ASTM C1183-04(2008)

(Test Method)Standard Test Method for Extrusion Rate of Elastomeric Sealants

Standard Test Method for Extrusion Rate of Elastomeric Sealants

SIGNIFICANCE AND USE

Sealants are supplied with various rheological properties ranging from pourable liquids to nonsagging pastes. Single-component sealants are supplied ready for use upon opening the container. Multicomponent sealants are supplied as a base component(s) and a curing agent separately packaged. After mixing the two or more parts, the sealant is ready for application. This test method is intended to provide a means to measure the extrusion rate spanning the range of rheological properties.

This test method also covers the option of measuring the freeze-thaw and heat stability of such sealants.

This test method provides for an option of either a metal or plastic nozzle. It is intended that the metal nozzle be used when greater precision is required, such as in ASTM specifications. The plastic nozzle may be used for general screening of sealant properties or for developmental purposes when a large number of test specimens are being tested.

This test method measures the volume of sealant extruded in 1 min at a given pressure (kPa or psi).

SCOPE

1.1 This test method covers two laboratory procedures for determining the extrusion rate of elastomeric sealants for use in building construction.

1.2 The values states in metric units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 There is no known ISO equivalent to this test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1183 − 04(Reapproved 2008)

Standard Test Method for

1

Extrusion Rate of Elastomeric Sealants

This standard is issued under the fixed designation C1183; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mixing the two or more parts, the sealant is ready for

application.This test method is intended to provide a means to

1.1 This test method covers two laboratory procedures for

measure the extrusion rate spanning the range of rheological

determiningtheextrusionrateofelastomericsealantsforusein

properties.

building construction.

4.2 Thistestmethodalsocoverstheoptionofmeasuringthe

1.2 The values states in metric units are to be regarded as

freeze-thaw and heat stability of such sealants.

the standard. The values in parentheses are for information

only.

4.3 Thistestmethodprovidesforanoptionofeitherametal

or plastic nozzle. It is intended that the metal nozzle be used

1.3 This standard does not purport to address all of the

when greater precision is required, such as in ASTM specifi-

safety concerns, if any, associated with its use. It is the

cations. The plastic nozzle may be used for general screening

responsibility of the user of this standard to establish appro-

of sealant properties or for developmental purposes when a

priate safety and health practices and determine the applica-

large number of test specimens are being tested.

bility of regulatory limitations prior to use.

1.4 There is no known ISO equivalent to this test method.

4.4 This test method measures the volume of sealant ex-

truded in 1 min at a given pressure (kPa or psi).

2. Referenced Documents

2

2.1 ASTM Standards:

5. Apparatus

C717Terminology of Building Seals and Sealants

5.1 High Density Polyethylene Cartridge, with plunger and

D1475Test Method For Density of Liquid Coatings, Inks,

cap, 177 mL(6 fluid oz) capacity, with the front end having an

and Related Products

inside diameter of 13.7 6 0.05 mm (0.540 6 0.002 in.).

D2452TestMethodforExtrudabilityofOil-andResin-Base

5.2 Nozzle.

Caulking Compounds

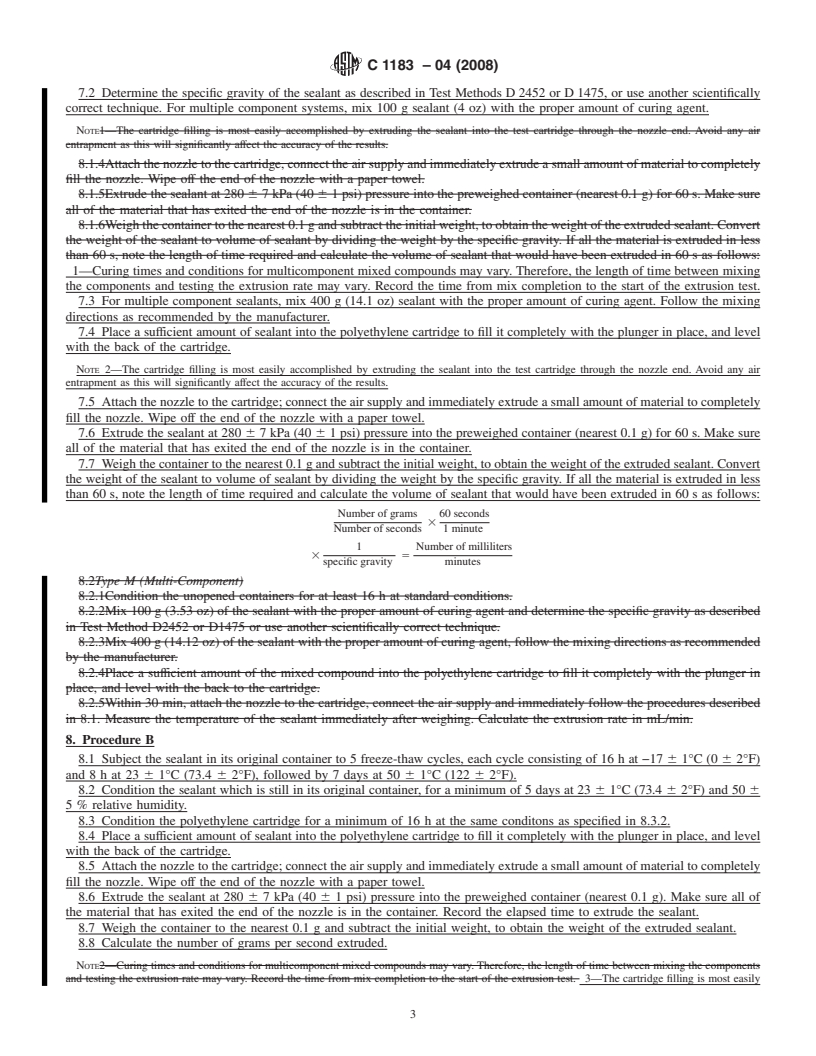

5.2.1 Metal Nozzle, threaded to fit threaded end of polyeth-

3. Terminology

ylene cartridge with the dimensions given in Fig. 1.

