ASTM A252-98(2002)

(Specification)Standard Specification for Welded and Seamless Steel Pipe Piles

Standard Specification for Welded and Seamless Steel Pipe Piles

SCOPE

1.1 This specification covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions of the values in inch-pound units to values in SI units.

1.3 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.4 The following precautionary caveat pertains only to the test method portion, Section 16 of this specification.This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 252 – 98 (Reapproved 2002)

Standard Specification for

Welded and Seamless Steel Pipe Piles

This standard is issued under the fixed designation A252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers nominal (average) wall steel 3.1 Definitions—Definitions of terms used in this specifica-

pipe piles of cylindrical shape and applies to pipe piles in tion shall be in accordance with Terminology A941.

which the steel cylinder acts as a permanent load-carrying 3.1.1 defect—an imperfection of sufficient size or magni-

member, or as a shell to form cast-in-place concrete piles. tude to be cause for rejection.

1.2 The values stated in inch-pound units are to be regarded 3.1.2 imperfection—any discontinuity or irregularity found

as standard. The values given in parentheses are mathematical in the pipe.

conversions of the values in inch-pound units to values in SI

4. Ordering Information

units.

1.3 The text of this specification contains notes and foot- 4.1 Ordersformaterialunderthisspecificationshallcontain

information concerning as many of the following items as are

notes that provide explanatory material. Such notes and foot-

notes, excluding those in tables and figures, do not contain any required to describe the desired material adequately:

4.1.1 Quantity (feet or number of lengths),

mandatory requirements.

1.4 The following precautionary caveat pertains only to the 4.1.2 Name of material (steel pipe piles),

4.1.3 Method of manufacture (seamless or welded),

test method portion, Section 16 of this specification. This

standard does not purport to address all of the safety problems, 4.1.4 Grade (Tables 1 and 2),

4.1.5 Size (outside diameter and nominal wall thickness),

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health 4.1.6 Lengths (single random, double random, or uniform)

(see Section 13),

practices and determine the applicability of regulatory limita-

4.1.7 End finish (Section 15), and

tions prior to use.

4.1.8 ASTM specification designation and year of issue,

2. Referenced Documents

4.1.9 Location of purchaser’s inspection (see 19.1), and

2.1 ASTM Standards: 4.1.10 Bar coding (see 22.2).

A370 TestMethodsandDefinitionsforMechanicalTesting

2 5. Materials and Manufacture

of Steel Products

A 751 Test Methods, Practices, and Terminology for 5.1 The piles shall be made by the seamless, electric

resistance welded, flash welded, or fusion welded process.The

Chemical Analysis of Steel Products

A941 Terminology Relating to Steel, Stainless Steel, Re- seams of welded pipe piles shall be longitudinal, helical-butt,

or helical-lap.

lated Alloys, and Ferroalloys

E29 Practice for Using Significant Digits in Test Data to

NOTE 1—For welded pipe piles, the weld should not fail when the

Determine Conformance with Specifications

product is properly fabricated and installed and subjected to its intended

end use.

6. Process

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

6.1 The steel shall be made by one or more of the following

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products. processes: open-hearth, basic-oxygen, or electric-furnace.

Current edition approved Sept. 10, 2002. Published September 1998. Originally

published as A252–44T. Last previous edition A252–96.

7. Chemical Composition

Annual Book of ASTM Standards, Vol 01.03.

7.1 The steel shall contain no more than 0.050% phospho-

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 14.02. rous.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 252 – 98 (2002)

TABLE 1 Tensile Requirements

NOTE—Where an ellipsis (.) appears in this table, there is no requirement.

Grade 1 Grade 2 Grade 3

Tensile strength, min, psi (MPa) 50 000 (345) 60 000 (415) 66 000 (455)

Yield point or yield strength, min, psi (MPa) 30 000 (205) 35 000 (240) 45 000 (310)

Basic minimum elongation for nominal wall thicknesses ⁄16 in. (7.9 mm) or more:

Elongation in 8 in. (203.2 mm), min, % 18 14 . . .

