ASTM D146/D146M-04(2012)e1

(Test Method)Standard Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing

Standard Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing

ABSTRACT

These test methods cover the sampling and examination of felts and woven fabrics, saturated or impregnated but not coated with asphaltic or coal-tar materials, for use in waterproofing or for the construction of built-up roof coverings. After appropriate sampling, representative specimens shall be examined for the mass of wrapping material and mandrel (core), net mass per unit area, appearance and dimension of rolls, detached comminuted surfacing, moisture, strength, pliability, and loss on heating. Consequently, desaturated felt or fabric shall be examined for weight, retained carbonaceous matter, total comminuted surfacing, bituminous saturant, thread count of fabrics, thickness of felts, and ash content.

SCOPE

1.1 These test methods cover the sampling and examination of felts or woven fabrics, saturated or impregnated but not coated with asphaltic or coal-tar materials, for use in waterproofing or for the construction of built-up roof coverings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D146/D146M −04 (Reapproved 2012)

Standard Test Methods for

Sampling and Testing Bitumen-Saturated Felts and Woven

Fabrics for Roofing and Waterproofing

This standard is issued under the fixed designation D146/D146M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Units information was editorially corrected in June 2012.

1. Scope D645/D645MTest Method for Thickness of Paper and

Paperboard (Withdrawn 2010)

1.1 These test methods cover the sampling and examination

D828Test Method for Tensile Properties of Paper and

of felts or woven fabrics, saturated or impregnated but not

PaperboardUsingConstant-Rate-of-ElongationApparatus

coated with asphaltic or coal-tar materials, for use in water-

(Withdrawn 2009)

proofing or for the construction of built-up roof coverings.

D1079Terminology Relating to Roofing and Waterproofing

1.2 The values stated in either SI units or inch-pound units

D1682Test Method for Breaking Load and Elongation of

are to be regarded separately as standard. The values stated in

Textile Fabric (Withdrawn 1992)

each system may not be exact equivalents; therefore, each

D1910Methods of Test for Construction Characteristics of

system shall be used independently of the other. Combining

Woven Fabrics; Replaced by D3773, D3774, D3775,

values from the two systems may result in non-conformance

D3776, D3882, D3883 (Withdrawn 1981)

with the standard.

D4072Test Method for Toluene-Insoluble (TI) Content of

1.3 This standard does not purport to address all of the

Tar and Pitch

safety concerns, if any, associated with its use. It is the D4312Test Method for Toluene-Insoluble (TI) Content of

responsibility of the user of this standard to establish appro-

Tar and Pitch (Short Method)

priate safety and health practices and determine the applica-

3. Sampling

bility of regulatory limitations prior to use.

3.1 From each shipment of the specified saturated felt or

2. Referenced Documents

fabric, select at random a number of rolls equal to one half the

2.1 ASTM Standards:

cube root of the total number of rolls in the lot. If the

D95Test Method for Water in Petroleum Products and

specification requires sampling during manufacture, consider

Bituminous Materials by Distillation

thelottobetheplannedproductionquantityandselecttherolls

at uniformly spaced time intervals throughout the production

1 period. The minimum sample shall consist of five rolls. If the

These test methods are under the jurisdiction of ASTM Committee D08 on

calculated number is fractional, express it as the next highest

Roofing and Waterproofing and are the direct responsibility of Subcommittee

D08.04 on Felts, Fabrics and Bituminous Sheet Materials.

whole number. For convenience, the following table, showing

Current edition approved May 1, 2012. Published June 2012. Originally

the number of rolls to be selected from lots of various sizes, is

approved in 1922. Last previous edition approved in 2004 as D146–04. DOI:

given:

10.1520/D0146_D0146M-04R12E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D146/D146M−04 (2012)

2 2

g/m 5 A/BC oz/yd 5 1728 A/BC (2)

Number of Rolls in Shipment Number of Rolls in Sample ~ !

where:

Up to 1 000 5

1 001 to 1 728 6

A = net mass of rolls, kg [lb],

1 729 to 2 744 7

B = width of material, m [ft], and

2 745 to 4 096 8

C = length of material, m [ft].

4 097 to 5 832 9

5 833 to 8 000 10

Calculate the average net mass per unit area for the rolls in

8 001 to 10 648 11

10 649 to 13 842 12 the representative sample and record it as the average for the

13 843 to 17 576 13

lot.

