ASTM B860-00

(Specification)Standard Specification for Zinc Master Alloys for Use in Hot Dip Galvanizing

Standard Specification for Zinc Master Alloys for Use in Hot Dip Galvanizing

SCOPE

1.1 This specification covers zinc master alloys which are used in hot dip galvanizing for the purpose of adjusting the concentration of certain alloying elements in the molten zinc bath. Table 1 covers the chemical composition of these materials which include three master alloys of zinc-aluminum (brightener) and one master alloy of zinc-antimony. ASTMCommonUNSType A-190/10 Zn/Al High PurityZ30750Type A-290/10 Zn/Al Low PurityZ31710Type A-395/5 Zn/Al High PurityZ30503Type A-495/5 Zn/Al Low PurityZ31510Type S-190/10 Zn/SbZ55710

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 860 – 00 An American National Standard

Standard Specification for

Zinc Master Alloys for Use in Hot Dip Galvanizing

This standard is issued under the fixed designation B 860; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

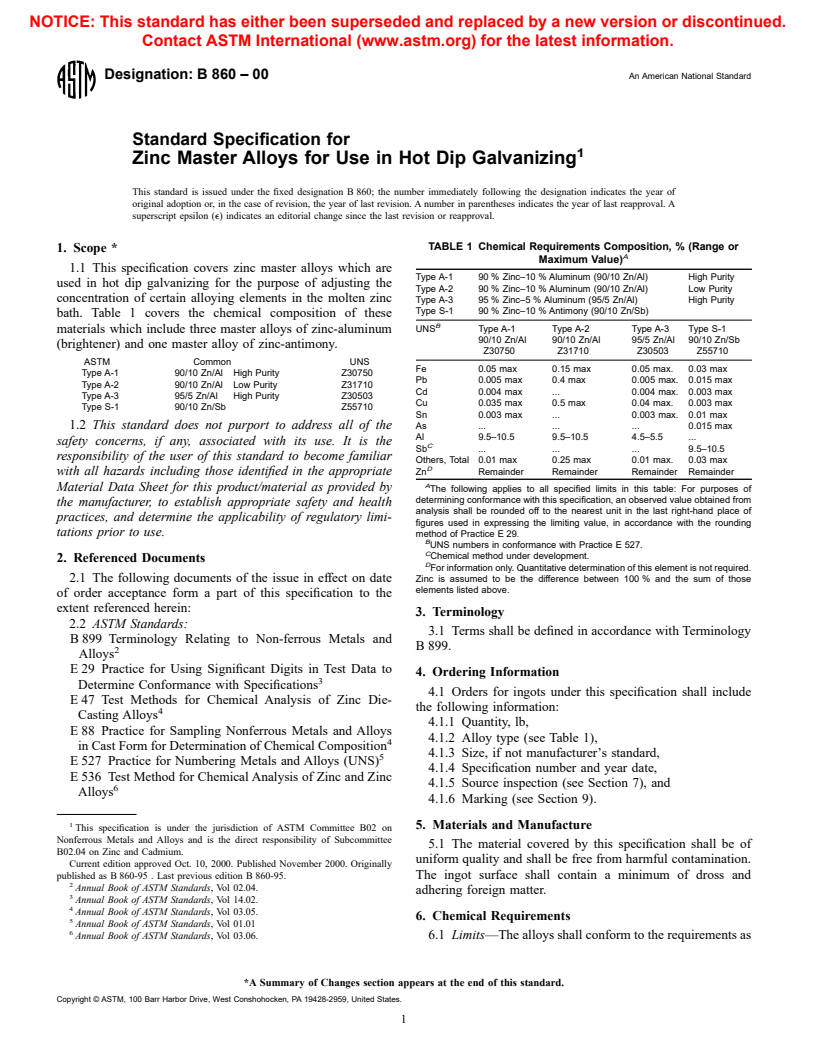

TABLE 1 Chemical Requirements Composition, % (Range or

1. Scope *

A

Maximum Value)

1.1 This specification covers zinc master alloys which are

Type A-1 90 % Zinc–10 % Aluminum (90/10 Zn/Al) High Purity

used in hot dip galvanizing for the purpose of adjusting the

Type A-2 90 % Zinc–10 % Aluminum (90/10 Zn/Al) Low Purity

concentration of certain alloying elements in the molten zinc

Type A-3 95 % Zinc–5 % Aluminum (95/5 Zn/Al) High Purity

Type S-1 90 % Zinc–10 % Antimony (90/10 Zn/Sb)

bath. Table 1 covers the chemical composition of these

B

UNS Type A-1 Type A-2 Type A-3 Type S-1

materials which include three master alloys of zinc-aluminum

90/10 Zn/Al 90/10 Zn/Al 95/5 Zn/Al 90/10 Zn/Sb

(brightener) and one master alloy of zinc-antimony.

