ASTM A949/A949M-00a

(Specification)Standard Specification for Spray-Formed Seamless Ferritic/Austenitic Stainless Steel Pipe

Standard Specification for Spray-Formed Seamless Ferritic/Austenitic Stainless Steel Pipe

SCOPE

1.1 This specification covers spray-formed seamless ferritic/austenitic stainless steel pipe intended for general corrosive service, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures.

1.2 Optional supplementary requirements are provided for pipe where a greater degree of testing is desired. These supplementary requirements call for additional tests to be made and when desired, one or more of these may be specified in the order.

1.3 Appendix X1 of this specification lists the dimensions of seamless stainless steel pipe as shown in ANSI B 36.19. Pipe having other dimensions may be furnished provided such pipe complies with all other requirements of this specification.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

Note 1--The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 949/A 949M – 00a An American National Standard

Standard Specification for

Spray-Formed Seamless Ferritic/Austenitic Stainless Steel

Pipe

This standard is issued under the fixed designation A 949/A 949M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 1.20.1 Pipe Threads, General Purpose

B 36.10M-1995 Welded and Seamless Wrought Steel Pipe

1.1 This specification covers spray-formed seamless ferritic/

B 36.19 Stainless Steel Pipe

austenitic stainless steel pipe intended for general corrosive

2.3 Other Standard:

service, with particular emphasis on resistance to stress corro-

SAE J1086 Practice for Numbering Metals and Alloys

sion cracking. These steels are susceptible to embrittlement if

(UNS)

used for prolonged periods at elevated temperatures.

1.2 Optional supplementary requirements are provided for

3. Ordering Information

pipe where a greater degree of testing is desired. These

3.1 Orders for material under this specification should

supplementary requirements call for additional tests to be made

include the following, as required, to describe the desired

and when desired, one or more of these may be specified in the

material adequately:

order.

3.1.1 Quantity (feet, metres, or number of lengths),

1.3 Appendix X1 of this specification lists the dimensions of

3.1.2 Name of material (ferritic/austenitic steel pipe),

seamless stainless steel pipe as shown in ANSI B 36.19. Pipe

3.1.3 Grade (Table 1),

having other dimensions may be furnished provided such pipe

3.1.4 Size (NPS designator or outside diameter and sched-

complies with all other requirements of this specification.

ule number of average wall thickness, or other),

1.4 The values stated in either inch-pound units or SI units

3.1.5 Length (specific or random) (Section 9),

are to be regarded separately as standard. Within the text, the

3.1.6 End finish (section on Ends of Specification A 999/

SI units are shown in brackets. The values stated in each

A 999M),

system are not exact equivalents; therefore, each system must

3.1.7 Optional requirements (Section 8), Supplementary

be used independently of the other. Combining values from the

Requirements S1 to S4,

two systems may result in nonconformance with the specifi-

3.1.8 Test report required (section on Certification of Speci-

cation. The inch-pound units shall apply unless the “M”

fication A 999/A 999M),

designation of this specification is specified in the order.

3.1.9 Specification designation, and

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

3.1.10 Special requirements or exception to the specifica-

been substituted in this standard for such traditional terms as “nominal

tion.

diameter,” “size,” and “nominal size.”

4. General Requirements

2. Referenced Documents

4.1 Material furnished under this specification shall con-

2.1 ASTM Standards:

form to the applicable requirements of the current edition of

A 450/A 450M Specification for General Requirements for

Specification A 999/A 999M unless otherwise provided herein.

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

A 999/A 999M Specification for General Requirements for

5. Materials and Manufacture

Alloy and Stainless Steel Pipe

5.1 Melting—The steel shall be made by the electric-

E 381 Method of Macroetch Testing Steel Bars, Billets,

furnace process or other primary processes approved by the

Blooms, and Forgings

purchaser.

E 527 Practice for Numbering Metals and Alloys (UNS)

5.2 Pipe Manufacture:

2.2 ANSI/ASME Standards:

5.2.1 The pipe shall be made by the spray forming process

using the melt from the primary melting as noted in 6.1.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products. Available from American National Standards Institute, 11 West 42nd St., 13th

Current edition approved Oct. 10, 2000. Published January 2001. Originally Floor, New York, NY 10036, and ASME International, Three Park Avenue, New

published as A 949/A 949M – 95. Last previous edition A 949/A 949M – 00. York, NY 10016–5990.