17 577 to 21 952 14

10. Selecting a Representative Specimen

The rolls so selected constitute the representative sample

used for all subsequent observations and tests pertaining to the

10.1 Examine in detail the roll having the unit net mass

lot of material being examined. Identify each individual roll.

closest to the average unit net mass of the lot. Discard the

outside convolution and cut a specimen the full width of the

EXAMINATION OF REPRESENTATIVE SAMPLE

roll. Make the cuts perpendicular to the sides of the roll,

straight and 750 mm [30 in.] apart, to the nearest 1 mm [ ⁄32

4. Gross Mass per Roll

in.]. Collect loose material, such as sand, if any, that may

4.1 Weigh each roll, intact, to the nearest 100 g [ ⁄4 lb], and

become detached from the specimen. Measure the width of the

record each weight as the gross mass of that roll.

specimen to the nearest 2 mm [ ⁄16 in.].Weigh it, together with

any detached surfacing, to the nearest 1 g. Calculate the net

5. Mass of Wrapping Material and Mandrel (Core)

mass per unit area as follows:

5.1 Strip each roll of its wrappings and weigh it to the

For Felts:

nearest100g[ ⁄4lb].Ifmandrels(cores)areused,collectthem

2 2

g/m 5 1333.3D/E lb/ft 5 1.0582 D/E (3)

~ !

after the rolls are unwound and weigh them together, to the

nearest 100 g [ ⁄4 lb]. Calculate the average mass of the For Fabrics:

wrappings and mandrels per roll and record.

2 2

g/m 5 1333.3D/E~oz/yd 5 1.5238 D/E! (4)

6. Mandrels (Cores)

where:

D = mass of the specimen, g, and

6.1 Determinetheshapeofthecrosssectionofthemandrels

E = width of the specimen, mm [in.].

(cores) and report. If circular, measure the outside diameter to

thenearest1mm[ ⁄32in.].Ifsquare,measureeachoutsideedge

The mass so determined shall be within 1% of the average

to the nearest 1 mm [ ⁄32 in.]. Measure and report the length of

net mass per unit area (Section 9). If the specimen so selected

the mandrel projecting beyond each end of each roll to the

fails to conform to this requirement, cut additional specimens

nearest 5 mm [ ⁄16 in.].

fromthesamerolluntiloneofthepropermassisobtained.Use

this specimen for further examination as described in Sections

7. Net Mass

11–16.

7.1 Subtract the average mass of the wrappings and man-

11. Detached Comminuted Surfacing

drels (Section 5) from the gross mass of each roll (Section 4)

11.1 If the material is surfaced with sand or other finely

and record as the net mass of each roll. Calculate the average

comminuted material, sweep the detached surfacing from the

netmassperrolloftherepresentativesampleandrecordasthe

representative specimen with an Osborn brush (or equivalent),

average for the lot.

brushing in one direction only. Combine the comminuted

8. Appearance and Dimensions of Rolls

material thus removed with the loose material, collected as

described in Section 10, and weigh both together to the nearest

8.1 Unwind the rolls. Observe the workmanship and finish,

2 2

1g.Calculatethismassing/m [lb⁄100ft ],record,andreport

and record pertinent defects. Measure and record the length of

as detached comminuted surfacing.

each roll to the nearest 25 mm [1 in.] and its width to the

nearest 1 mm [ ⁄16 in.]. Calculate and record the area of

NOTE 1—The Osborn No. 322 Master Duster is the brush prescribed in

2 2

material contained in each roll to the nearest 0.1 m [1 ft ]. Section 11. It is filled with Tampico fiber bristles projecting 73 mm [2.9

in.] from its holder.

8.2 Measureandrecordthewidthoftheselvageofeachroll

12. Moisture

to the nearest 1 mm [ ⁄16 in.].

