ASTM D6265-15

(Practice)Standard Practice for Separation of Contaminants in Polymers Using an Extruder Filter Test

Standard Practice for Separation of Contaminants in Polymers Using an Extruder Filter Test

SIGNIFICANCE AND USE

5.1 Problems with extrusion and subsequent processing of the material are caused, in part, by the presence of paper, metal, gels, incompatible polymers, or other extraneous contamination found in polymers.

SCOPE

1.1 This practice covers a means to separate the unmolten particles, gels, and impurities contaminating a polymer sample. The procedure may be used to remove gels and incompatible materials that may cause imperfections in the final extruded product. Under pressure, most gels will break up or deform and pass through a wire mesh filter, however high molecular weight gels may not break up or deform.

1.2 Materials isolated on a wire mesh filter can be identified by spectroscopic or other analytical means.

Note 1: Although not presented as a quantitative method, the procedure presented in this practice may be used to provide quantitative results at the discretion of the user. The user assumes the responsibility to verify the reproducibility of quantitative results. Detection limit depends on the mesh size of the filter screen, but the procedure is generally applicable to the separation of immiscible contaminants present at concentrations greater than 0.1 %.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see Section 8.

Note 2: There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6265 − 15

Standard Practice for

Separation of Contaminants in Polymers Using an Extruder

1

Filter Test

This standard is issued under the fixed designation D6265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D7209 Guide for Waste Reduction, Resource Recovery, and

Use of Recycled Polymeric Materials and Products (With-

1.1 This practice covers a means to separate the unmolten

3

drawn 2015)

particles,gels,andimpuritiescontaminatingapolymersample.

IEEE/ASTM SI-10 Practice for Use of the International

The procedure may be used to remove gels and incompatible

System of Units (SI) (the Modernized Metric System)

materials that may cause imperfections in the final extruded

product.Underpressure,mostgelswillbreakupordeformand

3. Terminology

passthroughawiremeshfilter,howeverhighmolecularweight

3.1 The terminology used in this practice is in accordance

gels may not break up or deform.

withTerminologyD1600andGuideD7209.Unitsandsymbols

1.2 Materials isolated on a wire mesh filter can be identified

are in accordance with Practice IEEE/ASTM SI-10.

by spectroscopic or other analytical means.

4. Summary of Practice

NOTE 1—Although not presented as a quantitative method, the proce-

dure presented in this practice may be used to provide quantitative results

4.1 This practice determines the relative contamination

at the discretion of the user. The user assumes the responsibility to verify

level that can cause undesirable imperfections in the extruded

the reproducibility of quantitative results. Detection limit depends on the

product due to contaminants and gels.Although this practice is

mesh size of the filter screen, but the procedure is generally applicable to

the separation of immiscible contaminants present at concentrations not designed to provide an absolute measurement of contami-

greater than 0.1 %.

nation level, using appropriate criteria, the rate of this pressure

rise can be correlated to the relative contamination level.

1.3 The values stated in SI units are to be regarded as

standard.

5. Significance and Use

1.4 This standard does not purport to address the safety

5.1 Problems with extrusion and subsequent processing of

concerns, if any, associated with its use. It is the responsibility

thematerialarecaused,inpart,bythepresenceofpaper,metal,

of the user of this standard to establish appropriate safety and

gels, incompatible polymers, or other extraneous contamina-

health practices and determine the applicability of regulatory

tion found in polymers.

limitations prior to use. For specific hazards statements, see

Section 8.

6. Apparatus

NOTE 2—There is no known ISO equivalent to this standard.

6.1 Extruder, designed to deliver a continuous supply of

molten resin to a filter at a uniform rate with good temperature

2. Referenced Documents

control. Extruders with 18 to 64-mm diameters have been

2

2.1 ASTM Standards:

found to be satisfactory.

