thicknesses 0.219 to 0.562 in., depending on size. Pipe having other dimensions (Note 2) may be furnished, provided such pipe complies with all other requirements of this specification.

Note 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

Note 2—A comprehensive listing of standardized pipe dimensions is contained in ANSI B36.10.

1.2 Pipe ordered under this specification is suitable for welding and for forming operations involving flaring, belling, and bending.

1.3 Pipe for this purpose shall be furnished in Grade A or Grade B as specified in the purchase order. Grade A is more suitable for forming operations involving bending, flaring, or belling and this grade is normally preferred. This provision is not intended to prohibit the cold bending, flaring, or belling of Grade B pipe.

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 The following hazard caveat applies to the test method portion, Section 20, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 523 – 96 (Reapproved 2001)

Standard Specification for

Plain End Seamless and Electric-Resistance-Welded Steel

Pipe for High-Pressure Pipe-Type Cable Circuits

This standard is issued under the fixed designation A523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A370 TestMethodsandDefinitionsforMechanicalTesting

of Steel Products

1.1 This specification covers seamless and electric-

A 751 Test Methods, Practices, and Terminology for

resistance-weldedsteelpipeusedasconduitfortheinstallation

Chemical Analysis of Steel Products

of high-pressure pipe-type electrical cables in NPS 4 to NPS

E59 Method of Sampling Steel and Iron for Determination

12,inclusive,withnominal(average)wallthicknesses0.219to

of Chemical Composition

0.562 in., depending on size. Pipe having other dimensions

2.2 ANSI Standard:

(Note 2) may be furnished, provided such pipe complies with

B36.10 Welded and Seamless Wrought Steel Pipe

all other requirements of this specification.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has 3. Ordering Information

been substituted in this standard for such traditional terms as “nominal

3.1 Orders for material under this specification should

diameter,” “size,” and “nominal size.”

include the following, as required, to describe the desired

NOTE 2—A comprehensive listing of standardized pipe dimensions is

material adequately:

contained in ANSI B36.10.

3.1.1 Quantity (feet or number of lengths),

1.2 Pipe ordered under this specification is suitable for

3.1.2 Name of material (steel pipe),

welding and for forming operations involving flaring, belling,

3.1.3 Method of manufacture (seamless or electric-

and bending.

resistance-welded),

1.3 Pipe for this purpose shall be furnished in Grade A or

3.1.4 Grade (Table 1),

Grade B as specified in the purchase order. Grade A is more

3.1.5 Size (outside diameter and nominal wall thickness or

suitable for forming operations involving bending, flaring, or

weight per foot),

belling and this grade is normally preferred. This provision is

3.1.6 Length when other than specified in Section 13,

not intended to prohibit the cold bending, flaring, or belling of

3.1.7 End finish (Section 16),

Grade B pipe.

3.1.8 Skelp for tension tests, if permitted 20.2,

1.4 The values stated in inch-pound units are to be regarded

3.1.9 When mill applied coating is required (Section 10),

as the standard.

and

1.5 The following hazard caveat applies to the test method

3.1.10 ASTM specification number.

portion, Section 20, of this specification: This standard does

not purport to address all of the safety concerns, if any,

4. Process

associatedwithitsuse.Itistheresponsibilityoftheuserofthis

4.1 Thesteelshallbemadebyoneormoreofthefollowing

standard to establish appropriate safety and health practices

processes: open-hearth, basic-oxygen, or electric-furnace.

and determine the applicability of regulatory limitations prior

4.2 Steel may be cast in ingots or may be strand cast.When

to use.

steels of different grades are sequentially strand cast, identifi-

cation of the resultant transition material is required. The

2. Referenced Documents

producer shall remove the transition material by any estab-

2.1 ASTM Standards:

lished procedure that positively separates the grades.

