ASTM D951-17

(Test Method)Standard Test Method for Water Resistance of Shipping Containers by Spray Method

Standard Test Method for Water Resistance of Shipping Containers by Spray Method

SIGNIFICANCE AND USE

4.1 This test method is used to determine the water resistance of shipping containers. It can be used to determine the ability of the container to resist deterioration caused by water or the ability of the container to protect the contents from water. It is frequently used in conjunction with other tests made prior to or after the spray test, such as the drop test, inclined impact test, vibration test or compression test.

SCOPE

1.1 This test method covers the determination of the water resistance of shipping containers.

1.2 This test method is frequently used in conjunction with other tests made prior to or after the spray test, such as the drop test, vibration test, inclined impact test, compression test or the environmental hazard test of Practice D4169, or combinations thereof.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D951 − 17

Standard Test Method for

1

Water Resistance of Shipping Containers by Spray Method

This standard is issued under the fixed designation D951; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Terminology

1.1 This test method covers the determination of the water 3.1 Definitions—For definitions of terms used in this test

resistance of shipping containers. method, refer to Terminology D996.

1.2 This test method is frequently used in conjunction with

4. Significance and Use

other tests made prior to or after the spray test, such as the drop

4.1 This test method is used to determine the water resis-

test, vibration test, inclined impact test, compression test or the

tance of shipping containers. It can be used to determine the

environmental hazard test of Practice D4169, or combinations

ability of the container to resist deterioration caused by water

thereof.

or the ability of the container to protect the contents from

1.3 The values stated in inch-pound units are to be regarded

water.Itisfrequentlyusedinconjunctionwithothertestsmade

as standard. The values given in parentheses are mathematical

prior to or after the spray test, such as the drop test, inclined

conversions to SI units that are provided for information only

impact test, vibration test or compression test.

and are not considered standard.

5. Apparatus

1.4 This standard does not purport to address all of the

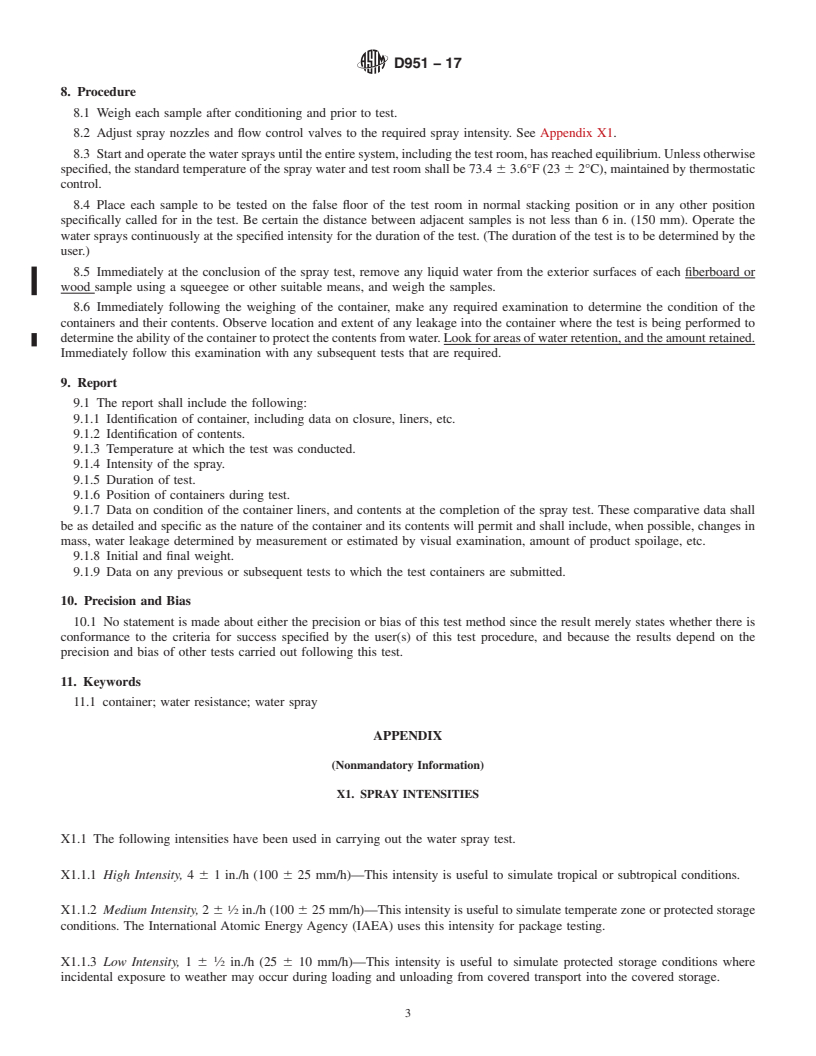

safety concerns, if any, associated with its use. It is the 5.1 The apparatus, illustrated schematically in Fig. 1, shall

consist of the components described in 5.2 – 5.8. Modifications

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- are permissible, such as the use of fresh tap water instead of a

recirculating system, as long as the specified temperature and

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor- spray intensity are achieved.

