ASTM A933/A933M-14

(Specification)Standard Specification for Vinyl-Coated Steel Wire and Welded Wire Reinforcement (Withdrawn 2016)

Standard Specification for Vinyl-Coated Steel Wire and Welded Wire Reinforcement (Withdrawn 2016)

ABSTRACT

This specification covers steel wire and steel welded wire fabrics which are either plain or deformed, and coated with protective polyvinyl chloride (PVC). Class A material is intended for use as concrete reinforcement and Class B for reinforcement in earth. Coating materials shall adhere to chemical resistance requirements. The surface of the material to be coated shall be cleaned by abrasive blast cleaning to near-white metal. The coating shall be applied to the cleaned surface as soon as possible after cleaning and before oxidation, as discernible to the unaided eye, occurs. The coating shall conform to set coating thickness and holidays. Adhesion of coating shall be evaluated by bending test. Guidelines for inspection, rejection and certification are also given.

SCOPE

1.1 This specification covers plain and deformed steel wire and plain and deformed steel welded wire reinforcement with protective vinyl (polyvinyl chloride, or polyvinyl chloride powder compound) coating. A Class A minimum coating thickness is required for wire and welded wire reinforcement intended for use in concrete and masonry. A Class B minimum coating thickness is required for wire and welded wire reinforcement intended for use in mechanically stabilized earth applications.

1.2 Other thermoplastic organic coatings may be used provided they meet the requirements of this specification. Note 1—The coating applicator is identified throughout this specification as the manufacturer.

1.3 Requirements for coatings are contained in Annex A1.

1.4 Requirements for patching materials are contained in Annex A2.

1.5 The text of this specification contains notes or footnotes, or both, that provide explanatory material. Such notes and footnotes, excluding those in tables or figures, do not contain any mandatory requirements.

1.6 This specification is applicable for orders in either inch-pound units (as Specification A933) or in SI units [as Specification A933M].

1.7 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

WITHDRAWN RATIONALE

This specification covers plain and deformed steel wire and plain and deformed steel welded wire reinforcement with protective vinyl (polyvinyl chloride, or polyvinyl chloride powder compound) coating.

Formerly under the jurisdiction of Committee A01 on Steel, Stainless Steel and Related Alloys, this specification was withdrawn in March 2016. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A933/A933M −14

StandardSpecification for

1

Vinyl-Coated Steel Wire and Welded Wire Reinforcement

This standard is issued under the fixed designationA933/A933M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers plain and deformed steel wire 2.1 ASTM Standards:

and plain and deformed steel welded wire reinforcement with A775/A775MSpecification for Epoxy-Coated Steel Rein-

protective vinyl (polyvinyl chloride, or polyvinyl chloride forcing Bars

powder compound) coating. A Class A minimum coating A884/A884MSpecification for Epoxy-Coated Steel Wire

thickness is required for wire and welded wire reinforcement and Welded Wire Reinforcement

intended for use in concrete and masonry.AClass B minimum A1064/A1064MSpecification for Carbon-Steel Wire and

coating thickness is required for wire and welded wire rein- Welded Wire Reinforcement, Plain and Deformed, for

forcement intended for use in mechanically stabilized earth Concrete

applications. B117Practice for Operating Salt Spray (Fog) Apparatus

D374Test Methods for Thickness of Solid Electrical Insu-

1.2 Other thermoplastic organic coatings may be used

3

lation (Withdrawn 2013)

provided they meet the requirements of this specification.

D2240Test Method for Rubber Property—Durometer Hard-

NOTE 1—The coating applicator is identified throughout this specifica-

ness

tion as the manufacturer.

D2967Test Method for Corner Coverage of Powder Coat-

1.3 Requirements for coatings are contained in Annex A1.

ings

D4060Test Method for Abrasion Resistance of Organic

1.4 Requirements for patching materials are contained in

Coatings by the Taber Abraser

Annex A2.

G8Test Methods for Cathodic Disbonding of Pipeline Coat-

1.5 Thetextofthisspecificationcontainsnotesorfootnotes,

ings

or both, that provide explanatory material. Such notes and

G12Test Method for Nondestructive Measurement of Film

footnotes, excluding those in tables or figures, do not contain

Thickness of Pipeline Coatings on Steel (Withdrawn

any mandatory requirements.

3

2013)

1.6 This specification is applicable for orders in either

G14TestMethodforImpactResistanceofPipelineCoatings

inch-pound units (as Specification A933) or in SI units [as

(Falling Weight Test)

Specification A933M].

