ASTM F1326-96

(Test Method)Standard Test Method for Measuring Maximum Dry Volume of Utility Vacuum Cleaners

Standard Test Method for Measuring Maximum Dry Volume of Utility Vacuum Cleaners

SCOPE

1.1 This test method is applicable to any vacuum cleaner that is classified as a utility vac.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

Designation: F 1326 – 96

Standard Test Method for

Measuring Maximum Dry Volume of Utility Vacuum

1

Cleaners

This standard is issued under the fixed designation F 1326; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 1—See Appendix X1 for a method for determining 90 % confi-

1. Scope

dence level.

1.1 This test method is applicable to any vacuum cleaner

that is classified as a utility vac.

6. Conditioning

1.2 This standard does not purport to address all of the

6.1 Test Room—The test room should be maintained at 70°F

safety concerns, if any, associated with its use. It is the

6 5°F (21°C 6 3°C) and 45 to 55 % relative humidity.

responsibility of the user of this standard to establish appro-

6.2 Condition the water in accordance with 6.1.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

7. Procedure

1.3 The values stated in inch-pound units are to be regarded

7.1 Dry Pick Up Capacity:

as standard. The values in parentheses are for information only.

7.1.1 Calculate the volume in gallons of the dust drum using

the appropriate formulas, neglecting all projections into the

2. Significance and Use

drum.

2.1 This test method describes a procedure to determine the

7.1.2 Calculate all projections into the drum using the

maximum functional dry volume that the utility vac is capable

appropriate formulas in gallons.

of collecting.

7.1.3 Subtract the total projection volumes from the dirt

drum volume to arrive at the maximum dry volume. Round

3. Apparatus

1

down to the nearest ⁄4 gal (0.936 L).

3.1 Voltmeter, to measure input to the cleaner, to provide

7.1.4 Record the maximum functional volume in gallons

measurements accurately to within 61%.

1

(litres) within ⁄4 gal (0.936 L).

3.2 Voltage regulator system, to control the input voltage to

the cleaner. The regulator shall be capable of maintaining 120

8. Procedure

6 1 V rms with a wave form that is essentially sinusoidal with

8.1 Dry Pick Up Capacity (Alternative Method):

3 % maximum harmonic distortion.

8.1.1 An alternative method is allowed when the shape of

3.3 Temperature and humidity indicators, to provide tem-

the vacuum cleaner is irregular, and the calculations of Section

1

perature measurements accurate to within 61°F (6 ⁄2 °C) and

6 become complex.

humidity measurements accurate to within 62 % relative

8.1.1.1 Block the inlet of the dust drum and fill it with water.

humidity.

8.1.1.2 Line the projections into the drum with an appropri-

3.4 Weighing Scale, the scale shall be accurate to 4 oz (114

ate water-proof material and submerse into the dust drum.

g) and have a weighing capacity of at least 120 lbs. (54.4 Kg).

8.1.1.3 Allow the excess water to flow out of the dust drum

and then measure the volume of the water remaining in the dust

4. Materials

1

drum. Round down to the nearest ⁄4 gal.

4.1 Water.

8.1.1.4 Record the maximum functional volume in gallons

1

(litres) within ⁄4 gal (0.936 L).

5. Sampling

8.1.1.5 Repeat steps 8.1.1-8.1.1.4 two more times. The

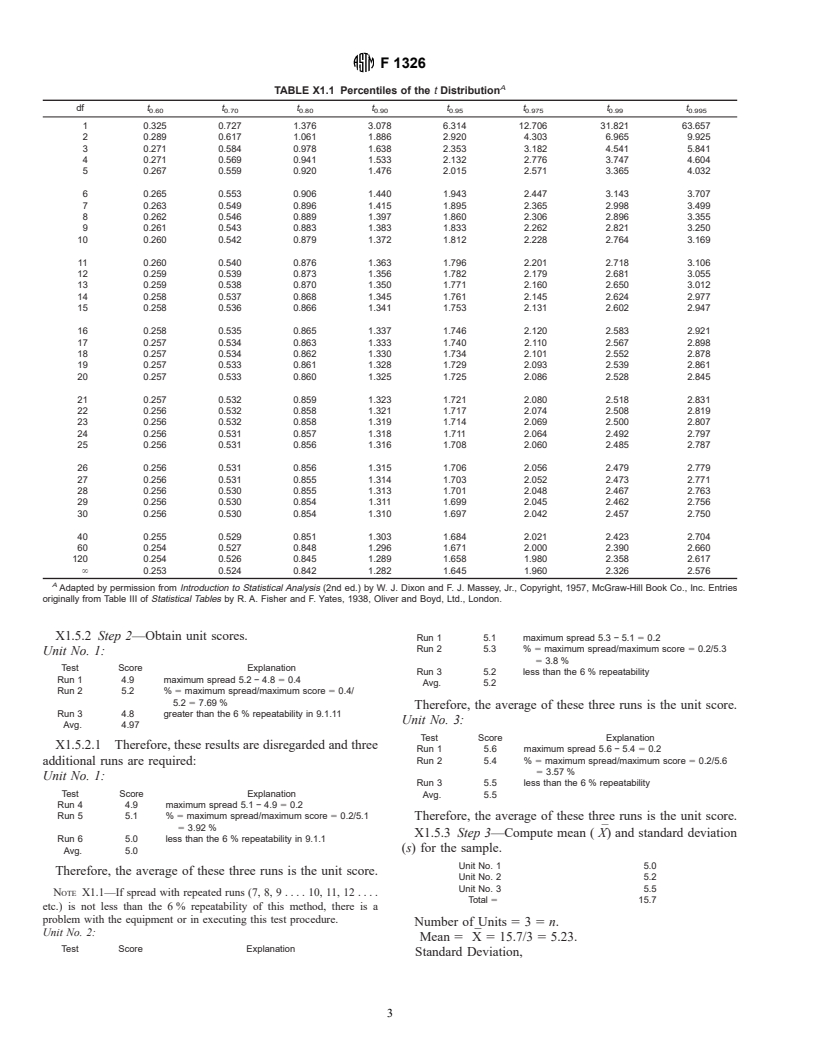

5.1 Test a sample of each basic model until a 90 %

average of the three tests represents the maximum dry func-

confidence level (about the mean) is established within 65%

tional volume that the utility vacuum is capable of collecting.

of the mean value. Test a minimum of three samples. Select all

2

samples at random in accordance with good statistical practice.

9. Precision and Bias

9.1 Precision—These statements are based on an interlabo-

ratory test involving six laboratories and four units. The range

1

This test method is under the jurisdiction of ASTM Committee F-11 on Vacuum

Cleaners and is the direct responsibility of Subcommittee F11.23 on Filtration.

Current edition approved March 10, 1996. Published May 1996. Originally

2

Supporting data are available from ASTM Headquarters. Request RR-F11-

published as F 1326 – 91. Last previous edition F 1326 – 91.

1009.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1326

of maximum functional volume of the units was from 4.8 to 9.1.2 Reproducibility, multi laboratory, multi-day:

14.6 gal. 9.1.2.1 Reproducibility—the standard deviation divided by

9.1.1 Repeatability, single-operator-laboratory, multi-day: the average (coefficient of variation) with a single unit tested in

9.1.1.1 Repeatability for dry volume values of 5 gal and different laboratories was found to be 7.8 % or less. Two such

under, the standard deviation within a laboratory divided by the values should be considered suspect (at the 95 % confidence

average (coefficient of variation) was found to be 1.4 % or less. level) if they differ by more than 22 %.

Two values from a sample of three shoul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.