ASTM B907-00a

(Specification)Standard Specification for Zinc, Tin and Cadmium Base Solders

Standard Specification for Zinc, Tin and Cadmium Base Solders

SCOPE

1.1 This specification covers solder metal alloys (commonly known as soft solders), including zinc-aluminum, zinc-aluminum-copper, zinc-tin, zinc-tin-copper, zinc-cadmium-tin, zinc-cadmium, tin-zinc, cadmium-zinc, cadmium-zinc-silver, and cadmium-silver, used for the purpose of joining together two or more metals at temperatures below their melting points.

1.1.1 Certain alloys are also used in Thermal Spray Wire by the electronics industry (as noted in the Annex part of this specification). B833 covers Zinc and Zinc Alloy Wire for Thermal Spraying (Metallizing) used primarily for the corrosion protection of steel (as noted in the Annex part of this specification).

1.1.2 Tin base alloys are included in this specification because their use in the electronics industry is different than the major use of the tin and lead solder compositions specified in B32.

1.1.3 These solders include alloys having a nominal liquidus temperature not exceeding 850oF (455oC).

1.1.4 This specification includes solder in the form of solid bars, ingots, powder and special forms, and in the form of solid wire, and solder paste.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 Toxicity--Warning: Soluble and respirable forms of cadmium may be harmful to human health and the environment in certain forms and concentrations. Therefore, ingestion and inhalation of cadmium should be controlled under the appropriate regulations of the U.S. Occupational Safety and Health Administration (OSHA). Cadmium-containing alloys and coatings should not be used on articles that will contact food or beverages, or for dental and other equipment that is normally inserted in the mouth. Similarly, if articles using cadmium-containing alloys or coatings are welded, soldered, brazed, ground, flame-cut, or otherwise heated during fabrication, adequate ventilation must be provided to maintain occupational cadmium exposure below the OSHA Permissible Exposure Level (PEL).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 907 – 00a

Standard Specification for

Zinc, Tin and Cadmium Base Solders

This standard is issued under the fixed designation B 907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * cadmium exposure below the OSHA Permissible Exposure

Level (PEL).

1.1 This specification covers solder metal alloys (commonly

1.4 This standard does not purport to address all of the

known as soft solders), including zinc-aluminum, zinc-

safety concerns, if any, associated with its use. It is the

aluminum-copper, zinc-tin, zinc-tin-copper, zinc-cadmium-tin,

responsibility of the user of this standard to become familiar

zinc-cadmium, tin-zinc, cadmium-zinc, cadmium-zinc-silver,

with all hazards including those identified in the appropriate

and cadmium-silver, used for the purpose of joining together

Material Data Sheet for this product/material as provided by

two or more metals at temperatures below their melting points.

the manufacturer, to establish appropriate safety and health

1.1.1 Certain alloys are also used in Thermal Spray Wire by

practices, and determine the applicability of regulatory limi-

the electronics industry (as noted in the Annex part of this

tations prior to use.

specification). B 833 covers Zinc and Zinc Alloy Wire for

Thermal Spraying (Metallizing) used primarily for the corro-

2. Referenced Documents

sion protection of steel (as noted in the Annex part of this

2.1 ASTM Standards:

specification).

B 32 Specification for Solder Metal

1.1.2 Tin base alloys are included in this specification

B 833 Specification for Zinc and Zinc Alloy Wire for

because their use in the electronics industry is different than the

Thermal Spraying (Metallizing)

major use of the tin and lead solder compositions specified in

B 899 Terminology Relating to Non-ferrous Metals and

B 32.

Alloys

1.1.3 These solders include alloys having a nominal liqui-

E 29 Practice for using Significant Digits in Test Data to

dus temperature not exceeding 850°F (455°C).

Determine Conformance with Specifications.

1.1.4 This specification includes solder in the form of solid

E 46 Test Methods for Chemical Analysis of Lead and

bars, ingots, powder and special forms, and in the form of solid

Tin-Base Solder; discontinued 1994

wire, and solder paste.

