ASTM D3295-97

(Specification)Standard Specification for PTFE Tubing, Miniature Beading and Spiral Cut Tubing

Standard Specification for PTFE Tubing, Miniature Beading and Spiral Cut Tubing

SCOPE

1.1 This specification covers PTFE tubing, miniature beading and spiral cut tubing-manufactured from PTFE resin produced from dispersion specified in Specification D 4895.

Note 1—PTFE tube and rod manufactured from resin specified in Specification D 4894 are covered in Specification D 1710.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 As PTFE resin produced from dispersion is not a true thermoplastic material, any reuse for the specification referenced above is impossible. However, markets do exist for non-virgin PTFE as additives and fillers.Note 2—There is currently no published ISO standard relating to this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3295 – 97

Standard Specification for

PTFE Tubing

This standard is issued under the fixed designation D 3295; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * D 3892 Practice for Packaging/Packing of Plastics

D 4894 Specification for Polytetrafluoroethylene Granular

1.1 This specification covers PTFE tubing manufactured

Molding and Ram Extrusion Materials

from PTFE resin produced from dispersion specified in Speci-

D 4895 Specification for Polytetrafluoroethylene Resin Pro-

fication D 4895.

duced From Dispersion

NOTE 1—PTFE tube and rod manufactured from resin specified in

E 691 Practice for Conducting an Interlaboratory Study to

Specification D 4894 are covered in Specification D 1710.

Determine the Precision of a Test Method

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard. The inch-pound units given in parentheses are for

information only.

3.1 Definitions:

1.3 The following hazard caveat pertains only to the test

3.1.1 The terminology given in Terminology D 883 is ap-

method portion, Section 8, of this specification: This standard

plicable to this specification.

does not purport to address all of the safety concerns, if any,

3.2 Description of Term Specific to This Standard:

associated with its use. It is the responsibility of the user of this

3.2.1 lot—a collection of units of product from which a

standard to establish appropriate safety and health practices

sample is to be drawn and inspected to determine conformance

and determine the applicability of regulatory limitations prior

with the acceptability criteria, and is to be accepted or rejected

to use.

as a whole. It may differ from a collection of units designated

1.4 There is currently no published ISO standard relating to

as a lot for other purposes, for example, production, shipment,

this specification.

etc.

2. Referenced Documents

4. Classification

2.1 ASTM Standards:

4.1 This specification provides for two types of PTFE

D 618 Practice for Conditioning Plastics and Electrical

tubing differentiated by size schedule as follows:

Insulating Materials for Testing

4.1.1 Type I—Tubing based upon the American Wire Gage

D 792 Test Methods for Specific Gravity (Relative Density)

(AWG) sizes.

and Density of Plastics by Displacement

4.1.2 Type II—Tubing based upon fractional inch sizes.

D 883 Terminology Relating to Plastics

4.2 The types are further differentiated in accordance with

D 1505 Test Method for Density of Plastics by the Density-

increasing wall thicknesses as follows:

Gradient Technique

4.2.1 Grade A—Tubing having walls tabulated in Table 1

D 1600 Terminology for Abbreviated Terms Relating to

listed as light-weight wall.

Plastics

4.2.2 Grade B—Tubing having walls of greater thickness

D 1675 Test Method for Polytetrafluoroethylene Tubing

than Class A listed as thin wall.

D 1710 Specification for Polytetrafluoroethylene (PTFE)

