ASTM D1670-04

(Test Method)Standard Test Method for Failure End Point in Accelerated and Outdoor Weathering of Bituminous Materials

Standard Test Method for Failure End Point in Accelerated and Outdoor Weathering of Bituminous Materials

SIGNIFICANCE AND USE

The extent of cracking or pitting of bituminous films is a measure of the extent of deterioration due to weathering. Failure due to cracking is more accurately determined electrically than visually.

Failure determined by this test method will depend not only on the characteristics of the bituminous material and the extent of weathering, but also on the film thickness, and the amount and type of mineral filler present.

Tests on a similar material of known weathering characteristics (a control) exposed at the same time as the test material is strongly recommended as a check on the validity of the test results.

SCOPE

1.1 This test method covers the use of a spark generating apparatus for determination of failure due to cracking of bituminous materials undergoing accelerated or outdoor weathering on electrically conductive backings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1670–04

Standard Test Method for

Failure End Point in Accelerated and Outdoor Weathering of

1

Bituminous Materials

This standard is issued under the fixed designation D1670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

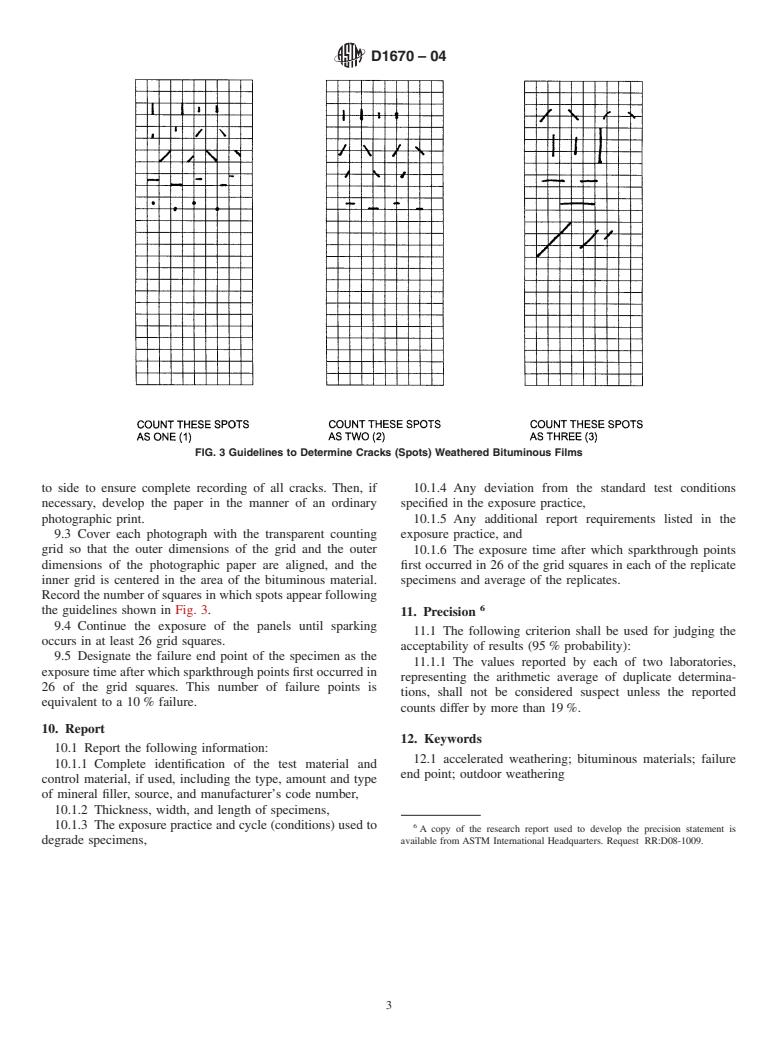

1. Scope copies are made of the front side of the paper on which the

spots caused by the sparks appear. The photographs are

1.1 This test method covers the use of a spark generating

covered with an acrylic grid and the number of squares

apparatus for determination of failure due to cracking of

containing the spark records are counted and reported. Spark-

bituminousmaterialsundergoingacceleratedoroutdoorweath-

ing in 26 or more grid squares is representative of failure.

ering on electrically conductive backings.

1.2 The values stated in SI units are to be regarded as the

4. Significance and Use

standard. The values given in parentheses are for information

4.1 The extent of cracking or pitting of bituminous films is

only.

a measure of the extent of deterioration due to weathering.

1.3 This standard does not purport to address all of the

Failure due to cracking is more accurately determined electri-

safety concerns, if any, associated with its use. It is the

cally than visually.

responsibility of the user of this standard to establish appro-

4.2 Failure determined by this test method will depend not

priate safety and health practices and determine the applica-

only on the characteristics of the bituminous material and the

bility of regulatory limitations prior to use.

extent of weathering, but also on the film thickness, and the

2. Referenced Documents amount and type of mineral filler present.

2

4.3 Tests on a similar material of known weathering char-

2.1 ASTM Standards:

acteristics (a control) exposed at the same time as the test

D529 Practice for Enclosed Carbon-Arc Exposures of Bi-

material is strongly recommended as a check on the validity of

tuminous Materials

the test results.

D1435 Practice for Outdoor Weathering of Plastics

D1669 Practice for Preparation of Test Panels for Acceler-

5. Apparatus

ated and Outdoor Weathering of Bituminous Coatings

3

5.1 Any Spark-Generating Apparatus —Fig. 1 is an ex-

D4798 Practice forAccelerated Weathering Test Conditions

ample of an acceptable configuration for the test feeler. Other

and Procedures for Bituminous Materials (Xenon-Arc

configurations are not prohibited, subject to the following

Method)

conditions:

D4799 Practice forAccelerated Weathering Test Conditions

5.1.1 The cross-dimension of the wire loop is to be 50 6 5

andProceduresforBituminousMaterials(FluorescentUV,

3 1

mm (1 ⁄4 6 ⁄8 in.).

Water Spray, and Condensation Method)

5.1.2 The device is capable of delivering a 5-kV peak

3. Summary of Test Method voltage and of operating at 60 Hz.

5.2 Photographic Equipment—A supply of sheets of matte

3.1 Dry, weathered, bituminous-coated test panels are

4

surface, regular weight, photocopy paper or linagraphic paper

grounded and a feeler electrode is passed over the back of a

cut to the dimensions of the test panel, developer, and fixing

linagraphicorultrahighsensitivitythermalfaxpaperplacedon

chemicals.

the bituminous surface with the emulsion side down. Photo-

5.3 Counting Grid, as shown in Fig. 2. Photocopy the grid

on a transparency film that is suitable for use with plain paper

1

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

3

and Waterproofing and is the direct responsibility of Subcommittee D08.02 on The sole source of supply of the apparatus known to the committee at this time

Prepared Roofings, Shingles, and Siding Materials. is Electrotechnic Model BD-40B Spark Generator, available from Electro-Technic

Current edition approved May 1, 2004. Published May 2004. Originally Products Co., 4642 N. Ravenswood Ave., Chicago, IL 60642. If you are aware of

approved in 1959. Last previous edition approved in 2003 as D1670 – 98 (2003). alternative suppliers, please provide this information to ASTM Headquarters. Your

DOI: 10.1520/D1670-04. comments will receive careful consideration at a meeting of the responsible

2

1

For referenced ASTM standards, visit the ASTM website, www.astm.org, or technical committee, which you may attend.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Thermal facsimile paper with ultra-high sensitivity rating has also been found

Standards volume information, refer to the standard’s Document Summary page on satisfactory for the same purpose. This paper is available nationwide from office

the ASTM website. supply stores or catalogs.

Copyright © ASTM Interna

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.