5. Chemical Composition

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

5.1 The steel shall conform to the requirements as to

StainlessSteel,andRelatedAlloys,andisthedirectresponsibilityofSubcommittee

A01.09 on Carbon Steel Tubular Products. chemical composition prescribed in Table 2 and the chemical

Current edition approved Oct. 10, 1996. Published November 1997. Originally

published as A523–64. Last previous edition A523–93.

This specification was initiated by the IEEE Insulated Conductors Committee in Annual Book of ASTM Standards, Vol 01.03.

recognition of the need for a specification embodying the special requirements of Annual Book of ASTM Standards, Vol 03.05.

pipeforhigh-voltageelectricalcircuits.ItwaspreparedforacceptanceasanASTM Available fromAmerican National Standards Institute, 11 West 42nd St., 13th

specification by a task group of Subcommittee A01.09 of ASTM Committee A-1. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 523 – 96 (2001)

TABLE 1 Tensile Requirements

7. Product Analysis

Grade A Grade B

7.1 Whenspecifiedinthepurchaseorder,aproductanalysis

Tensile strength, min, ksi (MPa) 48 (330) 60 (415)

report shall be furnished by the manufacturer on two pipes

Yield strength, min, ksi (MPa) 30 (205) 35 (240)

from each lot of 400 lengths, or fraction thereof, of 4 ⁄2-in.

Elongation in 2 in. or 50 mm, %:

Basic minimum elongation for walls ⁄16 in. (7.94 35 30 outside diameter and 5 ⁄16-in. outside diameter sizes and from

mm) and over in thickness, longitudinal strip

each lot of 200 lengths, or fraction thereof, of each size 6 ⁄8-in.

tests, and for small sizes tested in full section.

outside diameter through 12 ⁄4-in. outside diameter pipe.

When standard round 2-in. or 50-mm gage length 28 22

test specimen is used Samples for chemical analysis, except for spectrographic

A A

For longitudinal strip tests, the width of the gage 1.75 1.50

analysis, shall be taken in accordance with Method E59. The

section shall be 1 ⁄2 in. (38.1 mm) and a

1 chemical composition thus determined shall conform to the

deduction for each ⁄32in. (0.79 mm) decrease in

wall thickness below ⁄16 in. (7.94 mm) from the

requirements specified in Section 5.

basic minimum elongation of the following

7.2 Product Analysis Retests—If both lengths of pipe rep-

percentage points

resentingthelotfailthespecifiedproductanalysis,thelotshall

A B

The following table gives the minimum computed values:

be rejected, or at the option of the manufacturer, all of the

remaining lengths of the lot shall be tested individually for

Wall Thickness Elongation in 2 in. or 50

conformance to the specified requirements. If only one of the

mm, min, %

lengths of pipe representing the lot fails the specified check

in. mm Grade A Grade B

analysis, the lot shall be rejected or, at the option of the

⁄16 (0.312) 7.94 35.0 30.0

manufacturer, two retest analyses shall be made on two

⁄32 (0.281) 7.14 33.2 28.5

1 additional lengths selected from the same lot. If both of these

⁄4 (0.250) 6.35 31.5 27.0

⁄32 (0.219) 5.56 29.8 25.5

retest analyses conform to the specified requirements, the lot

⁄16 (0.188) 4.76 28.0 24.0

shall be accepted except for the length which failed on the

⁄32 (0.156) 3.97 26.2 22.5

initial analysis. If one or both of the retest analyses fail the

⁄8 (0.125) 3.18 24.5 21.0

⁄32 (0.094) 2.38 22.8 19.5

specifiedrequirements,theentirelotshallberejected,or,atthe

⁄16 (0.062) 1.59 21.0 18.0

optionofthemanufacturer,eachoftheremaininglengthsshall

B

This table gives the computed minimum elongation values for each ⁄32 in. betestedindividually.Onlyanalysisoftherejectingelementor

(0.79 mm) decrease in wall thickness. Where the wall thickness lies between two

elements is necessary in checking the remaining lengths.

values shown above, the minimum elongation value shall be determined by the

following equation:

8. Tensile Requirements

Grade Equation

A E=56t + 17.50 8.1 The material shall conform to the requirements as to

B E=48t + 15.00

tensile properties prescribed in Table 1.

