ASTM F2880-14

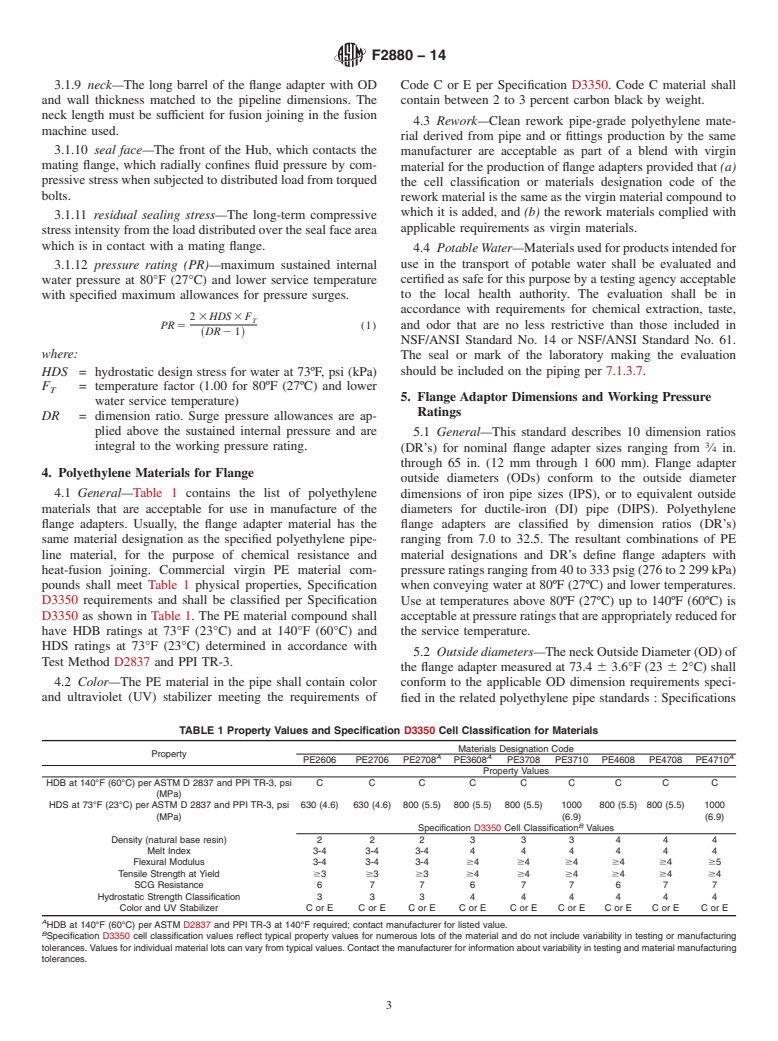

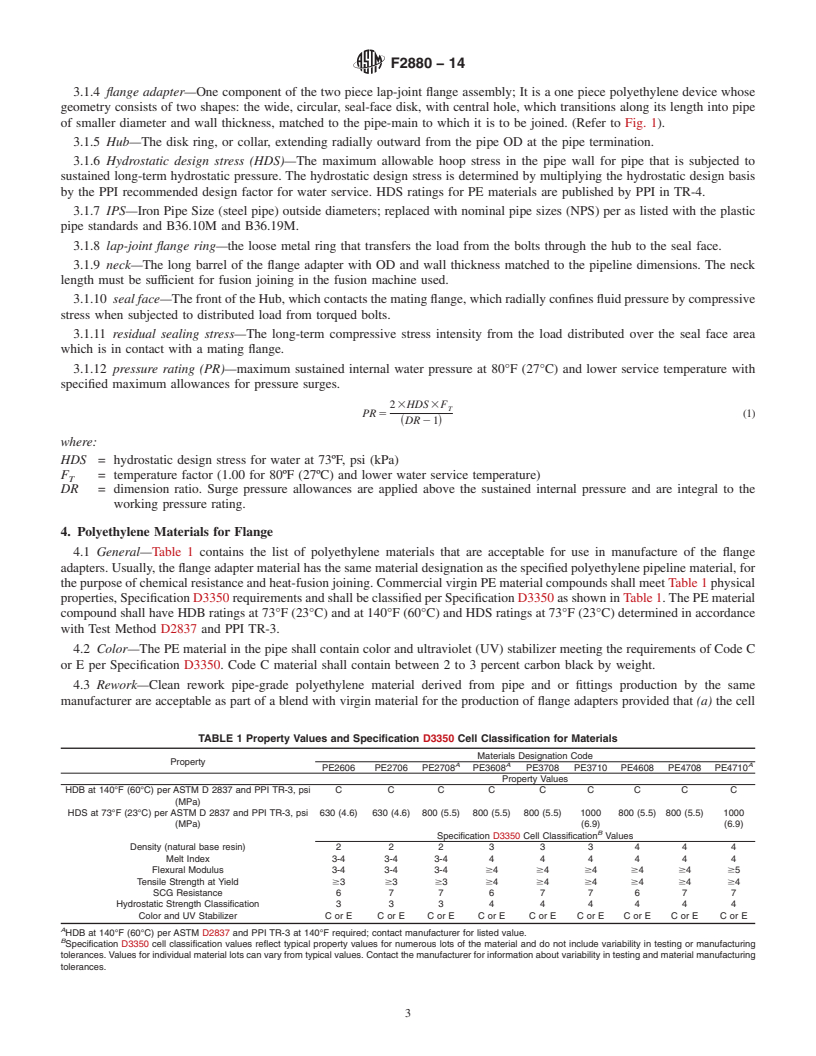

(Specification)Standard Specification for Lap-Joint Type Flange Adapters for Polyethylene Pressure Pipe in Nominal Pipe Sizes 3/4 in. to 65 in.

Standard Specification for Lap-Joint Type Flange Adapters for Polyethylene Pressure Pipe in Nominal Pipe Sizes <fraction><num>3/4</den></fraction > in. to 65 in.

ABSTRACT

This specification covers the polyethylene material and dimensions applicable to flange adapters (FAs) used to connect polyethylene pipes to other flanged pipe and components such as valves and flanged fittings. It describes outside diameter controlled polyethylene (PE) pipe FAs which may be manufactured by various methods including injection molding, compression molding, and machining from thick-wall polyethylene pipe.

SCOPE

1.1 This specification covers the polyethylene material and dimensions applicable to flange adapters (FAs) used to connect polyethylene pipes to other flanged pipe and components such as valves and flanged fittings. This standard describes outside diameter controlled polyethylene (PE) pipe flange adapters (FAs) in diameters ranging from 3/4 in. through 65 in. (12 mm through 1600 mm). The flange adapters may be manufactured by various methods including injection molding, compression molding, and machining from billet or thick-wall polyethylene pipe.

1.2 The flange adapter (FA) is the principal component of the lap-joint flanged assembly widely used for several decades in low-pressure to high-pressure polyethylene pipe systems for all types of pressurized flow (gas and liquid) applications. The flange adapter’s physical shape consists of the pipe-like Neck which is monolithic with its Hub. The Neck is intended to be butt-fused or fusion coupled to the pipe-line; while the Hub face is intended to affect the seal when subjected