ASTM B851-04(2014)

(Specification)Standard Specification for Automated Controlled Shot Peening of Metallic Articles Prior to Nickel, Autocatalytic Nickel, or Chromium Plating, or as Final Finish

Standard Specification for Automated Controlled Shot Peening of Metallic Articles Prior to Nickel, Autocatalytic Nickel, or Chromium Plating, or as Final Finish

ABSTRACT

This specification covers the requirements for automated, controlled shot peening of metallic articles prior to electrolytic or autocatalytic deposition of nickel or chromium, or as a final finish, using shot made of cast steel, conditioned cut wire, or ceramic media. The process is applicable to those materials on which test work has shown it to be beneficial within given intensity ranges. It is not suitable for brittle materials. Hand peening and rotary flap peening are excluded specifically. Shot peening induces residual compressive stresses in the surface and near-surface layers of metallic articles, controlling or limiting the reduction in fatigue properties that occurs from nickel or chromium plating of the article, or the fatigue properties of unplated articles. It is a process for cold working surfaces by bombarding the product with shot of a solid and spherical nature propelled at a relatively high velocity. Cast steel, cut wire, and ceramic shot shall all be spherical in shape and shall all be free of sharp edges, corners, and broken pieces. Prior to shot peening, the following operations shall be done first: heat treatment, machining, grinding, flaw test, crack test, corrosion detection, cleaning, and masking. Peened surfaces shall be uniform in appearance and completely dented so that the original surface is obliterated entirely. After shot peening, the following methods shall be done: residual shot removal, surface finishing, chemical cleaning of nonferrous metals and their alloys, thermal and heat treatments, and corrosion protection.

SIGNIFICANCE AND USE

5.1 Shot peening is a process for cold working surfaces by bombarding the product with shot of a solid and spherical nature propelled at a relatively high velocity. In general, shot peening will increase the fatigue life of a product that is subject to bending or torsional stress. It will improve resistance to stress corrosion cracking. It can be used to form parts or correct their shapes. See Appendix X1 for additional information.

5.2 It is essential that the shot peening process parameters be controlled rigidly to ensure repeatability from part to part and lot to lot.

5.3 This specification covers techniques and methods necessary for proper control of the shot peening process.

SCOPE

1.1 This specification covers the requirements for automated, controlled shot peening of metallic articles prior to electrolytic or autocatalytic deposition of nickel or chromium, or as a final finish, using shot made of cast steel, conditioned cut wire, or ceramic media. The process is applicable to those materials on which test work has shown it to be beneficial within given intensity ranges. It is not suitable for brittle materials. Hand peening and rotary flap peening are excluded specifically.

1.2 Shot peening induces residual compressive stresses in the surface and near-surface layers of metallic articles, controlling or limiting the reduction in fatigue properties that occurs from nickel or chromium plating of the article, or the fatigue properties of unplated articles.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B851 −04 (Reapproved 2014)

Standard Specification for

Automated Controlled Shot Peening of Metallic Articles

Prior to Nickel, Autocatalytic Nickel, or Chromium Plating,

1

or as Final Finish

This standard is issued under the fixed designation B851; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B320 Practice for Preparation of Iron Castings for Electro-

plating

1.1 This specification covers the requirements for

B322 Guide for Cleaning Metals Prior to Electroplating

automated, controlled shot peening of metallic articles prior to

B607 Specification forAutocatalytic Nickel Boron Coatings

electrolytic or autocatalytic deposition of nickel or chromium,

for Engineering Use

or as a final finish, using shot made of cast steel, conditioned

B650 Specification for Electrodeposited Engineering Chro-

cut wire, or ceramic media. The process is applicable to those

mium Coatings on Ferrous Substrates

materials on which test work has shown it to be beneficial

B656 Guide for Autocatalytic (Electroless) Nickel-

within given intensity ranges. It is not suitable for brittle

Phosphorus Deposition on Metals for Engineering Use

materials. Hand peening and rotary flap peening are excluded

3

(Discontinued 2000) (Withdrawn 2000)

specifically.

B689 Specification for Electroplated Engineering Nickel

1.2 Shot peening induces residual compressive stresses in

Coatings

the surface and near-surface layers of metallic articles, control-

B733 Specification for Autocatalytic (Electroless) Nickel-

ling or limiting the reduction in fatigue properties that occurs

Phosphorus Coatings on Metal

from nickel or chromium plating of the article, or the fatigue

E11 Specification for Woven Wire Test Sieve Cloth and Test

properties of unplated articles.

