ASTM B975-18

(Test Method)Standard Test Method for Measurement of Internal Stress of Metallic Coatings by Split Strip Evaluation (Deposit Stress Analyzer Method)

Standard Test Method for Measurement of Internal Stress of Metallic Coatings by Split Strip Evaluation (Deposit Stress Analyzer Method)

SIGNIFICANCE AND USE

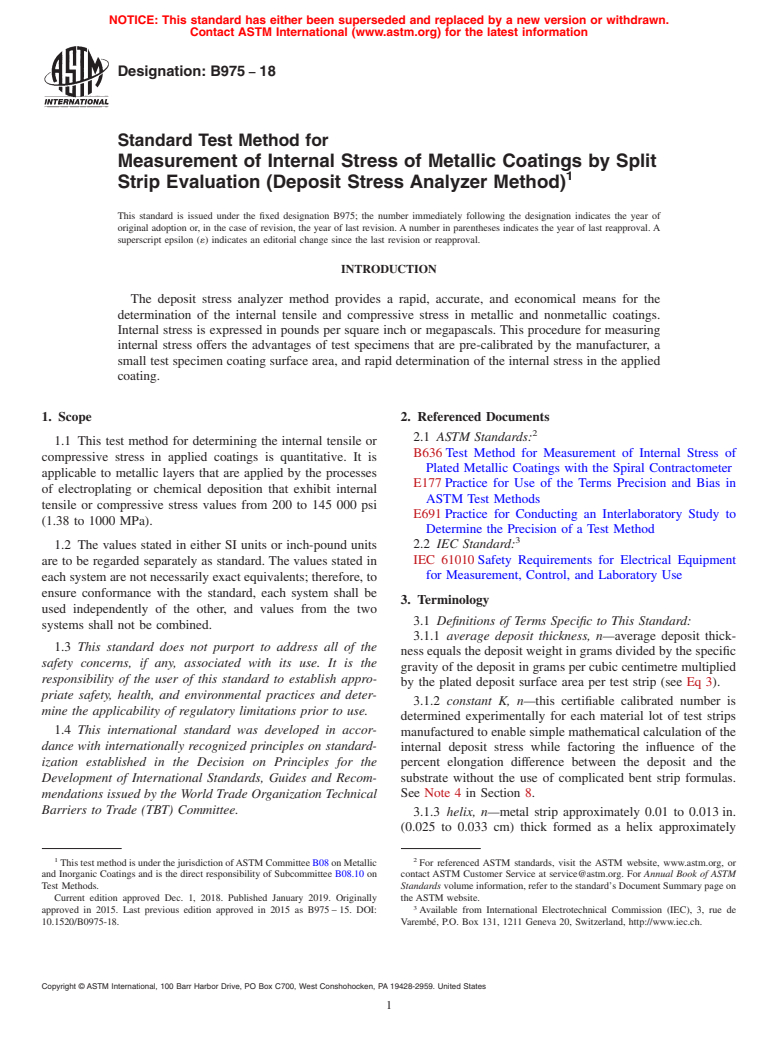

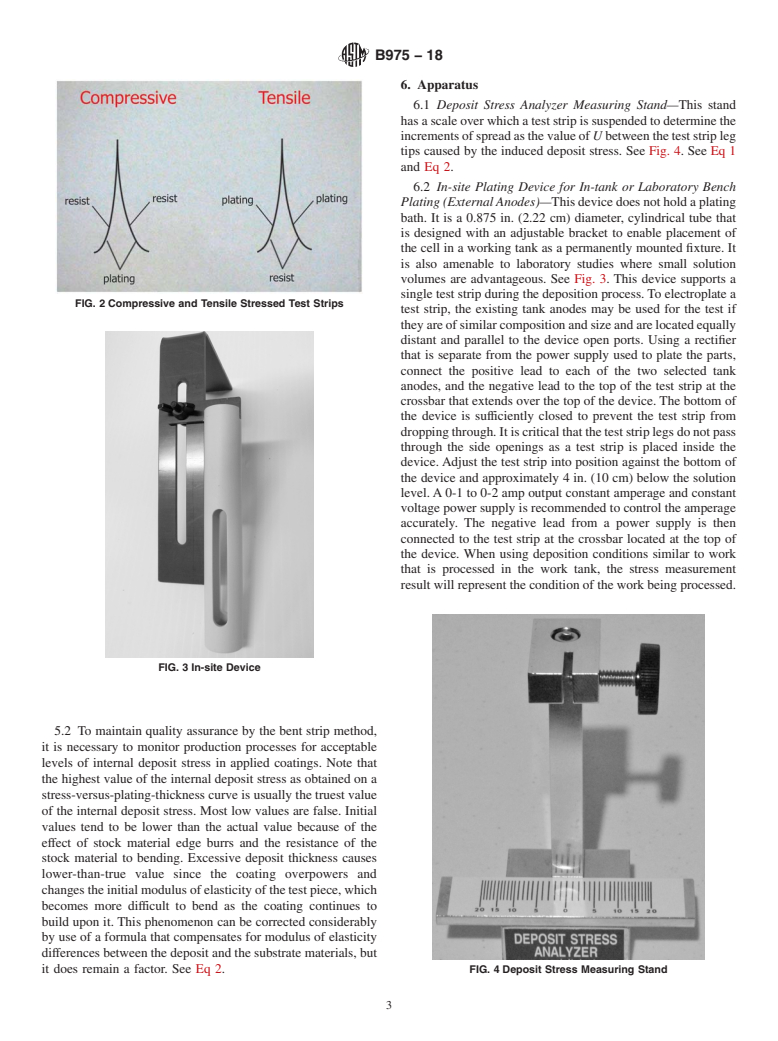

5.1 Internal stress in applied coatings exhibits potential to cause a breakdown of resistance to corrosion and erosion as a result of the formation of fractures from micro-cracking and macro-cracking within the applied coating. This phenomenon can also cause blistering, peeling, reduction of fatigue strength, and loss. The resulting stress can be tensile in nature, causing the deposit to contract, or compressive in nature, causing the deposit to expand.

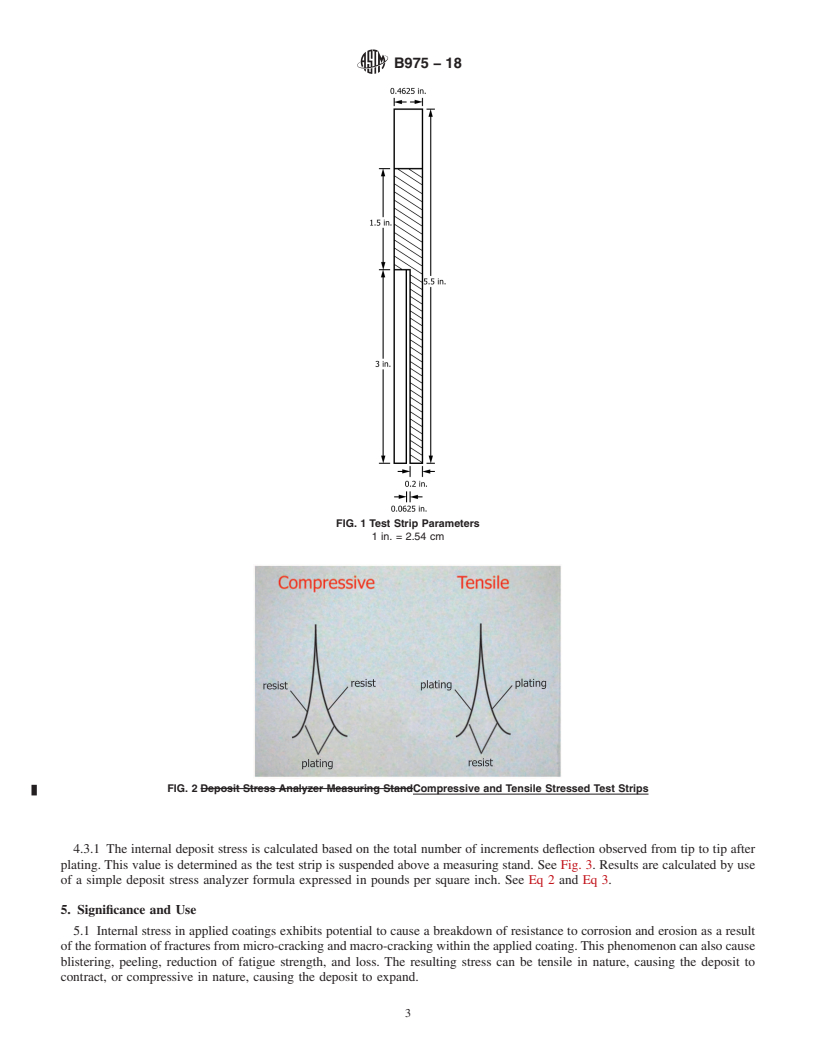

5.2 To maintain quality assurance by the bent strip method, it is necessary to monitor production processes for acceptable levels of internal deposit stress in applied coatings. Note that the highest value of the internal deposit stress as obtained on a stress-versus-plating-thickness curve is usually the truest value of the internal deposit stress. Most low values are false. Initial values tend to be lower than the actual value because of the effect of stock material edge burrs and the resistance of the stock material to bending. Excessive deposit thickness causes lower-than-true value since the coating overpowers and changes the initial modulus of elasticity of the test piece, which becomes more difficult to bend as the coating continues to build upon it. This phenomenon can be corrected considerably by use of a formula that compensates for modulus of elasticity differences between the deposit and the substrate materials, but it does remain a factor. See Eq 2.