12.1 From the representative specimen, cut four 50- by

9. Net Mass per Unit Area

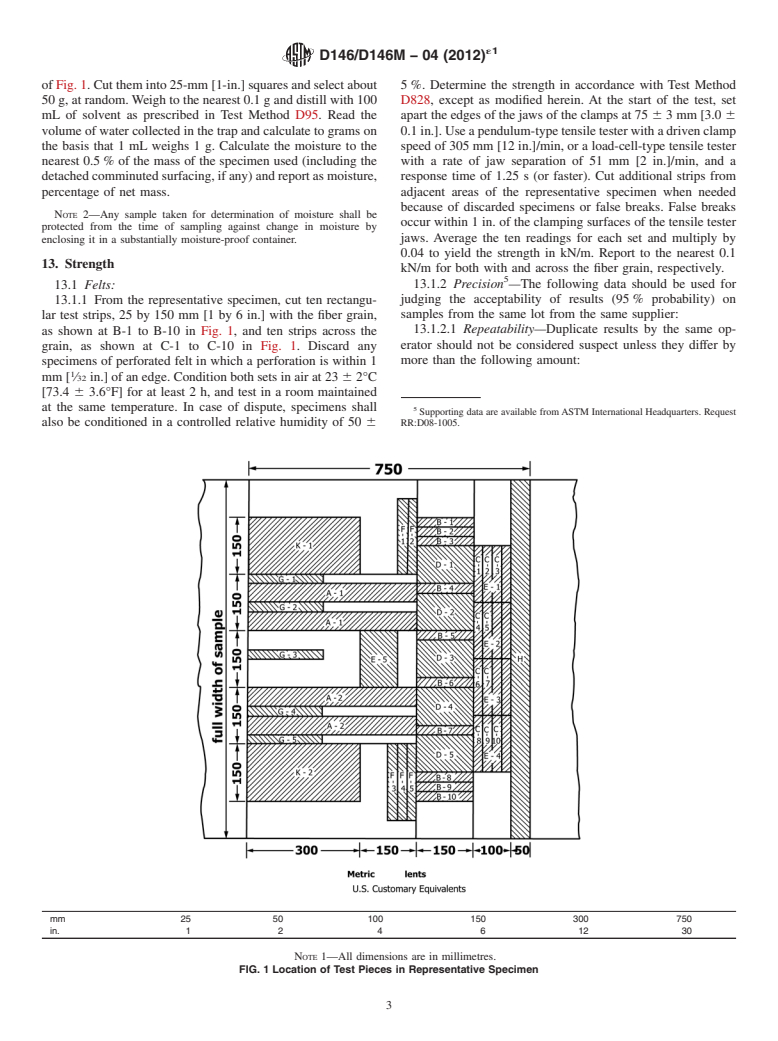

460-mm[2-by18-in.]testspecimens,asshowninA-1andA-2

9.1 From the net mass (Section 7) and the dimensions

(Section 8), calculate the net mass per unit area for each roll,

The sole source of supply of the apparatus (Osborn No. 322 Master Duster)

known to the committee at this time is Osborn Manufacturing Co., 5401 Hamilton

as follows:

Ave., Cleveland, OH 44114. (If required in less than dozen lots, the order must be

For Felts:

marked “ForASTMTest.”) If you are aware of alternative suppliers, please provide

2 2

this information toASTM International Headquarters. Your comments will receive

g/m 5 A/BC lb/100 ft 5 1200 A/BC (1)

~ !

careful consideration at a meeting of the responsible technical committee, which

For Fabrics: you may attend.

´1

D146/D146M−04 (2012)

ofFig.1.Cuttheminto25-mm[1-in.]squaresandselectabout 5%. Determine the strength in accordance with Test Method

50g,atrandom.Weightothenearest0.1ganddistillwith100 D828, except as modified herein. At the start of the test, set

mL of solvent as prescribed in Test Method D95. Read the apart the edges of the jaws of the clamps at 75 6 3 mm [3.0 6

volumeofwatercollectedinthetrapandcalculatetogramson 0.1in.].Useapendulum-typetensiletesterwithadrivenclamp

the basis that 1 mL weighs 1 g. Calculate the moisture to the speed of 305 mm [12 in.]/min, or a load-cell-type tensile tester

nearest 0.5% of the mass of the specimen used (including the with a rate of jaw separation of 51 mm [2 in.]/min, and a

detachedcomminutedsurfacing,ifany)andreportasmoisture, response time of 1.25 s (or faster). Cut additional strips from

percentage of net mass. adjacent areas of the representative specimen when needed

because of discarded specimens or false breaks. False breaks

NOTE 2—Any sample taken for determination of moisture shall be

occur within 1 in. of the clamping surfaces of the tensile tester

protected from the time of sampling against change in moisture by

jaws. Average the ten readings for each set and multiply by

enclosing it in a substantially moisture-proof container.