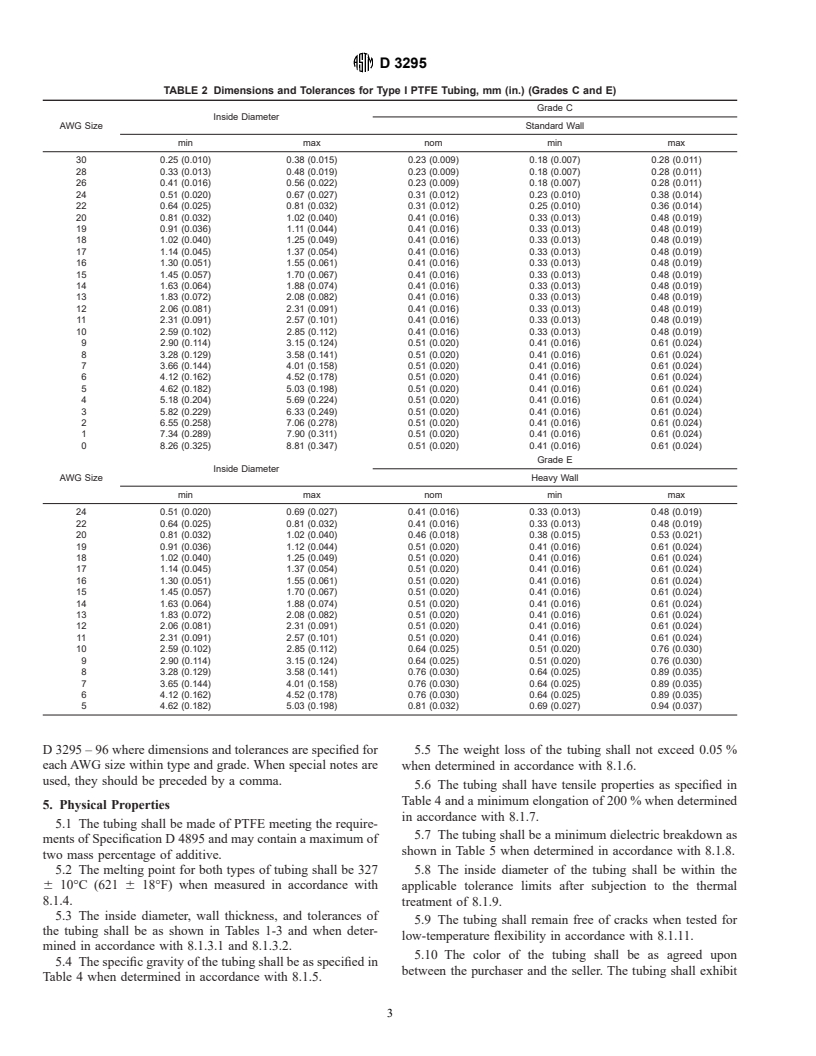

4.2.3 Grade C—Tubing having walls tabulated in Table 2

Basic Shapes, Rod, and Heavy-Walled Tubing

listed as standard wall.

D 1898 Practice for Sampling of Plastics

4.2.4 Grade D—Tubing having walls tabulated in Table 3

listed as chemical tubing.

4.2.5 Grade E—Tubing having walls tabulated in Table

2and Table 3 listed as heavy wall.

This specification is under the jurisdiction of ASTM Committee D-20 on

4.3 A one-line system may be used to specify materials

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials (Section D20.15.12).

covered by this specification. The system uses predefined cells

Current edition approved Nov. 10, 1997. Published April 1998. Originally

published as D 3295 – 74. Last previous edition D 3295 – 96.

Annual Book of ASTM Standards, Vol 08.01.

3 5

Annual Book of ASTM Standards, Vols 08.01 and 08.04. Annual Book of ASTM Standards, Vol 08.02.

4 6

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3295

TABLE 1 Dimensions and Tolerances for Type I PTFE Tubing, mm (in.) (Grades A and B)

Grade A

Inside Diameter

AWG Size Lightweight Wall

min max nom min max

30 0.25 (0.010) 0.38 (0.015) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

28 0.33 (0.013) 0.46 (0.018) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

26 0.41 (0.016) 0.53 (0.021) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

24 0.51 (0.020) 0.66 (0.026) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

22 0.64 (0.025) 0.81 (0.032) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

20 0.81 (0.032) 1.01 (0.040) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

19 0.91 (0.036) 1.12 (0.044) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

18 1.02 (0.040) 1.25 (0.049) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

17 1.14 (0.045) 1.37 (0.054) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

16 1.30 (0.051) 1.55 (0.061) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

15 1.45 (0.057) 1.70 (0.067) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

14 1.65 (0.064) 1.88 (0.074) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

13 1.83 (0.072) 2.08 (0.082) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

12 2.06 (0.081) 2.31 (0.091) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

11 2.31 (0.091) 2.57 (0.101) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

10 2.59 (0.102) 2.85 (0.112) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

9 2.90 (0.114) 3.15 (0.124) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

8 3.28 (0.129) 3.58 (0.141) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010)

7 3.66 (0.144) 4.01 (0.158) 0.20 (0.008) 0.15 (0.005) 0.25 (0.011)

6 4.12 (0.162) 4.52 (0.178) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

5 4.62 (0.182) 5.03 (0.198) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

4 5.18 (0.204) 5.69 (0.224) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

3 5.82 (0.229) 6.33 (0.249) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

2 6.55 (0.258) 7.06 (0.278) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

1 7.34 (0.289) 7.90 (0.311) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

0 8.26 (0.325) 8.81 (0.347) 0.25 (0.012) 0.22 (0.009) 0.38 (0.015)

Grade B

Inside Diameter

AWG Size Thin Wall

min max nom min max

30 0.25 (0.010) 0.38 (0.015) 0.23 (0.009) 0.19 (0.007) 0.28 (0.011)

28 0.33 (0.013) 0.48 (0.019) 0.23 (0.009) 0.18 (0.007) 0.28 (0.011)

26 0.41 (0.016) 0.56 (0.022) 0.23 (0.009) 0.18 (0.007) 0.28 (0.011)

24 0.51 (0.020) 0.69 (0.027) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

