ASTM F326-96(2001)e1

(Test Method)Standard Test Method for Electronic Measurement for Hydrogen Embrittlement from Cadmium-Electroplating Processes

Standard Test Method for Electronic Measurement for Hydrogen Embrittlement from Cadmium-Electroplating Processes

SCOPE

1.1 This test method covers an electronic hydrogen detection instrument procedure for measurement of plating permeability to hydrogen. This method measures a variable related to hydrogen absorbed by steel during plating and to the hydrogen permeability of the plate during post plate baking. A specific application of this method is controlling cadmium-plating processes in which the plate porosity relative to hydrogen is critical, such as cadmium on high-strength steel.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statement, see Section 8.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation: F 326 – 96 (Reapproved 2001)

Standard Test Method for

Electronic Measurement for Hydrogen Embrittlement From

Cadmium-Electroplating Processes

This standard is issued under the fixed designation F326; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made throughout the standard and in Fig. 3 in May 2001.

1. Scope 3.2 Symbols:

3.2.1 HP =calibration hydrogen pressure peak.

1.1 This test method covers an electronic hydrogen detec-

3.2.2 HP =plating hydrogen pressure peak.

p

tion instrument procedure for measurement of plating perme-

3.2.3 I =probe cathode emission current.

abilitytohydrogen.Thismethodmeasuresavariablerelatedto E

3.2.4 I =probe hydrogen pressure.

H

hydrogen absorbed by steel during plating and to the hydrogen

3.2.5 I =integral of I curve from probe on to HP.

permeability of the plate during post plate baking. A specific g H

3.2.6 lambda =time in seconds for hydrogen pressure

application of this method is controlling cadmium-plating

peak to drop to half its value.

processes in which the plate porosity relative to hydrogen is

3.2.7 l=lambda obtained from a calibration run.

critical, such as cadmium on high-strength steel.

3.2.8 l =lambda obtained from a plating run.

p

1.2 This standard does not purport to address all of the

3.2.9 l =normalized test lambda, obtained as follows:

pc

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- l 5l 40/l (1)

~ !

pc p

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

3.2.10 l¯ =arithmetic average of normalized lambdas for

pc

statement, see Section 8.

a set of tests.

1.3 The values stated in SI units are to be regarded as the

3.2.11 range =difference between maximum l and mini-

pc

standard. The values given in parentheses are for information

mum l for a given set of tests.

pc

only.

3.2.12 run =calibration or plating of a probe.

3.2.13 test =single evaluation of a plating solution for

2. Referenced Documents

hydrogen embrittlement determination; run using a previously

2.1 ASTM Standards:

calibrated probe.

D1193 Specification for Reagent Water

3.2.14 set of tests—all consecutive tests on a plating solu-

F519 Test Method for Mechanical Hydrogen Embrittle-

tion for a given operator-instrument-day evaluation.

mentEvaluationofPlatingProcessesandServiceEnviron-

3.2.15 window—test surface of a probe described in Fig.

ments

1(A).

3. Terminology

4. Summary of Test Method

3.1 Definitions of Terms Specific to This Standard:

4.1 This method uses a metal-shelled vacuum probe as an

3.1.1 hydrogen pressure peak—the maximum hydrogen

ion gage to evaluate electrodeposited cadmium characteristics

pressure value (see I ) obtained when the probe is heated

H

relative to hydrogen permeation.After calibration, a section of

following calibration, plating, or fluid testing.

the probe shell is electroplated at the lowest current density

encountered in the cadmium electroplating process. During the

subsequent baking of the probe at a closely controlled tem-

This test method is under the jurisdiction of ASTM Committee F07 on

perature, the probe ion current, proportional to hydrogen

Aerospace andAircraft and is the direct responsibility of Subcommitteee F07.04 on

Hydrogen Embrittlement. pressure,isrecordedasafunctionoftime.Fromthesedataand

Current edition approved Oct. 10, 1996. Published December 1996. Originally

the calibration data of the probe, a number related to the

e1

published as F326–78. Last previous edition F326–78(1995) .

porosity of the electroplated metal relative to hydrogen is

Annual Book of ASTM Standards, Vol 11.01.

obtained.