D1238 Test Method for Melt Flow Rates of Thermoplastics

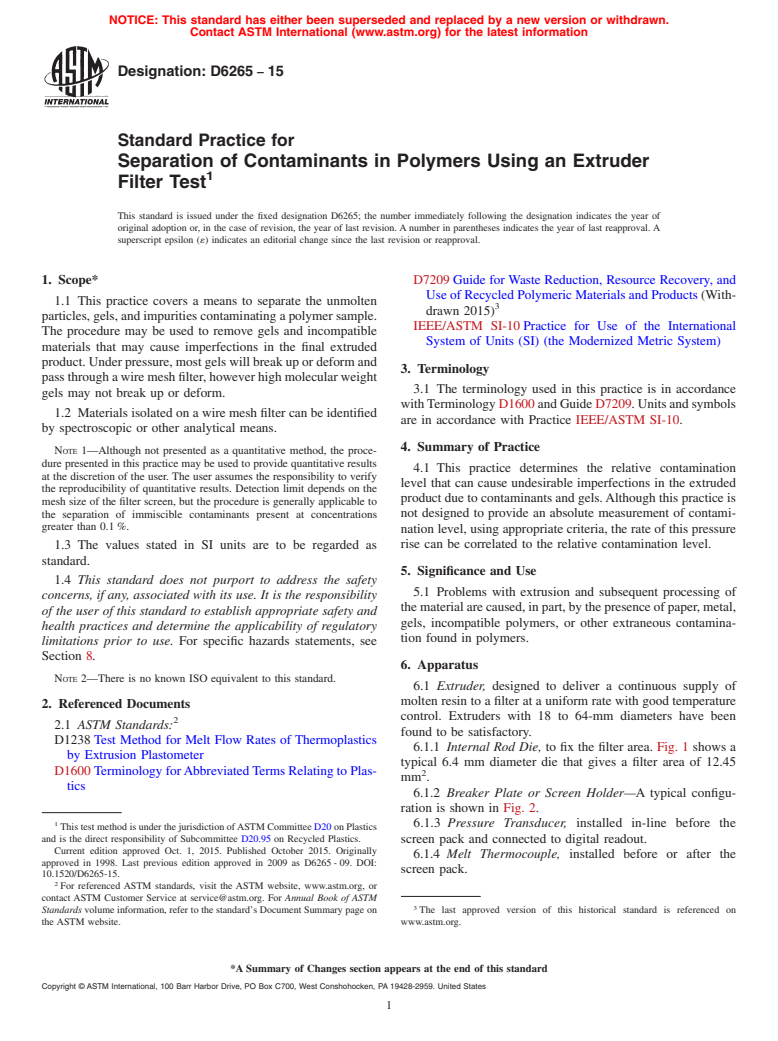

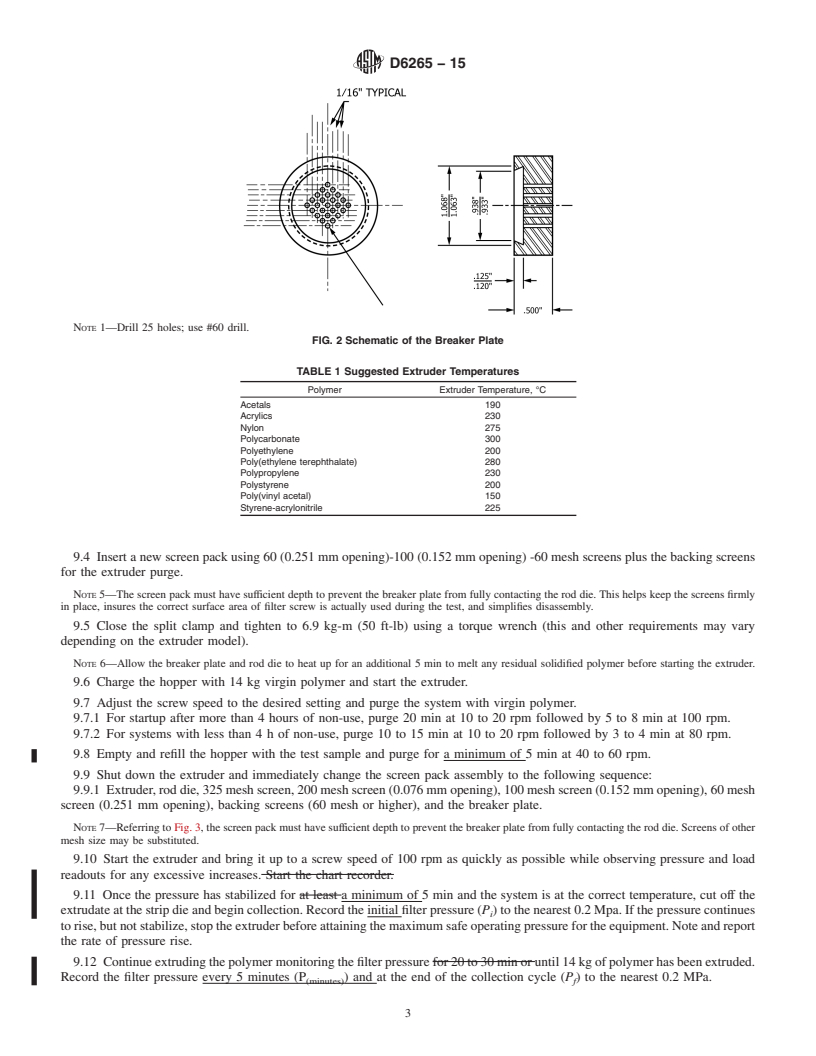

6.1.1 Internal Rod Die, to fix the filter area. Fig. 1 shows a

by Extrusion Plastometer

typical 6.4 mm diameter die that gives a filter area of 12.45

D1600 Terminology forAbbreviatedTerms Relating to Plas-

2

mm .