Elongation in 2 in. (50.8 mm), min, % 30 25 20

A A A

For nominal wall thicknesses less than ⁄16 in. (7.9 mm), the deduction from 1.50 1.25 1.0

the basic minimum elongation in 2 in. (50.08 mm) for each ⁄32 - in. (0.8 mm)

decrease in nominal wall thickness below ⁄16 in. (7.9 mm), in percentage points

A

Table 2 gives the computed minimum values:

A

TABLE 2 Calculated Minimum Elongation Values

Nominal Wall Thickness Elongation in 2 in. (50.8 mm), min, %

in. mm Grade 1 Grade 2 Grade 3

⁄16 or 0.312 7.9 30.00 25.00 20.00

⁄32 or 0.281 7.1 28.50 23.75 19.00

⁄4 or 0.250 6.4 27.00 22.50 18.00

⁄32 or 0.219 5.6 25.50 21.25 17.00

⁄16 or 0.188 4.8 24.00 20.00 16.00

⁄64 or 0.172 4.4 23.25 19.50 15.50

⁄32 or 0.156 4.0 22.50 18.75 15.00

⁄64 or 0.141 3.6 21.75 18.25 14.50

⁄8 or 0.125 3.2 21.00 17.50 14.00

⁄64 or 0.109 2.8 20.25 16.75 13.50

A

The above table gives the calculated minimum elongation values for various nominal wall thicknesses. Where the specified nominal wall thickness is intermediate to

those shown above, the minimum elongation value shall be determined as follows:

Grade

1 E =48t + 15.00

2 E =40t + 12.50

3 E =32t + 10.00

where:

E = elongation in 2 in., %, and

t = specified nominal wall thickness, in.

8. Heat Analysis specified requirement, the lot shall be rejected or analyses of

twoadditionalsamplesselectedfromthelotshallbemade,and

8.1 Each heat analysis shall conform to the requirement

each shall conform to the specified requirement.

specified in 7.1. When requested by the purchaser, the appli-

cable heat analyses shall be reported to the purchaser ro the

10. Tensile Requirements Tensile Requirements

purchaser’s representative.

10.1 The material shall conform to the requirements as to

9. Product Analysis tensile properties prescribed in Tables 1 and 2.

10.2 The yield point shall be determined by the drop of the

9.1 Chemical analysis shall be in accordance with Test

beam,bythehaltinthegageofthetestingmachine,bytheuse

Methods, Practices, and Terminology A751.

of dividers, or by other approved methods. When a definite

9.2 Itshallbepermissibleforthepurchasertomakeproduct

yieldpointisnotexhibited,theyieldstrengthcorrespondingto

analyses using samples from lots of pipe piles as follows:

apermanentoffsetof0.2%ofthegagelengthofthespecimen,

Pipe Size Outside Number of Samples and Size of Lot

or to a total extension of 0.5% of the gage length under load

Diameter, in. (mm)

Under 14 (355.6) 2 from 200 pipe or fraction thereof

shall be determined.

14 to 36, incl (355.6 2 from 100 pipe or fraction thereof

to 914)

