ASTM D4365-95(2001)

(Test Method)Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

SCOPE

1.1 This test method covers the determination of total surface area and mesopore area. From these results are calculated the zeolite area and micropore volume of a zeolite containing catalyst. The micropore volume is related to the percent zeolite in the catalyst. The zeolite area, a number related to the surface area within the zeolite pores, may also be calculated. Zeolite area, however, is difficult to intepret in physical terms because of the manner in which nitrogen molecules pack within the zeolite.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statement, see Note 2.

General Information

Relations

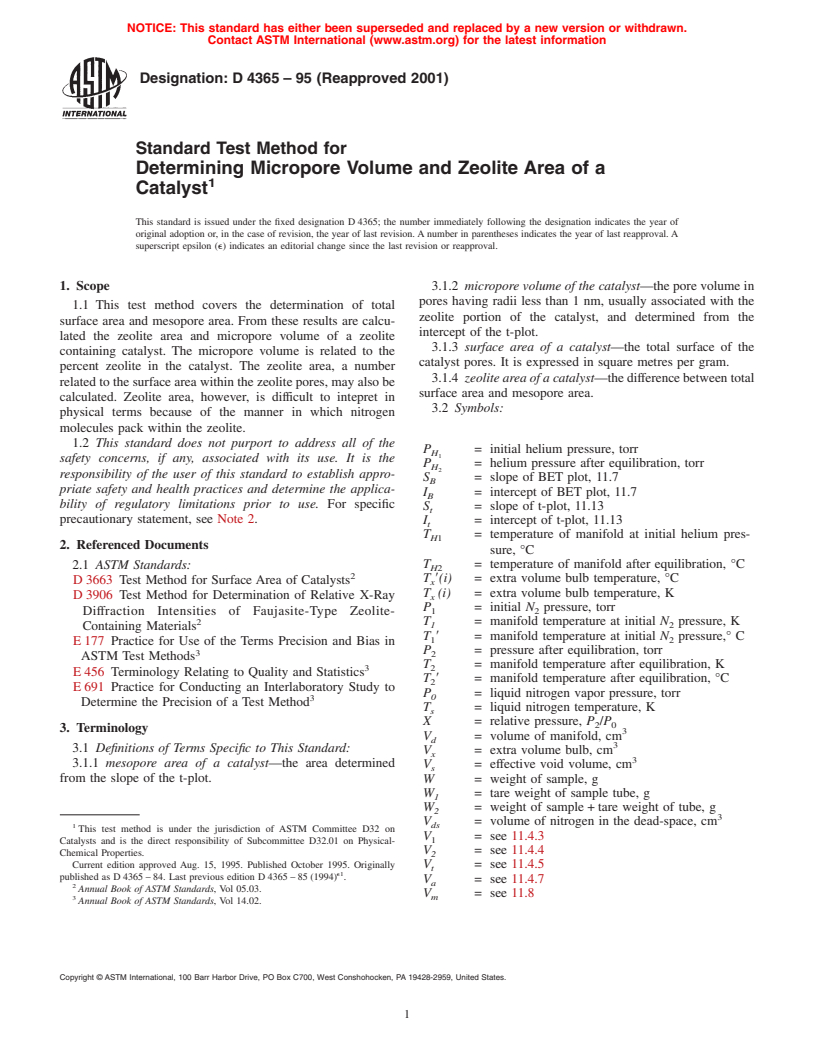

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4365–95 (Reapproved 2001)

Standard Test Method for

Determining Micropore Volume and Zeolite Area of a

1

Catalyst

This standard is issued under the fixed designation D4365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 micropore volume of the catalyst—the pore volume in

pores having radii less than 1 nm, usually associated with the

1.1 This test method covers the determination of total

zeolite portion of the catalyst, and determined from the

surface area and mesopore area. From these results are calcu-

intercept of the t-plot.

lated the zeolite area and micropore volume of a zeolite

3.1.3 surface area of a catalyst—the total surface of the

containing catalyst. The micropore volume is related to the

catalyst pores. It is expressed in square metres per gram.

percent zeolite in the catalyst. The zeolite area, a number

3.1.4 zeoliteareaofacatalyst—thedifferencebetweentotal

relatedtothesurfaceareawithinthezeolitepores,mayalsobe

surface area and mesopore area.

calculated. Zeolite area, however, is difficult to intepret in

3.2 Symbols:

physical terms because of the manner in which nitrogen

molecules pack within the zeolite.

