ASTM E37-05(2011)

(Test Method)Standard Test Methods for Chemical Analysis of Pig Lead (Withdrawn 2020)

Standard Test Methods for Chemical Analysis of Pig Lead (Withdrawn 2020)

SIGNIFICANCE AND USE

These test methods for the chemical analysis of metals and alloys are primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 These test methods cover the chemical analysis of pig lead having chemical compositions within the following limits:

WITHDRAWN RATIONALE

These test methods covered the chemical analysis of pig lead.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, these test methods were withdrawn in July 2020 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E37 − 05 (Reapproved 2011)

Standard Test Methods for

Chemical Analysis of Pig Lead

This standard is issued under the fixed designation E37; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

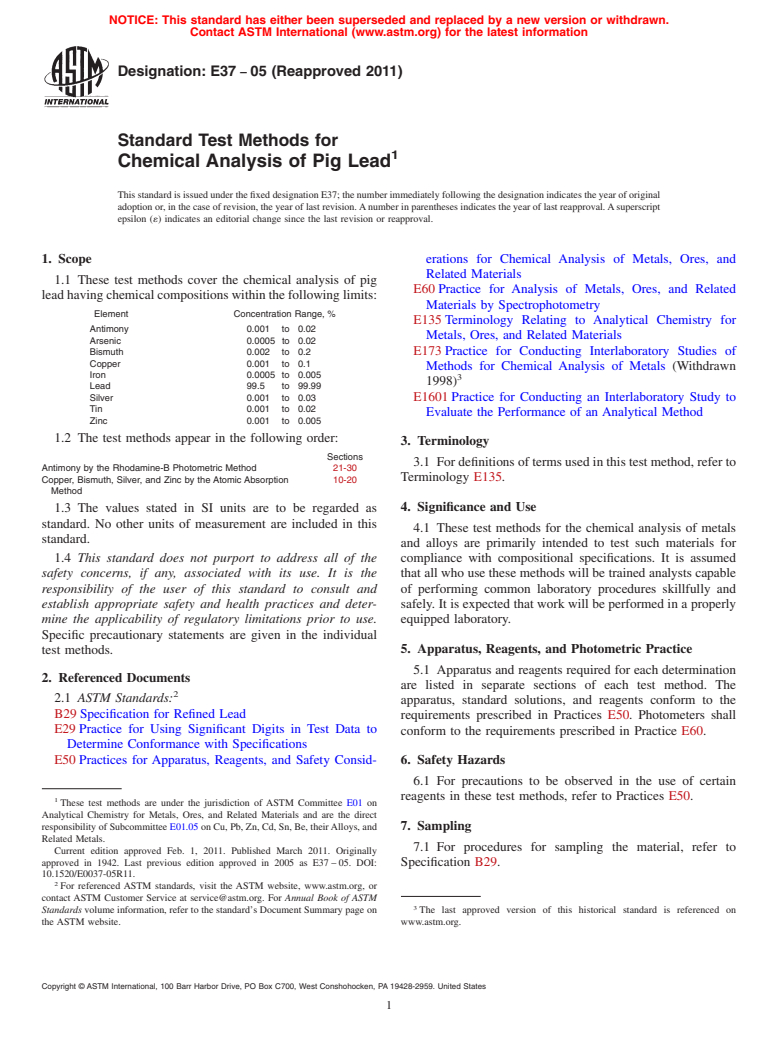

1. Scope erations for Chemical Analysis of Metals, Ores, and

Related Materials

1.1 These test methods cover the chemical analysis of pig

E60 Practice for Analysis of Metals, Ores, and Related

lead having chemical compositions within the following limits:

Materials by Spectrophotometry

Element Concentration Range, %

E135 Terminology Relating to Analytical Chemistry for

Antimony 0.001 to 0.02

Metals, Ores, and Related Materials

Arsenic 0.0005 to 0.02

Bismuth 0.002 to 0.2 E173 Practice for Conducting Interlaboratory Studies of

Copper 0.001 to 0.1

Methods for Chemical Analysis of Metals (Withdrawn

Iron 0.0005 to 0.005

1998)

Lead 99.5 to 99.99

E1601 Practice for Conducting an Interlaboratory Study to

Silver 0.001 to 0.03

Tin 0.001 to 0.02

Evaluate the Performance of an Analytical Method

Zinc 0.001 to 0.005

1.2 The test methods appear in the following order:

3. Terminology

Sections

3.1 For definitions of terms used in this test method, refer to

Antimony by the Rhodamine-B Photometric Method 21-30

Terminology E135.