E 47 Test Methods for Chemical Analysis of Zinc Die

1.2 The values stated in inch-pound units are to be regarded

Casting Alloys

as the standard. The values given in parentheses are for

E 51 Method for Spectrographic Analysis of Tin-based

information only.

Alloys by the Powder Technique; discontinued 1984

1.3 Toxicity—Warning: Soluble and respirable forms of

E 55 Practice for sampling Wrought Nonferrous Metals and

cadmium may be harmful to human health and the environment

Alloys for Determination of Chemical Composition

in certain forms and concentrations. Therefore, ingestion and

E 87 Methods for Chemical Analysis of Lead, Tin, Anti-

inhalation of cadmium should be controlled under the appro-

mony, and Their Alloys (Photometry Method); discontin-

priate regulations of the U.S. Occupational Safety and Health

ued 1984

Administration (OSHA). Cadmium-containing alloys and coat-

E 88 Practice for Sampling Nonferrous Metals and Alloys

ings should not be used on articles that will contact food or

in Cast Form for Determination of Chemical Composition

beverages, or for dental and other equipment that is normally

E 527 Practice for Numbering Metals and Alloys

inserted in the mouth. Similarly, if articles using cadmium-

E 536 Test Method for Chemical Analysis of Zinc and Zinc

containing alloys or coatings are welded, soldered, brazed,

Alloys

ground, flame-cut, or otherwise heated during fabrication,

2.2 Federal Standard:

adequate ventilation must be provided to maintain occupational

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1 2

This specification is under the jurisdiction of ASTM Committee B02 on Annual Book of ASTM Standards, Vol 02.04.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 14.02.

B02.04 Zinc and Cadmium. Annual Book of ASTM Standards, Vol 03.05.

Current edition approved Oct. 10, 2000. Published November 2000. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as B 907-00. Last previous edition B 907-00 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 907

2.3 Military Standard: 4.1.1 Alloy Composition—The composition is identified by

Mil-Std-129 Marking for Shipment and Storage a two or four-letter symbol and a number. The letters typically

indicate the chemical symbol for the critical element in the

3. Terminology

solder and the number indicates the nominal percentage, by

3.1 Terms shall be defined in accordance with Terminology

weight, of the critical element in the solder (see Table 1).

B 899.

4.1.2 Form—The form is indicated by a single letter in

3.2 Definitions of Terms Specific to This Standard:

accordance with Table 2.

3.2.1 lot, n—The term “lot” as used in this specification is

4.1.3 Powder Mesh Size (applicable only to solder paste)—

defined as follows:

The powder mesh size is identified by a single letter in

3.2.1.1 Discussion—For solid solder metal, a lot consists of

accordance with Table 3.

all solder of the same type designation, produced from the

same batch of raw materials under essentially the same

5. Ordering Information

conditions, and offered for inspection at one time.

5.1 Orders for material under this specification indicate the

3.2.2 lot number, n—The term “lot number” as used in this

following information, as required, to adequately describe the

specification refers to a numerical designation for a lot which

desired material.

is traceable to a date of manufacture.

5.1.1 Type designation (see 4.1),

4. Classification

5.1.2 Detailed requirements for special forms,

5.1.3 Dimensions of ribbon and wire solder (see 9.2),

4.1 Type Designation—The type designation uses the fol-

lowing symbols to properly identify the material: 5.1.4 Unit weight,

TABLE 1 Solder Compositions

Table 1a: Zinc Base Alloys

A,B,C

Composition % Temperature

D

UNS Cd Zn Sn Pb Sb Ag Cu Al Bi As Fe Ni Mg Solidus Liquidus

FCF C

Zn 98 Z30402 0.005 REM 0.003 0.005 0.10 0.015 0.005 1.5–2.5 0.02 0.002 0.02 0.005 0.02 720 382 770 410

Zn 97 Z30505 0.005 REM 0.003 0.005 0.10 0.015 0.005 2.5–3.5 0.02 0.002 0.02 0.005 0.02 720 382 743 395

Zn 95 Z30502 0.005 REM 0.003 0.005 0.10 0.015 0.005 4.5–5.5 0.02 0.002 0.02 0.005 0.02 720 382 720 382

Zn 90 Z34550 0.004 88.0–92.0 0.003 0.005 0.10 0.015 3.0–6.0 3.0–6.0 0.02 0.002 0.100 0.005 0.05 720 382 797 425