0.04 to yield the strength in kN/m. Report to the nearest 0.1

13. Strength

kN/m for both with and across the fiber grain, respectively.

13.1.2 Precision —The following data should be used for

13.1 Felts:

judging the acceptability of results (95% probability) on

13.1.1 From the representative specimen, cut ten rectangu-

samples from the same lot from the same supplier:

lar test strips, 25 by 150 mm [1 by 6 in.] with the fiber grain,

13.1.2.1 Repeatability—Duplicate results by the same op-

as shown at B-1 to B-10 in Fig. 1, and ten strips across the

erator should not be considered suspect unless they differ by

grain, as shown at C-1 to C-10 in Fig. 1. Discard any

more than the following amount:

specimens of perforated felt in which a perforation is within 1

mm [ ⁄32 in.] of an edge. Condition both sets in air at 23 6 2°C

[73.4 6 3.6°F] for at least 2 h, and test in a room maintained

at the same temperature. In case of dispute, specimens shall 5

Supporting data are available fromASTM International Headquarters. Request

also be conditioned in a controlled relative humidity of 50 6 RR:D08-1005.

mm 25 50 100 150 300 750

in. 1 2 4 6 12 30

NOTE 1—All dimensions are in millimetres.

FIG. 1Location of Test Pieces in Representative Specimen

´1

D146/D146M−04 (2012)

weigh each specimen. Calculate the average loss to the nearest

Pendulum method ±15 %

Load-Cell method ±15 %

0.5% of the specimen weights (including the detached com-

minuted surfacing, if any). Report this figure as the loss on

13.1.2.2 Reproducibility—The results submitted by each of

two laboratories should not be considered suspect unless they heating. Subtract the percentage of moisture and report as the

differ by more than the following amounts: loss on heating exclusive of moisture.

Pendulum method ±15 %

EXAMINATION OF DESATURATED FELT OR

Load-Cell method ±15 %

FABRIC

13.2 Fabrics—From the representative specimen, cut five

100- by 150-mm [4- by 6-in.] test pieces with the longer

16. Weight of Desaturated Felt or Fabric

dimensionparalleltothewarpyarns,asshownatE-1toE-5in

Fig. 1. Test these pieces at 21 6 1°C [69.8 6 1.8°F] in

16.1 Cut a 50 6 0.5-mm [2 6 ⁄64-in.] strip from the

accordance with the grab method described in Test Methods

representative specimen as shown at H in Fig. 1. Measure its

D1682.

lengthtothenearest1mm[ ⁄32in.]andcalculateitsareatothe

2 2

nearest 500 mm [1 in. ]. Extract the test strip with 1,1,1-

NOTE 3—As a referee method, or in case any dispute arises regarding

trichloroethane or other suitable solvent (see Note 4)ina

thestrength,repeatthetest,withtheexceptionthatthefabricbeforebeing

tested shall be exposed at least2hinan atmosphere of 65% relative suitable extractor (such as the one shown in Fig. 2)or

humidity at 21 6 1°C [69.8 6 1.8°F].

centrifuge until washings are colorless. Dry the extracted

specimen in the basket or thimble, first at room temperature in

14. Pliability

aventilatedfumechamberandtheninaventilatedovenat105

14.1 Felts—From the representative specimen, cut ten 25- 6 3°C [221 6 5°F], and cool in a desiccator. Remove the

by200-mm[1-by8-in.]testpieces,fiveinthedirectionofand desaturated felt or fabric, brush off any adherent comminuted

five across the fiber grain, as shown at F-1 to F-5, and at G-1 surfacing into the filter, and quickly weigh the felt or fabric to

to G-5 in Fig. 1, respectively. Immerse them in water at 25 6 thenearest0.1g.Repeattheheating,coolingindesiccator,and

1°C[77 61.8°F]for10to15min;thenremoveeachspecimen weighing of the desaturated felt or fabric to constant weight.

separately and immediately bend it 90° over the rounded edge Fromtheareaofthespecimensandthemassofthedesaturated

of a block at a uniform speed in approximately 2 s. The block felt or fabric, calculate the mass per unit area of moisture-free

shall be 75 mm [3 in.] square by 50 mm [2 in.] thick, with one desaturated felt or fabric. Report this mass to the nearest 5