to the distributed load from the back up ring with its properly torqued bolt-studs and nuts.Note 1—Polyethylene pipe flange adapters with slip on bolt rings are intended for use being bolted to each other or to be bolted to metal flanges having (primarily) Class 150 bolt hole patterns such as those presented in metal flange standards ASME B16.5, ASME B16.47 and AWWA C207.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The use of gaskets and gasket selection are often an integral component of the flange adapter assembly. See the Plastic Pipe Institute Technical Note TN-38 for more information regarding HDPE flanged joints.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2880 −14 An American National Standard

Standard Specification for

Lap-Joint Type Flange Adapters for Polyethylene Pressure

1

3

Pipe in Nominal Pipe Sizes ⁄4 in. to 65 in.

This standard is issued under the fixed designation F2880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This specification covers the polyethylene material and

responsibility of the user of this standard to establish appro-

dimensionsapplicabletoflangeadapters(FAs)usedtoconnect

priate safety and health practices and determine the applica-

polyethylene pipes to other flanged pipe and components such

bility of regulatory limitations prior to use.

as valves and flanged fittings. This standard describes outside

diameter controlled polyethylene (PE) pipe flange adapters

2. Referenced Documents

3

(FAs) in diameters ranging from ⁄4 in. through 65 in. (12 mm

2

2.1 ASTM Standards:

through 1600 mm). The flange adapters may be manufactured

D2122Test Method for Determining Dimensions of Ther-

by various methods including injection molding, compression

moplastic Pipe and Fittings

molding, and machining from billet or thick-wall polyethylene

D2513Specification for Polyethylene (PE) Gas Pressure

pipe.

