ASTM F595-01

(Test Method)Standard Test Methods for Vacuum Cleaner Hose—Durability and Reliability (All-Plastic Hose)

Standard Test Methods for Vacuum Cleaner Hose—Durability and Reliability (All-Plastic Hose)

SCOPE

1.1 These test methods cover the determination of the effect of anticipated stresses and strains that vacuum cleaner hoses will receive in normal use.

1.2 These test methods apply to all-plastic, nonelectric vacuum cleaner hoses for household use.

Note 1—For information on plastic wire-reinforced, nonelectric vacuum cleaner hoses for household use, refer to Test Method F 450.

1.3 These test methods are individual tests as agreed upon between the hose manufacturer and the vacuum cleaner manufacturer.

1.4 The following tests are included: SectionTorsional flex6Hot and cold flex with aging (optional)7Abrasion (external surface) (optional)8Flex9Pull test on hose fittings with aging10Crush11

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathmatical conversions to SI units, which are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F595–01

Standard Test Methods for

Vacuum Cleaner Hose—Durability and Reliability

1

(All-Plastic Hose)

This standard is issued under the fixed designation F595; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F450 Test Methods for Vacuum Cleaner Hose for Durabil-

4

ity and Reliability (Plastic Wire Reinforced)

1.1 These test methods cover the determination of the effect

of anticipated stresses and strains that vacuum cleaner hoses

3. Terminology

will receive in normal use.

3.1 Definitions

1.2 These test methods apply to all-plastic, nonelectric

3.1.1 Refer to Terminology F395.

vacuum cleaner hoses for household use.

4. Significance and Use

NOTE 1—For information on plastic wire-reinforced, nonelectric

vacuum cleaner hoses for household use, refer to Test Method F450.

4.1 These test methods can be used by buyers of vacuum

1.3 These test methods are individual tests as agreed upon cleaner hose to specify the test criteria the hose must meet to

between the hose manufacturer and the vacuum cleaner manu-

be acceptable for their purposes.

facturer.

5. Sampling

1.4 The following tests are included:

5.1 The sample size shall be one that is mutually agreed

Section

Torsional flex 6

upon between the hose manufacturer and the vacuum cleaner

Hot and cold flex with aging (optional) 7

manufacturer.

Abrasion (external surface) (optional) 8

Flex 9

TEST METHODS

Pull test on hose fittings with aging 10

Crush 11

6. Torsional Flex

1.5 The values stated in inch-pound units are to be regarded

6.1 Scope—This test method covers the determination of

as standard. The values given in parentheses are mathmatical

resistance to failure while twisting under stress in a bend.

conversions to SI units, which are provided for information

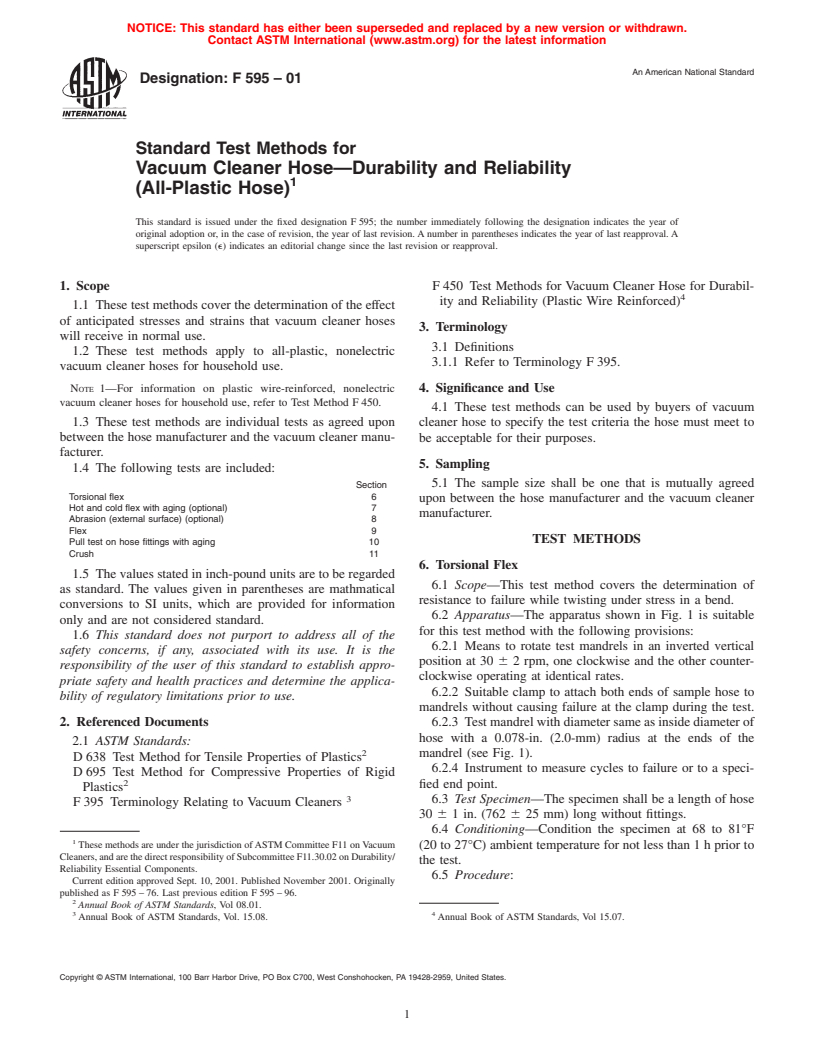

6.2 Apparatus—The apparatus shown in Fig. 1 is suitable

only and are not considered standard.

for this test method with the following provisions:

1.6 This standard does not purport to address all of the

6.2.1 Means to rotate test mandrels in an inverted vertical

safety concerns, if any, associated with its use. It is the

position at 30 6 2 rpm, one clockwise and the other counter-

responsibility of the user of this standard to establish appro-

clockwise operating at identical rates.

priate safety and health practices and determine the applica-

6.2.2 Suitable clamp to attach both ends of sample hose to

bility of regulatory limitations prior to use.

mandrels without causing failure at the clamp during the test.