2 2 2

long edge rounded on a radius of 12.7 mm [0.50 in.] and g/m [0.1 lb/100ft ] for felts and to the nearest 10 g/m [ ⁄2

another edge on the same 75 mm [3 in.] face rounded on a oz/yd ] for fabrics.

radius of 19 mm [0.75 in.]. In bending, hold the specimen

16.2 Wherecoal-tarsaturanthasbeenused(seeSection17),

tightly against the upper 50-mm [2-in.] face of the block and

correctthemoisture-freeweightofthedesaturatedfeltorfabric

benditsprojectingendoverthespecifiedroundededgewithout

forcarbonaceousmatterretainedmechanicallyinitsinterstices

exerting any stress other than that required to keep the

by multiplying by (100-F)/100, where F is the percentage of

specimen in contact with the block and to avoid kinking.

retained carbonaceous matter as determined in Section 17.

Consider any sur

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D146–04 Designation: D146/D146M – 04 (Reapproved 2012)

Standard Test Methods for

Sampling and Testing Bitumen-Saturated Felts and Woven

Fabrics for Roofing and Waterproofing

This standard is issued under the fixed designation D146/D146M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Units information was editorially corrected in June 2012.

1. Scope

1.1 These test methods cover the sampling and examination of felts or woven fabrics, saturated or impregnated but not coated

with asphaltic or coal-tar materials, for use in waterproofing or for the construction of built-up roof coverings.

1.2The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D645/D645M Test Method for Thickness of Paper and Paperboard

D828 Test Method for Tensile Properties of Paper and Paperboard Using Constant-Rate-of-Elongation Apparatus

D1079 Terminology Relating to Roofing and Waterproofing

D1682 Methods of Test Method for Breaking Load and Elongation of Textile Fabrics Fabric

D1910 Methods of Test for Construction Characteristics of Woven Fabrics Methods of Test for Construction Characteristics

of Woven Fabrics; Replaced by D3773, D3774, D3775, D3776, D3882, D3883

D4072 Test Method for Toluene-Insoluble (TI) Content of Tar and Pitch

D4312 Test Method for Toluene-Insoluble (TI) Content of Tar and Pitch (Short Method)

3. Sampling

3.1 From each shipment of the specified saturated felt or fabric, select at random a number of rolls equal to one half the cube

root of the total number of rolls in the lot. If the specification requires sampling during manufacture, consider the lot to be the

plannedproductionquantityandselecttherollsatuniformlyspacedtimeintervalsthroughouttheproductionperiod.Theminimum

sample shall consist of five rolls. If the calculated number is fractional, express it as the next highest whole number. For

convenience, the following table, showing the number of rolls to be selected from lots of various sizes, is given:

These test methods are under the jurisdiction ofASTM Committee D08 on Roofing andWaterproofing and are the direct responsibility of Subcommittee D08.04 on Felts

and Fabrics.

Current edition approved Aug. 1, 2004. Published August 2004. Originally approved in 1922. Last previous edition approved in 2003 as D146–03. DOI:

10.1520/D0146-04.on Felts, Fabrics and Bituminous Sheet Materials.

Current edition approved May 1, 2012. Published June 2012. Originally approved in 1922. Last previous edition approved in 2004 as D146 – 04. DOI:

10.1520/D0146_D0146M-04R12E01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D146/D146M – 04 (2012)

Number of Rolls in Shipment Number of Rolls in Sample

Up to 1 000 5

1 001 to 1 728 6

1 729 to 2 744 7

2 745 to 4 096 8

4 097 to 5 832 9

5 833 to 8 000 10

8 001 to 10 648 11

10 649 to 13 842 12

13 843 to 17 576 13

17 577 to 21 952 14

The rolls so selected constitute the representative sample used for all subsequent observations and tests pertaining to the lot of

material being examined. Identify each individual roll.

EXAMINATION OF REPRESENTATIVE SAMPLE

4. Gross Mass per Roll

4.1 Weigh each roll, intact, to the nearest 100 g ([ ⁄4 lb),lb], and record each weight as the gross mass of that roll.

5. Mass of Wrapping Material and Mandrel (Core)

5.1 Strip each roll of its wrappings and weigh it to the nearest 100 g ([ ⁄4 lb).lb]. If mandrels (cores) are used, collect them after

the rolls are unwound and weigh them together, to the nearest 100 g ([ ⁄4 lb).lb]. Calculate the average mass of the wrappings and

mandrels per roll and record.