G20Test Method for Chemical Resistance of Pipeline Coat-

ings

1.7 The values stated in either inch-pound units or SI units

2.2 National Association of Corrosion Engineers Stan-

are to be regarded separately as standard. Within the text, the

4

dards:

SI units are shown in brackets. The values stated in each

RP-287-87Field Measurement of Surface Profile of Abra-

system may not be exact equivalents; therefore, each system

sive Blast Cleaned Steel Surface Using a Replica Tape

shall be used independently of the other. Combining values

TM-01-70Visual Standard for Surfaces of New Steel Air

from the two systems may result in non-conformance with the

Blast Cleaned with Sand Abrasive (NACE No. 2)

standard.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, Standards volume information, refer to the standard’s Document Summary page on

Stainless Steel and Related Alloys and is under the direct responsibility of the ASTM website.

3

Subcommittee A01.05 on Steel Reinforcement. The last approved version of this historical standard is referenced on

Current edition approved May 1, 2014. Published May 2014. Originally www.astm.org.

4

approved in 1995. Last previous edition approved in 2010 as A993/A993M–10. Available from National Association of Corrosion Engineers (NACE), 1440

DOI: 10.1520/A0933_A0933M-14. South Creek Dr., Houston, TX 77084-4906, http://www.nace.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A933/A933M−14

TM-01-75Visual Standard for Surfaces of New Steel Cen- A1064/A1064Mandshallbefreeofsurfacecontaminantssuch

trifugally Blast Cleaned with Steel Shot or Steel Grit as oil, grease, or paint when received at the manufacturer’s

(NACE No. 2) plant and prior to cleaning and coating.

5

2.3 Steel Structures Painting Council Specifications:

5.2 The coating material shall meet the requirements listed

SSPC-PA2Measurement of Dry Coating Thickness with

in AnnexA1. In addition to the requirements of AnnexA1, the

Magnetic

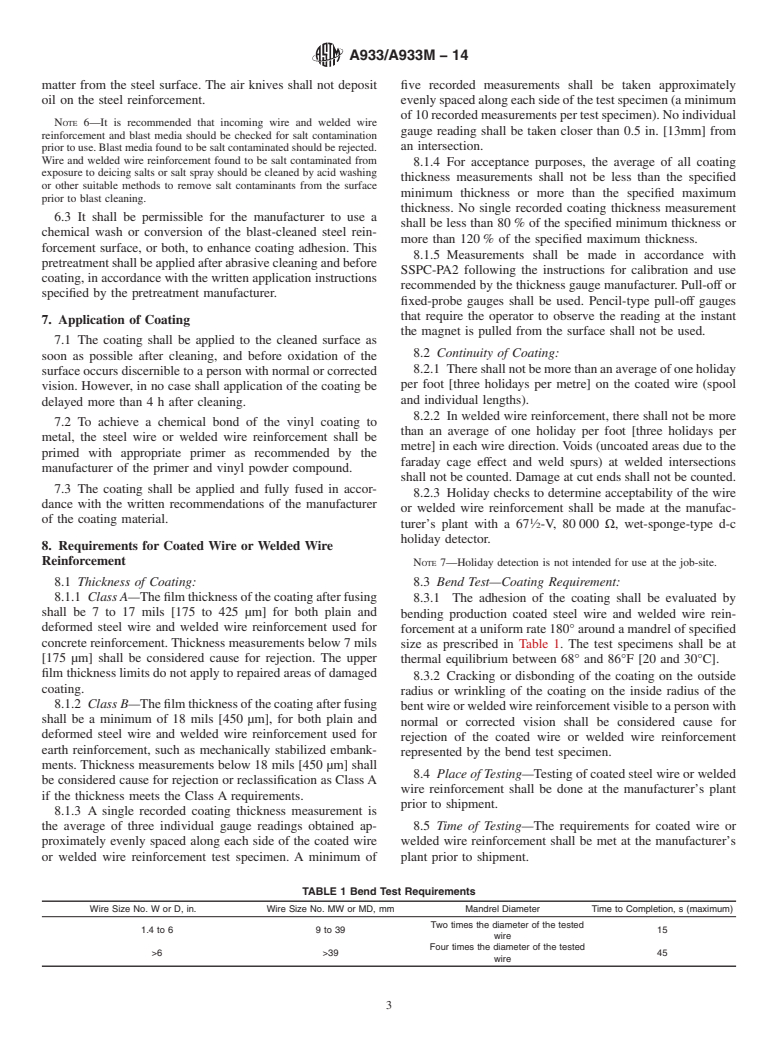

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.