SCOPE

1.1 This test method for determining the internal tensile or compressive stress in applied coatings is quantitative. It is applicable to metallic layers that are applied by the processes of electroplating or chemical deposition that exhibit internal tensile or compressive stress values from 200 to 145 000 psi (1.38 to 1000 MPa).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B975 − 18

Standard Test Method for

Measurement of Internal Stress of Metallic Coatings by Split

1

Strip Evaluation (Deposit Stress Analyzer Method)

This standard is issued under the fixed designation B975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The deposit stress analyzer method provides a rapid, accurate, and economical means for the

determination of the internal tensile and compressive stress in metallic and nonmetallic coatings.

Internal stress is expressed in pounds per square inch or megapascals. This procedure for measuring

internal stress offers the advantages of test specimens that are pre-calibrated by the manufacturer, a

small test specimen coating surface area, and rapid determination of the internal stress in the applied

coating.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method for determining the internal tensile or

B636Test Method for Measurement of Internal Stress of

compressive stress in applied coatings is quantitative. It is

Plated Metallic Coatings with the Spiral Contractometer

applicable to metallic layers that are applied by the processes

E177Practice for Use of the Terms Precision and Bias in

of electroplating or chemical deposition that exhibit internal

ASTM Test Methods

tensile or compressive stress values from 200 to 145 000 psi

E691Practice for Conducting an Interlaboratory Study to

(1.38 to 1000 MPa).

Determine the Precision of a Test Method

3

2.2 IEC Standard:

1.2 The values stated in either SI units or inch-pound units

IEC 61010Safety Requirements for Electrical Equipment

are to be regarded separately as standard. The values stated in

for Measurement, Control, and Laboratory Use

eachsystemarenotnecessarilyexactequivalents;therefore,to

ensure conformance with the standard, each system shall be

3. Terminology

used independently of the other, and values from the two

3.1 Definitions of Terms Specific to This Standard:

systems shall not be combined.

3.1.1 average deposit thickness, n—average deposit thick-

1.3 This standard does not purport to address all of the

nessequalsthedepositweightingramsdividedbythespecific

safety concerns, if any, associated with its use. It is the

gravity of the deposit in grams per cubic centimetre multiplied

responsibility of the user of this standard to establish appro-

by the plated deposit surface area per test strip (see Eq 3).

priate safety, health, and environmental practices and deter-

3.1.2 constant K, n—this certifiable calibrated number is

mine the applicability of regulatory limitations prior to use.

determined experimentally for each material lot of test strips

1.4 This international standard was developed in accor-

manufactured to enable simple mathematical calculation of the

dance with internationally recognized principles on standard-

internal deposit stress while factoring the influence of the

ization established in the Decision on Principles for the

percent elongation difference between the deposit and the

Development of International Standards, Guides and Recom- substrate without the use of complicated bent strip formulas.

mendations issued by the World Trade Organization Technical See Note 4 in Section 8.

Barriers to Trade (TBT) Committee.

3.1.3 helix, n—metal strip approximately 0.01 to 0.013in.

(0.025 to 0.033 cm) thick formed as a helix approximately

1 2

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Test Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2018. Published January 2019. Originally the ASTM website.

3

approved in 2015. Last previous edition approved in 2015 as B975–15. DOI: Available from International Electrotechnical Commission (IEC), 3, rue de

10.1520/B0975-18. Varembé, P.O. Box 131, 1211 Geneva 20, Switzerland, http://www.iec.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B975 − 18