2 5

Annual Book of ASTM Standards, Vol 01.01. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 03.01. Warrendale, PA 15096.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 949/A 949M

TABLE 1 Heat Treatment

7.2 The results of these analyses shall be reported to the

UNS purchaser or the purchaser’s representative, and shall conform

Designation Temperature Quench

to the requirements specified in Section 4.

S31803 1870–2010°F [1020–1100°C] rapid cooling in air or water

7.3 If the analysis of one of the tests specified in 7.1 does

S31500 1800–1900°F [980–1040°C] rapid cooling in air or water

not conform to the requirements specified in Section 4, an

S31200 1920–2010°F [1050–1100°C] rapid cooling in water

S32550 1900°F [1040°C] min rapid cooling in air or water analysis of each pipe from the same heat or lot may be made,

S31260 1870–2010°F [1020–1100°C] rapid cooling in water

and all pipes conforming to the requirements shall be accepted.

S32304 1700–1920°F [925–1050°C] rapid cooling in air or water

S32750 1880–2060°F [1025–1125°C] rapid cooling in air or water

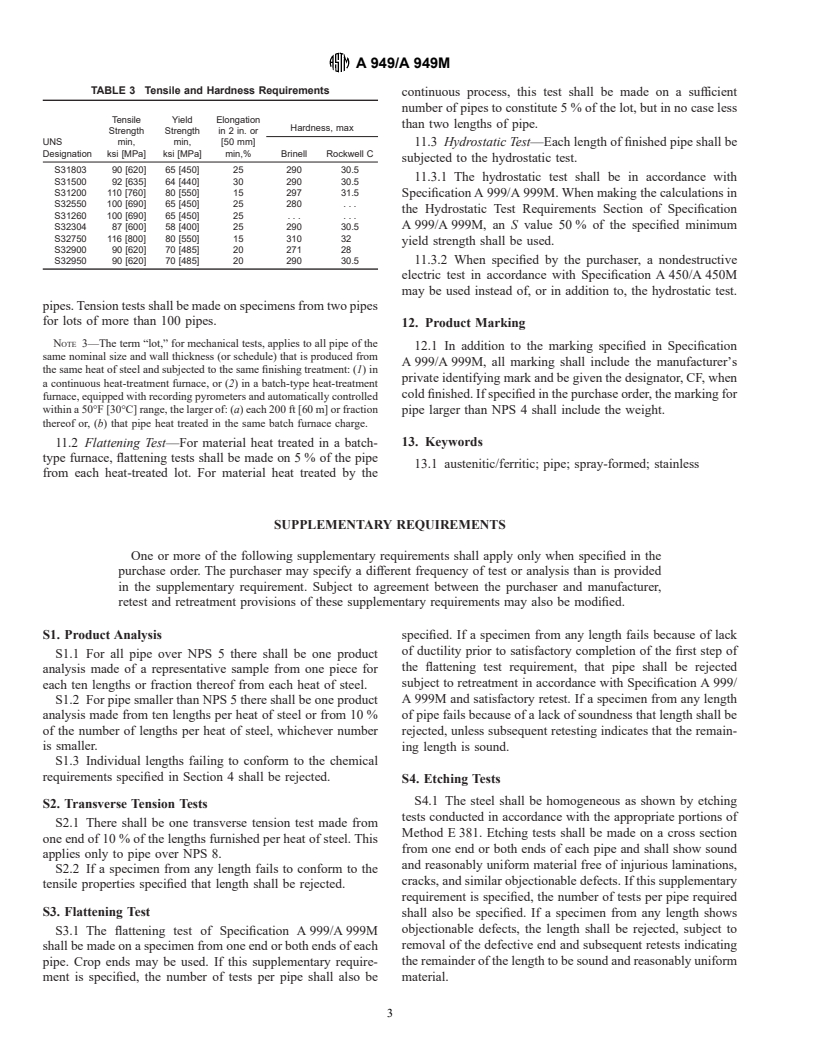

8. Tensile and Hardness Properties

S32900 1700–1750°F [925–955°C] rapid cooling in air or water

S32950 1820–1880°F [995–1025°C] air cool

8.1 The material shall conform to the tensile and hardness

properties prescribed in Table 3.