Annual Book of ASTM Standards, Vol 15.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

F 326 – 96 (2001)

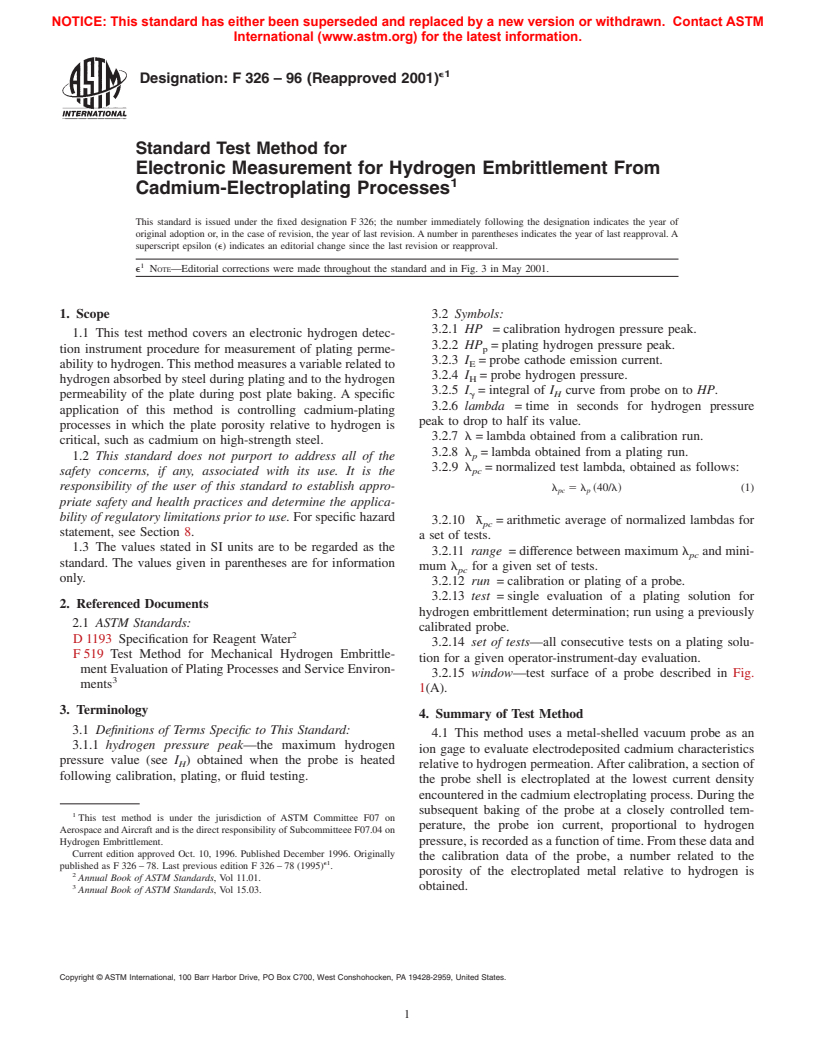

FIG. 1 Probe Configuration

4.2 During the initial part of the bakeout, hydrogen contin- 6. Apparatus

ues to diffuse through the metal shell of the probe and the ion

6.1 Hydrogen Detection Instrument—A system consisting

current increases. Within a short time, however, a maximum

of a control unit, two special ovens, auxiliary heater, recorder,

current is observed and then falls off as hydrogen is driven out 4

test probes, and associated equipment.

of the system.

6.2 Oven—The oven warms the probe to increase the

4.3 Observations of the ion current-time curve indicate that

hydrogen diffusion rate into the probe. Oven parameters are

theslopeofthecurvehasanempiricalrelationshipwithfailure

selected by apparatus manufacturer to provide a standard

data on stress rupture specimens such as those in Test Method

reading for all hydrogen detection instruments.

