ASTM E634-18

(Practice)Standard Practice for Sampling of Zinc and Zinc Alloys for Analysis by Spark Atomic Emission Spectrometry

Standard Practice for Sampling of Zinc and Zinc Alloys for Analysis by Spark Atomic Emission Spectrometry

SIGNIFICANCE AND USE

3.1 This practice, used in conjunction with an appropriate quantitative spark atomic emission spectrochemical method, is suitable for use in manufacturing control, material or product acceptance, and development and research.

SCOPE

1.1 This practice covers the sampling of zinc and zinc alloys to obtain a sample suitable for quantitative spark atomic emission spectrochemical analysis. Included are procedures for obtaining representative samples from molten metal, from fabricated or cast products that can be melted, and from other forms that cannot be melted.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E634 − 18

Standard Practice for

Sampling of Zinc and Zinc Alloys for Analysis by Spark

1

Atomic Emission Spectrometry

This standard is issued under the fixed designation E634; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope suitable for use in manufacturing control, material or product

acceptance, and development and research.

1.1 This practice covers the sampling of zinc and zinc alloys

to obtain a sample suitable for quantitative spark atomic

4. Apparatus

emission spectrochemical analysis. Included are procedures for

obtaining representative samples from molten metal, from

4.1 Ladle, of steel, designed to hold sufficient molten metal

fabricated or cast products that can be melted, and from other

to completely fill the sample mold, with a handle of sufficient

forms that cannot be melted.

length to reach into a furnace, trough, pot, or crucible.

1.2 The values stated in SI units are to be regarded as

NOTE 1—Pure zinc metal (Special High Grade) is sampled using a

standard. The values given in parentheses are for information

ceramic or graphite ladle, as the solubility of iron in Special High Grade

Zinc is sufficient to cause a measurable contamination.

only.

4.2 Sample Molds, designed to produce homogeneous chill-

1.3 This standard does not purport to address all of the

cast specimens having smooth surfaces, free from surface

safety concerns, if any, associated with its use. It is the

pockets and pores. The specimens shall be representative (in

responsibility of the user of this standard to establish appro-

the region to be excited) of the product metal. The samples

priate safety, health, and environmental practices and deter-

shall have a spectrochemical response similar to the standards

mine the applicability of regulatory limitations prior to use.

used in preparing the analytical curves. This is ensured by

1.4 This international standard was developed in accor-

casting standards and specimens in the same manner. Also, the

dance with internationally recognized principles on standard-

specimens shall have a repeatability of measurement for major

ization established in the Decision on Principles for the

elements from excitation-to-excitation with a relative error of

Development of International Standards, Guides and Recom-

no more than 2 %. Several types of molds have been found

mendations issued by the World Trade Organization Technical

acceptable.

Barriers to Trade (TBT) Committee.