Sieves

1.3 The values stated in SI units are to be regarded as E165 Practice for Liquid Penetrant Examination for General

Industry

standard. No other units of measurement are included in this

standard. E709 Guide for Magnetic Particle Testing

4

2.2 Federal Standards:

1.4 This standard does not purport to address all of the

QQ-N-290 Nickel Plating (Electrodeposited)

safety concerns, if any, associated with its use. It is the

QQ-C-320 Chromium Plating (Electrodeposited)

responsibility of the user of this standard to establish appro-

4

priate safety and health practices and determine the applica-

2.3 Military Standards:

bility of regulatory limitations prior to use.

MIL-S-851 Steel Grit, Shot, and Cut Wire Shot, and Iron

Grit and Shot Blast Cleaning and Peening

2. Referenced Documents

MIL-S-13165 Shot Peening of Metal Parts

2

MIL-C-26074 Coating, Electroless Nickel

2.1 ASTM Standards:

MIL-STD-45662 Calibration System Requirements

B183 Practice for Preparation of Low-Carbon Steel for

5

Electroplating

2.4 SAE Standards:

B242 Guide for Preparation of High-Carbon Steel for Elec-

SAE J441 Cut Steel Wire Shot

troplating

SAE J442 Test Strip, Holder and Gage for Shot Peening

SEA J827 Cast Steel Shot

SAE J1830 Size, Classification and Characteristics of Ce-

1

This specification is under the jurisdiction of ASTM Committee B08 on

ramic Shot for Peening

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

B08.02 on Pre Treatment.

Current edition approved Nov. 1, 2014. Published November 2014. Originally

3

approved in 1994. Discontinued January 2004 and reinstated in 2004 as B851–04. The last approved version of this historical standard is referenced on

Last previous edition approved in 2009 as B851–09. DOI: 10.1520/B0851-04R14. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers, 400 Commonwealth Drive,

the ASTM website. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B851−04 (2014)

3. Terminology

3.1 Definitions:

3.1.1 Almen strip—UNS G10700 carbon steel specimens

that are used to calibrate the energy of a shot peening stream

(see Fig. 1).