dance with internationally recognized principles on standard-

5.2 Test Room—A test room or cabinet shall be of water-

ization established in the Decision on Principles for the

resistant construction, insulated and heated when necessary so

Development of International Standards, Guides and Recom-

that proper temperature control can be maintained. The bottom

mendations issued by the World Trade Organization Technical

shall be covered with a false floor of wood, plastic, or metal

Barriers to Trade (TBT) Committee.

slats, or other perforations, and have an outlet drain.

5.3 Sprays—Spray nozzles shall be of such size and so

2. Referenced Documents

spaced that the specified intensity of spray falls uniformly

2

2.1 ASTM Standards:

distributed over the floor area. The spray nozzles shall be so

D996 Terminology of Packaging and Distribution Environ-

located that the droplets are falling from gravitational force

ments

only when they strike the specimens.

D4169 Practice for Performance Testing of Shipping Con-

5.4 Flow Control Valves—Flow control valves, to control

tainers and Systems

the intensity of the spray, are required.

D4332 Practice for Conditioning Containers, Packages, or

Packaging Components for Testing

5.5 Circulating System—A circulating system shall, where

used, consist of a fine-mesh strainer, pump, relief by-pass,

gages, and pressure regulating valve, together with the neces-

1

This test method is under the jurisdiction of ASTM Committee D10 on

sary piping between the flow control valves, spray nozzles, and

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

Containers and Systems - Application of Performance Test Methods.

water reservoir.

Current edition approved Sept. 1, 2017. Published September 2017. Originally

5.6 Reservoir—A reservoir for storage and conditioning of

approved in 1947. Last previous edition approved in 2010 as D951 – 99 (2010).

DOI: 10.1520/D0951-17.

the spray water shall, where used, be equipped with an

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

overflow to a sewer and with a drain to facilitate changing the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

water at the start of each test. Make-up water, regulated by a

Standards volume information, refer to the standard’s Document Summary pag

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D951 − 99 (Reapproved 2010) D951 − 17

Standard Test Method for

1

Water Resistance of Shipping Containers by Spray Method

This standard is issued under the fixed designation D951; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the water resistance of shipping containers.

1.2 This test method is frequently used in conjunction with other tests made prior to or after the spray test, such as the drop

test, vibration test, inclined impact test, or compression test.compression test or the environmental hazard test of Practice D4169,

or combinations thereof.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D685 Practice for Conditioning Paper and Paper Products for Testing

D996 Terminology of Packaging and Distribution Environments

D4169 Practice for Performance Testing of Shipping Containers and Systems

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology D996.

4. Significance and Use

4.1 This test method is used to determine the water resistance of shipping containers. It can be used to determine the ability of

the container to resist deterioration caused by water or the ability of the container to protect the contents from water. It is frequently

used in conjunction with other tests made prior to or after the spray test, such as the drop test, inclined impact test, vibration test

or compression test.

5. Apparatus

5.1 The apparatus, illustrated schematically in Fig. 1, shall consist of the components described in 5.2 – 5.8. Modifications are

permissible, such as the use of fresh tap water instead of a recirculating system, as long as the specified temperature and spray

intensity are achieved.

1

This test method is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

Systems - Application of Performance Test Methods.

Current edition approved April 1, 2010Sept. 1, 2017. Published May 2010September 2017. Originally approved in 1947. Last previous edition approved in 20042010 as

D951 – 99 (2004).(2010). DOI: 10.1520/D0951-99R10.10.1520/D0951-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D951 − 17

FIG. 1 Schematic Diagram of Spray Apparatus

5.2 Test Room—A test room or cabinet shall be of water-resistant construction, insulated and heated when necessary so that

proper temperature control can be maintained. The bottom shall be covered with a false floor of slats wood, plastic, or metal slats,

or other perforations, and have an outlet drain.

5.3 Sprays—Spray nozzles shall be of such size and so spaced that the specified intensity of spray falls uniformly distributed

over the floor area. The spray nozzles shall be so located that the droplets are falling from gravitational force only when they strike

the specimens.

5.4 Flow Control Valves—Flow control valve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.