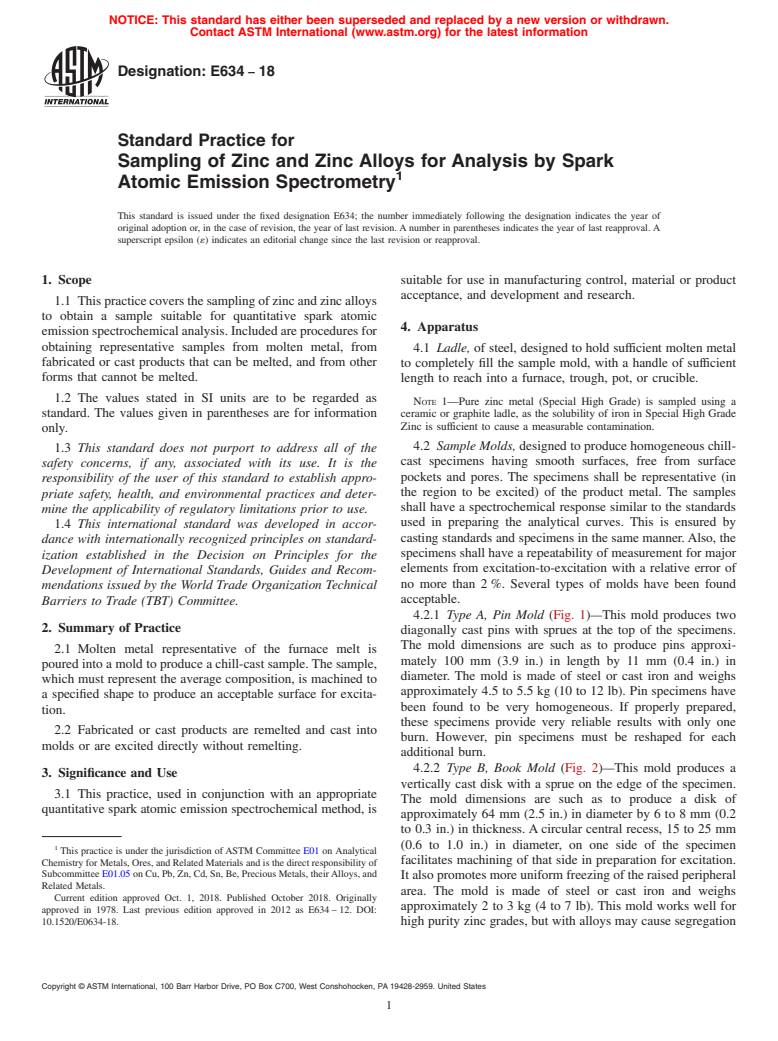

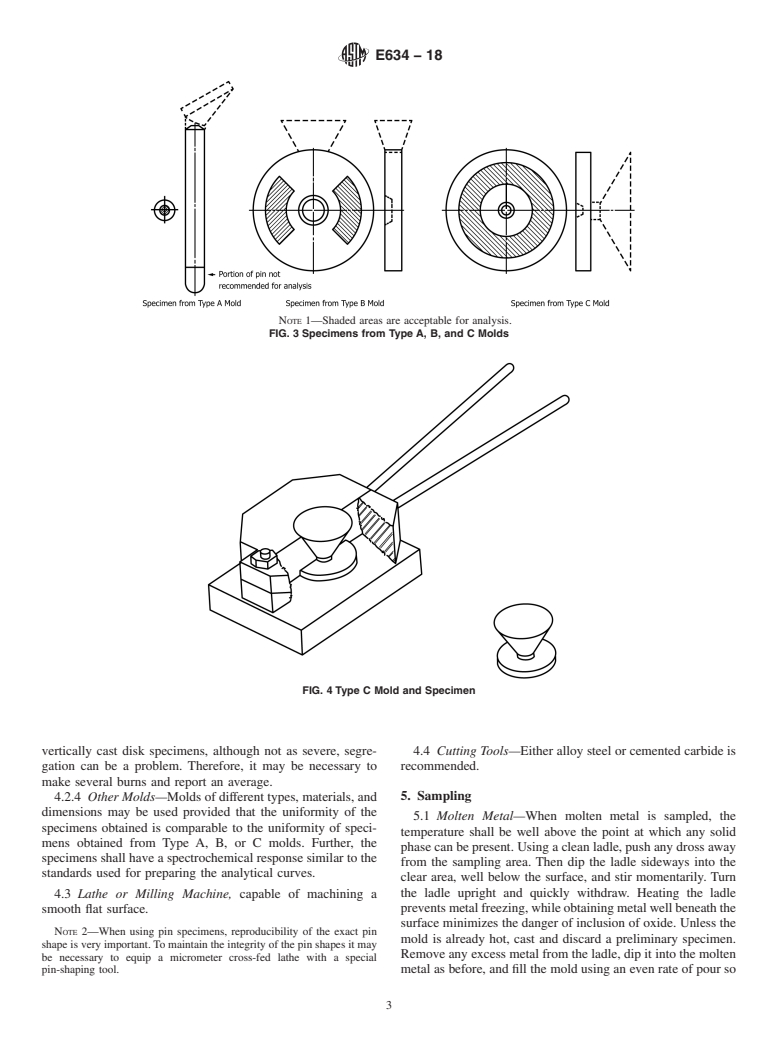

4.2.1 Type A, Pin Mold (Fig. 1)—This mold produces two

2. Summary of Practice

diagonally cast pins with sprues at the top of the specimens.