22 0.64 (0.025) 0.81 (0.032) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013)

20 0.81 (0.032) 1.01 (0.040) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

19 0.91 (0.036) 1.11 (0.044) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

18 1.02 (0.040) 1.25 (0.049) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

17 1.14 (0.045) 1.38 (0.054) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

16 1.30 (0.051) 1.55 (0.061) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

15 1.45 (0.057) 1.70 (0.067) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

14 1.63 (0.064) 1.88 (0.074) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

13 1.83 (0.072) 2.08 (0.082) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

12 2.06 (0.081) 2.31 (0.091) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

11 2.31 (0.091) 2.57 (0.101) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

10 2.59 (0.102) 2.85 (0.112) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015)

9 2.90 (0.114) 3.15 (0.124) 0.38 (0.015) 0.31 (0.012) 0.46 (0.018)

8 3.28 (0.129) 3.58 (0.141) 0.38 (0.015) 0.31 (0.012) 0.46 (0.018)

7 3.66 (0.144) 4.01 (0.158) 0.38 (0.015) 0.31 (0.012) 0.46 (0.018)

6 4.12 (0.162) 4.52 (0.178) 0.38 (0.015) 0.31 (0.012) 0.46 (0.018)

5 4.62 (0.182) 5.03 (0.198) 0.38 (0.015) 0.35 (0.012) 0.46 (0.018)

4 5.18 (0.204) 5.69 (0.224) 0.38 (0.015) 0.35 (0.012) 0.46 (0.018)

3 5.82 (0.229) 6.33 (0.249) 0.38 (0.015) 0.35 (0.012) 0.46 (0.018)

2 6.55 (0.258) 7.06 (0.278) 0.38 (0.015) 0.35 (0.012) 0.46 (0.018)

1 7.34 (0.289) 7.90 (0.311) 0.38 (0.015) 0.35 (0.012) 0.46 (0.018)

0 8.26 (0.325) 8.81 (0.347) 0.38 (0.015) 0.35 (0.012) 0.46 (0.018)

to refer to specific aspects of this specification, as illustrated and grade in the appropriate specified properties, tables, or

below. both, in the specification identified. A comma is used as the

separator between the standard number and the type. Separa-

Specification

Type : Grade : Class

tors are not needed between the type, and grade. Provision for

Standard Number: Block Special Notes

:: :::

special notes is included so that other information can be

Example: Specification

IA

provided when required. An example would be in Specification

D3295–97

For this example, the line callout would be Specification

D 3295 – 97, IA and would specify tubing having walls listed

See the Form and Style Manual for ASTM Standards, available from ASTM

as lightweight wall that has all the properties listed for that type Headquarters.

D 3295

TABLE 2 Dimensions and Tolerances for Type I PTFE Tubing, mm (in.) (Grades C and E)

Grade C

Inside Diameter

AWG Size Standard Wall

min max nom min max

30 0.25 (0.010) 0.38 (0.015) 0.23 (0.009) 0.18 (0.007) 0.28 (0.011)

28 0.33 (0.013) 0.48 (0.019) 0.23 (0.009) 0.18 (0.007) 0.28 (0.011)

26 0.41 (0.016) 0.56 (0.022) 0.23 (0.009) 0.18 (0.007) 0.28 (0.011)

24 0.51 (0.020) 0.67 (0.027) 0.31 (0.012) 0.23 (0.010) 0.38 (0.014)

22 0.64 (0.025) 0.81 (0.032) 0.31 (0.012) 0.25 (0.010) 0.36 (0.014)

20 0.81 (0.032) 1.02 (0.040) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

19 0.91 (0.036) 1.11 (0.044) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

18 1.02 (0.040) 1.25 (0.049) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

17 1.14 (0.045) 1.37 (0.054) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

16 1.30 (0.051) 1.55 (0.061) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

15 1.45 (0.057) 1.70 (0.067) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

14 1.63 (0.064) 1.88 (0.074) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

13 1.83 (0.072) 2.08 (0.082) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

12 2.06 (0.081) 2.31 (0.091) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

11 2.31 (0.091) 2.57 (0.101) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

10 2.59 (0.102) 2.85 (0.112) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

9 2.90 (0.114) 3.15 (0.124) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

8 3.28 (0.129) 3.58 (0.141) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

7 3.66 (0.144) 4.01 (0.158) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

6 4.12 (0.162) 4.52 (0.178) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

5 4.62 (0.182) 5.03 (0.198) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

4 5.18 (0.204) 5.69 (0.224) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

3 5.82 (0.229) 6.33 (0.249) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

2 6.55 (0.258) 7.06 (0.278) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

1 7.34 (0.289) 7.90 (0.311) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

0 8.26 (0.325) 8.81 (0.347) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

Grade E

Inside Diameter

AWG Size Heavy Wall

min max nom min max

24 0.51 (0.020) 0.69 (0.027) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

