ASTM B764-04(2014)

(Test Method)Standard Test Method for Simultaneous Thickness and Electrode Potential Determination of Individual Layers in Multilayer Nickel Deposit (STEP Test)

Standard Test Method for Simultaneous Thickness and Electrode Potential Determination of Individual Layers in Multilayer Nickel Deposit (STEP Test)

SIGNIFICANCE AND USE

4.1 The ability of a multilayer nickel deposit to enhance corrosion resistance is a function of the difference in the electrode potentials of the nickel layers (as measured individually at a fixed current density in a given electrolyte versus a reference electrode) and the thicknesses of the layers. The potential differences must be sufficient to cause the bright nickel or top layer to corrode preferentially and sacrificially with respect to the semi-bright nickel layer beneath it.

4.2 This test procedure allows the measurement of these potential differences directly on an electroplated part rather than on separate foil specimens in such a way that time determines the thickness of each layer, while the potential difference between nickel layers is an indication of the corrosion resistance of the total nickel deposit.

4.3 The interpretation and evaluation of the results of this test should be by agreement between the purchaser and the manufacturer.Note 1—This test may be used as a quality assurance test of the multilayer nickel coatings applied in production. It should be understood that due to many factors that influence the progress of corrosion during actual use of the part, the performance of different multilayer nickel deposits in the test cannot be taken as an absolute indicator of the relative corrosion resistance of these deposits in service.

SCOPE

1.1 This test method closely estimates the thickness of individual layers of a multilayer nickel electrodeposit and the potential differences between the individual layers while being anodically stripped at constant current density.2,3

1.2 This test method does not cover deposit systems other than multilayer electroplated nickel deposits.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B764 − 04 (Reapproved 2014)

Standard Test Method for

Simultaneous Thickness and Electrode Potential

Determination of Individual Layers in Multilayer Nickel

1

Deposit (STEP Test)

This standard is issued under the fixed designation B764; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

