ASTM D3061-97e1

(Guide)Standard Guide for Three-Piece Steel and Tinplate Straight-Wall and Necked-In Aerosol Cans

Standard Guide for Three-Piece Steel and Tinplate Straight-Wall and Necked-In Aerosol Cans

SCOPE

1.1 This specification covers tin-plate fabricated aerosol cans.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 3061 – 97

Standard Guide for

Three-Piece Steel and Tinplate Straight-Wall and Necked-In

1

Aerosol Cans

This standard is issued under the fixed designation D 3061; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

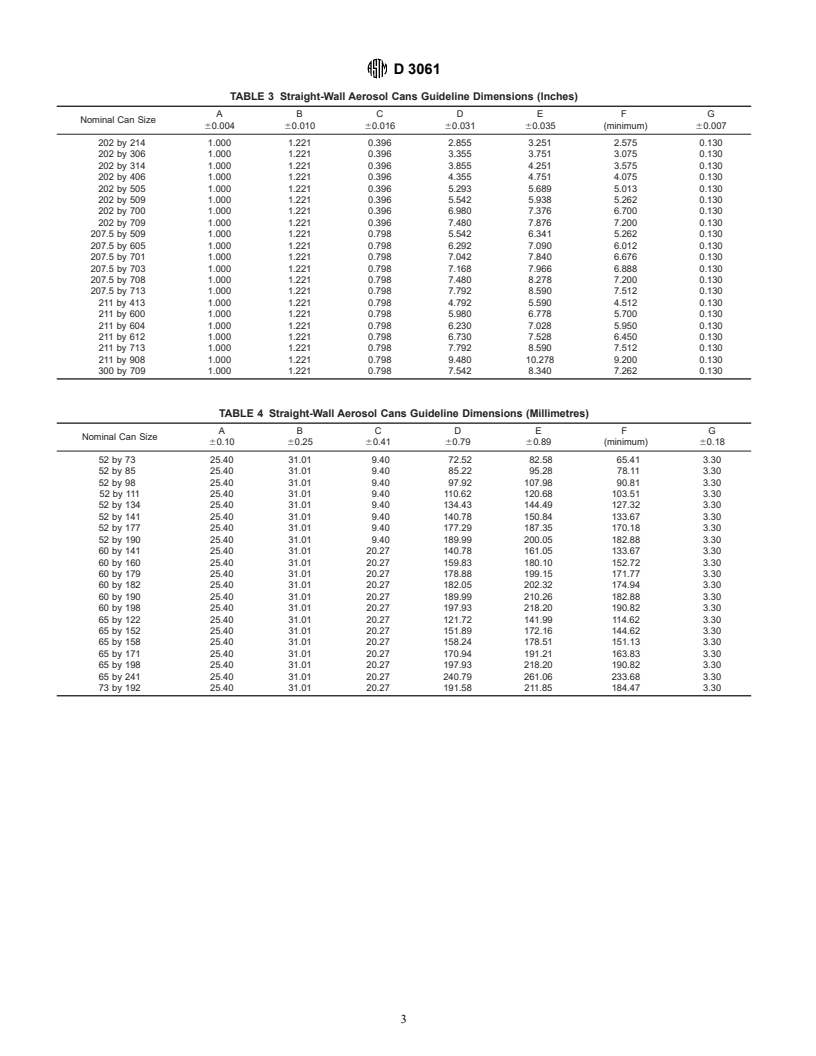

e NOTE—Corrections were made to the dimensions in Tables 3 and 4 in March 2000.