Z30750 Z31710 Z30503 Z55710

ASTM Common UNS

Fe 0.05 max 0.15 max 0.05 max. 0.03 max

Type A-1 90/10 Zn/Al High Purity Z30750

Pb 0.005 max 0.4 max 0.005 max. 0.015 max

Type A-2 90/10 Zn/Al Low Purity Z31710

Cd 0.004 max . 0.004 max. 0.003 max

Type A-3 95/5 Zn/Al High Purity Z30503

Cu 0.035 max 0.5 max 0.04 max. 0.003 max

Type S-1 90/10 Zn/Sb Z55710

Sn 0.003 max . 0.003 max. 0.01 max

As . . . 0.015 max

1.2 This standard does not purport to address all of the

Al 9.5–10.5 9.5–10.5 4.5–5.5 .

safety concerns, if any, associated with its use. It is the

C

Sb . . . 9.5–10.5

responsibility of the user of this standard to become familiar

Others, Total 0.01 max 0.25 max 0.01 max. 0.03 max

D

Zn Remainder Remainder Remainder Remainder

with all hazards including those identified in the appropriate

A

Material Data Sheet for this product/material as provided by

The following applies to all specified limits in this table: For purposes of

determining conformance with this specification, an observed value obtained from

the manufacturer, to establish appropriate safety and health

analysis shall be rounded off to the nearest unit in the last right-hand place of

practices, and determine the applicability of regulatory limi-

figures used in expressing the limiting value, in accordance with the rounding

tations prior to use. method of Practice E 29.

B

UNS numbers in conformance with Practice E 527.

C

Chemical method under development.

2. Referenced Documents

D

For information only. Quantitative determination of this element is not required.

2.1 The following documents of the issue in effect on date Zinc is assumed to be the difference between 100 % and the sum of those

elements listed above.

of order acceptance form a part of this specification to the

extent referenced herein:

3. Terminology

2.2 ASTM Standards:

3.1 Terms shall be defined in accordance with Terminology

B 899 Terminology Relating to Non-ferrous Metals and

B 899.

Alloys

E 29 Practice for Using Significant Digits in Test Data to

4. Ordering Information

Determine Conformance with Specifications

4.1 Orders for ingots under this specification shall include

E 47 Test Methods for Chemical Analysis of Zinc Die-

the following information:

Casting Alloys

4.1.1 Quantity, lb,

E 88 Practice for Sampling Nonferrous Metals and Alloys

4.1.2 Alloy type (see Table 1),

in Cast Form for Determination of Chemical Composition

4.1.3 Size, if not manufacturer’s standard,

E 527 Practice for Numbering Metals and Alloys (UNS)

4.1.4 Specification number and year date,

E 536 Test Method for Chemical Analysis of Zinc and Zinc

4.1.5 Source inspection (see Section 7), and

Alloys

4.1.6 Marking (see Section 9).

5. Materials and Manufacture

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

5.1 The material covered by this specification shall be of

B02.04 on Zinc and Cadmium.

uniform quality and shall be free from harmful contamination.

Current edition approved Oct. 10, 2000. Published November 2000. Originally

The ingot surface shall contain a minimum of dross and

published as B 860-95 . Last previous edition B 860-95.

Annual Book of ASTM Standards, Vol 02.04.

adhering foreign matter.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.05.

6. Chemical Requirements

Annual Book of ASTM Standards, Vol 01.01

Annual Book of ASTM Standards, Vol 03.06. 6.1 Limits—The alloys shall conform to the requirements as

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 860

to chemical composition prescribed in Table 1. Conformance 7. Source Inspection

shall be determined by the producer by analyzing samples

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.