Copper, Bismuth, Silver, and Zinc by the Atomic Absorption 10-20

Method

4. Significance and Use

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4.1 These test methods for the chemical analysis of metals

standard.

and alloys are primarily intended to test such materials for

1.4 This standard does not purport to address all of the compliance with compositional specifications. It is assumed

safety concerns, if any, associated with its use. It is the that all who use these methods will be trained analysts capable

responsibility of the user of this standard to consult and of performing common laboratory procedures skillfully and

establish appropriate safety and health practices and deter- safely. It is expected that work will be performed in a properly

mine the applicability of regulatory limitations prior to use.

equipped laboratory.

Specific precautionary statements are given in the individual

test methods. 5. Apparatus, Reagents, and Photometric Practice

5.1 Apparatus and reagents required for each determination

2. Referenced Documents

are listed in separate sections of each test method. The

2.1 ASTM Standards:

apparatus, standard solutions, and reagents conform to the

B29 Specification for Refined Lead

requirements prescribed in Practices E50. Photometers shall

E29 Practice for Using Significant Digits in Test Data to

conform to the requirements prescribed in Practice E60.

Determine Conformance with Specifications

E50 Practices for Apparatus, Reagents, and Safety Consid- 6. Safety Hazards

6.1 For precautions to be observed in the use of certain

reagents in these test methods, refer to Practices E50.

These test methods are under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

responsibility of Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, theirAlloys, and

7. Sampling

Related Metals.

7.1 For procedures for sampling the material, refer to

Current edition approved Feb. 1, 2011. Published March 2011. Originally

approved in 1942. Last previous edition approved in 2005 as E37 – 05. DOI:

Specification B29.

10.1520/E0037-05R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E37 − 05 (2011)

8. Rounding Calculated Values 12.1.4 If the minimum response is not achieved, prepare

another dilute standard solution to provide a higher concentra-

8.1 Calculated values shall be rounded to the desired num-

tionrange,andrepeat12.1.2and12.1.3.Ifthecalibrationcurve

ber of places as directed in Practice E29.

does not meet the linearity criterion, prepare another dilute

9. Interlaboratory Studies

standard solution to provide a lower concentration range, and

repeat 12.1.2 and 12.1.3. If a concentration range cannot be

9.1 These test methods have been evaluated in accordance

found for which both criteria can be met, do not use this

with Practice E173, unless otherwise noted in the precision

method until the performance of the apparatus has been

section.

improved.

COPPER, BISMUTH, SILVER, AND ZINC BY THE

12.1.5 Perform the stability test as directed in 14.1.3.If

ATOMIC ABSORPTION METHOD

either of the minimum stability requirements is not met, do not

use this method until the repeatability of the readings has been

10. Scope

suitably improved.

10.1 This test method covers the determination of bismuth

in concentrations from 0.002 to 0.2 %, copper from 0.001 to

13. Interferences

0.1 %, silver from 0.001 to 0.03 %, and zinc from 0.001 to

0.005 %.

13.1 Elements ordinarily present do not interfere if their

concentrations are under the maximum limits shown in 1.1.

11. Summary of Test Method

11.1 The sample is dissolved in a nitric-perchloric acid

14. Apparatus

mixture, the solution is fumed, and hydrochloric acid is added

14.1 Atomic Absorption Spectrophotometer—Use hollow-

to precipitate lead chloride. The hydrochloric-perchloric acid

cathode lamps, operated in accordance with manufacturers’

solution is aspirated into the air-acetylene flame of an atomic

recommendations as sources for the following lines: Cu 324.7,

absorption spectrophotometer. The absorption of the resonance

Bi 223.0, Ag 328.0, and Zn 213.8 nm. Aspirate the solutions

line energy from the spectrum of each element is measured and

compared with that of calibration solutions of the same into an air-acetylene flame of a premix burner. Determine that

element. The lines used were Cu 324.7, Bi 223.0, Ag 328.0, the atomic absorption spectrophotometer is satisfactory for use

and Zn 213.8 nm in this method by proceeding as directed in 14.1.1-14.1.3.