1

5.2.2 Polyethylene Cartridge Nozzle, 64 mm (2 ⁄2 in.) in

3.1 Definitions—SeeTerminologyC717forapplicabledefi-

1

length with 3–mm ( ⁄8 –in.) orifice

nitions of the following terms: caulking, compound, elasto-

meric and nonsag sealant, sealant, latex sealant.

5.3 Air Supply,toprovide280 67kPa(40 61psi)pressure

with appropriate fittings and air lines to attach to an air

4. Significance and Use

powered gun for convenience of use.

4.1 Sealantsaresuppliedwithvariousrheologicalproperties

5.4 Caulking Gun, 177 mL (6 fluid oz) capacity, air pow-

ranging from pourable liquids to nonsagging pastes. Single-

ered.

component sealants are supplied ready for use upon opening

5.5 Freezer, capable of maintaining −17 6 1°C (0 6 2°F).

the container. Multicomponent sealants are supplied as a base

component(s) and a curing agent separately packaged. After

5.6 Circulating Air Oven, capable of maintaining 50 6 1°C

(122 6 2°F).

1

5.7 Time Device, a clock or stop-watch graduated in sec-

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on

onds.

General Test Methods.

5.8 Small Container, can, cup, and so forth, as receiver for

Current edition approved May 1, 2008. Published June 2008. Originally

approved in 1991. Last previous edition approved in 2004 as C1183-04. DOI:

extruded sealant.

10.1520/C1183-04R08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.9 Balance, accurate to 60.1 g (0.035 oz).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.10 Pycnometer, or suitable apparatus to obtain a specific

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. gravity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1183 − 04 (2008)

extruded in less than 60 s, note the length of time required and

calculate the volume of sealant that would have been extruded

in 60 s as follows:

Numberofgrams 60seconds

3

Numberofseconds 1 minute

1 Numberofmilliliters

3 5

specificgravity minutes

8. Procedure B

8.1 Subject the sealant in its original container to 5 freeze-

thaw cycles, each cycle consisting of 16 h at −17 6 1°C (0 6

2°F) and8hat23 6 1°C (73.4 6 2°F), followed by 7 days at

50 6 1°C (122 6 2°F).

FIG. 1 Metal Nozzle Dimensions

8.2

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1183 –91(Reapproved 1997) Designation:C1183 –04 (Reapproved 2008)

Standard Test Method for

1

Extrusion Rate of Elastomeric Sealants

This standard is issued under the fixed designation C1183; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers two laboratory procedures for determining the extrusion rate of elastomeric sealants for use in

building construction.

1.2 The values states in metric units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 There is no known ISO equivalent to this test method.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

D1475 Test Method forFor Density of Liquid Coatings, Inks, and Related Products

D2452 Test Method for Extrudability of Oil- and Resin-Base Caulking Compounds

3. Terminology

3.1 Definitions—SeeTerminologyC717forapplicabledefinitionsofthefollowingterms:caulking,compound,elastomericand

nonsag sealant, sealant, latex sealant.

4. Significance and Use

4.1 Sealants are supplied with various rheological properties ranging from pourable liquids to nonsagging pastes. Single-

component sealants are supplied ready for use upon opening the container. Multicomponent sealants are supplied as a base

component(s)andacuringagentseparatelypackaged.Aftermixingthetwoormoreparts,thesealantisreadyforapplication.This

test method is intended to provide a means to measure the extrusion rate spanning the range of rheological properties.

4.2This test method measures the volume of sealant extruded in 1 min at a given pressure (kPa or psi).

4.2 This test method also covers the option of measuring the freeze-thaw and heat stability of such sealants.

4.3 This test method provides for an option of either a metal or plastic nozzle. It is intended that the metal nozzle be used when

greater precision is required, such as in ASTM specifications. The plastic nozzle may be used for general screening of sealant

properties or for developmental purposes when a large number of test specimens are being tested.

4.4 This test method measures the volume of sealant extruded in 1 min at a given pressure (kPa or psi).

5. Classification of Sealants

5.1The sealant shall be classified by type as follows:

5.1.1Type S—single-component sealant, and

5.1.2Type M—multi-component sealant.

6.Apparatus

6.1

1

This test method is under the jurisdiction of ASTM Committee C-24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.32 on

Chemically Curing Sealants.

Current edition approved April 15, 1991. Published June 1991.

1

This test method is under the jurisdiction ofASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on General

Test Methods.

Current edition approved May 1, 2008. Published June 2008. Originally approved in 1991. Last previous edition approved in 2004 as C1183-04.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 04.07.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1183 –04 (2008)

5.1 High Density Polyethylene Cartridge , with plunger and cap, 177 mL (6 fluid oz) capacity, with the front end having an

inside diameter of 13.7 6 0.05 mm (0.540 6 0.002 in.).

6.2

5.2 Nozzle.

5.2.1 Metal Nozzle, threaded to fit threaded end of polyethylene cartridge with the dimensions given in Fig. 1.

6.3

1 1

5.2.2 Polyethylene Cartridge Nozzle,64mm(2 ⁄2 in.) in length with 3–mm ( ⁄8 –in.) orifice

5.3 Air Supply, to provide 280 6 7 kPa (40 6 1 psi) pressure with appropriate fittings and air lines to attach to an air powered

gun for convenience of use.

6.4

5.4 Caulking Gun, 177 mL (6 fluid oz) capacity, air powered.

6.5

5.5 Freezer, capable of maintaining −17 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.