8.2 The yield point shall be determined by the drop of the

where:

E = elongation in 2 in. or 50 mm, %, and

beam or by the halt in the gage of the testing machine, by the

t = actual thickness of specimen, in.

useofdividers,orbyotherapprovedmethods.Whenadefinite

yieldpointisnotexhibited,theyieldstrengthcorrespondingto

a permanent offset of 0.2% of the gage length of the specimen

TABLE 2 Chemical Requirements

or to a total extension of 0.5% of the gage length of the

Composition, %

specimen under load shall be determined.

Carbon, Manganese, Phosphorus, Sulfur,

8.3 The test specimen taken across the weld shall show a

max max max max

tensile strength not less than the minimum tensile strength

Heat Product Heat Product Heat Product Heat Product

specified for the grade of pipe ordered. This test will not be

Grade A

required for pipe under NPS 8.

Seamless 0.22 0.25 0.90 0.95 0.035 0.045 0.050 0.060

A

E.R.W. 0.21 0.25 0.90 0.95 0.035 0.045 0.050 0.060

Grade B

9. Flattening Test Requirements

Seamless 0.27 0.30 1.15 1.20 0.035 0.045 0.050 0.060

A

E.R.W. 0.26 0.30 1.15 1.20 0.035 0.045 0.050 0.060

9.1 Seamless Pipe—For seamless pipe, a section not less

A 1

Electric-Resistance-Welded pipe. than2 ⁄2in.(63.5mm)inlengthshallbeflattenedcoldbetween

parallelplatesintwosteps.Duringthefirststep,whichisatest

forductility,nocracksorbreaksontheinsideoroutsideorend

analysis shall be in accordance with Test Methods, Practices, surfaces, except as provided for in 9.5, shall occur until the

and Terminology A751.

distance between the plates is less than the value of H

calculated by the following equation:

6. Heat Analysis

~11e!t

H 5 (1)

6.1 When specified in the purchase order, the manufacturer

t

e1

D

shall report the heat analysis of each heat of steel used in the

manufacture of pipe to this specification. The analysis shall

where:

conform to the requirements specified in Section 5 for the

H = distance between flattening plates, in. (mm),

grade of pipe ordered.

A 523 – 96 (2001)