F519. For this method, I and l variables (see Section 3) must

6.3 Oven Stopper—Stopper covering the oven opening.

g

be empirically correlated with results from the stress rupture

Remove 10 s before inserting the probe.

specimens. This gives a quick means of measuring ease of

6.4 Window—The window is the unpainted, bare steel

baking hydrogen out of cadmium-electroplated parts.

portion of the probe, 0.63 6 0.03 in. in height, that is plated in

4.4 Before an electroplating test, calibration is accom- the solution under test. The window is shown in Fig. 1.

6.5 Abrasive Blast—Abrasive blast window area in the

plished by electrolyzing the probe in a standard solution and

bakingittodetermine I and loftheunplatedsteelshellofthe same way, using the same media, as used for the parts. Probe

g

should be rotated while being blasted to provide uniform

probe.

surface.

6.6 Electronic Bakeout Unit—This heats the probe electri-

5. Significance and Use

cally to remove hydrogen absorbed into the probe after testing.

5.1 Hydrogen is evolved during metal electrodeposition in

May be part of hydrogen detection instrument.

aqueous baths. Some of this hydrogen enters parts during

plating. If the absorbed hydrogen is at a level presenting

7. Reagents and Materials

embrittlement hazards to high-strength steel, it is removed by

7.1 Reagents:

baking parts after plating to expel this hydrogen. However, the

7.1.1 Purity of Reagents—Reagentgradechemicalsshallbe

lack of plate porosity itself may block hydrogen egress. Thus,

used in all tests. Unless otherwise indicated, it is intended that

it becomes important to know both the relative amount of

all reagents conform to the specifications of the Committee on

hydrogen absorbed and the plate porosity.

Analytical Reagents of theAmerican Chemical Society where

5.2 This test provides a quantitative control number for

such specifications are available. Other grades may be used,

cadmium plate porosity that can be used to control a cadmium

provided it is first ascertained that the reagent is of sufficient

plating process and the status of cadmium-plated hardware. It

high purity to permit its use without lessening the accuracy of

can also be used for plating process troubleshooting and

the determination.

research and development to determine the effects on plate

porosity by process variables, contaminants, and materials.

When used to control a critical process, control numbers for

A list of manufacturers of equipment and probes capable of performing these

plate porosity must be determined by correlation with stress

tests is available from ASTM Headquarters.

rupture specimens or other acceptable standards. 5

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

5.3 There is no prime standard for plate porosity. For this

listed by the American Chemical Society, see Analar Standards for Laboratory

reason, two ovens must be used, with tests alternated between

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

ovens. Data from the ovens are compared to ensure no

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

equipment change has occurred. MD.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

F 326 – 96 (2001)

7.1.2 Acetone (C H O), technical. notched tension specimen data. Oven stability is checked by

3 6

7.1.3 Anode Cleaning Solution—Concentrated nitric acid comparing ovens against each other in duplicate tests.

(HNO ), reagent grade.