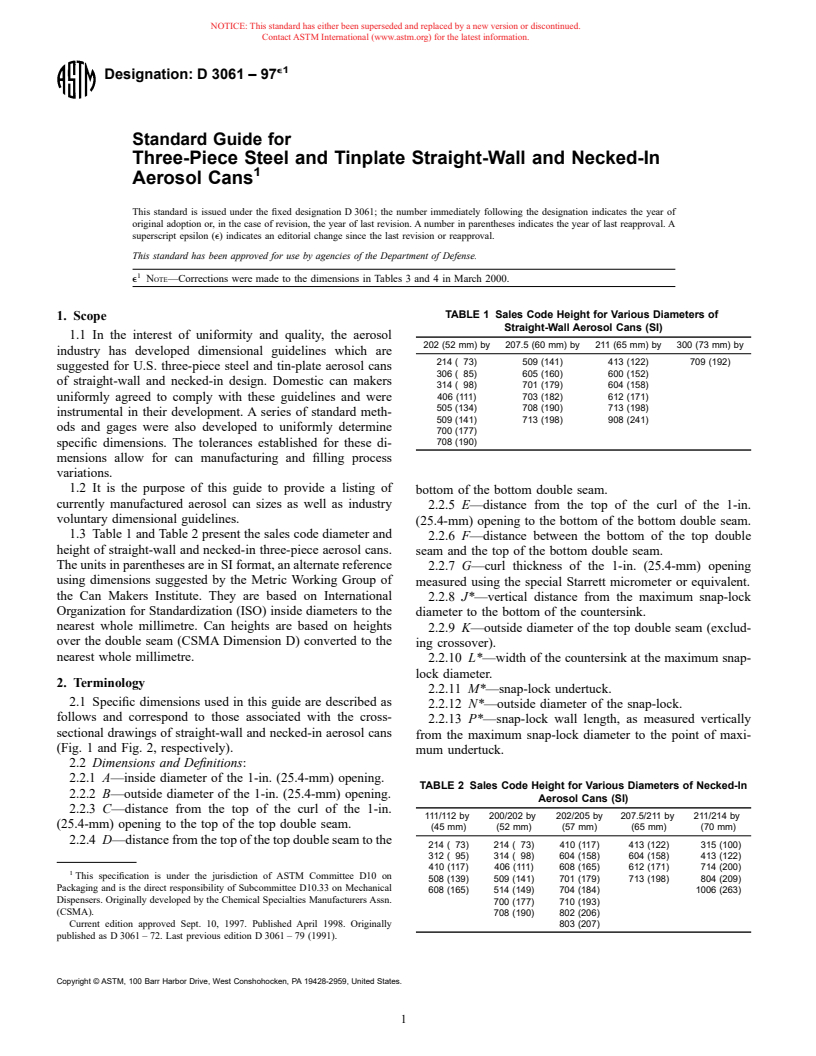

TABLE 1 Sales Code Height for Various Diameters of

1. Scope

Straight-Wall Aerosol Cans (SI)

1.1 In the interest of uniformity and quality, the aerosol

202 (52 mm) by 207.5 (60 mm) by 211 (65 mm) by 300 (73 mm) by

industry has developed dimensional guidelines which are

214 ( 73) 509 (141) 413 (122) 709 (192)

suggested for U.S. three-piece steel and tin-plate aerosol cans

306 ( 85) 605 (160) 600 (152)

of straight-wall and necked-in design. Domestic can makers

314 ( 98) 701 (179) 604 (158)

406 (111) 703 (182) 612 (171)

uniformly agreed to comply with these guidelines and were

505 (134) 708 (190) 713 (198)

instrumental in their development. A series of standard meth-

509 (141) 713 (198) 908 (241)

ods and gages were also developed to uniformly determine

700 (177)

specific dimensions. The tolerances established for these di- 708 (190)

mensions allow for can manufacturing and filling process

variations.

1.2 It is the purpose of this guide to provide a listing of

bottom of the bottom double seam.

currently manufactured aerosol can sizes as well as industry

2.2.5 E—distance from the top of the curl of the 1-in.

voluntary dimensional guidelines.

(25.4-mm) opening to the bottom of the bottom double seam.

1.3 Table 1 and Table 2 present the sales code diameter and

2.2.6 F—distance between the bottom of the top double

height of straight-wall and necked-in three-piece aerosol cans.

seam and the top of the bottom double seam.

The units in parentheses are in SI format, an alternate reference

2.2.7 G—curl thickness of the 1-in. (25.4-mm) opening

using dimensions suggested by the Metric Working Group of

measured using the special Starrett micrometer or equivalent.

the Can Makers Institute. They are based on International

2.2.8 J*—vertical distance from the maximum snap-lock

Organization for Standardization (ISO) inside diameters to the

diameter to the bottom of the countersink.

nearest whole millimetre. Can heights are based on heights

2.2.9 K—outside diameter of the top double seam (exclud-

over the double seam (CSMA Dimension D) converted to the

ing crossover).

nearest whole millimetre.

2.2.10 L*—width of the countersink at the maximum snap-

lock diameter.

2. Terminology

2.2.11 M*—snap-lock undertuck.

2.1 Specific dimensions used in this guide are described as

2.2.12 N*—outside diameter of the snap-lock.

follows and correspond to those associated with the cross-

2.2.13 P*—snap-lock wall length, as measured vertically

sectional drawings of straight-wall and necked-in aerosol cans

from the maximum snap-lock diameter to the point of maxi-

(Fig. 1 and Fig. 2, respectively).

mum undertuck.

2.2 Dimensions and Definitions:

2.2.1 A—inside diameter of the 1-in. (25.4-mm) opening.

TABLE 2 Sales Code Height for Various Diameters of Necked-In

2.2.2 B—outside diameter of the 1-in. (25.4-mm) opening.

Aerosol Cans (SI)

2.2.3 C—distance from the top of the curl of the 1-in.

111/112 by 200/202 by 202/205 by 207.5/211 by 211/214 by

(25.4-mm) opening to the top of the top double seam.

(45 mm) (52 mm) (57 mm) (65 mm) (70 mm)

2.2.4 D—distance from the top of the top double seam to the

214 ( 73) 214 ( 73) 410 (117) 413 (122) 315 (100)

312 ( 95) 314 ( 98) 604 (158) 604 (158) 413 (122)

410 (117) 406 (111) 608 (165) 612 (171) 714 (200)

1

This specification is under the jurisdiction of ASTM Committee D10 on

508 (139) 509 (141) 701 (179) 713 (198) 804 (209)

Packaging and is the direct responsibility of Subcommittee D10.33 on Mechanical

608 (165) 514 (149) 704 (184) 1006 (263)

Dispensers. Originally developed by the Chemical Specialties Manufacturers Assn.

700 (177) 710 (193)

(CSMA).

708 (190) 802 (206)

Current edition approved Sept. 10, 1997. Published April 1998. Originally 803 (207)

published as D 3061 – 72. Last previous edition D 3061 – 79 (1991).

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3061

FIG. 1 Straight-Wall Aerosol Can

FIG. 2 Necked-In Aerosol Can

2.2.14 S—vertical distance, tangent to the outside diameter

of the dome double seam, from the top of the dome double

depending on end diameter and unit of measure.

seam to the necked-in area of the can sidewall.

E 5 C 1 D 5 0.798 in. 1 4.792 in. 5 5.590 in. (2)

2.2.15 T—width or height of the top double seam.

2.2.16 V*—body outside diameter of necked-in can

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.