22 0.64 (0.025) 0.81 (0.032) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

20 0.81 (0.032) 1.02 (0.040) 0.46 (0.018) 0.38 (0.015) 0.53 (0.021)

19 0.91 (0.036) 1.12 (0.044) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

18 1.02 (0.040) 1.25 (0.049) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

17 1.14 (0.045) 1.37 (0.054) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

16 1.30 (0.051) 1.55 (0.061) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

15 1.45 (0.057) 1.70 (0.067) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

14 1.63 (0.064) 1.88 (0.074) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

13 1.83 (0.072) 2.08 (0.082) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

12 2.06 (0.081) 2.31 (0.091) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

11 2.31 (0.091) 2.57 (0.101) 0.51 (0.020) 0.41 (0.016) 0.61 (0.024)

10 2.59 (0.102) 2.85 (0.112) 0.64 (0.025) 0.51 (0.020) 0.76 (0.030)

9 2.90 (0.114) 3.15 (0.124) 0.64 (0.025) 0.51 (0.020) 0.76 (0.030)

8 3.28 (0.129) 3.58 (0.141) 0.76 (0.030) 0.64 (0.025) 0.89 (0.035)

7 3.65 (0.144) 4.01 (0.158) 0.76 (0.030) 0.64 (0.025) 0.89 (0.035)

6 4.12 (0.162) 4.52 (0.178) 0.76 (0.030) 0.64 (0.025) 0.89 (0.035)

5 4.62 (0.182) 5.03 (0.198) 0.81 (0.032) 0.69 (0.027) 0.94 (0.037)

D 3295 – 96 where dimensions and tolerances are specified for 5.5 The weight loss of the tubing shall not exceed 0.05 %

each AWG size within type and grade. When special notes are when determined in accordance with 8.1.6.

used, they should be preceded by a comma.

5.6 The tubing shall have tensile properties as specified in

Table 4 and a minimum elongation of 200 % when determined

5. Physical Properties

in accordance with 8.1.7.

5.1 The tubing shall be made of PTFE meeting the require-

5.7 The tubing shall be a minimum dielectric breakdown as

ments of Specification D 4895 and may contain a maximum of

shown in Table 5 when determined in accordance with 8.1.8.

two mass percentage of additive.

5.2 The melting point for both types of tubing shall be 327 5.8 The inside diameter of the tubing shall be within the

6 10°C (621 6 18°F) when measured in accordance with

applicable tolerance limits after subjection to the thermal

8.1.4.

treatment of 8.1.9.

5.3 The inside diameter, wall thickness, and tolerances of

5.9 The tubing shall remain free of cracks when tested for

the tubing shall be as shown in Tables 1-3 and when deter-

low-temperature flexibility in accordance with 8.1.11.

mined in accordance with 8.1.3.1 and 8.1.3.2.

5.10 The color of the tubing shall be as agreed upon

5.4 The specific gravity of the tubing shall be as specified in

between the purchaser and the seller. The tubing shall exhibit

Table 4 when determined in accordance with 8.1.5.

D 3295

TABLE 3 Dimensions and Tolerances for Type II PTFE Tubing, mm (in.)

Inside Diameter Wall Thickness

Fractional

Grade A, B, C Grade A Grade B Grade C

Sizes

nom min max nom min max nom min max nom min max

0.79 ( ⁄32) 0.79 (0.031) 0.74 (0.031) 0.84 (0.014) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008) 0.25 (0.010) 0.20 (0.008) 0.31 (0.012) 0.31 (0.012) 0.25 (0.010) 0.36 (0.014)

1.6 ( ⁄16) 1.7 (0.063) 1.6 (0.063) 1.85 (0.063) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

2.4 ( ⁄32) 2.4 (0.094) 2.3 (0.091) 2.5 (0.099) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010) 0.31 (0.012) 0.23 (0.009) 0.38 (0.015) 0.41 (0.016) 0.33 (0.013) 0.48 (0.019)

3.2 ( ⁄8) 3.2 (0.125) 3.1 (0.120) 3.3 (0.130) 0.20 (0.008) 0.15 (0.006) 0.25 (0.010) 0.38 (0.015) 0.28 (0.011) 0.48 (0.019) 0.51 (0.020) 0.40 (0.016) 0.61 (0.024)

4.8 ( ⁄16) 4.7 (0.192) 4.6 (0.192) 5.0 (0.198) 0.25 (0.010) 0.18 (0.007) 0.33 (0.013) 0.38 (0.015) 0.28 (0.011) 0.48 (0.019) 0.51 (0.020) 0.40 (0.016) 0.61 (0.024)

6.4 ( ⁄4) 6.5 (0.255) 6.4 (0.250) 6.6 (0.260) 0.24 (0.010) 0.18 (0.007) 0.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.