tics

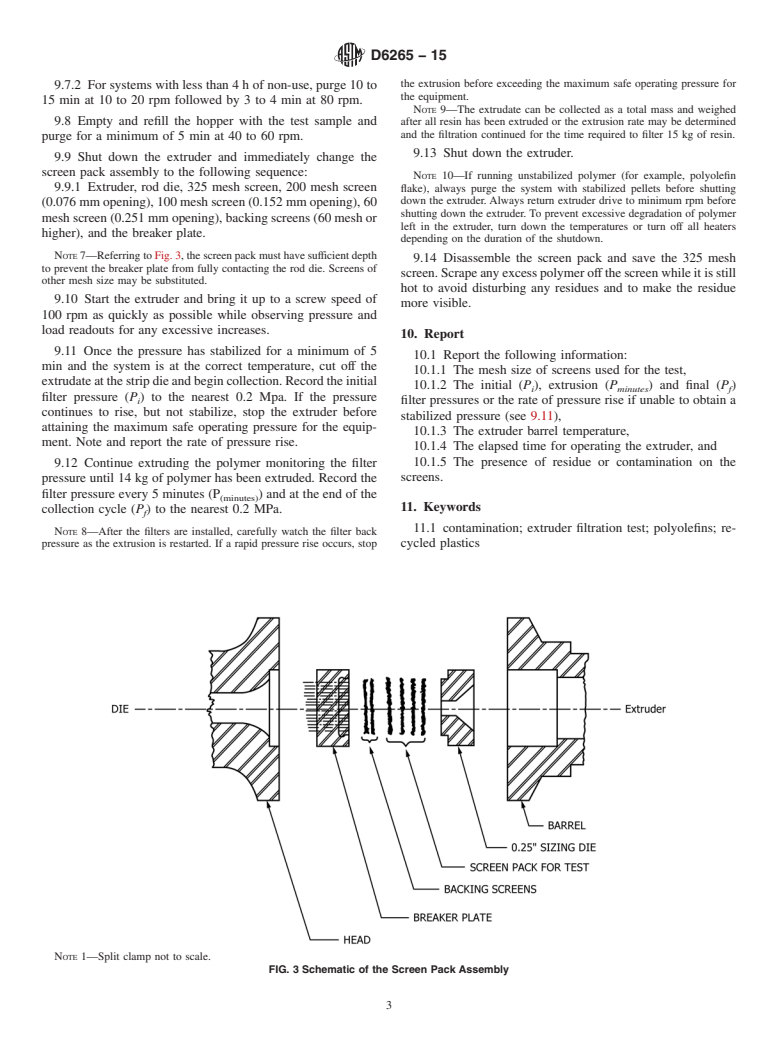

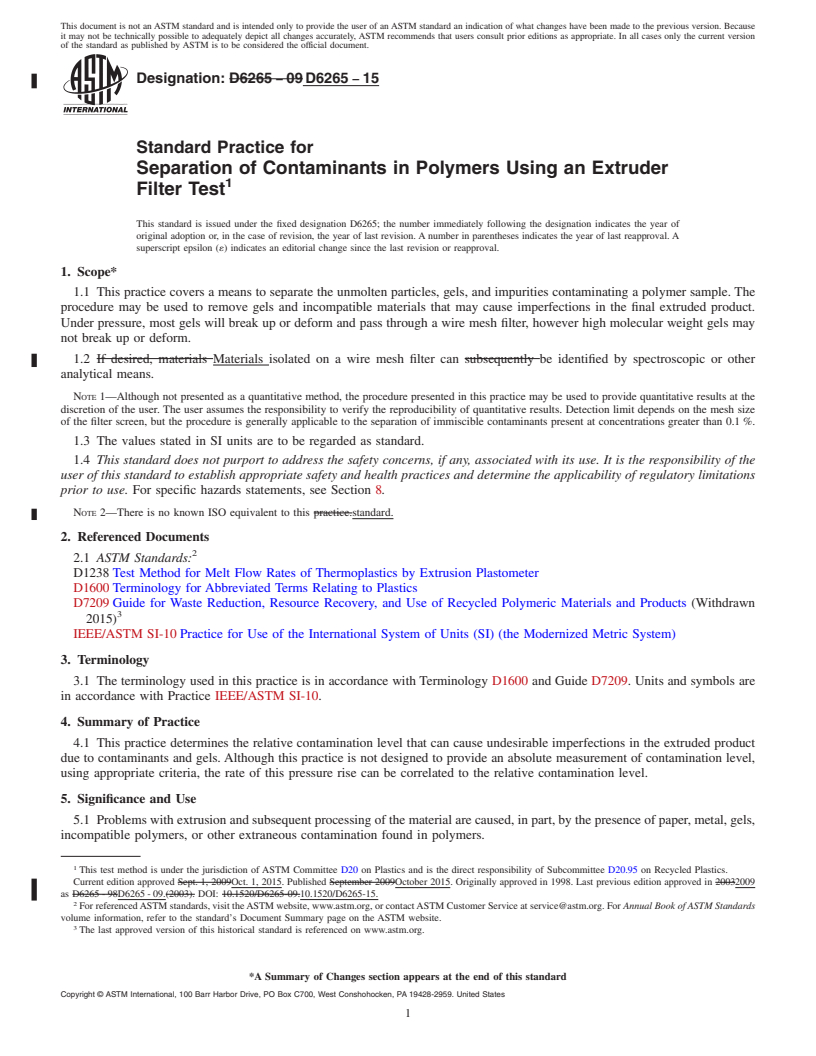

6.1.2 Breaker Plate or Screen Holder—A typical configu-

ration is shown in Fig. 2.

1

6.1.3 Pressure Transducer, installed in-line before the

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.95 on Recycled Plastics.

screen pack and connected to digital readout.

Current edition approved Oct. 1, 2015. Published October 2015. Originally

6.1.4 Melt Thermocouple, installed before or after the

approved in 1998. Last previous edition approved in 2009 as D6265 - 09. DOI:

screen pack.

10.1520/D6265-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6265 − 15

6.6 Spatulas and Scrapers, brass, assorted sizes for remov-

ing molten polymer from equipment.

7. Materials

7.1 Virgin Polymer, free of gels and contaminants, for

purging the extruder equipment.

8. Hazards

8.1 Hot polymer can cause serious burns. D

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6265 − 09 D6265 − 15

Standard Practice for

Separation of Contaminants in Polymers Using an Extruder

1

Filter Test

This standard is issued under the fixed designation D6265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers a means to separate the unmolten particles, gels, and impurities contaminating a polymer sample. The

procedure may be used to remove gels and incompatible materials that may cause imperfections in the final extruded product.

Under pressure, most gels will break up or deform and pass through a wire mesh filter, however high molecular weight gels may

not break up or deform.

1.2 If desired, materials Materials isolated on a wire mesh filter can subsequently be identified by spectroscopic or other

analytical means.

NOTE 1—Although not presented as a quantitative method, the procedure presented in this practice may be used to provide quantitative results at the

discretion of the user. The user assumes the responsibility to verify the reproducibility of quantitative results. Detection limit depends on the mesh size

of the filter screen, but the procedure is generally applicable to the separation of immiscible contaminants present at concentrations greater than 0.1 %.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use. For specific hazards statements, see Section 8.

