ASTM D4365-95(2001)

(Test Method)Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

SCOPE

1.1 This test method covers the determination of total surface area and mesopore area. From these results are calculated the zeolite area and micropore volume of a zeolite containing catalyst. The micropore volume is related to the percent zeolite in the catalyst. The zeolite area, a number related to the surface area within the zeolite pores, may also be calculated. Zeolite area, however, is difficult to intepret in physical terms because of the manner in which nitrogen molecules pack within the zeolite.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statement, see Note 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4365–95 (Reapproved 2001)

Standard Test Method for

Determining Micropore Volume and Zeolite Area of a

Catalyst

This standard is issued under the fixed designation D4365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 micropore volume of the catalyst—the pore volume in

pores having radii less than 1 nm, usually associated with the

1.1 This test method covers the determination of total

zeolite portion of the catalyst, and determined from the

surface area and mesopore area. From these results are calcu-

intercept of the t-plot.

lated the zeolite area and micropore volume of a zeolite

3.1.3 surface area of a catalyst—the total surface of the

containing catalyst. The micropore volume is related to the

catalyst pores. It is expressed in square metres per gram.

percent zeolite in the catalyst. The zeolite area, a number

3.1.4 zeoliteareaofacatalyst—thedifferencebetweentotal

relatedtothesurfaceareawithinthezeolitepores,mayalsobe

surface area and mesopore area.

calculated. Zeolite area, however, is difficult to intepret in

3.2 Symbols:

physical terms because of the manner in which nitrogen

molecules pack within the zeolite.

1.2 This standard does not purport to address all of the

P = initial helium pressure, torr

H

safety concerns, if any, associated with its use. It is the

P = helium pressure after equilibration, torr

H

responsibility of the user of this standard to establish appro-

S = slope of BET plot, 11.7

B

priate safety and health practices and determine the applica-

I = intercept of BET plot, 11.7

B

bility of regulatory limitations prior to use. For specific

S = slope of t-plot, 11.13

t

precautionary statement, see Note 2.

I = intercept of t-plot, 11.13

t

T = temperature of manifold at initial helium pres-

H1

2. Referenced Documents

sure, °C

2.1 ASTM Standards: T = temperature of manifold after equilibration, °C

H2

T 8(i) = extra volume bulb temperature, °C

D3663 Test Method for Surface Area of Catalysts

x

T (i) = extra volume bulb temperature, K

D3906 Test Method for Determination of Relative X-Ray x

P = initial N pressure, torr

Diffraction Intensities of Faujasite-Type Zeolite- 1 2

2 T = manifold temperature at initial N pressure, K

1 2

Containing Materials

T 8 = manifold temperature at initial N pressure,° C

1 2

E177 Practice for Use of the Terms Precision and Bias in

P = pressure after equilibration, torr

ASTM Test Methods

T = manifold temperature after equilibration, K

3 2

E456 Terminology Relating to Quality and Statistics

T 8 = manifold temperature after equilibration, °C

E691 Practice for Conducting an Interlaboratory Study to

P = liquid nitrogen vapor pressure, torr

Determine the Precision of a Test Method

T = liquid nitrogen temperature, K

s

X = relative pressure, P /P

2 0

3. Terminology

V = volume of manifold, cm

d

3.1 Definitions of Terms Specific to This Standard:

V = extra volume bulb, cm

x

3.1.1 mesopore area of a catalyst—the area determined

V = effective void volume, cm

s

from the slope of the t-plot. W = weight of sample, g

W = tare weight of sample tube, g

W = weight of sample+tare weight of tube, g

V = volume of nitrogen in the dead-space, cm

ds

This test method is under the jurisdiction of ASTM Committee D32 on

V = see 11.4.3

Catalysts and is the direct responsibility of Subcommittee D32.01 on Physical- 1

V = see 11.4.4

Chemical Properties.

Current edition approved Aug. 15, 1995. Published October 1995. Originally

V = see 11.4.5

t

e1

published as D4365–84. Last previous edition D4365–85(1994) .

V = see 11.4.7

a

Annual Book of ASTM Standards, Vol 05.03.