12. Concentration Range NOTE 1—Optimum settings for the operating parameters of the atomic

absorption spectrophotometer vary from instrument to instrument.

12.1 The concentration range for each element must be

determined experimentally because the optimum range will 14.1.1 Minimum Response— Calculate the difference be-

tween the readings of the two highest of five equally spaced

depend upon the individual instrument. Determine the appro-

priate concentration range of each element as follows: (16.2) calibration solutions. This difference must be at least 40

12.1.1 Prepare a dilute standard solution as directed in scale units.

Section 16. Refer to 16.1 for suggested initial concentrations.

NOTE 2—The scale unit is defined as the smallest numerical interval

12.1.2 Prepare the instrument for use as directed in 18.1.

that is estimated in taking each reading on the instrument. If the scale is

Measure the instrument response while aspirating water, the

non-linear, the largest unit defined in this manner is used.

calibration solution with the lowest concentration, and the two

14.1.2 Curve Linearity— Calculate the difference between

with the highest concentrations. Determine the minimum

the scale readings obtained with water and the lowest of the

response and the curve linearity as directed in 14.1.1 and

five equally spaced calibration solutions. If necessary, convert

14.1.2, respectively.

this difference and the difference calculated in 14.1.1 to

12.1.3 If the instrument meets or surpasses the minimum

absorbance. Divide the difference for the highest interval by

response and curve linearity criteria, the initial concentration

range may be considered suitable for use. In this case proceed that for the lowest interval. If this ratio is not 0.70 or greater,

as directed in 12.1.5. proceed as directed in 12.1.4.

E37 − 05 (2011)

14.1.3 Minimum Stability—If the variability of the readings concentrations equal to that of the corresponding test solution,

of the highest calibration solution and of water is not less than dilute to volume, and mix. Do not use solutions that have stood

1.8 % and 1.4 %, respectively, as calculated below, proceed as more than 24 h.

directed in 12.1.5.

17. Procedure

¯

100 ~C 2 C!

(

Œ

V 5 (1) 17.1 Test Solution:

C

¯ n 2 1

C

17.1.1 Transfer a 10 g sample, weighed to the nearest 10

mg, to a 300-mL Erlenmeyer flask (Note 3). Add 3 mL of

¯

100 ~O 2 O!

(

ΠHNO and 15 mL of HClO , and heat until dissolution is

V 5 (2)

o 3 4

¯ n 2 1

C

complete. Evaporate to strong fumes of perchloric acid and

cool.

where:

V = percent variability of the highest calibration

NOTE 3—Due to the limited solubility of silver chloride, the silver

C

concentration in the sample solution should be less than 1 mg/100 mL. If

readings,

¯ the expected silver concentration is higher than 0.01 %, choose a sample

C = average absorbance value for the highest cali-

weight that limits the silver concentration to less than 1 mg/100 mL.

bration solution,

¯

∑ (C−X) = sum of the squares of the n differences be- 17.1.2 Add 50 mL of water and, while swirling, heat to

tween the absorbance readings of the highest boiling.Add 25 mL of HCl. If less than a 10-g sample is used,

calibration solution and their average,

add 20 mL HCl plus 0.5 mL for each gram of sample used.

V = percent variability of the readings on water

Heat again to boiling and cool to room temperature.

O

¯

relative to C,

17.1.3 Transfer the solution and precipitate to a 100-mL

¯

O = average absorbance value of water,

volumetric flask, dilute to volume with water, and mix thor-

¯

∑(O−O) = sumofthesquaresofthendifferencebetween

oughly. Allow the precipitated lead chloride to settle. Use the

the absorbance readings of water and their

supernatant solution, or dilute an appropriate aliquot of the

average, and

supernatant solution to provide a concentration of the element

n = number of determinations, three or more.

being measured which lies within the concentration range

determined in Section 12.