Zn 87 Z30705 0.005 REM 0.003 0.005 0.10 0.015 0.005 12.5–13.5 0.02 0.002 0.05 0.005 0.02 720 382 815 435

Zn 85 Z30702 0.005 REM 0.003 0.005 0.10 0.015 0.005 14.0–16.0 0.02 0.002 0.06 0.005 0.02 720 382 842 450

Zn 80 Z30800 0.005 REM 0.003 0.005 0.10 0.015 0.005 19.5–20.5 0.02 0.002 0.08 0.005 0.02 720 382 896 480

Zn/Sn 50 Z56900 0.005 REM 49.0–51.0 0.05 0.10 0.015 0.005 0.100 0.02 0.002 0.02 0.005 0.02 388 198 680 360

Zn/Sn 49 Z56930 0.005 REM 47.5–50.5 0.05 0.10 0.015 0.8–1.3 0.100 0.02 0.002 0.02 0.005 0.05 392 200 592 311

Zn/Sn 27 33.0 26.0–28.0 REM 0.05 0.10 0.015 0.05 0.050 0.02 0.020 0.02 0.005 0.05 351 177 500 260

Zn/Cd 90 Z50940 REM 89.0–91.0 0.003 0.05 0.10 0.015 0.05 0.100 0.02 0.002 0.02 0.005 0.05 509 265 738 392

Zn/Cd 60 Z50980 REM 59.0–61.0 0.003 0.05 0.10 0.015 0.05 0.100 0.02 0.002 0.02 0.005 0.05 509 265 648 342

Table 1b: Tin Base Alloys

A,B,C

Composition % Temperature

D

UNS Cd Zn Sn Pb Sb Ag Cu Al Bi As Fe Ni Mg Solidus Liquidus

FCF C

Sn/Zn 60 0.005 REM 59.0–61.0 0.05 0.10 0.015 0.01 0.100 0.005 0.002 0.02 0.005 0.05 390 199 666 352

Sn/Zn 70 0.005 REM 69.0–71.0 0.005 0.10 0.015 0.01 0.100 0.005 0.002 0.02 0.005 0.05 390 199 601 316

Sn/Zn 75 0.004 REM 74.0–76.0 0.20 0.10 0.015 0.05 0.050 0.020 0.020 0.02 0.005 0.05 390 199 572 300

Sn/Zn 80 0.005 REM 79.0–81.0 0.05 0.10 0.015 0.01 0.100 0.005 0.002 0.02 0.005 0.05 390 199 536 280

Sn/Zn 91 0.005 REM 90.0–92.0 0.05 0.10 0.015 0.01 0.100 0.005 0.002 0.02 0.005 0.05 390 199 390 199

Table 1c: Cadmium Base Alloys

A,B,C

Composition % Temperature

D

UNS Cd Zn Sn Pb Sb Ag Cu Al Bi As Fe Ni Mg Solidus Liquidus

FCF C

Cd 60 REM 39.0–41.0 0.003 0.05 0.10 0.015 0.05 0.100 0.02 0.002 0.02 0.005 0.05 509 265 601 316

Cd 70 REM 29.0–31.0 0.003 0.05 0.10 0.015 0.05 0.100 0.02 0.002 0.02 0.005 0.05 509 265 572 300

Cd 78 REM 11.0–13.0 0.003 0.05 0.10 4.5–5.5 0.05 0.100 0.02 0.002 0.02 0.005 0.05 480 249 601 316

Cd 83 REM 16.0–18.0 0.003 0.05 0.10 0.015 0.05 0.100 0.02 0.002 0.02 0.005 0.05 509 265 509 265

Cd 95 REM 0.007 0.003 0.05 0.10 4.5–5.5 0.05 0.100 0.02 0.002 0.02 0.005 0.05 640 338 739 393

A

For purposes of acceptance and rejection, the observed value or calculated value obtained from analysis should be rounded to the nearest unit in the last right-hand

place of figures, used in expressing the specified limit, in accordance with the rounding procedure prescribed in Practice E 29.

