ASTM F439-01

(Specification)Standard Specification for Socket-Type Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

Standard Specification for Socket-Type Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

SCOPE

1.1 This specification covers chlorinated poly(vinyl chloride) (CPVC) Schedule 80 pipe fittings. Included are requirements for materials, workmanship, dimensions, and burst pressure.

Note 1--The threaded CPVC fittings covered by this specification were covered previously in Specification F437.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: F 439 – 01

Standard Specification for

Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe

1

Fittings, Schedule 80

This standard is issued under the fixed designation F 439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

2

1. Scope (CPVC) Compounds

D 2122 Test Method for Determining Dimensions of Ther-

1.1 This specification covers chlorinated poly(vinyl chlo-

3

moplastic Pipe and Fittings

ride) (CPVC) Schedule 80 pipe fittings. Included are require-

3

D 2749 Symbols for Dimensions of Plastic Pipe Fittings

ments for materials, workmanship, dimensions, and burst

3

F 412 Terminology Relating to Plastic Piping Systems

pressure.

F 437 Specification for Threaded Chlorinated Poly (Vinyl

NOTE 1—The threaded CPVC fittings covered by this specification 3

Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

were covered previously in Specification F 437.

F 1498 Specification for Taper Pipe Threads 60° for Ther-

3

1.2 The text of this specification references notes, footnotes,

moplastic Pipe and Fittings

and appendixes which provide explanatory material. These

2.2 Federal Standard:

4

notesandfootnotes(excludingthoseintablesandfigures)shall

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

not be considered as requirements of this specification.

2.3 Military Standard:

4

1.3 The values stated in inch-pound units are to be regarded

MIL-STD-129 Marking for Shipment and Storage

as the standard. The values in parentheses are given for

2.4 NSF Standard:

information only.

Standard No. 14 for Plastic Piping Components and Related

5

1.4 The following safety hazards caveat pertains only to the

Materials

test method portion, Section 8, of this specification: This

Standard No. 61 for Drinking Water System Components—

5

standard does not purport to address all of the safety concerns,

Health Effects

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

3.1 Definitions—Definitions are in accordance with Termi-

tions prior to use.

nology F 412 and abbreviations are in accordance with Termi-

nology D 1600, unless otherwise indicated. The abbreviation

2. Referenced Documents

for chlorinated poly(vinyl chloride) is CPVC.

2.1 ASTM Standards:

4. Classification

D 618 Practice for Conditioning Plastics and Electrical

2

Insulating Materials for Testing

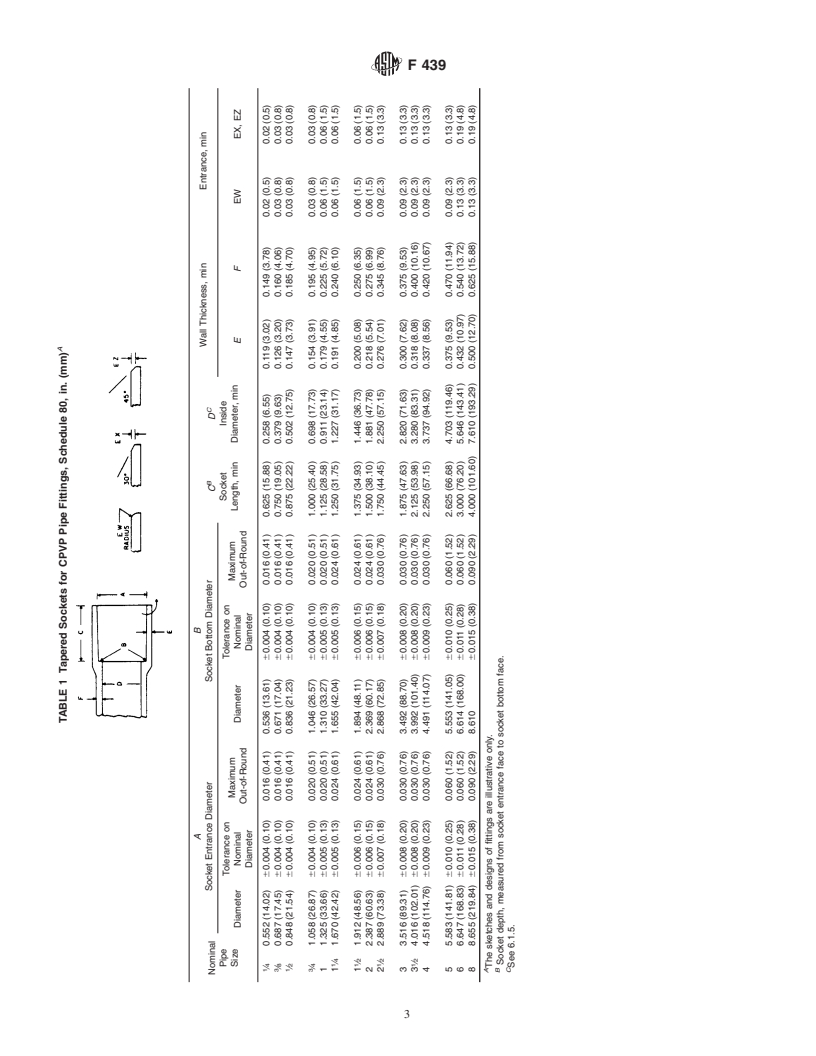

4.1 General—This specification covers Schedule 80 CPVC

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

pipe fittings, intended for use with Iron Pipe Size (IPS)

3

sure of Plastic Pipe, Tubing, and Fittings

outside-diameter plastic pipe.

D 1600 Terminology for Abbreviated Terms Relating to

4.1.1 Fittings covered by this specification are normally

2

Plastics

molded. In-line fittings, such as couplings, unions, bushings,

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

caps, nipples, and so forth, shall be molded or machined from

Compounds and Chlorinated Poly(Vinyl Chloride)

extruded stock.

4.1.2 Fittings fabricated by back welding or butt fusion are

not included in this specification.

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

4

Current edition approved April 10, 2001. Published June 2001. Originally AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

published as part of D 2467 – 74. Last previous edition F 439 – 99a. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

2 5

Annual Book of ASTM Standards, Vol 08.01. Available from NSF International, P.O. Box 130140, Ann Arbor, MI 48113-

3

Annual Book of ASTM Standards, Vol 08.04. 0140.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 439

5. Materials and Manufacture 6.3.2 Pressures shown are minimum burst pressures and do

not imply rated working pressures. The burst pressure shall be

5.1 This specification covers CPVC pipe fittings made from

used only as an indication of quality.

compoundsmeetingtherequirementsofClass23447andClass

23448 as defined in Specification D 1784.

7. Workmanship, Finish and Appearance

NOTE 2—Mechanical strength, heat resistance, flammability, and

7.1 The fittings shall be homogeneous throughout and free

chemical resistance requirements are covered in Specification D 1784.

of cracks, holes, foreign inclusions, or other defects. The

5.2 Rework Material—The manufacturers shall use only

fittings shall be as uniform as commercially practicable in

th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.