ASTM B500/B500M-09

(Specification)Standard Specification for Metallic Coated Stranded Steel Core for Use in Overhead Electrical Conductors

Standard Specification for Metallic Coated Stranded Steel Core for Use in Overhead Electrical Conductors

ABSTRACT

This specification covers zinc-coated (galvanized), zinc-aluminum-mischmetal alloy-coated, and aluminum-coated (aluminized) stranded steel wire core inserted for use in aluminum conductors, steel reinforced (ACSR). Prior to stranding, the metallic coated steel wire to be used in the production of the stranded core shall meet all of the requirements of the appropriate specification. Requirements for (1) coated steel wire joints, (2) stranding of the core such as lay length and lay direction, (3) construction of ACSR, and (4) tensile properties of stranded core are detailed. The standard stranded core lengths and methods of determining rated strength and calculating loads are given.

SCOPE

1.1 This specification covers 7-wire, 19-wire, 37-wire, and 61-wire zinc-coated (galvanized), zinc-5 % aluminum-mischmetal alloy-coated stranded steel core intended for use in overhead electrical conductors.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B500/B500M – 09

Standard Specification for

Metallic Coated Stranded Steel Core for Use in Overhead

1

Electrical Conductors

This standard is issued under the fixed designation B500/B500M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.2 production lot—all of the wire spools loaded into a

stranding machine that are used to produce a completed strand

1.1 This specification covers 7-wire, 19-wire, 37-wire, and

cable.

61-wire zinc-coated (galvanized), zinc-5 % aluminum-

mischmetalalloy-coatedstrandedsteelcoreintendedforusein

4. Ordering Information

overhead electrical conductors.

4.1 Ordersformaterialunderthisspecificationshallinclude

1.2 The values stated in either SI units or inch-pound units

the following information:

are to be regarded separately as standard. The values stated in

4.1.1 Length of each construction,

each system may not be exact equivalents; therefore, each

4.1.2 Constructional description of stranded core (for ex-

system shall be used independently of the other. Combining

ample, 7 3 0.0943 in. or 19 3 0.0977 in.) (8.1 and 8.2),

values from the two systems may result in non-conformance

4.1.3 The multiple length of stranded core and the total

with the standard.

numberofmultiplelengthsperreel,ifallowed(8.3andSection

2. Referenced Documents 15),

2

4.1.4 Strength and coating type (Section 8),

2.1 ASTM Standards:

4.1.5 Direction of lay of outer layer (Section 7),

B498/B498M Specification for Zinc-Coated (Galvanized)

4.1.6 Packaging (Section 15), and

SteelCoreWireforUseinOverheadElectricalConductors

4.1.7 Place of inspection (Section 13).

B606 Specification for High-Strength Zinc-Coated (Galva-

nized) Steel Core Wire for Aluminum and Aluminum-

5. Material

Alloy Conductors, Steel Reinforced

5.1 The coated steel wire used in the production of the

B802/B802M Specification for Zinc−5 % Aluminum-

stranded core shall, prior to stranding, meet all of the require-

Mischmetal Alloy-Coated Steel Core Wire for Aluminum

ments of the appropriate specification that follows:

Conductors, Steel Reinforced (ACSR)

5.1.1 Specification B498/B498M,

B803 Specification for High-Strength Zinc−5 %

5.1.2 Specification B606,

Aluminum-Mischmetal Alloy-Coated Steel Core Wire for

5.1.3 Specification B802/B802M, and

Use in Overhead Electrical Conductors

5.1.4 Specification B803.

E83 Practice for Verification and Classification of Exten-

someter Systems

6. Joints

3. Terminology 6.1 Thereshallbenojointsofanykindmadeinthefinished

zinc-coated,zinc-5%aluminum-mischmetalalloy-coatedsteel

3.1 Definitions of Terms Specific to This Standard:

wires.

3.1.1 lot—unless otherwise specified in the contract or

order, a lot shall consist of all coils or reels of strand of the

7. Stranding

same diameter and unit lengths submitted for inspection at the

7.1 The lay length of the 6-wire layer of 7 and 19-wire

same time.

stranded core shall be not less than 16 or more than 26 times

the outside diameter of the 6-wire layer. (Outside diameter is

1

This specification is under the jurisdiction of ASTM Committee B01 on

three times nominal wire diameter.)

Electrical Conductors and is the direct responsibility of Subcommittee B01.05 on

7.2 Thelaylengthofthe12-wirelayerofa19-wirestranded

Conductors of Ferrous Metals.

coreshallbenotlessthan14ormorethan22timestheoutside

Current edition approved March 15, 2009. Published April 2009. Originally

approved in 1969. Last previous edition approved in 2002 as B500/B500M–98

diameter of the 12-wire layer. (Outside diameter is five times

(2002). DOI: 10.1520/B0500_B0500M-09.