B

All values not given as a range are maximum values unless stated otherwise.

C

Remainder (REM) determined arithmetically by difference.

D

The USN designations were established in accordance with Practice E 527. The last digit of a UNS number differentiates between alloys of similar composition.

B 907

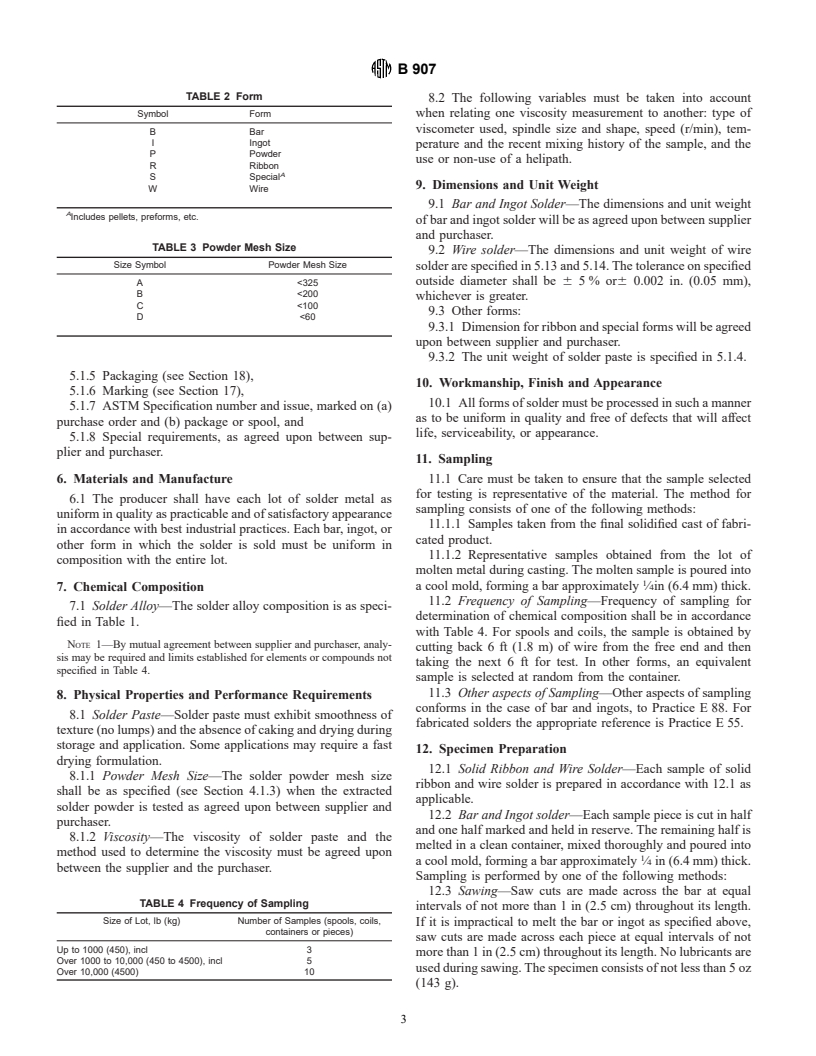

TABLE 2 Form

8.2 The following variables must be taken into account

Symbol Form when relating one viscosity measurement to another: type of

viscometer used, spindle size and shape, speed (r/min), tem-

B Bar

I Ingot

perature and the recent mixing history of the sample, and the

P Powder

use or non-use of a helipath.

R Ribbon

A

S Special

9. Dimensions and Unit Weight

W Wire

9.1 Bar and Ingot Solder—The dimensions and unit weight

A

Includes pellets, preforms, etc.

of bar and ingot solder will be as agreed upon between supplier

and purchaser.

TABLE 3 Powder Mesh Size

9.2 Wire solder—The dimensions and unit weight of wire

Size Symbol Powder Mesh Size

solder are specified in 5.13 and 5.14. The tolerance on specified

outside diameter shall be 6 5% or6 0.002 in. (0.05 mm),

A <325

B <200

whichever is greater.