11. Weights Per Unit Length

Over 36 (914) 2 from 3000 ft (914 m) or fraction thereof

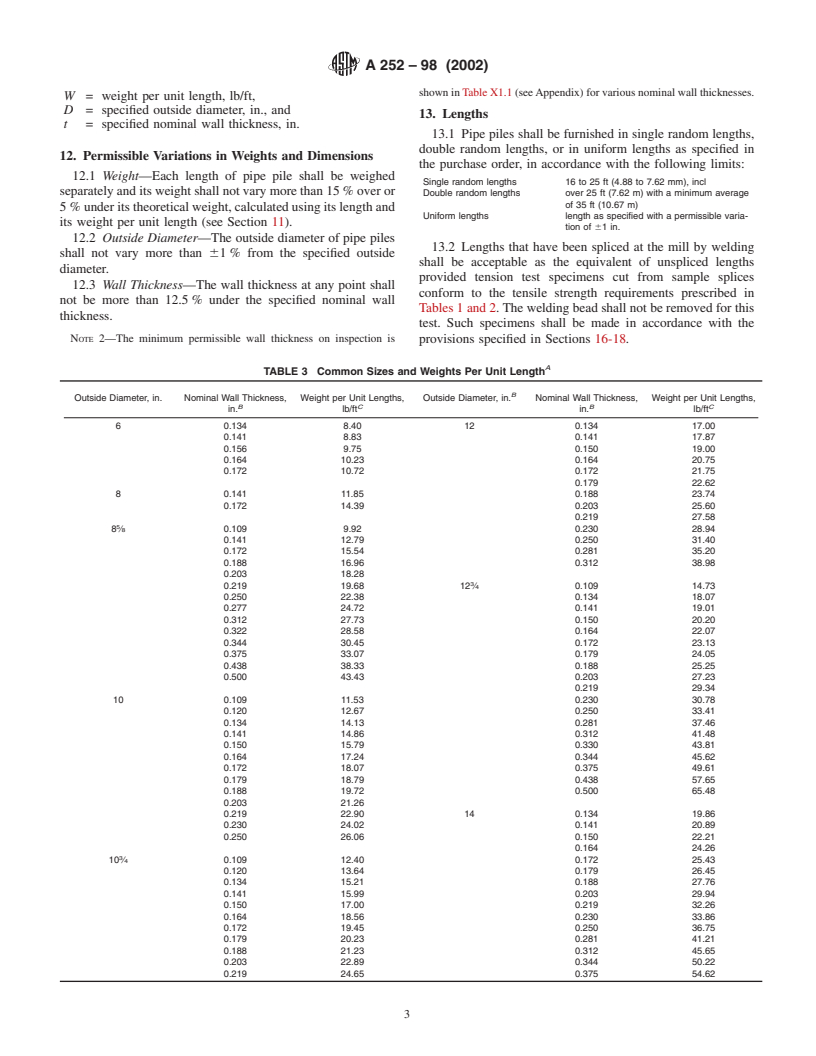

11.1 The weights per unit length for various sizes of pipe

The product analyses shall conform to the requirement in

piles are listed in Table 3.

7.1.

11.2 For pipe pile sizes not listed in Table 3, the weight per

9.3 If the chemical compositions of both of the samples

unit length shall be calculated as follows:

representing a lot fail to conform to the specified requirement,

the lot shall be rejected or analyses of four additional samples W510.69~D 2 t!t (1)

selected from the lot shall be made, and each shall conform to

the specified requirement. If the chemical composition of only

where:

one of the samples representing a lot fails to conform to the

A 252 – 98 (2002)

showninTableX1.1(seeAppendix)forvariousnominalwallthicknesses.

W = weight per unit length, lb/ft,

D = specified outside diameter, in., and

13. Lengths

t = specified nominal wall thickness, in.

13.1 Pipe piles shall be furnished in single random lengths,

double random lengths, or in uniform lengths as specified in

12. Permissible Variations in Weights and Dimensions

the purchase order, in accordance with the following limits:

12.1 Weight—Each length of pipe pile shall be weighed

Single random lengths 16 to 25 ft (4.88 to 7.62 mm), incl

separatelyanditsweightshallnotvarymorethan15%overor

Double random lengths over 25 ft (7.62 m) with a minimum average

of 35 ft (10.67 m)

5%underitstheoreticalweight,calculatedusingitslengthand

Uniform lengths length as specified with a permissible varia-

its weight per unit length (see Section 11).

tion of 61in.

12.2 Outside Diameter—The outside diameter of pipe piles

13.2 Lengths that have been spliced at the mill by welding

shall not vary more than 61% from the specified outside

shall be acceptable as the equivalent of unspliced lengths

diameter.

provided tension test specimens cut from sample splices

12.3 Wall Thickness—The wall thickness at any point shall

conform to the tensile strength requirements prescribed in

not be more than 12.5% under the specified nominal wall

Tables1and2.Theweldingbeadshallnotberemovedforthis

thickness.

test. Such specimens shall be made in accordance with the

NOTE 2—The minimum permissible wall thickness on inspection is provisions specified in Sections 16-18.

A

TABLE 3 Common Sizes and Weights Per Unit Length

B

Outside Diameter, in. Nominal Wall Thickness, Weight per Unit Lengths, Outside Diameter, in. Nominal Wall Thickness, Weight per Unit Lengths,

B C B C

in. lb/ft in. lb/ft

6 0.134 8.40 12 0.134 17.00

0.141 8.83 0.141 17.87

0.156 9.75 0.150 19.00

0.164 10.23 0.164 20.75

0.172 10.72 0.172 21.75

0.179 22.62

8 0.141 11.85 0.188 23.74

0.172 14.39 0.203 25.60

0.219 27.58

8 ⁄8 0.109 9.92 0.230 28.94

0.141 12.79 0.250 31.40

0.172 15.54 0.281 35.20

0.188 16.96 0.312 38.98

0.203 18.28

0.219 19.68 12 ⁄4 0.109 14.73

0.250 22.38 0.134 18.07

0.277 24.72 0.141 19.01

0.312 27.73 0.150 20.20

0.322 28.58 0.164 22.07

0.344 30.45 0.172 23.13

0.375 33.07 0.179 24.05

0.438 38.33 0.188 25.25

0.500 43.43 0.203 27.23

0.219 29.34

10 0.109 11.53 0.230 30.78

0.120 12.67 0.250 33.41

0.134 14.13 0.281 37.46

0.141 14.86 0.312 41.48

0.150 15.79 0.330 43.81

0.164 17.24 0.344 45.62

0.172 18.07 0.375 49.61

0.179 18.79 0.438 57.65

0.188 19.72 0.500 65.48

0.203 21.26

0.219 22.90 14 0.134 19.86

0.230 24.02 0.141 20.89

0.250 26.06 0.150 22.21

0.164 24.26

10 ⁄4 0.109 12.40 0.172 25.43

0.120 13.64 0.179 26.45

0.134 15.21 0.188 27.76

0.141 15.99 0.203 29.94

0.150 17.00 0.219 32.26

0.164 18.56 0.230 33.86

0.172 19.45 0.250 36.75

0.179 20.23 0.281 41.21

0.188 21.23 0.312 45.65

0.203 22.89 0.344 50.22

0.219 24.65 0.375 54.62

A 252 – 98 (2002)