15. Reagents

17.2 Reagent Blank Solution—Prepare a reagent blank by

15.1 Bismuth, Standard Solution (1 mL = 1 mg Bi)—

adding 3 mL of HNO and 15 mL of HClO to a 300-mL

3 4

Transfer1gof bismuth (purity: 99.9 % min) to a 400-mL

Erlenmeyer flask and proceed as directed in 17.1.

beaker and dissolve in 50 mL of HNO (1 + 1), heating gently

if necessary. When dissolution is complete, cool, transfer to a

18. Measurement

1-L volumetric flask, add 100 mL of HNO (1 + 1), dilute to

18.1 Instrument Adjustment—Optimize the response of the

volume, and mix. Store in a polyethylene bottle.

instrument as directed in 18.1.1-18.1.4.

15.2 Copper, Standard Solution (1 mL = 1 mg Cu)—

18.1.1 Set the instrument parameters approximately at the

Proceedasdirectedin15.1,butsubstitute1gofcopper(purity:

values obtained in 14.1, and light the burner.

99.9 % min) for the bismuth.

18.1.2 Adjust the instrument to the approximate wavelength

15.3 Silver, Standard Solution (1 mL = 1 mg Ag)—Proceed

for the element to be determined, permit the instrument to

as directed in 15.1 but substitute1gof silver (purity: 99.9 % reach thermal equilibrium, and complete the wavelength ad-

min) for the bismuth.

justment to obtain maximum absorption while aspirating the

highest calibration solution.

15.4 Zinc, Standard Solution (1 mL = 0.1 mg Zn)—Proceed

18.1.3 Optimize fuel, air, and burner adjustments while

as directed in 15.1 but substitute 0.1 g of zinc (purity: 99.9 %

aspirating the highest calibration solution.

min) for the bismuth.

18.1.4 Aspirate water long enough to establish that the

absorbance reading is stable and then set the initial reading

16. Calibration

(approximately zero absorbance or 100 % transmittance).

16.1 Dilute Standard Solution—Using pipets, transfer to

18.2 Photometry:

500-mL volumetric flasks the following volumes of each

18.2.1 Aspirate the test solution and note, but do not record

standard solution: bismuth, 20 mL; copper, 10 mL; silver, 5

the reading.

mL; and zinc, 10 mL. Dilute to volume and mix. Adjust the

concentration of a dilute standard solution if the proper range

NOTE 4—Avoid transferring particles of precipitated lead chloride that

is not obtained when the 5, 10, 15, 20, and 25-mL portions are may clog the aspirator during the measurements of the test solution.

diluted to 100 mL and tested.

18.2.2 Aspirate water until the initial reading is again

16.2 Calibration Solutions—Prepare five calibration solu- obtained.Aspirate the calibration solutions and test solution in

order of increasing instrument response, starting with the

tions for each element to be determined. Using pipets, transfer

5, 10, 15, 20, and 25-mL portions of the appropriate dilute reagent blank. When a stable response is obtained for each

solution, record the reading.

standard solution to 100-mL volumetric flasks. Add sufficient

volumes of HCl and HClO to each flask to yield final acid 18.2.3 Proceed as directed in 18.2.2 at least twice more.

E37 − 05 (2011)

19. Calculations ANTIMONY BY THE RHODAMINE-B

PHOTOMETRIC METHOD

19.1 Calculate the variability of the readings for water and

the highest calibration solution as directed in 14.1.3 to deter-

21. Scope

mine whether they are less than 1.4 % and 1.8 %, respectively.

21.1 This test method covers the determination of antimony

If they are not, disregard the data, readjust the instrument, and

in pig lead in concentrations from 0.0008 to 0.005 %.

proceed again as directed in 18.2.

19.2 If necessary, convert the average of the readings for

22. Summary of Test Method

each calibration solution to absorbance. Calculate the net

22.1 After nitric acid dissolution of the sample, lead is

absorbanceofthetestsolutionbysubtractingtheabsorbanceof

separated as the sulfate.Antimony is oxidized with sulfatoceric

the reagent blank solution.

acid and extracted into isopropyl ether; rhodamine-B is added

19.3 Prepare a calibration curve by plotting the absorbance

and photometric measurement is made at approximately 550

values for the calibration solutions against milligrams of the

nm.

elements per millilitre.

19.4 Convert the net absorbance value of the test solution to 23. Concentration Range

milligrams of the element per millilitre by means

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.