The mold dimensions are such as to produce pins approxi-

2.1 Molten metal representative of the furnace melt is

mately 100 mm (3.9 in.) in length by 11 mm (0.4 in.) in

poured into a mold to produce a chill-cast sample. The sample,

diameter. The mold is made of steel or cast iron and weighs

which must represent the average composition, is machined to

approximately 4.5 to 5.5 kg (10 to 12 lb). Pin specimens have

a specified shape to produce an acceptable surface for excita-

been found to be very homogeneous. If properly prepared,

tion.

these specimens provide very reliable results with only one

2.2 Fabricated or cast products are remelted and cast into

burn. However, pin specimens must be reshaped for each

molds or are excited directly without remelting.

additional burn.

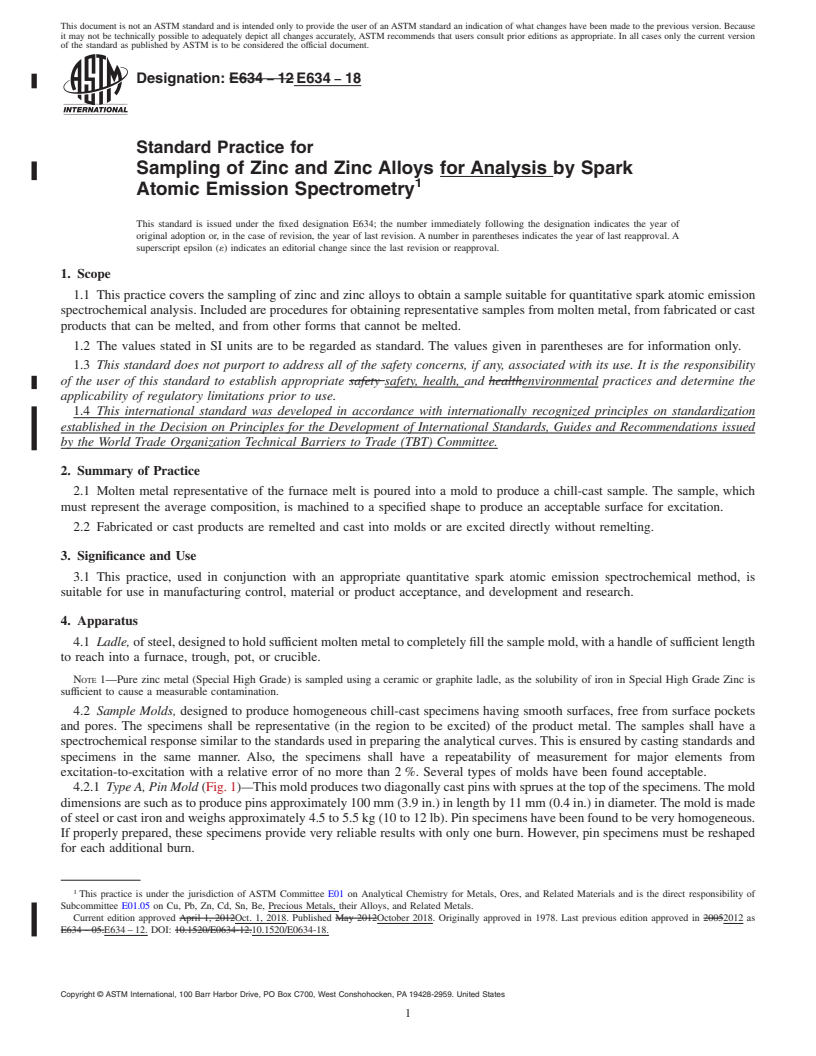

4.2.2 Type B, Book Mold (Fig. 2)—This mold produces a

3. Significance and Use

vertically cast disk with a sprue on the edge of the specimen.