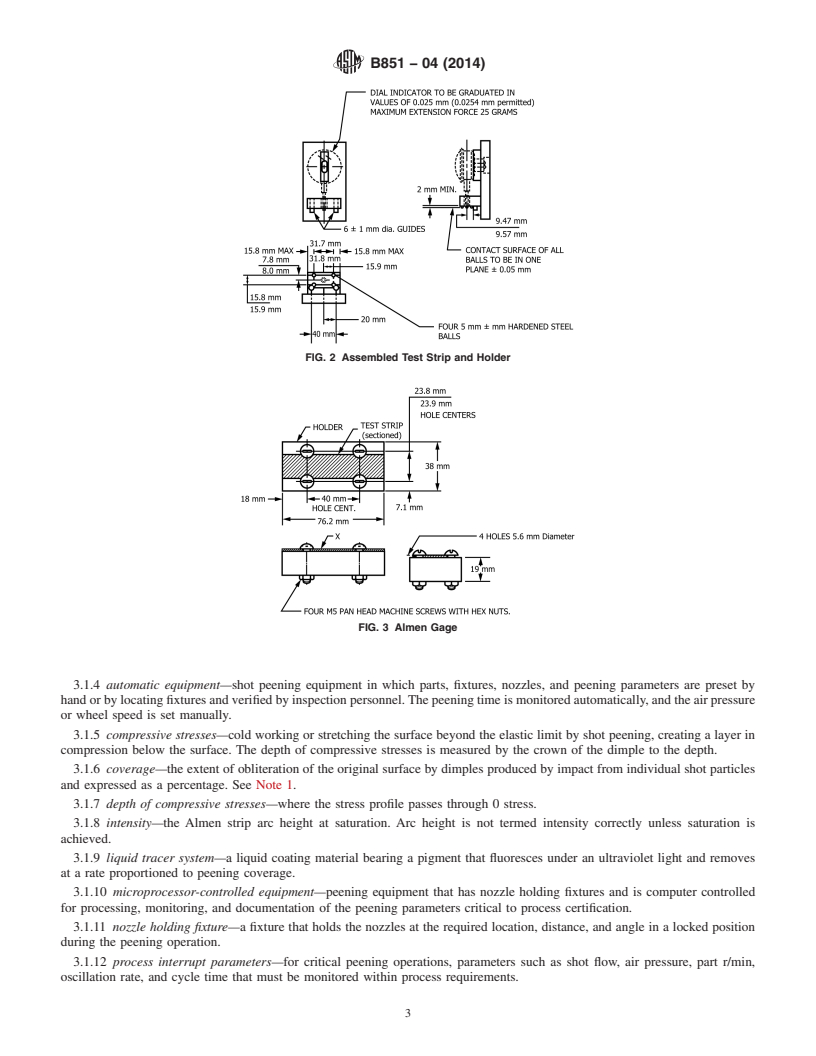

3.1.2 Almen strip holding fixture—a fixture for holding

Almen strips in suitable locations that represent the position

andangularorientationofthesurfacesofapartwhereintensity

is to be determined and verified (see Fig. 2).

3.1.3 arc height—flat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B851 − 04 (Reapproved 2009) B851 − 04 (Reapproved 2014)

Standard Specification for

Automated Controlled Shot Peening of Metallic Articles

Prior to Nickel, Autocatalytic Nickel, or Chromium Plating,

1

or as Final Finish

This standard is issued under the fixed designation B851; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for automated, controlled shot peening of metallic articles prior to electrolytic

or autocatalytic deposition of nickel or chromium, or as a final finish, using shot made of cast steel, conditioned cut wire, or

ceramic media. The process is applicable to those materials on which test work has shown it to be beneficial within given intensity

ranges. It is not suitable for brittle materials. Hand peening and rotary flap peening are excluded specifically.

1.2 Shot peening induces residual compressive stresses in the surface and near-surface layers of metallic articles, controlling or

limiting the reduction in fatigue properties that occurs from nickel or chromium plating of the article, or the fatigue properties of

unplated articles.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B183 Practice for Preparation of Low-Carbon Steel for Electroplating

B242 Guide for Preparation of High-Carbon Steel for Electroplating

B320 Practice for Preparation of Iron Castings for Electroplating

B322 Guide for Cleaning Metals Prior to Electroplating

B607 Specification for Autocatalytic Nickel Boron Coatings for Engineering Use

B650 Specification for Electrodeposited Engineering Chromium Coatings on Ferrous Substrates

B656 Guide for Autocatalytic (Electroless) Nickel-Phosphorus Deposition on Metals for Engineering Use (Discontinued 2000)

3

(Withdrawn 2000)

B689 Specification for Electroplated Engineering Nickel Coatings

B733 Specification for Autocatalytic (Electroless) Nickel-Phosphorus Coatings on Metal

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E165 Practice for Liquid Penetrant Examination for General Industry

E709 Guide for Magnetic Particle Testing

4

2.2 Federal Standards:

QQ-N-290 Nickel Plating (Electrodeposited)

QQ-C-320 Chromium Plating (Electrodeposited)

4

2.3 Military Standards:

MIL-S-851 Steel Grit, Shot, and Cut Wire Shot, and Iron Grit and Shot Blast Cleaning and Peening

MIL-S-13165 Shot Peening of Metal Parts

1

This specification is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.02 on Pre

Treatment.

Current edition approved Sept. 1, 2009Nov. 1, 2014. Published December 2009November 2014. Originally approved in 1994. Discontinued January 2004 and reinstated

in 2004 as B851–04. Last previous edition approved in 20042009 as B851–04.–09. DOI: 10.1520/B0851-04R09.10.1520/B0851-04R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B851 − 04 (2014)

MIL-C-26074 Coating, Electroless Nickel

MIL-STD-45662 Calibration System Requirements

5

2.4 SAE Standards:

SAE J441 Cut Steel Wire Shot

SAE J442 Test Strip, Holder and Gage for Shot Peening

SEA J827 Cast Steel Shot

SAE J1830 Size, Classification and Characteristics of Ceramic Shot for Peening

3. Terminology

3.1 Definitions:

3.1.1 Almen strip—UNS G10700 carbon steel specimens that are used to calibrate the energy of a shot peen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.