TABLE 3 Continued

B

Outside Diameter, in. Nominal Wall Thickness, Weight per Unit Lengths, Outside Diameter, in. Nominal Wall Thickness, Weight per Unit Lengths,

B C B C

in. lb/ft in. lb/ft

0.230 25.87 0.438 63.50

0.250 28.06 0.469 67.84

0.279 31.23 0.500 72.16

0.307 34.27

0.344 38.27 16 0.134 22.73

0.141 23.90

0.150 25.42

0.164 27.76

16 0.172 29.10 20 0.188 31.78

0.179 30.27 0.219 46.31

0.250 52.78

0.188 30.61 0.281 59.23

0.203 34.28 0.312 65.66

0.219 36.95 0.344 72.28

0.230 38.77 0.375 78.67

0.250 42.09 0.438 91.59

0.281 47.22 0.469 97.92

0.312 52.32 0.500 104.23

0.344 57.57

0.375 62.64 22 0.172 40.13

0.438 72.86 0.188 43.84

0.469 77.87 0.219 50.99

0.500 82.85 0.250 58.13

0.281 65.24

18 0.141 26.92 0.312 72.34

0.172 32.78 0.375 86.69

0.188 35.80 0.438 100.96

0.219 41.63 0.469 107.95

0.230 43.69 0.500 114.92

0.250 47.44

0.281 53.23 24 0.172 43.81

0.312 58.99 0.188 47.86

0.344 64.93 0.219 55.67

0.375 70.65 0.250 63.47

0.438 82.23 0.281 71.25

0.469 87.89 0.312 79.01

0.500 93.54 0.375 94.71

0.438 110.32

20 0.141 29.93 0.469 117.98

0.172 36.46 0.500 125.62

A

Subject to agreement between the manufacturer and the purchaser, sizes and weights per unit length other than those listed shall be permitted.

B

1 in. = 25.4 mm

C

1 lb/ft = 1.49 kg/m.

14. Workmanship, Finish, and Appearance angleof30+5,−0°,measuredfromalinedrawnperpendicular

to the axis of the pipe pile.

14.1 The finished pipe piles shall be reasonably straight and

shall not contain imperfections in such number or of such

16. Number of Tests

character as to render the pipe unsuitable for pipe piles.

16.1 One tension test shall be made on one length or

14.2 Surface imperfections having a depth not in excess of

fractionthereofofeachsize,oronepieceofskelprepresenting

25% of the specified nominal wall thickness shall be accept-

each lot of 200 lengths or fraction thereof of each size.

able. It shall be permissible to establish the depth of such

16.2 A retest shall be allowed if the percentage of elonga-

imperfections by grinding or filing.

tion of any test tension specimen is less than that prescribed in

14.3 Surfaceimperfectionshavingadepthinexcessof25%

Tables 1 and 2 and any part of the fracture is more than ⁄4 in.

of the specified nominal wall thickness shall be considered to

(19 mm) from the center of the gage length for test specimens

be defects. It shall be permissible for defects not deeper than

havinga2–in.(50mm)gagelength,orisoutsideofthemiddle

33 ⁄3 % of the specified nominal wall thickness to be repaired

thirdofthegagelengthfortestspecimenshavingan8–in.(200

by welding, provided that the defect is completely removed

mm) gage length, as indicated by scribe scratches marked on

prior to welding.

the specimen before testing. A retest shall also be allowed if

15. Ends

any part of the fracture is in an inside or outside surface

15.1 Pipe piles shall be furnished with plain ends. Unless imperfection.

otherwise specified, pipe piles shall have either flame–cut or 16.3 Itshallbepermissibletodiscardanytestspecimenthat

machine–cut ends, with the burrs at the ends removed. Where shows defective machining or develops imperfections and

ends are specified to be beveled, they shall be beveled to an substitute another test specimen.

A 252 – 98 (2002)

17. Retests shall be so conducted as not to interfere unnecessarily with the

operation of the works.

17.1 Iftheresultsofthetensiontestrepresentinganylotfail

to conform to the applicable requirements prescribed inTables

20. Rejection

1 and 2, the lot shall be rejected or retested using two

20.1 It shall be permissible for the purchaser inspect the

additional lengths from the lot, with each such test being

pipe piles received from the manufacturer and reject any pipe

required to conform to such specified requirements.

pile that does not meet the requirements of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.