6. Mandrels (Cores)

6.1 Determine the shape of the cross section of the mandrels (cores) and report. If circular, measure the outside diameter to the

1 1

nearest 1 mm ([ ⁄32 in.).in.]. If square, measure each outside edge to the nearest 1 mm ([ ⁄32 in.).in.]. Measure and report the length

of the mandrel projecting beyond each end of each roll to the nearest 5 mm ([ ⁄16 in.). in.].

7. Net Mass

7.1 Subtracttheaveragemassofthewrappingsandmandrels(Section5)fromthegrossmassofeachroll(Section4)andrecord

as the net mass of each roll. Calculate the average net mass per roll of the representative sample and record as the average for the

lot.

8. Appearance and Dimensions of Rolls

8.1 Unwind the rolls. Observe the workmanship and finish, and record pertinent defects. Measure and record the length of each

roll to the nearest 25 mm (1 in.)[1 in.] and its width to the nearest 1 mm ([ ⁄16 in.).in.]. Calculate and record the area of material

2 [1 ft

contained in each roll to the nearest 0.1 m (1 ft ).].

8.2 Measure and record the width of the selvage of each roll to the nearest 1 mm ([ ⁄16 in.). in.].

9. Net Mass per UnitArea

9.1 From the net mass (Section 7) and the dimensions (Section 8), calculate the net mass per unit area for each roll, as follows:

For Felts:

2 2

g/m 5 A/BC [lb/100 ft (1)

2 2

g/m 5 A/BC [lb/100 ft (1)

5 1200 A/BC] D0146_D0146M-04R12E01_1

For Fabrics:

2 2

g/m 5 A/BC [ oz/yd (2)

2 2

g/m 5 A/BC [ oz/yd (2)

5 1728 A/BC] D0146_D0146M-04R12E01_2

where:

A = net mass of rolls, kg (lb), [lb],

B = width of material, m (ft),[ft], and

C = length of material, m (ft).[ft].

Calculate the average net mass per unit area for the rolls in the representative sample and record it as the average for the lot.

10. Selecting a Representative Specimen

10.1 Examine in detail the roll having the unit net mass closest to the average unit net mass of the lot. Discard the outside

convolution and cut a specimen the full width of the roll. Make the cuts perpendicular to the sides of the roll, straight and 750 mm

´1

D146/D146M – 04 (2012)

(30 in.)[30 in.] apart, to the nearest 1 mm ([ ⁄32 in.).in.]. Collect loose material, such as sand, if any, that may become detached

from the specimen. Measure the width of the specimen to the nearest 2 mm ([ ⁄16 in.).in.]. Weigh it, together with any detached

surfacing, to the nearest 1 g. Calculate the net mass per unit area as follows:

For Felts:

2 2

g/m 5 1333.3 D/E [lb/100 ft

5 1.0582 D/E]

(3)

2 2

g/m 5 1333.3 D/E [lb/100 ft

5 1.0582 D/E]

(3)

D0146_D0146M-04R12E01_3

For Fabrics:

2 2

g/m 5 1333.3 D/E [ oz/yd (4)

2 2

g/m 5 1333.3 D/E [ oz/yd (4)

5 1.5238 D/E] D0146_D0146M-04R12E01_4

where:

D = mass of the specimen, g, and

E = width of the specimen, mm (in.).[in.].

The mass so determined shall be within 1 % of the average net mass per unit area (Section 9). If the specimen so selected fails

to conform to this requirement, cut additional specimens from the same roll until one of the proper mass is obtained. Use this

specimen for further examination as described in Sections 11-16.

11. Detached Comminuted Surfacing

11.1 If the material is surfaced with sand or other finely comminuted material, sweep the detached surfacing from the

representative specimen with an Osborn brush (or equivalent), brushing in one direction only. Combine the comminuted material

thus removed with the loose material, collected as described in Section 10, and weigh both together to the nearest 1 g. Calculate

2 [lb/100 ft

this mass in g/m (lb/100 ft ),], record, and report as detached comminuted surfacing.

NOTE 1—The Osborn No. 322 Master Duster is the brush prescribed in Section 11. It is filled withTampico fiber bristles projecting 73 mm (2.9 in.)[2.9

in.] from its holder.