1.2 This standard does not purport to address all of the

P = initial helium pressure, torr

H

1

safety concerns, if any, associated with its use. It is the

P = helium pressure after equilibration, torr

H

2

responsibility of the user of this standard to establish appro-

S = slope of BET plot, 11.7

B

priate safety and health practices and determine the applica-

I = intercept of BET plot, 11.7

B

bility of regulatory limitations prior to use. For specific

S = slope of t-plot, 11.13

t

precautionary statement, see Note 2.

I = intercept of t-plot, 11.13

t

T = temperature of manifold at initial helium pres-

H1

2. Referenced Documents

sure, °C

2.1 ASTM Standards: T = temperature of manifold after equilibration, °C

H2

2

T 8(i) = extra volume bulb temperature, °C

D3663 Test Method for Surface Area of Catalysts

x

T (i) = extra volume bulb temperature, K

D3906 Test Method for Determination of Relative X-Ray x

P = initial N pressure, torr

Diffraction Intensities of Faujasite-Type Zeolite- 1 2

2 T = manifold temperature at initial N pressure, K

1 2

Containing Materials

T 8 = manifold temperature at initial N pressure,° C

1 2

E177 Practice for Use of the Terms Precision and Bias in

P = pressure after equilibration, torr

3

2

ASTM Test Methods

T = manifold temperature after equilibration, K

3 2

E456 Terminology Relating to Quality and Statistics

T 8 = manifold temperature after equilibration, °C

2

E691 Practice for Conducting an Interlaboratory Study to

P = liquid nitrogen vapor pressure, torr

0

3

Determine the Precision of a Test Method

T = liquid nitrogen temperature, K

s

X = relative pressure, P /P

2 0

3. Terminology

3

V = volume of manifold, cm

d

3

3.1 Definitions of Terms Specific to This Standard:

V = extra volume bulb, cm

x

3

3.1.1 mesopore area of a catalyst—the area determined

V = effective void volume, cm

s

from the slope of the t-plot. W = weight of sample, g

W = tare weight of sample tube, g

1

W = weight of sample+tare weight of tube, g

2

3

V = volume of nitrogen in the dead-space, cm

1

ds

This test method is under the jurisdiction of ASTM Committee D32 on

V = see 11.4.3

Catalysts and is the direct responsibility of Subcommittee D32.01 on Physical- 1

V = see 11.4.4

Chemical Properties.

2

Current edition approved Aug. 15, 1995. Published October 1995. Originally

V = see 11.4.5

t

e1

published as D4365–84. Last previous edition D4365–85(1994) .

V = see 11.4.7

a

2

Annual Book of ASTM Standards, Vol 05.03.

V = see 11.8

3 m

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4365–95 (2001)

analyze multiple samples simultaneously and may use sample tubes with

BET (i) = see 11.4.8

volumes outside of the range specified in this test method.

t(i) = see 11.10

3 3

6.2 Sample Tubes, with volumes from 5 cm to 25 cm

4. Summary of Test Method

depending on the application. Markings should be placed on

4.1 The volume of nitrogen gas adsorbed by the catalyst at the sample tubes about 30 to 50 mm below the connectors to

liquid nitrogen temperature is measured at various low- indicate the desired liquid nitrogen level.

pressure levels. This is done by measuring pressure differen- 6.3 Heating Mantles or Small Furnaces.

tials caused by introducing a fixed volume of nitrogen to the 6.4 Dewar Flasks.

−7

degassed catalyst in the tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.