ASTM B69-01a(2005)

(Specification)Standard Specification for Rolled Zinc

Standard Specification for Rolled Zinc

ABSTRACT

This specification covers two types of commercial rolled zinc. Type I are coils or sheets cut from strip rolled zinc, and Type II are zinc plates such as boiler and hull plates produced by any rolling method. The products shall be produced by casting, rolling, and other processes found in mill product plant. The material shall be tested and conform to the required chemical composition. The testing of wrought zinc for determination of tensile properties shall be conducted. The testing of zinc for hardness shall be made on a Rockwell superficial hardness tester or on a microhardness tester. The determination of chemical composition shall be performed by either an appropriate chemical method or by optical emission spectrographic methods.

SCOPE

1.1 This specification covers two types of commercial rolled zinc as described in 1.2. It should be understood that the specification is general. Any closer limitations on permissible variations shall be a matter of agreement between the supplier (manufacturer) and the purchaser.

1.2 Rolled zinc is furnished in two types as follows:

1.2.1 Type I - Coils or sheets cut from strip (ribbon) rolled zinc and

1.2.2 Type II - Zinc plates such as boiler and hull plates produced by any rolling method.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 69 – 01a (Reapproved 2005)

Standard Specification for

Rolled Zinc

ThisstandardisissuedunderthefixeddesignationB 69;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 Thisspecificationcoverstwotypesofcommercialrolled

E55 PracticeforSamplingWroughtNonferrousMetalsand

zinc as described in 1.2. It should be understood that the

Alloys for Determination of Chemical Composition

specification is general. Any closer limitations on permissible

E60 Practice for Analysis of Metals, Ores, and Related

variations shall be a matter of agreement between the supplier

Materials by Molecular Absorption Spectrometry

(manufacturer) and the purchaser.

E88 Practice for Sampling Nonferrous Metals and Alloys

1.2 Rolled zinc is furnished in two types as follows:

in Cast Form for Determination of Chemical Composition

1.2.1 Type I - Coils or sheets cut from strip (ribbon) rolled

E 384 Test Method for Microindentation Hardness of Ma-

zinc and

terials

1.2.2 Type II - Zinc plates such as boiler and hull plates

E 527 Practice for Numbering Metals and Alloys (UNS)

produced by any rolling method.

E 536 TestMethodsforChemicalAnalysisofZincandZinc

1.3 The values stated in inch-pound units are to be regarded

Alloys

as the standard. The values given in parentheses are for

E 634 Practice for Sampling of Zinc and Zinc Alloys for

information only.

Optical Emission Spectrometric Analysis

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to become familiar

3.1 Terms shall be defined in accordance with Terminology

with all hazards including those identified in the appropriate

B 899.

Material Safety Data Sheet (MSDS) for this product/material

3.2 Definitions of Terms Specific to This Standard:

as provided by the manufacturer, to establish appropriate

3.2.1 coiled sheet, n—sheet coils with either slit or unslit

safety and health practices, and determine the applicability of

edges.

regulatory limitations prior to use.

3.2.2 flat sheet, n—sheet with sheared, slit, or sawed edges

2. Referenced Documents that has been flattened or leveled.

3.2.3 plate, n—rolled product, rectangular in cross section

2.1 The issue of each of the following reference documents

and form, or thickness of more than 0.125 in. (3.175 mm) with

shall be that which is current on the date the purchase order is

either untrimmed, sheared or sawed edges.

accepted by the supplier (manufacturer).

2 3.2.4 ribbon anode, n—a long, continuous sacrificial anode

2.2 ASTM Standards:

shape, with a diamond, square, rectangular, oval, or other

B 899 Terminology Relating to Non-ferrous Metals and

cross-section, most commonly made of zinc, magnesium or

Alloys

aluminum, having a core wire normally made of steel, that is

E8 Test Methods for Tension Testing of Metallic Materials

usually supplied in coils or reels of 100 to 3600 ft depending

E18 Test Methods for Rockwell Hardness and Rockwell

upon size and cross-section.

Superficial Hardness of Metallic Materials

3.2.5 rolled zinc, n—wrought zinc or zinc alloy sheet, strip,

or plate produced by hot and/or cold rolling.

3.2.6 sheet, n—rolled product, rectangular in cross section

This specification is under the jurisdiction of ASTM Committee B02 on

and form of thickness of 0.003 in. (0.076 mm) through 0.125

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

in. (3.175 mm) with sheared, slit, untrimmed or sawed edges.

B02.04 on Zinc and Cadmium.

Current edition approved Nov. 1, 2005. Published February 2006. Originally

4. Ordering Information

approved in 1926. Last previous edition approved in 2001 as B 69 - 01a.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 Orders for materials under this specification shall in-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

clude the following information:

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1.1 ASTM designation and year of issue,

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 69 – 01a (2005)