V = see 11.8

3 m

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4365–95 (2001)

analyze multiple samples simultaneously and may use sample tubes with

BET (i) = see 11.4.8

volumes outside of the range specified in this test method.

t(i) = see 11.10

3 3

6.2 Sample Tubes, with volumes from 5 cm to 25 cm

4. Summary of Test Method

depending on the application. Markings should be placed on

4.1 The volume of nitrogen gas adsorbed by the catalyst at the sample tubes about 30 to 50 mm below the connectors to

liquid nitrogen temperature is measured at various low- indicate the desired liquid nitrogen level.

pressure levels. This is done by measuring pressure differen- 6.3 Heating Mantles or Small Furnaces.

tials caused by introducing a fixed volume of nitrogen to the 6.4 Dewar Flasks.

−7

degassed catalyst in the test apparatus. This procedure is the 6.5 Laboratory Balance, with 0.1 mg (10 kg) sensitivity.

same as Test Method D3663, that gives total surface area, but 6.6 Thermometer, for measuring the temperature of the

extends the pressure range to permit calculation of micropore distribution manifold, T 8(i)or T 8(i), in degrees Celsius.

1 2

volume and matrix surface area, by the t-plot method. Zeolite 6.7 Thermometer, for measuring the temperature of the

area is the difference between total area and matrix area. liquid nitrogen bath T (i) in kelvins. This will preferably be a

s

nitrogenvapor-pressure-thermometerthatgivesP directlyand

5. Significance and Use

has greater precision, or a resistance thermometer from which

5.1 This gas adsorption method complements the X-ray P values may be derived.

procedure of Test Method D3906. This test method will be 6.8 Thermometer, for measuring the temperature of the EV

useful to laboratories that do not have X-ray diffractometers. bulb, T 8(i), if different from T 8(i)or T 8(i).

x 1 2

Each test method can be calibrated by use of an appropriate

series of mechanical mixtures to provide what may be termed 7. Reagents

percentzeolite.Ifthereisdisorderinthezeolite,theadsorption

7.1 Purity of Reagents—Reagent grade chemicals shall be

method will yield higher values than the X-ray method. The

used in all tests. Unless otherwise indicated, it is intended that

reverse will be true if some zeolite pores (micropores) are

all reagents shall conform to the specifications of the Commit-

blocked or filled.