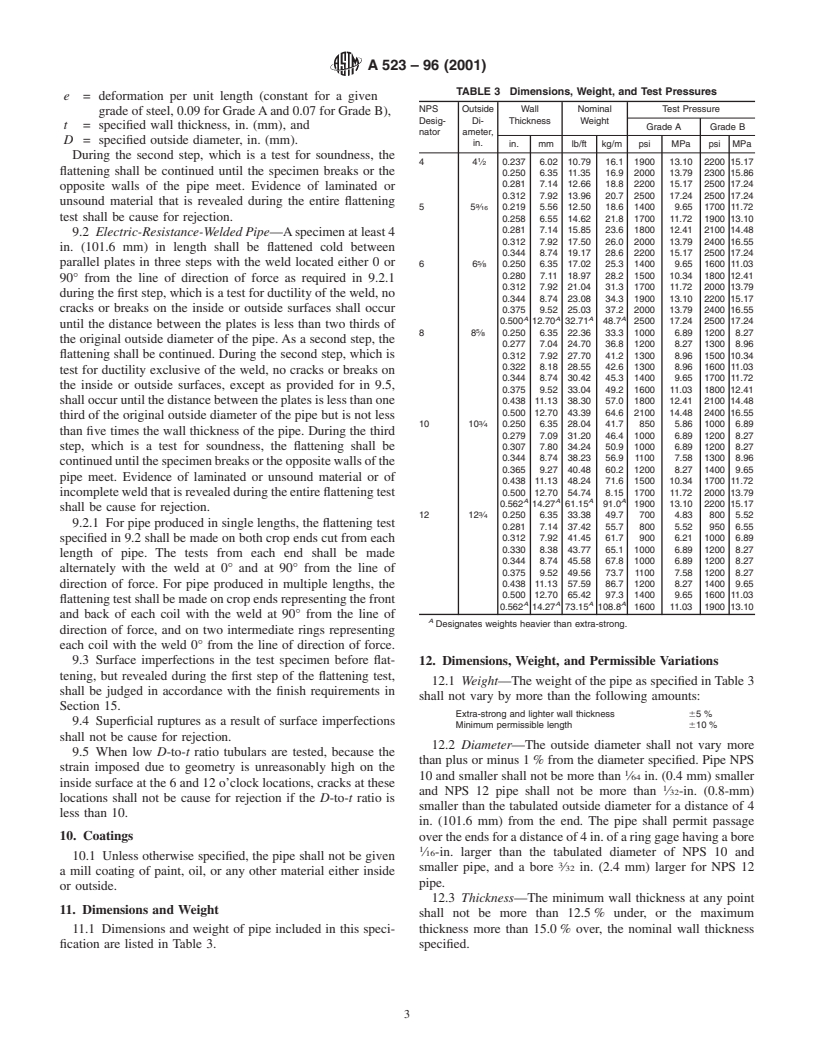

TABLE 3 Dimensions, Weight, and Test Pressures

e = deformation per unit length (constant for a given

NPS Outside Wall Nominal Test Pressure

gradeofsteel,0.09forGradeAand0.07forGradeB),

Desig- Di- Thickness Weight

t = specified wall thickness, in. (mm), and Grade A Grade B

nator ameter,

D = specified outside diameter, in. (mm).

in.

in. mm lb/ft kg/m psi MPa psi MPa

During the second step, which is a test for soundness, the

44 ⁄2 0.237 6.02 10.79 16.1 1900 13.10 2200 15.17

flattening shall be continued until the specimen breaks or the

0.250 6.35 11.35 16.9 2000 13.79 2300 15.86

0.281 7.14 12.66 18.8 2200 15.17 2500 17.24

opposite walls of the pipe meet. Evidence of laminated or

0.312 7.92 13.96 20.7 2500 17.24 2500 17.24

unsound material that is revealed during the entire flattening

55 ⁄16 0.219 5.56 12.50 18.6 1400 9.65 1700 11.72

test shall be cause for rejection.

0.258 6.55 14.62 21.8 1700 11.72 1900 13.10

0.281 7.14 15.85 23.6 1800 12.41 2100 14.48

9.2 Electric-Resistance-WeldedPipe—Aspecimenatleast4

0.312 7.92 17.50 26.0 2000 13.79 2400 16.55

in. (101.6 mm) in length shall be flattened cold between

0.344 8.74 19.17 28.6 2200 15.17 2500 17.24

parallel plates in three steps with the weld located either 0 or

66 ⁄8 0.250 6.35 17.02 25.3 1400 9.65 1600 11.03

0.280 7.11 18.97 28.2 1500 10.34 1800 12.41

90° from the line of direction of force as required in 9.2.1

0.312 7.92 21.04 31.3 1700 11.72 2000 13.79

duringthefirststep,whichisatestforductilityoftheweld,no

0.344 8.74 23.08 34.3 1900 13.10 2200 15.17

cracks or breaks on the inside or outside surfaces shall occur 0.375 9.52 25.03 37.2 2000 13.79 2400 16.55

A A A A

0.500 12.70 32.71 48.7 2500 17.24 2500 17.24

until the distance between the plates is less than two thirds of

88 ⁄8 0.250 6.35 22.36 33.3 1000 6.89 1200 8.27

the original outside diameter of the pipe.As a second step, the

0.277 7.04 24.70 36.8 1200 8.27 1300 8.96

flattening shall be continued. During the second step, which is 0.312 7.92 27.70 41.2 1300 8.96 1500 10.34