9. Lengths

5.2.2 The pipe shall be made by spraying the melt on to a

thin-walled collector tube. The as spray formed tube shall be

9.1 Pipe lengths shall be in accordance with the following

machined on both the inner and outer surfaces. The remaining

regular practice:

metal shall be homogeneous, sound, and meet the requirements

9.1.1 Unless otherwise agreed upon, all sizes from NPS ⁄8

of Section 10.

to and including NPS 8 are available in a length up to 24 ft

5.2.3 Unless specified by the purchaser, pipe may be fur-

(Note 2) with the permissible range of 15 to 24 ft (Note 2).

nished as spray formed or as spray-formed and cold-finished.

Short lengths are acceptable and the number and minimum

5.2.4 All pipe shall be furnished in the heat-treated condi-

length shall be agreed upon between the manufacturer and the

tion as shown in Table 1.

purchaser.

5.2.5 All pipe shall be furnished in the descaled condition

NOTE 2—This value applies when the inch-pound designation of this

and be free of contaminating iron particles. Pickling, blasting

specification is the basis of purchase. When the “M” designation of this

or surface finishing is not mandatory when pipe is bright

specification is the basis of purchase, the corresponding metric value(s)

annealed. The purchaser may request that a passivating treat-

shall be agreed upon between the manufacturer and the purchaser.

ment be applied.

9.1.2 If definite cut lengths are desired, the lengths required

shall be specified in the order. No pipe shall be less than the

6. Chemical Composition

specified length and no more than ⁄4 in. [6 mm] over it.

6.1 The steel shall conform to the chemical requirements as

prescribed in Table 2.

10. Workmanship, Finish, and Appearance

10.1 The finished pipes shall be reasonably straight and

7. Product Analysis

shall have a workmanlike finish. Imperfections may be re-

7.1 At the request of the purchaser, an analysis of two pipes

moved by grinding, provided the wall thicknesses are not

from each lot shall be made by the manufacturer. A lot of pipe

decreased to less than that permitted, in the Permissible

shall consist of the following number of lengths of the same

Variations in Wall Thickness Section of Specification A 999/

size and wall thickness from any one heat of stainless steel:

A 999M.

NPS Designator Lengths of Pipe in Lot

11. Mechanical Tests Required

Under 2 400 or fraction thereof

2 to 5, incl 200 or fraction thereof 11.1 Transverse or Longitudinal Tension Test—One tension

6 and over 100 or fraction thereof

test shall be made on a specimen for lots of not more than 100

TABLE 2 Chemical Requirements

UNS

A

Designation C Mn P S Si Ni Cr Mo N Cu Others

S31803 0.030 2.00 0.030 0.020 1.00 4.5–6.521.0–23.0 2.5–3.5 0.08–0.20 . . .

max max max max max

S31500 0.030 1.20–2.00 0.030 0.030 1.40–2.00 4.3–5.2 18.0–19.0 2.50–3.00 0.05–0.10 . . .

max max max

S32550 0.040 1.50 0.040 0.030 1.00 4.5–6.5 24.0–27.0 2.9–3.9 0.10–0.25 1.50–2.50

max max max max max

S31200 0.030 2.00 0.045 0.030 1.00 5.5–6.5 24.0–26.0 1.20–2.00 0.14–0.20 . . .

max max max max max

S31260 0.030 1.00 0.030 0.030 0.75 5.5–7.5 24.0–26.0 2.5–3.5 0.10–0.30 0.20–0.80 W 0.10–0.50

max max max max max

S32304 0.030 2.50 0.040 0.040 1.00 3.0–5.5 21.5–24.5 0.05–0.60 0.05–0.20 0.05–0.60

max max max max max

S32750 0.030 1.20 0.035 0.020 0.80 6.0–8.0 24.0–26.0 3.0–5.0 0.24–0.32 0.50 .

max max max max max max

S32900 0.08 1.00 0.040

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.