NOTE 2—There is no known ISO equivalent to this practice.standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1600 Terminology for Abbreviated Terms Relating to Plastics

D7209 Guide for Waste Reduction, Resource Recovery, and Use of Recycled Polymeric Materials and Products (Withdrawn

3

2015)

IEEE/ASTM SI-10 Practice for Use of the International System of Units (SI) (the Modernized Metric System)

3. Terminology

3.1 The terminology used in this practice is in accordance with Terminology D1600 and Guide D7209. Units and symbols are

in accordance with Practice IEEE/ASTM SI-10.

4. Summary of Practice

4.1 This practice determines the relative contamination level that can cause undesirable imperfections in the extruded product

due to contaminants and gels. Although this practice is not designed to provide an absolute measurement of contamination level,

using appropriate criteria, the rate of this pressure rise can be correlated to the relative contamination level.

5. Significance and Use

5.1 Problems with extrusion and subsequent processing of the material are caused, in part, by the presence of paper, metal, gels,

incompatible polymers, or other extraneous contamination found in polymers.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.95 on Recycled Plastics.

Current edition approved Sept. 1, 2009Oct. 1, 2015. Published September 2009October 2015. Originally approved in 1998. Last previous edition approved in 20032009

as D6265 - 98D6265 - 09.(2003). DOI: 10.1520/D6265-09.10.1520/D6265-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6265 − 15

6. Apparatus

6.1 Extruder, designed to deliver a continuous supply of molten resin to a filter at a uniform rate with good temperature control.

Extruders with 18 to 64-mm diameters have been found to be satisfactory.

2

6.1.1 Internal Rod Die, to fix the filter area. Fig. 1 shows a typical 6.4 mm diameter die that gives a filter area of 12.45 mm .

6.1.2 Breaker Plate or Screen Holder—A typical configuration is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.