ASTM D6356-98

(Test Method)Standard Test Method for Hydrogen Gas Generation of Aluminum Emulsified Asphalt Used as a Protective Coating for Roofing

Standard Test Method for Hydrogen Gas Generation of Aluminum Emulsified Asphalt Used as a Protective Coating for Roofing

SCOPE

1.1 This test method covers a hydrogen gas and stability test for aluminum emulsified asphalt coatings.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6356 – 98

Standard Test Method for

Hydrogen Gas Generation of Aluminum Emulsified Asphalt

Used as a Protective Coating for Roofing

This standard is issued under the fixed designation D 6356; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus and Materials

1.1 This test method covers a hydrogen gas and stability test 5.1 The assembly of the hydrogen gas generation test

for aluminum emulsified asphalt coatings. apparatus is illustrated in Fig. 1. Details of the component part

1.2 The values stated in inch-pound units are to be regarded are as follows:

as the standard. The SI units given in parentheses are for 5.1.1 Wide Mouth Glass Erlenmeyer Flask, 250-mL capac-

information only. ity.

1.3 This standard does not purport to address all of the 5.1.2 Beaker, glass, 250-mL.

safety concerns, if any, associated with its use. It is the 5.1.3 Burette, standard glass 100-mL graduated with glass

responsibility of the user of this standard to establish appro- stop cock and 0.2 mL divisions.

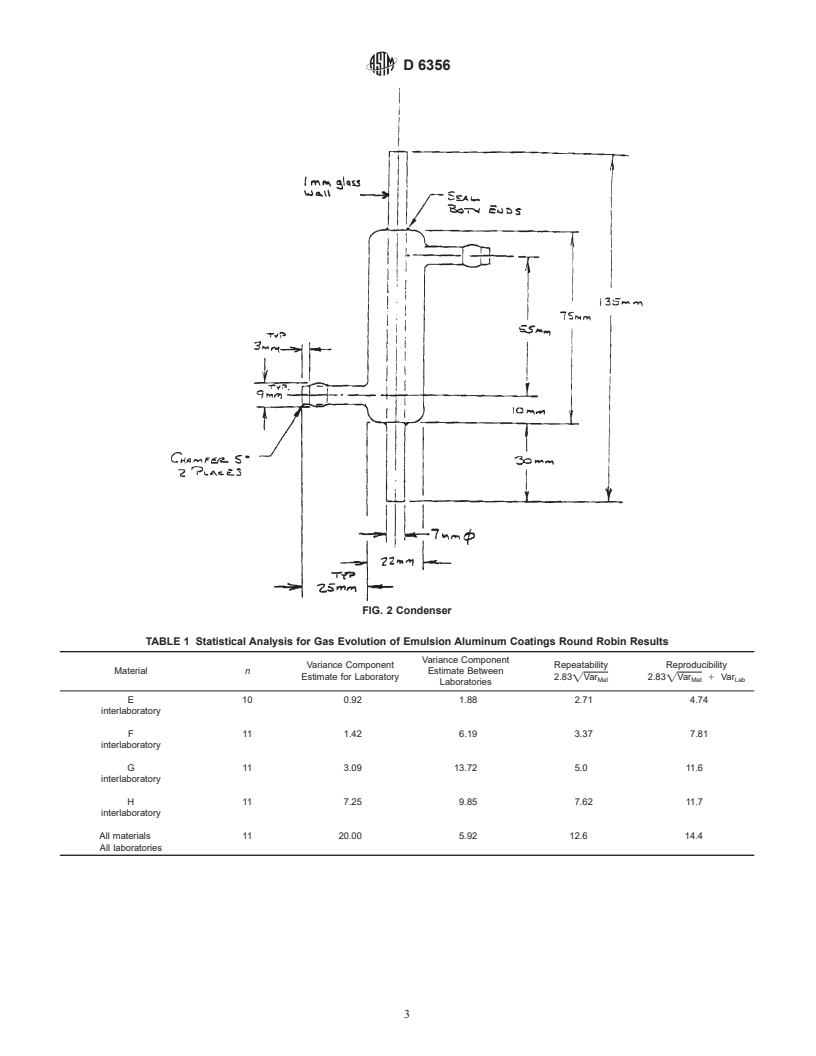

priate safety and health practices and determine the applica- 5.1.4 Condenser, glass jacketed, having the dimensions

bility of regulatory limitations prior to use. shown in Fig. 2.

5.1.5 Glass Tubing, standard glass ⁄4 in. (6.35 mm) inside

2. Referenced Documents

diameter ⁄16 in. (7.94 mm) outside diameter and 5 in. (127

2.1 ASTM Standards: mm) length for forming the J tube.

D 1079 Terminology Relating to Roofing, Waterproofing,

5.1.6 Tubing, pure latex amber rubber tubing, ⁄4 in. (6.35

and Bituminous Materials mm).

D 2939 Test Methods for Emulsified Bitumens Used as

5.1.7 Neoprene Rubber Stopper, No. 8 with one hole (pre-

Protective Coatings ferred connection for glass condenser to 250-mL Erlenmeyer

E 1 Specification for ASTM Thermometers

flask).

5.1.8 Oil or Water Bath—Constant temperature immersion

3. Summary of Test Method

circulating bath capable of temperature control.

3.1 A 200 g sample of water based aluminized coating is

5.1.9 Oil—Commercially available mineral oil or suitable

heated to 125 6 2°F (51.7 6 1°C) in an Erlenmeyer flask and

heat transfer fluid.

the volume in millilitres of hydrogen gas evolved is measured.

5.1.10 Thermometer—ASTM thermometer having a range

The test is conducted for one week (168 h) with a reading taken

from 30 to 180°F (–2 to + 80°C) and conforming to the

every 24 h. The test room is to be maintained at 73.4 6 3.6°F

requirements for thermometer 15F or 15C as prescribed in

in order to standardize gas collection temperature in the burette

Specification E 1.

recepticle.

6. Sampling

4. Significance and Use

6.1 Sample the material in accordance with Test Methods

4.1 This procedure measures the amount of hydrogen gas

D 2939.

generation potential of aluminized emulsion roof coating.

7. Procedure

There is the possibility of water reacting with aluminum

pigment to generate hydrogen gas. This situation is to be

7.1 Weigh 200 g of the sample directly in the 250-mL

avoided, so this test was designed to evaluate coating formu- Erlenmeyer flask assuring that none coats the neck where the

lations and assess the propensity to gassing.

stopper is placed.

7.2 Insert the filled flask into the oil or water bath (tempera-

ture controlled to 125 6 2°F (51.7 6 1°C) and connect the

This test method is under the jurisdiction of ASTM Committee D-8 on Roofing,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.