12. Moisture

12.1 From the representative specimen, cut four 50- by 460-mm (2-[2- by 18-in.)18-in.] test specimens, as shown in A-1 and

A-2 of Fig. 1. Cut them into 25-mm (1-in.)[1-in.] squares and select about 50 g, at random. Weigh to the nearest 0.1 g and distill

with 100 mL of solvent as prescribed in Test Method D95. Read the volume of water collected in the trap and calculate to grams

on the basis that 1 mL weighs 1 g. Calculate the moisture to the nearest 0.5 % of the mass of the specimen used (including the

detached comminuted surfacing, if any) and report as moisture, percentage of net mass.

NOTE 2—Any sample taken for determination of moisture shall be protected from the time of sampling against change in moisture by enclosing it in

a substantially moisture-proof container.

13. Strength

13.1 Felts:

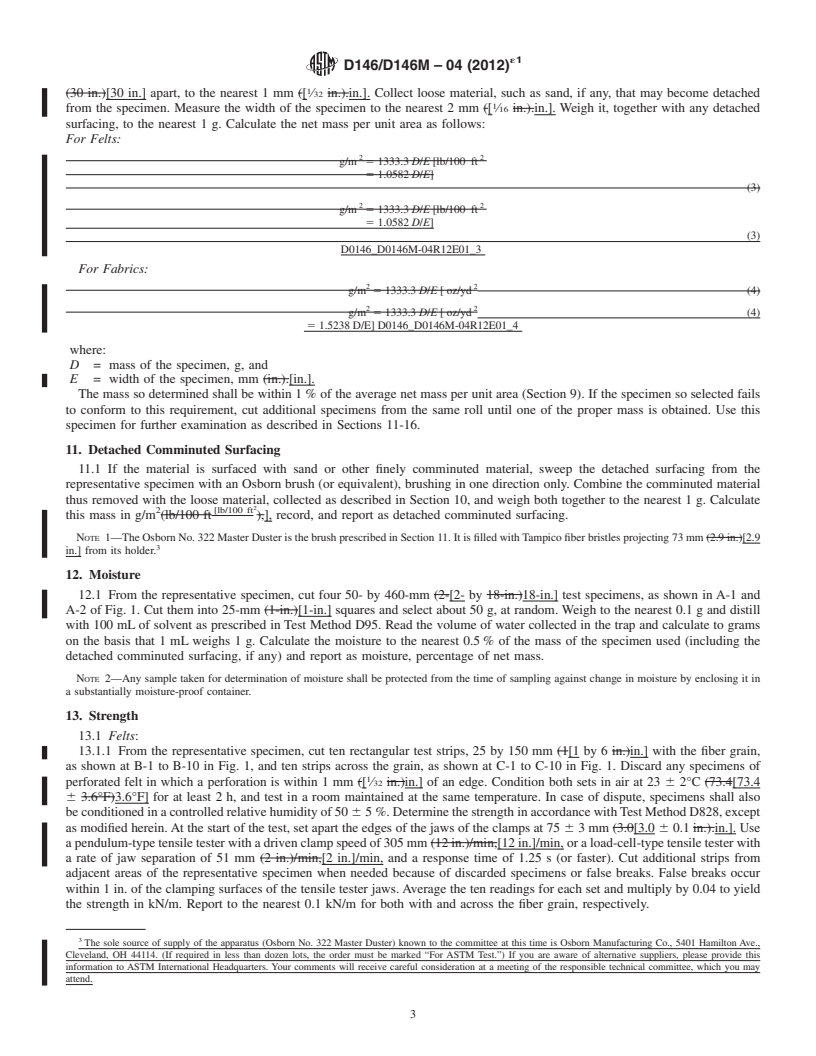

13.1.1 From the representative specimen, cut ten rectangular test strips, 25 by 150 mm (1[1 by 6 in.)in.] with the fiber grain,

as shown at B-1 to B-10 in Fig. 1, and ten strips across the grain, as shown at C-1 to C-10 in Fig. 1. Discard any specimens of

perforated felt in which a perforation is within 1 mm ([ ⁄32 in.)in.] of an edge. Condition both sets in air at 23 6 2°C (73.4[73.4