Pipe, Tubing, and Fittings

1.2 The flange adapter (FA) is the principal component of

D2837Test Method for Obtaining Hydrostatic Design Basis

the lap-joint flanged assembly widely used for several decades

forThermoplasticPipeMaterialsorPressureDesignBasis

inlow-pressuretohigh-pressurepolyethylenepipesystemsfor

for Thermoplastic Pipe Products

all types of pressurized flow (gas and liquid) applications. The

D3035SpecificationforPolyethylene(PE)PlasticPipe(DR-

flange adapter’s physical shape consists of the pipe-like Neck

PR) Based on Controlled Outside Diameter

which is monolithic with its Hub. The Neck is intended to be

D3261SpecificationforButtHeatFusionPolyethylene(PE)

butt-fused or fusion coupled to the pipe-line; while the Hub

Plastic Fittings for Polyethylene (PE) Plastic Pipe and

face is intended to affect the seal when subjected to the

Tubing

distributedloadfromthebackupringwithitsproperlytorqued

D3350Specification for Polyethylene Plastics Pipe and Fit-

bolt-studs and nuts.

tings Materials

F714Specification for Polyethylene (PE) Plastic Pipe (DR-

NOTE 1—Polyethylene pipe flange adapters with slip on bolt rings are

intendedforusebeingboltedtoeachotherortobeboltedtometalflanges

PR) Based on Outside Diameter

having (primarily) Class 150 bolt hole patterns such as those presented in

F2206Specification for Fabricated Fittings of Butt-Fused

metal flange standards ASME B16.5, ASME B16.47 and AWWA C207.

Polyethylene (PE)

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

F3034Specification for Billets made by Winding Molten

as standard. The values given in parentheses are mathematical

Extruded Stress-Rated High Density Polyethylene

conversions to SI units that are provided for information only

(HDPE)

3

and are not considered standard.

2.2 ASME Standards:

B16.5“Pipe Flanges and Flanged Fittings”

1.4 The use of gaskets and gasket selection are often an

B16.47“Large Diameter Steel Flanges: NPS 26 through

integral component of the flange adapter assembly. See the

NPS 60” Class #150 – Series A

Plastic Pipe Institute Technical Note TN-38 for more informa-

tion regarding HDPE flanged joints.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

PipingSystemsandisthedirectresponsibilityofSubcommitteeF17.10onFittings. the ASTM website.

3

Current edition approved May 1, 2014. Published June 2014. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 2011. Last previous edition approved in 2011 as F2880–11a. DOI: International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

10.1520/F2880-14. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2880−14

B36.10MWelded and Seamless Wrought Steel Pipe 3.1.1 billet, n—a mass formed from a single polyethylene

B36.19MStainless Steel Pipe compound in the approximate shape of a thick-walled cylin-

4

2.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2880 − 11a F2880 − 14 An American National Standard

Standard Specification for

Lap-Joint Type Flange Adapters for Polyethylene Pressure

1

3

Pipe in Nominal Pipe Sizes ⁄4 in. to 65 in.

This standard is issued under the fixed designation F2880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Table 5 has been included, editorial changes were made throughout, and the year date was changed on July 22, 2011.

1. Scope Scope*

1.1 This specification covers the polyethylene material and dimensions applicable to flange adapters (FAs) used to connect

polyethylene pipes to other flanged pipe and components such as valves and flanged fittings. This standard describes outside

3

diameter controlled polyethylene (PE) pipe flange adapters (FAs) in diameters ranging from ⁄4 in. through 65 in. (12 mm through

1600 mm). The flange adapters may be manufactured by various methods including injection molding, compression molding, and

machining from billet or thick-wall polyethylene pipe.

1.2 The flange adapter (FA) is the principal component of the lap-joint flanged assembly widely used for several decades in

low-pressure to high-pressure polyethylene pipe systems for all types of pressurized flow (gas and liquid) applications. The flange

adapter’s physical shape consists of the pipe-like Neck which is monolithic with its Hub. The Neck is intended to be butt-fused

or fusion coupled to the pipe-line; while the Hub face is intended to affect the seal when subjected to the distributed load from

the back up ring with its properly torqued bolt-studs and nuts.

NOTE 1—Polyethylene pipe flange adapters with slip on bolt rings are intended for use being bolted to each other or to be bolted to metal flanges having

(primarily) Class 150 bolt hole patterns such as those presented in metal flange standards ASME B16.5, ASME B16.47 and AWWA C207.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The use of gaskets and gasket selection are often an integral component of the flange adapter assembly. See the Plastic Pipe

Institute Technical Note TN-38 for more information regarding HDPE flanged joints.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2513 Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

D3035 Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter

D3261 Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

F714 Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Outside Diameter

F2206 Specification for Fabricated Fittings of Butt-Fused Polyethylene (PE) Plastic Pipe, Fittings, Sheet Stock, Plate Stock, or

Block Stock

F3034 Specification for Billets made by Winding Molten Extruded Stress-Rated High Density Polyethylene (HDPE)

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved July 22, 2011May 1, 2014. Published July 2011June 2014. Originally approved in 2011. Last previous edition approved in 2011 as

F2880–11.–11a. DOI: 10.1520/F2880-11A.10.1520/F2880-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.