0.322 8.18 28.55 42.6 1300 8.96 1600 11.03

test for ductility exclusive of the weld, no cracks or breaks on

0.344 8.74 30.42 45.3 1400 9.65 1700 11.72

the inside or outside surfaces, except as provided for in 9.5,

0.375 9.52 33.04 49.2 1600 11.03 1800 12.41

shalloccuruntilthedistancebetweentheplatesislessthanone 0.438 11.13 38.30 57.0 1800 12.41 2100 14.48

0.500 12.70 43.39 64.6 2100 14.48 2400 16.55

third of the original outside diameter of the pipe but is not less

10 10 ⁄4 0.250 6.35 28.04 41.7 850 5.86 1000 6.89

than five times the wall thickness of the pipe. During the third

0.279 7.09 31.20 46.4 1000 6.89 1200 8.27

step, which is a test for soundness, the flattening shall be 0.307 7.80 34.24 50.9 1000 6.89 1200 8.27

0.344 8.74 38.23 56.9 1100 7.58 1300 8.96

continueduntilthespecimenbreaksortheoppositewallsofthe

0.365 9.27 40.48 60.2 1200 8.27 1400 9.65

pipe meet. Evidence of laminated or unsound material or of

0.438 11.13 48.24 71.6 1500 10.34 1700 11.72

incompleteweldthatisrevealedduringtheentireflatteningtest 0.500 12.70 54.74 8.15 1700 11.72 2000 13.79

A A A A

0.562 14.27 61.15 91.0 1900 13.10 2200 15.17

shall be cause for rejection.

12 12 ⁄4 0.250 6.35 33.38 49.7 700 4.83 800 5.52

9.2.1 For pipe produced in single lengths, the flattening test

0.281 7.14 37.42 55.7 800 5.52 950 6.55

0.312 7.92 41.45 61.7 900 6.21 1000 6.89

specified in 9.2 shall be made on both crop ends cut from each

0.330 8.38 43.77 65.1 1000 6.89 1200 8.27

length of pipe. The tests from each end shall be made

0.344 8.74 45.58 67.8 1000 6.89 1200 8.27

alternately with the weld at 0° and at 90° from the line of

0.375 9.52 49.56 73.7 1100 7.58 1200 8.27

direction of force. For pipe produced in multiple lengths, the 0.438 11.13 57.59 86.7 1200 8.27 1400 9.65

0.500 12.70 65.42 97.3 1400 9.65 1600 11.03

flatteningtestshallbemadeoncropendsrepresentingthefront

A A A A

0.562 14.27 73.15 108.8 1600 11.03 1900 13.10

and back of each coil with the weld at 90° from the line of

A

Designates weights heavier than extra-strong.

direction of force, and on two intermediate rings representing

each coil with the weld 0° from the line of direction of force.

9.3 Surface imperfections in the test specimen before flat-

12. Dimensions, Weight, and Permissible Variations

tening, but revealed during the first step of the flattening test,

12.1 Weight—The weight of the pipe as specified inTable 3

shall be judged in accordance with the finish requirements in

shall not vary by more than the following amounts:

Section 15.

Extra-strong and lighter wall thickness 65%

9.4 Superficial ruptures as a result of surface imperfections

Minimum permissible length 610 %

shall not be cause for rejection.

12.2 Diameter—The outside diameter shall not vary more

9.5 When low D-to-t ratio tubulars are tested, because the

than plus or minus 1% from the diameter specified. Pipe NPS

strain imposed due to geometry is unreasonably high on the

10 and smaller shall not be more than ⁄64 in. (0.4 mm) smaller

insidesurfaceatthe6and12o’clocklocations,cracksatthese

and NPS 12 pipe shall not be more

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.