C <100

9.3 Other forms:

D <60

9.3.1 Dimension for ribbon and special forms will be agreed

upon between supplier and purchaser.

9.3.2 The unit weight of solder paste is specified in 5.1.4.

5.1.5 Packaging (see Section 18),

10. Workmanship, Finish and Appearance

5.1.6 Marking (see Section 17),

10.1 All forms of solder must be processed in such a manner

5.1.7 ASTM Specification number and issue, marked on (a)

as to be uniform in quality and free of defects that will affect

purchase order and (b) package or spool, and

life, serviceability, or appearance.

5.1.8 Special requirements, as agreed upon between sup-

plier and purchaser.

11. Sampling

11.1 Care must be taken to ensure that the sample selected

6. Materials and Manufacture

for testing is representative of the material. The method for

6.1 The producer shall have each lot of solder metal as

sampling consists of one of the following methods:

uniform in quality as practicable and of satisfactory appearance

11.1.1 Samples taken from the final solidified cast of fabri-

in accordance with best industrial practices. Each bar, ingot, or

cated product.

other form in which the solder is sold must be uniform in

11.1.2 Representative samples obtained from the lot of

composition with the entire lot.

molten metal during casting. The molten sample is poured into

a cool mold, forming a bar approximately ⁄4in (6.4 mm) thick.

7. Chemical Composition

11.2 Frequency of Sampling—Frequency of sampling for

7.1 Solder Alloy—The solder alloy composition is as speci-

determination of chemical composition shall be in accordance

fied in Table 1.

with Table 4. For spools and coils, the sample is obtained by

NOTE 1—By mutual agreement between supplier and purchaser, analy-

cutting back 6 ft (1.8 m) of wire from the free end and then

sis may be required and limits established for elements or compounds not

taking the next 6 ft for test. In other forms, an equivalent

specified in Table 4.

sample is selected at random from the container.

11.3 Other aspects of Sampling—Other aspects of sampling

8. Physical Properties and Performance Requirements

conforms in the case of bar and ingots, to Practice E 88. For

8.1 Solder Paste—Solder paste must exhibit smoothness of

fabricated solders the appropriate reference is Practice E 55.

texture (no lumps) and the absence of caking and drying during

storage and application. Some applications may require a fast

12. Specimen Preparation

drying formulation.

12.1 Solid Ribbon and Wire Solder—Each sample of solid

8.1.1 Powder Mesh Size—The solder powder mesh size

ribbon and wire solder is prepared in accordance with 12.1 as

shall be as specified (see Section 4.1.3) when the extracted

applicable.

solder powder is tested as agreed upon between supplier and

12.2 Bar and Ingot solder—Each sample piece is cut in half

purchaser.

and one half marked and held in reserve. The remaining half is

8.1.2 Viscosity—The viscosity of solder paste and the

melted in a clean container, mixed thoroughly and poured into

method used to determine the viscosity must be agreed upon

a cool mold, forming a bar approximately ⁄4 in (6.4 mm) thick.

between the supplier and the purchaser.

Sampling is performed by one of the following methods:

12.3 Sawing—Saw cuts are made across the bar at equal

TABLE 4 Frequency of Sampling

intervals of not more than 1 in (2.5 cm) throughout its length.

Size of Lot, lb (kg) Number of Samples (spools, coils,

If it is impractical to melt the bar or ingot as specified above,

containers or pieces)

saw cuts are made across each piece at equal intervals of not

Up to 1000 (450), incl 3

more than 1 in (2.5 cm) throughout its length. No lubricants are

Over 1000 to 10,000 (450 to 4500), incl 5

used during sawing. The specimen consists of not less than 5 oz

Over 10,000 (4500) 10

(143 g).

B 907

12.4 Drilling—The bar is drilled at least halfway through producer’s certification must be furnished to the purchaser that

from the opposite sides. A drill of about ⁄2 in (12.7 mm) in

the material was manufactured, sampled, tested, and inspected

diameter is preferred. In drilling, the holes are placed along a

in accordance with this specification and has been f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.