2. Referenced Documents 6.2.3 Testmandrelwithdiametersameasinsidediameterof

hose with a 0.078-in. (2.0-mm) radius at the ends of the

2.1 ASTM Standards:

2

mandrel (see Fig. 1).

D638 Test Method for Tensile Properties of Plastics

6.2.4 Instrument to measure cycles to failure or to a speci-

D695 Test Method for Compressive Properties of Rigid

2

fied end point.

Plastics

3

6.3 Test Specimen—The specimen shall be a length of hose

F395 Terminology Relating to Vacuum Cleaners

30 6 1 in. (762 6 25 mm) long without fittings.

6.4 Conditioning—Condition the specimen at 68 to 81°F

1

These methods are under the jurisdiction ofASTM Committee F11 onVacuum (20 to 27°C) ambient temperature for not less than 1 h prior to

Cleaners,andarethedirectresponsibilityofSubcommitteeF11.30.02onDurability/

the test.

Reliability Essential Components.

6.5 Procedure:

Current edition approved Sept. 10, 2001. Published November 2001. Originally

published as F595–76. Last previous edition F595–96.

2

Annual Book of ASTM Standards, Vol 08.01.

3 4

Annual Book of ASTM Standards, Vol. 15.08. Annual Book of ASTM Standards, Vol 15.07.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

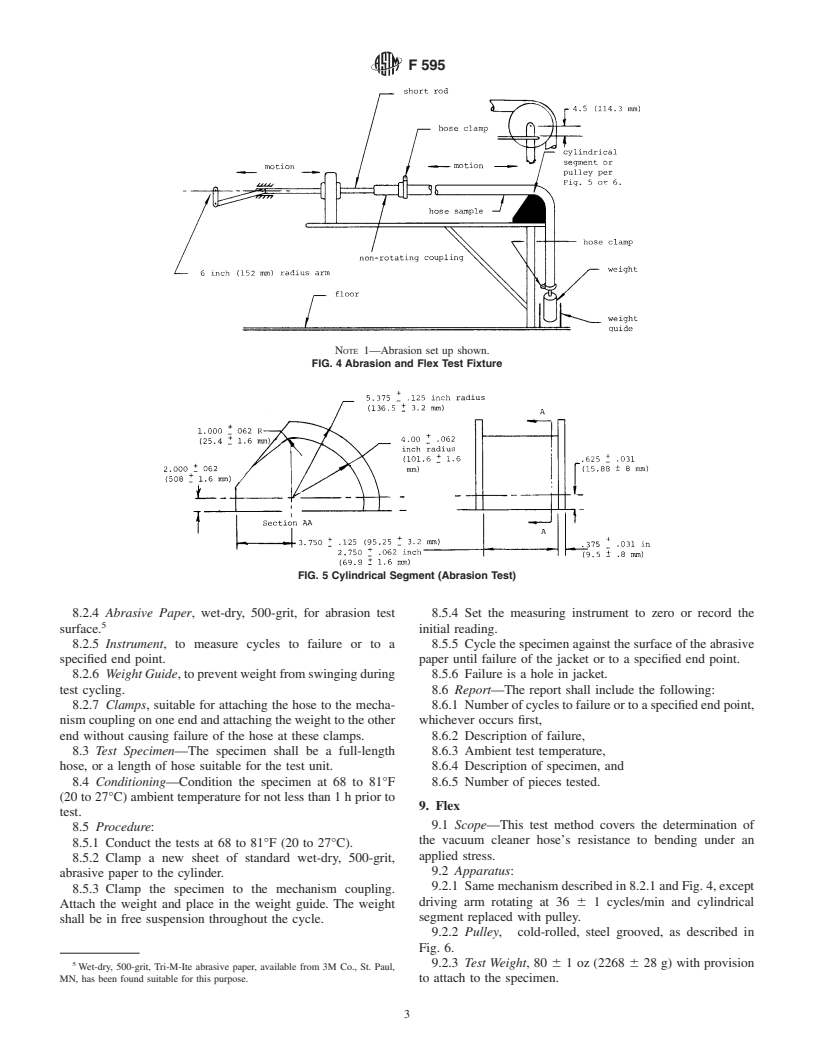

F595

FIG. 2 Hose Position During Heat and Cold Soak

7.5.4 Next place the specimen in the cold box, which has

been brought to a steady temperature of 20 6 1°F (−6.76

FIG. 1 Schematic for Torsional Flex Test

0.5°C) for 2 h.

7.5.5 Remove the specimen from the cold box, untie, and

6.5.1 Conduct the tests at 68 to 81°F (20 to 27°C). immediately flex it 360 deg, three times, 1 s per flex, as shown

6.5.2 Clamp both ends of the test specimen to the test in Fig. 3.

mandrels as shown in Fig. 1.

7.5.6 Failure may be evidenced by a broken reinforcing

6.5.3 Set the measuring instrument at zero or record initial

wire,tear,orholethatpenetratesthehosejacket,oracollapsed

reading.

coil or ply for a lined-type hose, or any combination thereof.

6.5.4 Test the specimen by rotating at 30 6 2 rpm until

7.5.7 Retie the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.