ASTM D1561/D1561M-13

(Practice)Standard Practice for Preparation of Bituminous Mixture Test Specimens by Means of California Kneading Compactor (Withdrawn 2022)

Standard Practice for Preparation of Bituminous Mixture Test Specimens by Means of California Kneading Compactor (Withdrawn 2022)

SIGNIFICANCE AND USE

3.1 This practice can be used to prepare cylindrical specimens of bituminous mix for subsequent testing. The procedure incorporates the use of the California Kneading Compactor in an attempt to duplicate the kneading action that is provided by the equipment now being used for the compaction of asphalt concrete pavement.Note 1—The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of the standard are cautioned that compliance with Specification D3666 alone does not completely assure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 The practice covers the preparation of test specimens of bituminous paving mixtures by means of a mechanical compactor that imparts a kneading action to the test specimens by a series of individual impressions made with a ram.

1.2 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covered the preparation of test specimens of bituminous paving mixtures by means of a mechanical compactor that imparts a kneading action to the test specimens by a series of individual impressions made with a ram.

Formerly under the jurisdiction of Committee D04 on Road and Paving Materials, this practice was withdrawn in January 2022 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1561/D1561M − 13

Standard Practice for

Preparation of Bituminous Mixture Test Specimens by

1

Means of California Kneading Compactor

This standard is issued under the fixed designation D1561/D1561M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Adjuncts:

3

California Kneading Compactor

1.1 The practice covers the preparation of test specimens of

bituminous paving mixtures by means of a mechanical com-

3. Significance and Use

pactor that imparts a kneading action to the test specimens by

3.1 This practice can be used to prepare cylindrical speci-

a series of individual impressions made with a ram.

mens of bituminous mix for subsequent testing. The procedure

1.2 The text of this standard references notes and footnotes

incorporates the use of the California Kneading Compactor in

which provide explanatory material. These notes and footnotes

an attempt to duplicate the kneading action that is provided by

(excluding those in tables and figures) shall not be considered

the equipment now being used for the compaction of asphalt

as requirements of the standard.

concrete pavement.

1.3 Units—The values stated in either SI units or inch-

NOTE 1—The quality of the results produced by this standard are

pound units are to be regarded separately as standard. The

dependent on the competence of the personnel performing the procedure

values stated in each system may not be exact equivalents;

and the capability, calibration, and maintenance of the equipment used.

therefore,eachsystemshallbeusedindependentlyoftheother. Agencies that meet the criteria of Specification D3666 are generally

considered capable of competent and objective testing/sampling/

Combining values from the two systems may result in non-

inspection/etc. Users of the standard are cautioned that compliance with

conformance with the standard.

Specification D3666 alone does not completely assure reliable results.

1.4 This standard does not purport to address all of the

Reliable results depend on many factors; following the suggestions of

Specification D3666 or some similar acceptable guideline provides a

safety problems, if any, associated with its use. It is the

means of evaluating and controlling some of those factors.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Apparatus

bility of regulatory limitations prior to use.

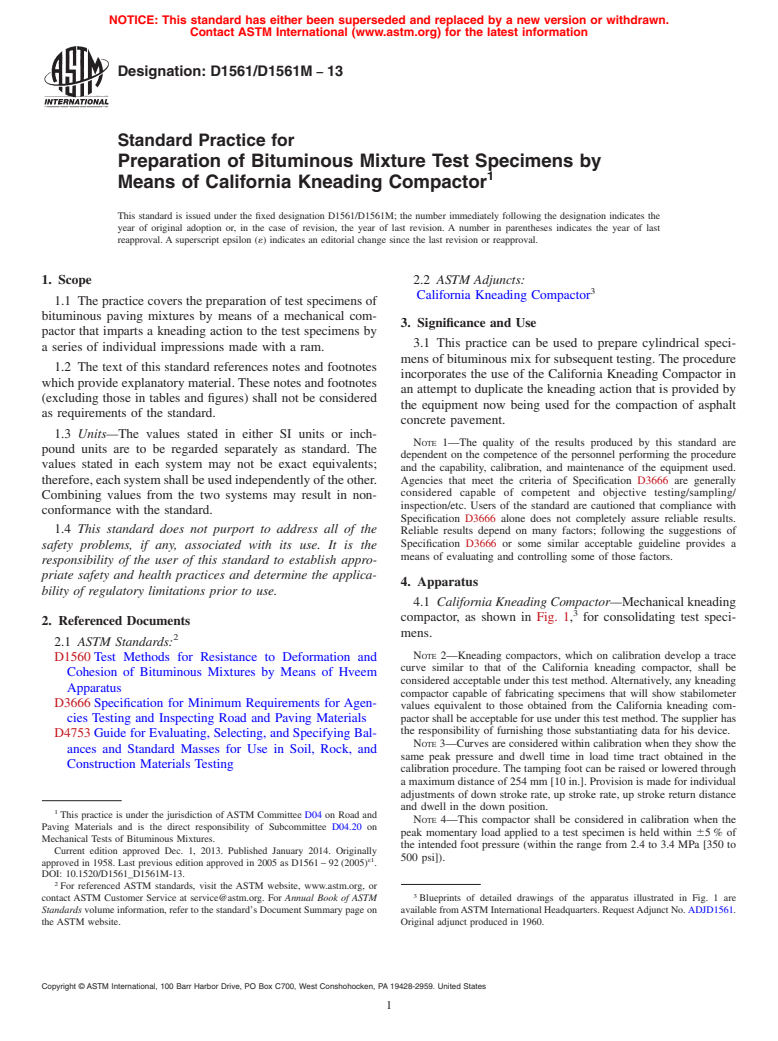

4.1 CaliforniaKneadingCompactor—Mechanical kneading

3

compactor, as shown in Fig. 1, for consolidating test speci-

2. Referenced Documents

mens.

2

2.1 ASTM Standards:

NOTE 2—Kneading compactors, which on calibration develop a trace

D1560 Test Methods for Resistance to Deformation and

curve similar to that of the California kneading compactor, shall be

Cohesion of Bituminous Mixtures by Means of Hveem

considered acceptable under this test method.Alternatively, any kneading

Apparatus

compactor capable of fabricating specimens that will show stabilometer

D3666 Specification for Minimum Requirements for Agen-

values equivalent to those obtained from the California kneading com-

pactor shall be acceptable for use under this test method. The supplier has

cies Testing and Inspecting Road and Paving Materials

the responsibility of furnishing those substantiating data for his device.

D4753 Guide for Evaluating, Selecting, and Specifying Bal-

NOTE 3—Curves are considered within calibration when they show the

ances and Standard Masses for Use in Soil, Rock, and

same peak pressure and dwell time in load time tract obtained in the

Construction Materials Testing

calibration procedure. The tamping foot can be raised or lowered through

a maximum distance of 254 mm [10 in.]. Provision is made for individual

adjustments of down stroke rate, up stroke rate, up stroke return distance

and dwell in the down position.

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and

NOTE 4—This compactor shall be considered in calibration when the

Paving Materials and is the direct responsibility of Subcommittee D04.20 on

peak momentary load applied to a test specimen is held within 65%of

Mechanical Tests of Bituminous Mixtures.

the intended foot pressure (within the range from 2.4 to 3.4 MPa [350 to

Current edition approved Dec. 1, 2013. Published January 2014. Originally

ε1 500 psi]).

approved in 1958. Last previous edition approved in 2005 as D1561 – 92 (2005) .

DOI: 10.1520/D1561_D1561M-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.