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

6. Apparatus

used, provided it is first ascertained that the reagent is of

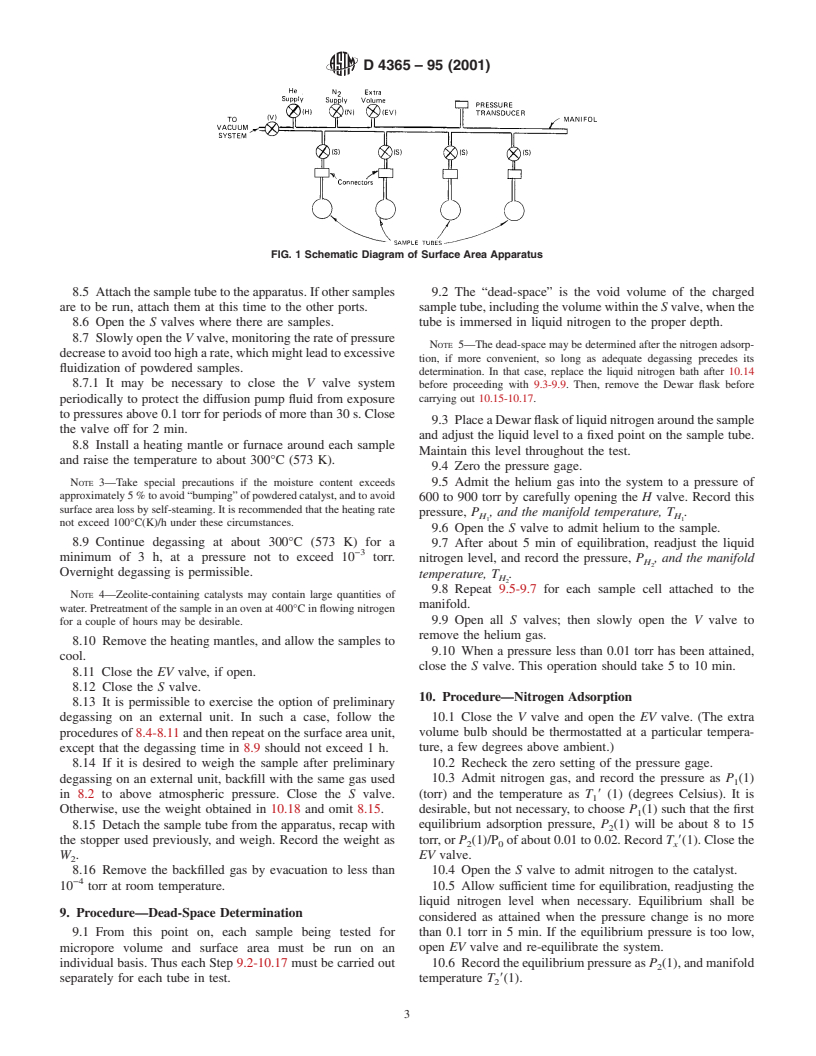

6.1 AschematicdiagramoftheapparatusisshowninFig.1.

sufficiently high purity to permit its use without lessening the

It may be constructed of glass or of metal. It has the following

accuracy of the determination.

features:

7.2 Helium Gas—A cylinder of helium gas at least 99.9%

6.1.1 Distribution Manifold, having a volume between 20

pure.

3 3

and 35 cm,(V ), known to the nearest 0.05 cm . This volume

d 7.3 Liquid Nitrogen, of such purity that P is not more than

is defined as the volume between the stopcocks or valves and

20 torr above barometric pressure. A fresh daily supply is

includes the pressure gage. It is preferred that this volume be

recommended.

thermostatted.

7.4 Nitrogen Gas—A cylinder of nitrogen gas at least

6.1.2 Vacuum System, capable of attaining pressures below

99.9% pure.

−4

10 torr (1 torr=133.3 Pa). This will include a vacuum gage

(not shown in Fig. 1). Access to the distribution manifold is

8. Procedure—Sample Preparation and Degassing

through the valve V. 3

8.1 Selectasampletubeofthedesiredsize.A5-cm sample

6.1.3 Constant-Volume Gage or Mercury Manometer, ca-

tube is preferred for samples not exceeding about 1 g, to

pable of measurements to the nearest 0.1-torr sensitivity in the 3

minimizethedead-space.However,a25-cm sampletubemay

range from 0 to 1000 torr (1 torr=133.3 Pa).

be preferred for finely powdered catalysts, to avoid “boiling”

NOTE 1—See, for example, the article by Joy, A. S., Vacuum, Vol 3, when degassing is started.

1953, p. 254 for a description of a constant-volume manometer.

8.2 Fill the sample tube with nitrogen or helium, at atmo-

sphericpressure,afterremovingairbyevacuation.Thismaybe

6.1.4 Valve (H), from the helium supply to the distribution

done on the surface area unit, or on a separate piece of

manifold.

equipment.

6.1.5 Value (N),fromthenitrogensupplytothedistribution

8.3 Remove the sample tube from the system, cap, and

manifold.

weigh. Record the weight as W .

6.1.6 The connection between the sample tube and the S 1

8.4 Place the catalyst sample, whose weight is known

valve can be a standard-taper glass joint, a glass-to-glass seal,

approximately,intothesampletube.Choosethesamplesizeto

or a compression fitting.

provideanestimatedtotalsamplesurfaceareaof20to100m .

6.1.7 Extra Volume Bulb, may be attached through valve

EV. Its volume (V ) should be 100 to 150 cm , known to the

x

nearest 0.05 cm . V includes the volume of the stopcock bore

x

in the glass apparatus. It is preferred that this volume be held 4

Reagent Chemicals, American Chemical Society Specifications, American

at the same temperature as that of the distribution manifold. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

NOTE 2—Modern commercial instruments automatically adjust the

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

amounts dosed in order to produce data points at user-selected target

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

pressures.Hence,theuseofanEVbulbisoptional.Someinstrumentscan MD.

D4365–95 (2001)

FIG. 1 Schematic Diagram of Surface Area Apparatus

8.5 Attachthesampletubetotheapparatus.Ifothersamples 9.2 The “dead-space” is the void volume of the charged

are to be run, attach them at this time to the other ports. sampletube,includingthevolumewithintheSvalve,whenthe

8.6 Open the S valves where there are samples. tube is immersed in liquid nitrogen to the proper depth.

8.7 SlowlyopentheVvalve,monitoringtherateofpressure

NOTE 5—The dead-space may be determined after the nitrogen adsorp-

decreasetoavoidtoohigharate,whichmightleadtoexcessive

tion, if more convenient, so long as adequate degassing precedes its

fluidization of powdered samples.

determination. In that case, replace the liquid nitrogen bath after 10.14

8.7.1 It may be necessary to close the V valve system

before proceeding with 9.3-9.9. Then, remove the Dewar flask before

carrying out 10.15-10.17.

periodically to protect the diffusion pump fluid from exposure

topressuresabove0.1torrforperiodsofmorethan30s.Close

9.3 PlaceaDewarflaskofliquidnitrogenaroundthesample

the valve off for 2 min.

and adjust the liquid level to a fixed point on the sample tube.