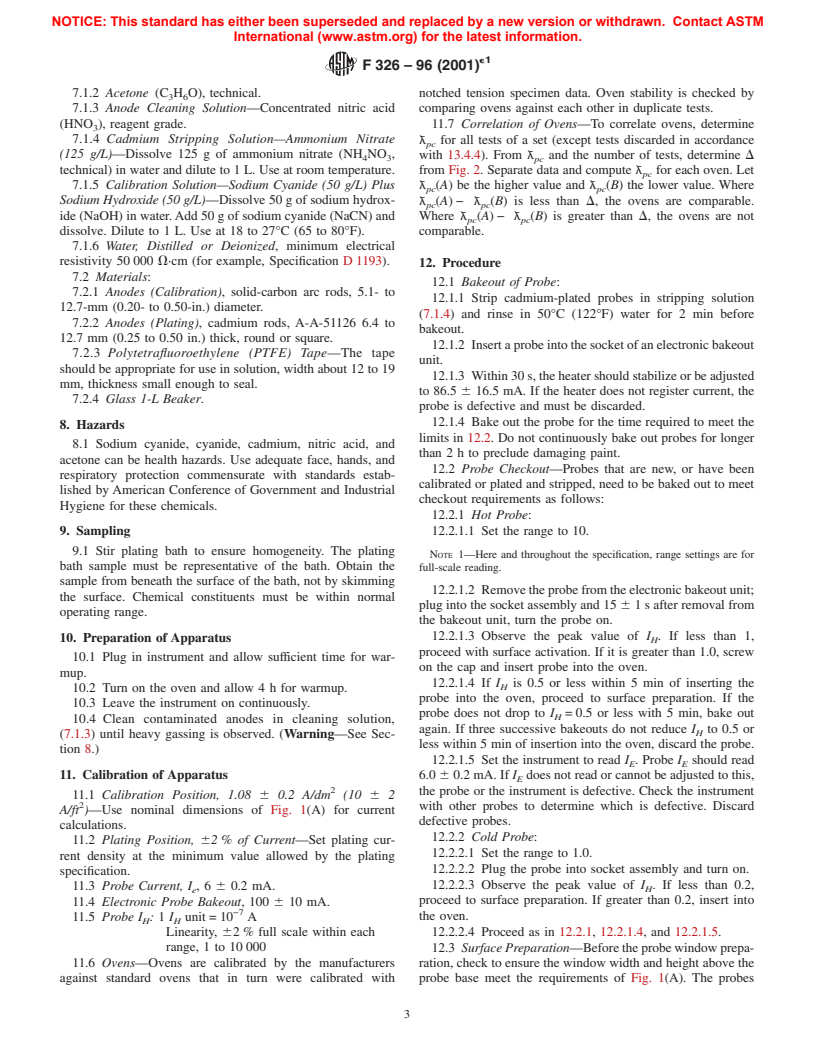

11.7 Correlation of Ovens—To correlate ovens, determine

7.1.4 Cadmium Stripping Solution—Ammonium Nitrate l¯ for all tests of a set (except tests discarded in accordance

pc

(125 g/L)—Dissolve 125 g of ammonium nitrate (NH NO ,

with 13.4.4). From l¯ and the number of tests, determine D

4 3

pc

technical) in water and dilute to 1 L. Use at room temperature. from Fig. 2. Separate data and compute l¯ for each oven. Let

pc

7.1.5 Calibration Solution—Sodium Cyanide (50 g/L) Plus

l¯ (A) be the higher value and l¯ (B) the lower value. Where

pc pc

Sodium Hydroxide (50 g/L)—Dissolve 50 g of sodium hydrox- l¯ (A)− l¯ (B) is less than D, the ovens are comparable.

pc pc

ide(NaOH)inwater.Add50gofsodiumcyanide(NaCN)and

Where l¯ (A)− l¯ (B) is greater than D, the ovens are not

pc pc

dissolve. Dilute to 1 L. Use at 18 to 27°C (65 to 80°F). comparable.

7.1.6 Water, Distilled or Deionized, minimum electrical

resistivity 50000 V·cm (for example, Specification D1193). 12. Procedure

7.2 Materials:

12.1 Bakeout of Probe:

7.2.1 Anodes (Calibration), solid-carbon arc rods, 5.1- to

12.1.1 Strip cadmium-plated probes in stripping solution

12.7-mm (0.20- to 0.50-in.) diameter.

(7.1.4) and rinse in 50°C (122°F) water for 2 min before

7.2.2 Anodes (Plating), cadmium rods, A-A-51126 6.4 to

bakeout.

12.7 mm (0.25 to 0.50 in.) thick, round or square.

12.1.2 Insertaprobeintothesocketofanelectronicbakeout

7.2.3 Polytetrafluoroethylene (PTFE) Tape—The tape

unit.

should be appropriate for use in solution, width about 12 to 19

12.1.3 Within30s,theheatershouldstabilizeorbeadjusted

mm, thickness small enough to seal.

to 86.5 6 16.5 mA. If the heater does not register current, the

7.2.4 Glass 1-L Beaker.

probe is defective and must be discarded.