3.1 This practice, used in conjunction with an appropriate

The mold dimensions are such as to produce a disk of

quantitative spark atomic emission spectrochemical method, is

approximately 64 mm (2.5 in.) in diameter by 6 to 8 mm (0.2

to 0.3 in.) in thickness. A circular central recess, 15 to 25 mm

(0.6 to 1.0 in.) in diameter, on one side of the specimen

1

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

facilitates machining of that side in preparation for excitation.

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, Precious Metals, their Alloys, and

It also promotes more uniform freezing of the raised peripheral

Related Metals.

area. The mold is made of steel or cast iron and weighs

Current edition approved Oct. 1, 2018. Published October 2018. Originally

approximately 2 to 3 kg (4 to 7 lb). This mold works well for

approved in 1978. Last previous edition approved in 2012 as E634 – 12. DOI:

10.1520/E0634-18. high purity zinc grades, but with allo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E634 − 12 E634 − 18

Standard Practice for

Sampling of Zinc and Zinc Alloys for Analysis by Spark

1

Atomic Emission Spectrometry

This standard is issued under the fixed designation E634; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the sampling of zinc and zinc alloys to obtain a sample suitable for quantitative spark atomic emission

spectrochemical analysis. Included are procedures for obtaining representative samples from molten metal, from fabricated or cast

products that can be melted, and from other forms that cannot be melted.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Summary of Practice

2.1 Molten metal representative of the furnace melt is poured into a mold to produce a chill-cast sample. The sample, which

must represent the average composition, is machined to a specified shape to produce an acceptable surface for excitation.

2.2 Fabricated or cast products are remelted and cast into molds or are excited directly without remelting.

3. Significance and Use

3.1 This practice, used in conjunction with an appropriate quantitative spark atomic emission spectrochemical method, is

suitable for use in manufacturing control, material or product acceptance, and development and research.

4. Apparatus

4.1 Ladle, of steel, designed to hold sufficient molten metal to completely fill the sample mold, with a handle of sufficient length

to reach into a furnace, trough, pot, or crucible.

NOTE 1—Pure zinc metal (Special High Grade) is sampled using a ceramic or graphite ladle, as the solubility of iron in Special High Grade Zinc is

sufficient to cause a measurable contamination.

4.2 Sample Molds, designed to produce homogeneous chill-cast specimens having smooth surfaces, free from surface pockets

and pores. The specimens shall be representative (in the region to be excited) of the product metal. The samples shall have a

spectrochemical response similar to the standards used in preparing the analytical curves. This is ensured by casting standards and

specimens in the same manner. Also, the specimens shall have a repeatability of measurement for major elements from

excitation-to-excitation with a relative error of no more than 2 %. Several types of molds have been found acceptable.

4.2.1 Type A, Pin Mold (Fig. 1)—This mold produces two diagonally cast pins with sprues at the top of the specimens. The mold

dimensions are such as to produce pins approximately 100 mm (3.9 in.) in length by 11 mm (0.4 in.) in diameter. The mold is made

of steel or cast iron and weighs approximately 4.5 to 5.5 kg (10 to 12 lb). Pin specimens have been found to be very homogeneous.

If properly prepared, these specimens provide very reliable results with only one burn. However, pin specimens must be reshaped

for each additional burn.

1

This practice is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, Precious Metals, their Alloys, and Related Metals.

Current edition approved April 1, 2012Oct. 1, 2018. Published May 2012October 2018. Originally approved in 1978. Last previous edition approved in 20052012 as

E634 – 05.E634 – 12. DOI: 10.1520/E0634-12.10.1520/E0634-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E634 − 18

FIG. 1 Type A Mold and Specimen

4.2.2 Type B, Book Mold (Fig. 2)—This mold produces a vertically cast disk with a spru

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.