4.1.2 Quantity (weight), 7. Mechanical Properties

4.1.3 Name of material (rolled zinc),

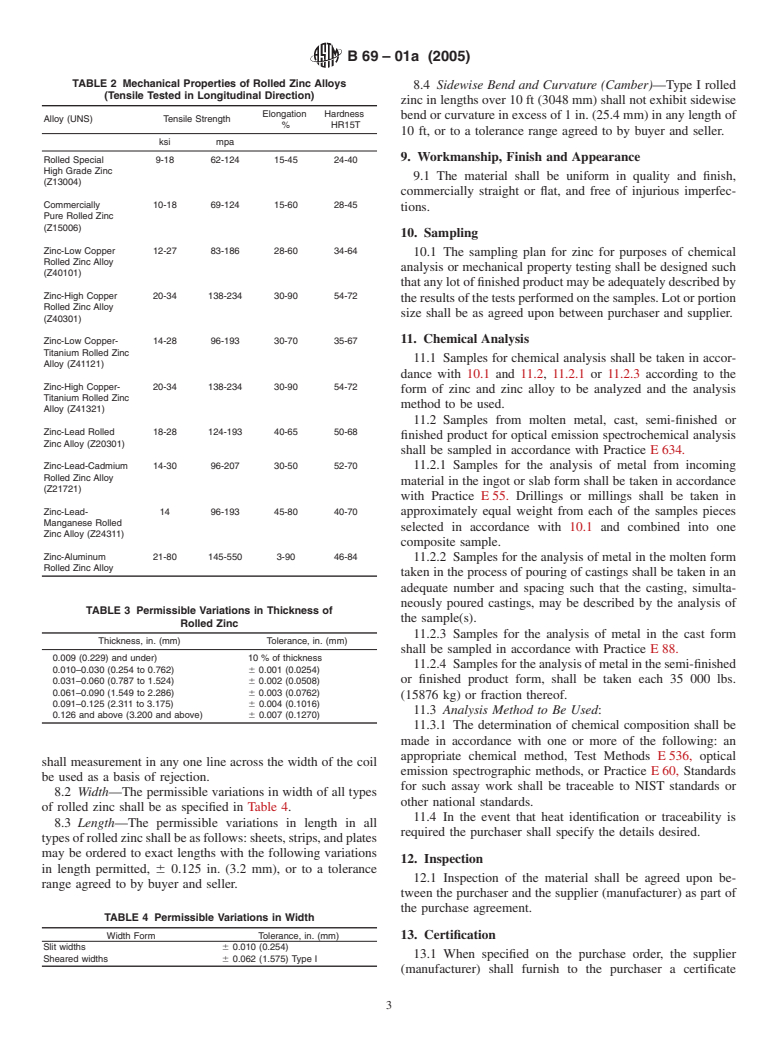

7.1 The material shall conform to the mechanical property

4.1.4 Type of rolled zinc,

requirements in the longitudinal rolling direction in Table 2.

4.1.5 Dimensions (thickness, width, length, or coil),

7.1.1 The testing wrought zinc for determination of tensile

4.1.6 Chemical composition/alloy, and

properties shall be conducted in accordance with Test Methods

4.1.7 Others as agreed upon between the purchaser and the

E8, with the additional recommendation that the rate of

supplier.

separation of the heads during a test be maintained between

0.115 to 0.135 in/in/min (0.115 to 0.135 mm/mm/min) at room

5. Materials and Manufacture

temperature (68 to 75°F (20 to 24°C) suggested).

5.1 Thesupplier(manufacturer)shallensurethateachrolled

7.1.2 The testing of zinc for hardness shall be made on a

zinc product:

Rockwell superficial hardness tester set up for the 15Tscale, in

(a) conforms to the chemical composition specified in the

accordance with Test Methods E 18, or on a microhardness

purchase order,

tester, in accordance with Test Method E 384. Zinc is a time

(b) is free of deleterious inclusions, and

dependent material; therefore, the dwell time of the major load

(c) is of satisfactory appearance.

shall be specified between supplier and customer, for example,

The products covered by this specification shall be produced

4to15s.

by casting, rolling, and other processes found in a mill product

plant.

8. Dimensions and Permissible Variations

6. Chemical Composition

8.1 Thickness—The permissible variations in thickness of

6.1 Alloys—The material shall conform to the chemical rolled zinc shall be as specified in Table 3, along the length of

requirements prescribed in Table 1. thecoilshallbemadewithin12in.(305mm)ofeachother,nor

A

TABLE 1 Chemical Composition of Rolled Zinc Alloys

B

Alloy (UNS) Cu Pb Fe Cd Ti Al Sn Mn Mg Zn

C

Rolled Special 0.003 max 0.003 max 0.003 max 0.003 max . . . 0.002 max 0.001 max

High Grade Zinc . .

(Z13004)

C

Commercially 0.08 max 0.03 max 0.02 max 0.01 max 0.02 max 0.01 max 0.003 max

Pure Rolled Zinc . .

(Z15006)

C

Zinc-Low Copper 0.08 to 0.01 max 0.01 max 0.005 max 0.02 max 0.01 max 0.003 max

Rolled Zinc Alloy 0.040 . .

(Z40101)

C

Zinc-High Copper 0.50 to 0.01 max 0.01 max 0.005 max 0.04 max 0.01 max 0.003 max

Rolled Zinc Alloy 1.0 . .

(Z40301)

C

Zinc-Low Copper- 0.08 to 0.01 max 0.01 max 0.005 max 0.05 to 0.01 max 0.003 max

Titanium Rolled Zinc 0.49 0.18 . .

Alloy (Z41121)

C

Zinc-High Copper- 0.50 to 0.01 max 0.01 max 0.005 max 0.08 to 0.01 max 0.003 max

Titanium Rolled Zinc 1.00 0.18 . .

Alloy (Z41321)

C

Zinc-Lead Rolled 0.005 max 0.10 max 0.01 max 0.01 max 0.02 max 0.002 max

... ... ...

Zinc Allo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.