0.9in. (2.3 cm) in diameter and 6.1in. (15.5 cm) long with or cable to this approach. A specific test piece comprises a

withoutapolytetrafluoroethylene(PTFE)coatingontheinside selected metallic material that exhibits spring-like properties

surface. with specified dimensions that define an end area split to give

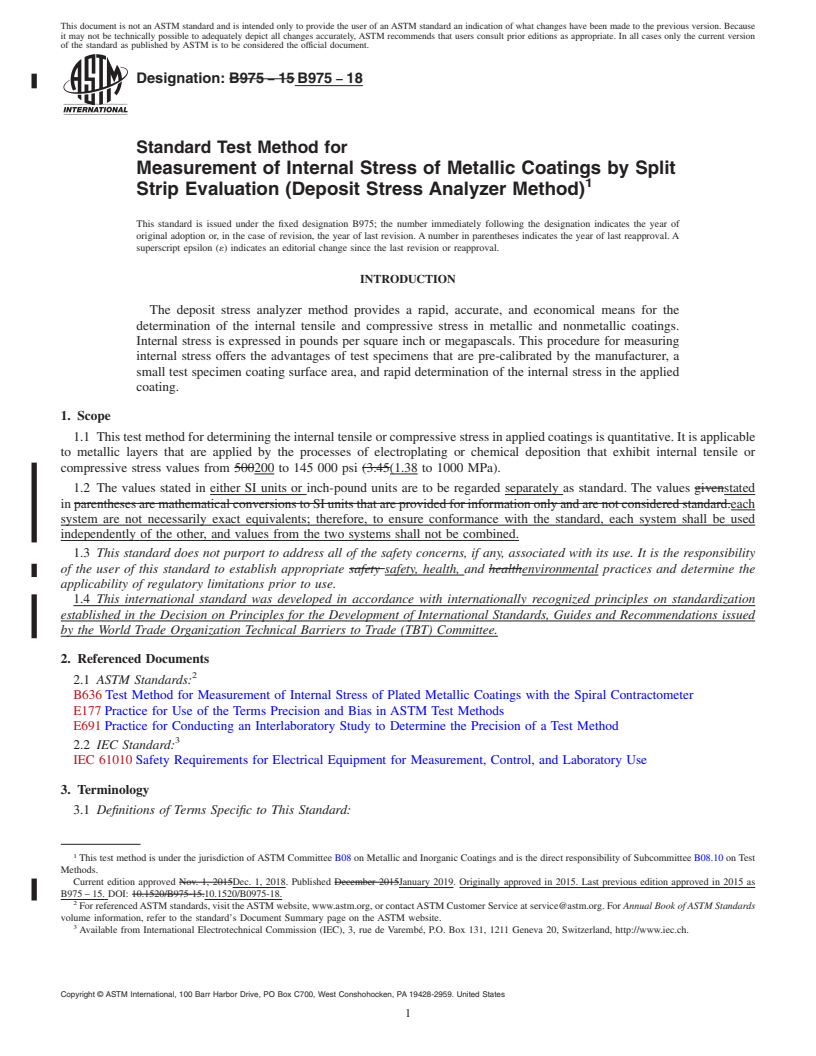

two legs (see Fig. 1). Thes

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B975 − 15 B975 − 18

Standard Test Method for

Measurement of Internal Stress of Metallic Coatings by Split

1

Strip Evaluation (Deposit Stress Analyzer Method)

This standard is issued under the fixed designation B975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The deposit stress analyzer method provides a rapid, accurate, and economical means for the

determination of the internal tensile and compressive stress in metallic and nonmetallic coatings.

Internal stress is expressed in pounds per square inch or megapascals. This procedure for measuring

internal stress offers the advantages of test specimens that are pre-calibrated by the manufacturer, a

small test specimen coating surface area, and rapid determination of the internal stress in the applied

coating.

1. Scope

1.1 This test method for determining the internal tensile or compressive stress in applied coatings is quantitative. It is applicable

to metallic layers that are applied by the processes of electroplating or chemical deposition that exhibit internal tensile or

compressive stress values from 500200 to 145 000 psi (3.45(1.38 to 1000 MPa).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values givenstated

in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.each

system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B636 Test Method for Measurement of Internal Stress of Plated Metallic Coatings with the Spiral Contractometer

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 IEC Standard:

IEC 61010 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on Test

Methods.

Current edition approved Nov. 1, 2015Dec. 1, 2018. Published December 2015January 2019. Originally approved in 2015. Last previous edition approved in 2015 as

B975 – 15. DOI: 10.1520/B975-15.10.1520/B0975-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Electrotechnical Commission (IEC), 3, rue de Varembé, P.O. Box 131, 1211 Geneva 20, Switzerland, http://www.iec.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B975 − 18

3.1.1 average deposit thickness, n—average deposit thickness equals the deposit weight in grams divided by the specific gravity

of the deposit in grams per cubic centimetre multiplied by the plated deposit surface area per test strip (see Eq 3).

3.1.2 constant K, n—this certifiable calibrated number is determined experimentally for each material lot of test strips

manufactured to enable simple mathematical calculation of the internal deposit stress while factoring the influence of the percent

elongation difference between the deposit and the substrate without the use of com

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.