6 3.6°F)3.6°F] for at least 2 h, and test in a room maintained at the same temperature. In case of dispute, specimens shall also

beconditionedinacontrolledrelativehumidityof50 65 %.DeterminethestrengthinaccordancewithTestMethodD828,except

as modified herein.At the start of the test, set apart the edges of the jaws of the clamps at 75 6 3 mm (3.0[3.0 6 0.1 in.).in.]. Use

apendulum-typetensiletesterwithadrivenclampspeedof305mm(12in.)/min,[12in.]/min,oraload-cell-typetensiletesterwith

a rate of jaw separation of 51 mm (2 in.)/min,[2 in.]/min, and a response time of 1.25 s (or faster). Cut additional strips from

adjacent areas of the representative specimen when needed because of discarded specimens or false breaks. False breaks occur

within 1 in. of the clamping surfaces of the tensile tester jaws.Average the ten readings for each set and multiply by 0.04 to yield

the strength in kN/m. Report to the nearest 0.1 kN/m for both with and across the fiber grain, respectively.

The sole source of supply of the apparatus (Osborn No. 322 Master Duster) known to the committee at this time is Osborn Manufacturing Co., 5401 Hamilton Ave.,

Cleveland, OH 44114. (If required in less than dozen lots, the order must be marked “For ASTM Test.”) If you are aware of alternative suppliers, please provide this

information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may

attend.

´1

D146/D146M – 04 (2012)

mm 25 50 100 150 300 750

in. 1 2 4 6 12 30

NOTE 1—All dimensions are in millimetres.

FIG. 1 Location of Test Pieces in Representative Specimen

13.1.2 Precision —The following data should be used for judging the acceptability of results (95 % probability) on samples

from the same lot from the same supplier:

13.1.2.1 Repeatability—Duplicateresultsbythesameoperatorshouldnotbeconsideredsuspectunlesstheydifferbymorethan

the following amount:

Pendulum method 615 %

Load-Cell method 615 %

13.1.2.2 Reproducibility—The results submitted by each of two laboratories should not be considered suspect unless they differ

by more than the following amounts:

Pendulum method 615 %

Load-Cell method 615 %

13.2 Fabrics—From the representative specimen, cut five 100- by 150-mm (4-[4- by 6-in.)6-in.] test pieces with the longer

dimension parallel to the warp yarns, as shown at E-1 to E-5 in Fig. 1. Test these pieces at 21 6 1°C (69.8[69.8 6 1.8°F)1.8°F]

in accordance with the grab method described in Test Methods D1682.

NOTE 3—As a referee method, or in case any dispute arises regarding the strength, repeat the test, with the exception that the fabric before being tested

shall be exposed at least2hinan atmosphere of 65 % relative humidity at 21 6 1°C (69.8[69.8 6 1.8°F). 1.8°F].

14. Pliability

14.1 Felts—From the representative specimen, cut ten 25- by 200-mm (1-[1- by 8-in.)8-in.] test pieces, five in the direction of

The sole source of supply of the apparatus (Osborn No. 322 Master Duster) known to the committee at this time is Osborn Manufacturing Co., 5401 Hamilton Ave.,

Cleveland, OH 44114. (If required in less than dozen lots, the order must be marked “For ASTM Test.”) If you are aware of alternative suppliers, please provide this

information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may

attend.

Supporting data are available from ASTM International Headquarters. Request RR:D08-1005.

´1

D146/D146M – 04 (2012)

and five across the fiber grain, as shown at F-1 to F-5, and at G-1 to G-5 in Fig. 1, respectively. Immerse them in water at 25 6

1°C (77[77 6 1.8°F)1.8°F] for 10 to 15 min; then remove each specimen separately and immediately bend it 90° over the rounded

edge of a block at a uniform speed in approximately 2 s. The block shall be 75 mm (3 in.)[3 in.] square by 50 mm (2 in.)[2 in.]

thick, with one long edge rounded on a radius of 12.7 mm (0.50 in.)[0.50 in.] and another edge on the same 75 mm (3 in.)[3 in.]

faceroundedonaradiusof19mm(0.75in.).[0.75in.].Inbending,holdthespecimentightlyagainsttheupper50-mm(2-in.)[2-in.]

face of the block and bend its projecting end over the specified rounded edge without exerting any stress other than that required

to keep the specimen in contact with the block and to avoid kinking. Consider any surf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.