12.1.4 Bake out the probe for the time required to meet the

8. Hazards

limits in 12.2. Do not continuously bake out probes for longer

8.1 Sodium cyanide, cyanide, cadmium, nitric acid, and

than2hto preclude damaging paint.

acetone can be health hazards. Use adequate face, hands, and

12.2 Probe Checkout—Probes that are new, or have been

respiratory protection commensurate with standards estab-

calibrated or plated and stripped, need to be baked out to meet

lished by American Conference of Government and Industrial

checkout requirements as follows:

Hygiene for these chemicals.

12.2.1 Hot Probe:

9. Sampling 12.2.1.1 Set the range to 10.

9.1 Stir plating bath to ensure homogeneity. The plating

NOTE 1—Here and throughout the specification, range settings are for

bath sample must be representative of the bath. Obtain the

full-scale reading.

sample from beneath the surface of the bath, not by skimming

12.2.1.2 Removetheprobefromtheelectronicbakeoutunit;

the surface. Chemical constituents must be within normal

plug into the socket assembly and 15 6 1 s after removal from

operating range.

the bakeout unit, turn the probe on.

12.2.1.3 Observe the peak value of I . If less than 1,

10. Preparation of Apparatus

H

proceed with surface activation. If it is greater than 1.0, screw

10.1 Plug in instrument and allow sufficient time for war-

on the cap and insert probe into the oven.

mup.

12.2.1.4 If I is 0.5 or less within 5 min of inserting the

H

10.2 Turn on the oven and allow 4 h for warmup.

probe into the oven, proceed to surface preparation. If the

10.3 Leave the instrument on continuously.

probe does not drop to I =0.5 or less with 5 min, bake out

H

10.4 Clean contaminated anodes in cleaning solution,

again. If three successive bakeouts do not reduce I to 0.5 or

H

(7.1.3) until heavy gassing is observed. (Warning—See Sec-

less within 5 min of insertion into the oven, discard the probe.

tion 8.)

12.2.1.5 Set the instrument to read I . Probe I should read

E E

11. Calibration of Apparatus 6.0 6 0.2 mA. If I does not read or cannot be adjusted to this,

E

the probe or the instrument is defective. Check the instrument

11.1 Calibration Position, 1.08 6 0.2 A/dm (10 6 2

with other probes to determine which is defective. Discard

A/ft )—Use nominal dimensions of Fig. 1(A) for current

defective probes.

calculations.

12.2.2 Cold Probe:

11.2 Plating Position, 62 % of Current—Set plating cur-

12.2.2.1 Set the range to 1.0.

rent density at the minimum value allowed by the plating

12.2.2.2 Plug the probe into socket assembly and turn on.

specification.

12.2.2.3 Observe the peak value of I . If less than 0.2,

11.3 Probe Current, I,6 6 0.2 mA.

H

e

proceed to surface preparation. If greater than 0.2, insert into

11.4 Electronic Probe Bakeout, 100 6 10 mA.

−7

the oven.

11.5 Probe I : 1 I unit=10 A

H H

12.2.2.4 Proceed as in 12.2.1, 12.2.1.4, and 12.2.1.5.

Linearity, 62% full scale within each

range, 1 to 10000 12.3 SurfacePreparation—Beforetheprobewindowprepa-

11.6 Ovens—Ovens are calibrated by the manufacturers ration, check to ensure the window width and height above the

against standard ovens that in turn were calibrated with probe base meet the requirements of Fig. 1(A). The probes

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

F 326 – 96 (2001)

FIG. 2 Oven-Correlation Limit

having windows out of limits must be cleaned and repainted in paper, taking care not to scratch the paint. Fingerprints or

accordance with the suppliers’ instructions or discarded. visible contamination on the window invalidate the run.

12.3.1 Mask the probe to meet the requirement of Fig. 1(B)

12.3.4 Visually inspect the window area for cleanliness and

using conforming masks, supplied with instruments or PTFE

uniformly textured surface representative of production parts.

adhesive tape. Edges of masks must coincide with edges of

Repeat Steps 12.3.1-12.3.3 as required to provide acceptable

window with no paint being visible. Prote

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.