nominal wire diameter.)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

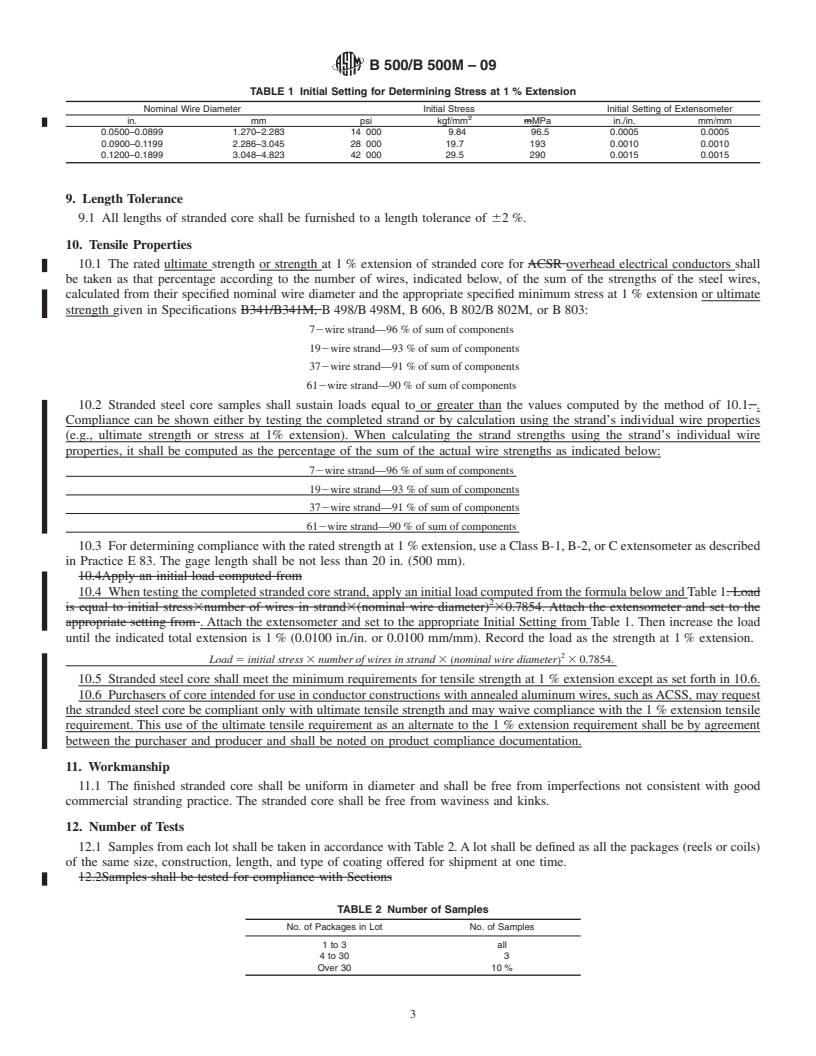

B500/B500M – 09

7.3 Thelaylengthofthe18-wirelayerofa37-wirestranded properties (e.g., ultimate strength or stress at 1% extension).

coreshallbenotlessthan14ormorethan20timestheoutside When calculating the strand strengths using the strand’s

diameterofthe18-wirelayer.(Outsidediameterisseventimes individual wire properties, it shall be computed as the percent-

nominal wire diameter.) age of the sum of the actual wire strengths as indicated below:

7.4 Thelaylengthofthe24-wirelayerofa61-wirestranded

72wirestrand—96%ofsumofcomponents

coresh

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B500/B500M–98 (Reapproved 2002) Designation: B 500/B 500M – 09

Standard Specification for

Metallic Coated Stranded Steel Core for Aluminum

Conductors, Steel Reinforced (ACSR)Metallic Coated

Stranded Steel Core for Use in Overhead Electrical

1

Conductors

This standard is issued under the fixed designation B 500/B 500M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This specification covers 7-wire, 19-wire, 37-wire, and 61-wire zinc-coated (galvanized), zinc-5% aluminum-mischmetal

alloy-coated, and aluminum-coated (aluminized) stranded steel core inserted for use in aluminum conductors, steel reinforced

(ACSR).

1.2The values stated in inch-pound units are to be regarded separately as standard. The values in each system are not exact

equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result

in nonconformance with this specification. *

1.1 This specification covers 7-wire, 19-wire, 37-wire, and 61-wire zinc-coated (galvanized), zinc-5 % aluminum-mischmetal

alloy-coated stranded steel core intended for use in overhead electrical conductors.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2.1 ASTM Standards:B232/B232MSpecification for Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced

(ACSR)

B341/B341MSpecification for Aluminum-Coated (Aluminized) Steel Core Wire for Aluminum Conductors, Steel Reinforced

2 2

(ACSR/AZ)

B 498/B 498M Specification for Zinc-Coated (Galvanized) Steel Core Wire for Aluminum Conductors, Steel Reinforced

2

(ACSR) Specification for Zinc-Coated (Galvanized) Steel Core Wire for Use in Overhead Electrical Conductors

B 606 Specification for High-Strength Zinc-Coated (Galvanized) Steel Core Wire for Aluminum and Aluminum-Alloy

Conductors, Steel Reinforced

B 802/B 802M Specification for Zinc-5% Zinc5 % Aluminum-Mischmetal Alloy-Coated Steel Core Wire for Aluminum

Conductors, Steel Reinforced (ACSR)

B 803 Specification for High-Strength Zinc-5% Aluminum-Mischmetal Alloy-Coated Steel Core Wire for Aluminum and

2

Aluminum-Alloy Conductors, Steel Reinforced Specification for High-Strength Zinc5 % Aluminum-Mischmetal Alloy-

Coated Steel Core Wire for Use in Overhead Electrical Conductors

E83 Practice for Verification and Classification of Extensometer SystemSystems

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot—unlessotherwisespecifiedinthecontractororder,alotshallconsistofallcoilsorreelsofstrandofthesamediameter

and unit lengths submitted for inspection at the same time.

3.1.2 production lot—all of the wire spools loaded into a stranding machine that are used to produce a completed strand cable.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.05 on Conductors

of Ferrous Metals.

Current edition approved Sept. 10, 1998. Published November 1998. Originally published as B500–69. Last previous edition B500–97.

Current edition approved March 15, 2009. Published April 2009. Originally approved in 1969. Last previous edition approved in 2002 as B 500/B 500M – 98 (2002).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 500/B 500M – 09

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Length of each construction,

4.1.2 Constructional description of stranded core (for example, 7 by3 0.0943 in. or 19 by3 0.0977 in.) (8.1 and 8.2),

4.1.3Nominal unit length of stranded core and multiple lengths, if allowed (

4.1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.