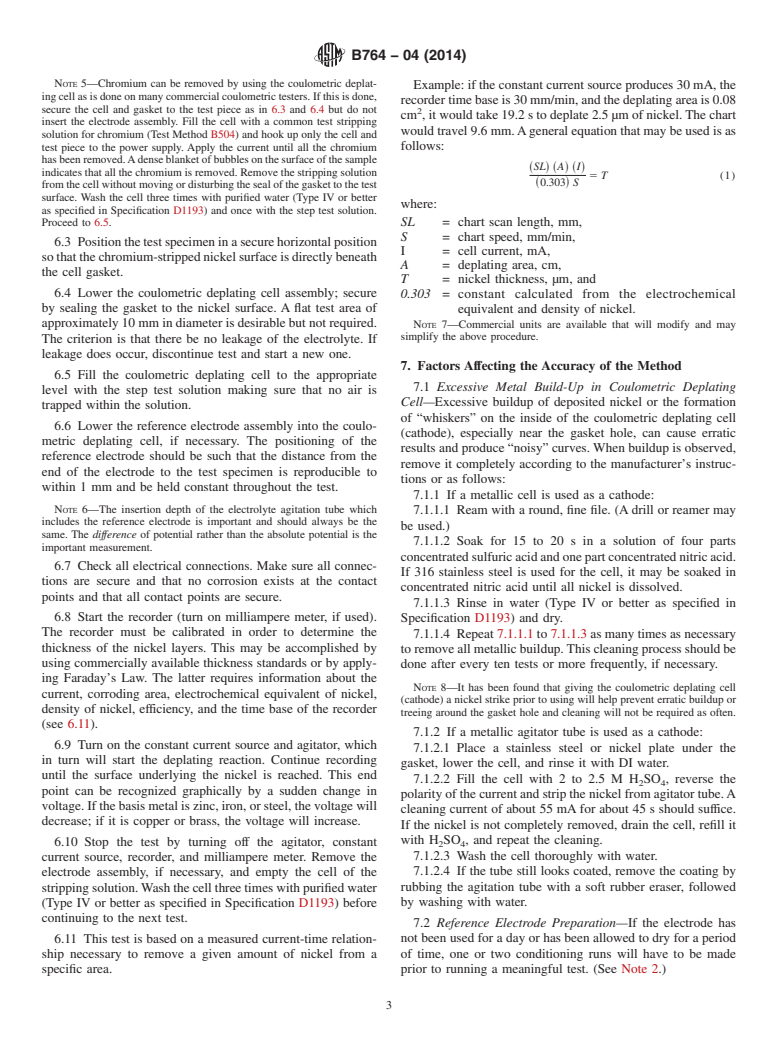

1. Scope 3.2 Coulometric thickness testing instruments are based on

the anodic dissolution (stripping) of the deposit at constant

1.1 This test method closely estimates the thickness of

current, while the time is measured to determine thickness.As

individual layers of a multilayer nickel electrodeposit and the

commonly practiced, the method employs a small cell that is

potential differences between the individual layers while being

2,3 filled with an appropriate electrolyte, and the test specimen

anodically stripped at constant current density.

serves as the bottom of the cell. To the bottom of the cell is

1.2 This test method does not cover deposit systems other

attached a rubber or plastic gasket whose opening defines the

than multilayer electroplated nickel deposits.

measuring(stripping,anodic)area.Ifametalliccellisused,the

1.3 This standard does not purport to address all of the

rubber gasket also electrically insulates the test specimen from

safety concerns, if any, associated with its use. It is the the cell.With the specimen as the anode and the cell or agitator

responsibility of the user of this standard to establish appro-

tube as the cathode, a constant direct current is passed through

priate safety and health practices and determine the applica- the cell until the nickel layer is dissolved. A sudden change in

bility of regulatory limitations prior to use.

voltagebetweentheelectrodesoccurswhenadifferentmetallic

layer starts to dissolve.

2. Referenced Documents

3.3 Each different metal or species of the same metal

4

2.1 ASTM Standards:

requires a given voltage to keep the current constant while

B456 Specification for Electrodeposited Coatings of Copper

being stripped. As one nickel layer is dissolved away and the

Plus Nickel Plus Chromium and Nickel Plus Chromium

next layer becomes exposed, there will be a voltage change

B504 Test Method for Measurement of Thickness of Metal-

(assuming a constant current and difference in the electro-

lic Coatings by the Coulometric Method

chemical characteristics of the two nickel layers). The elapsed

D1193 Specification for Reagent Water

timeatwhichthisvoltagechangeoccurs(relativetothestartof

the test or previous voltage change) is a measure of the deposit

3. Summary of Test Method

thickness.

3.1 This procedure is a modification of the well-known

3.4 At the same time, the amplitude of the voltage change

coulometric method of thickness testing (Test Method B504).

canbeobserved.Thatis,theease(ordifficulty)withwhichone

It is also known as the anodic dissolution or electrochemical

layer can be dissolved or stripped with reference to another

stripping method.

layer can be compared. The lower the voltage needed the more

active the metal or the greater the tendency to corrode

1

ThismethodisunderthejurisdictionofASTMCommitteeB08onMetallicand

preferentially to a more noble metal adjacent to it.

Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on Test

Methods.

3.5 Where the metallic layers are of such a similar nature

Current edition approved May 1, 2014. Published May 2014. Originally

that change of the stripping voltage is small, there can be

approved in 1986. Last previous edition approved in 2009 as B764 – 04(2009) .

problems in detecting this change if the voltage between the

DOI: 10.1520/B0764-04R14.

2

For discussion of this test, see Harbulak, E. P., “Simultaneous Thickness and

deplating cell (cathode) and the sample (anode) is measured.

Electrochemical Potential Determination of Individual Layers in Multilayer Nickel

As the sample is dissolved anodically, cathodic processes are

Deposits,” Plating and Surface Finishing, Vol 67, No. 2, February 1980, pp. 49–54.

occurring on the deplating cell (cathode) surface that can also

3

give rise to voltage changes, due to alterations of the cathode

U.S. Patent 4,310,389. Assignee: The Chrysler Corp., Highland Park, MI

48203.

surface, thus obscuring the anode voltage change. This diffi-

4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

culty can be avoided by measuring the potential of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

dissolving anodic sample with respect to an unpolarized third

Standards volume information, refer to the standard’s Docume

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.