8.8 Install a heating mantle or furnace around each sample

Maintain this level throughout the test.

and raise the temperature to about 300°C (573 K).

9.4 Zero the pressure gage.

NOTE 3—Take special precautions if the moisture content exceeds 9.5 Admit the helium gas into the system to a pressure of

approximately5%toavoid“bumping”ofpowderedcatalyst,andtoavoid

600 to 900 torr by carefully opening the H valve. Record this

surfacearealossbyself-steaming.Itisrecommendedthattheheatingrate

pressure, P , and the manifold temperature, T .

H H

1 1

not exceed 100°C(K)/h under these circumstances.

9.6 Open the S valve to admit helium to the sample.

8.9 Continue degassing at about 300°C (573 K) for a

9.7 After about 5 min of equilibration, readjust the liquid

−3

minimum of 3 h, at a pressure not to exceed 10 torr.

nitrogen level, and record the pressure, P , and the manifold

H

Overnight degassing is permissible.

temperature, T .

H

9.8 Repeat 9.5-9.7 for each sample cell attached to the

NOTE 4—Zeolite-containing catalysts may contain large quantities of

manifold.

water. Pretreatment of the sample in an oven at 400°C in flowing nitrogen

9.9 Open all S valves; then slowly open the V valve to

for a couple of hours may be desirable.

remove the helium gas.

8.10 Remove the heating mantles, and allow the samples to

9.10 When a pressure less than 0.01 torr has been attained,

cool.

close the S valve. This operation should take 5 to 10 min.

8.11 Close the EV valve, if open.

8.12 Close the S valve.

10. Procedure—Nitrogen Adsorption

8.13 It is permissible to exercise the option of preliminary

10.1 Close the V valve and open the EV valve. (The extra

degassing on an external unit. In such a case, follow the

volume bulb should be thermostatted at a particular tempera-

proceduresof8.4-8.11andthenrepeatonthesurfaceareaunit,

ture, a few degrees above ambient.)

except that the degassing time in 8.9 should not exceed 1 h.

8.14 If it is desired to weigh the sample after preliminary 10.2 Recheck the zero setting of the pressure gage.

degassing on an external unit, backfill with the same gas used 10.3 Admit nitrogen gas, and record the pressure as P (1)

in 8.2 to above atmospheric pressure. Close the S valve. (torr) and the temperature as T 8 (1) (degrees Celsius). It is

Otherwise, use the weight obtained in 10.18 and omit 8.15. desirable, but not necessary, to choose P (1) such that the first

8.15 Detach the sample tube from the apparatus, recap with equilibrium adsorption pressure, P (1) will be about 8 to 15

the stopper used previously, and weigh. Record the weight as torr,orP (1)/P ofabout0.01to0.02.RecordT 8(1).Closethe

2 0 x

W . EV valve.

8.16 Remove the backfilled gas by evacuation to less than 10.4 Open the S valve to admit nitrogen to the catalyst.

−4

10 torr at room temperature. 10.5 Allow sufficient time for equilibration, readjusting the

liquid nitrogen level when necessary. Equilibrium shall be

9. Procedure—Dead-Space Determination

considered as attained when the pressure change is no more

than 0.1 torr in 5 min. If the equilibrium pressure is too low,

9.1 From this point on, each sample being tested for

micropore volume and surface area must be run on an open EV valve and re-equilibrate the system.

individual basis. Thus each Step 9.2-10.17 must be carried out 10.6 RecordtheequilibriumpressureasP (1),andmanifold

separately for each tube in test. temperature T 8(1).

D4365–95 (2001)

10.7 Record the liquid nitrogen temperature T (1) or the 11.3.2 For vapor pressures, P (i), or liquid nitrogen tem-

s 0

nitrogen vapor pressure P (1). peratures, T (i), see 6.7, 10.7, 10.12.

0 s

11.3.2.1 If P (i) is not measured directly, the values of T (i)

10.8 Close the S valve and close the EV valve; then admit

0 s

nitrogengastoincreasethepressureasneeded(usuallyby100 can be converted to P (i) for 76 # T (i) # 8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.