ISO/TR 24857:2006

(Main)Synthetic industrial diamond grit products — Single-particle compressive failure strength — "DiaTest-SI" system

Synthetic industrial diamond grit products — Single-particle compressive failure strength — "DiaTest-SI" system

ISO/TS 24857:2006 gives the results of a study to determine the feasibility of the DiaTest-SI single particle strength tester as a system for measuring the compressive strength of synthetic industrial diamond grit products. Issues that were addressed included: the range of grit products (in terms of both size and strength) for which the DiaTest-SI system was appropriate, the choice of distribution statistics with which to describe diamond strength, and the similarities (at a statistically significant level) of the results from various test centres.

Produits en diamant synthétique industriel — Résistance à la compression des particules — Méthode "DiaTest SI"

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 24857

First edition

2006-03-15

Synthetic industrial diamond grit

products — Single-particle compressive

failure strength — “DiaTest-SI” system

Produits en diamant synthétique industriel — Résistance à la

compression des particules — Méthode «DiaTest SI»

Reference number

ISO/TR 24857:2006(E)

©

ISO 2006

---------------------- Page: 1 ----------------------

ISO/TR 24857:2006(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 24857:2006(E)

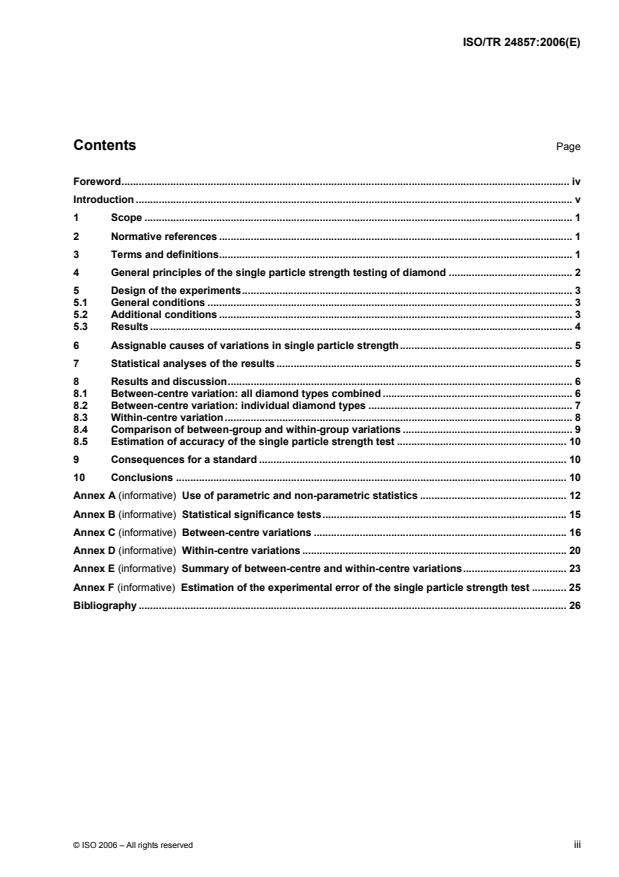

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 General principles of the single particle strength testing of diamond . 2

5 Design of the experiments. 3

5.1 General conditions . 3

5.2 Additional conditions . 3

5.3 Results . 4

6 Assignable causes of variations in single particle strength. 5

7 Statistical analyses of the results . 5

8 Results and discussion. 6

8.1 Between-centre variation: all diamond types combined . 6

8.2 Between-centre variation: individual diamond types . 7

8.3 Within-centre variation. 8

8.4 Comparison of between-group and within-group variations . 9

8.5 Estimation of accuracy of the single particle strength test . 10

9 Consequences for a standard . 10

10 Conclusions . 10

Annex A (informative) Use of parametric and non-parametric statistics . 12

Annex B (informative) Statistical significance tests. 15

Annex C (informative) Between-centre variations . 16

Annex D (informative) Within-centre variations . 20

Annex E (informative) Summary of between-centre and within-centre variations. 23

Annex F (informative) Estimation of the experimental error of the single particle strength test . 25

Bibliography . 26

© ISO 2006 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 24857:2006(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 24857 was prepared by Technical Committee ISO/TC 29, Small tools, Subcommittee SC 5, Grinding

wheels and abrasives.

iv © ISO 2006 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 24857:2006(E)

Introduction

A study has been performed to evaluate the suitability of the Vollstädt “DiaTest-SI” system for the single

particle compressive strength testing of synthetic industrial diamond particles.

Four distinct saw grit diamond products were measured repeatedly by six test centres, in order that the

variation in results between the centres and the variation in results within each centre could be established.

The principal measurement examined was the median single particle strength of a sample (that is, half of the

particles in the sample have a strength below this value). It was concluded from the study that within each test

centre, the median strength of a saw grit diamond product could be measured with a high degree of

repeatability: the average “scatter” of the medians being around 2 % to 4 %. Examining variations between

test centres, there were small systematic differences in the results from each test centre's strength testing

machine, their measurement “biases” being between −2 % and +5 %. The combination of between-centre and

within-centre variations resulted in an estimated experimental error of between ±7 % and ±15 %.

© ISO 2006 – All rights reserved v

---------------------- Page: 5 ----------------------

TECHNICAL REPORT ISO/TR 24857:2006(E)

Synthetic industrial diamond grit products — Single-particle

compressive failure strength — “DiaTest-SI” system

1 Scope

1)

This Technical Report gives the results of a study to determine the feasibility of the “DiaTest-SI” single

particle strength tester as a system for measuring the compressive strength of synthetic industrial diamond grit

products. Issues that were addressed included: the range of grit products (in terms of both size and strength)

for which the “DiaTest-SI” system was appropriate, the choice of distribution statistics with which to describe

diamond strength, and the similarities (at a statistically significant level) of the results from various test centres.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5725-1:1994, Accuracy (trueness and precision) of measurement methods and results — Part 1: General

principles and definitions

ISO 5725-2:1994, Accuracy (trueness and precision) of measurement methods and results — Part 2: Basic

method for the determination of repeatability and reproducibility of a standard measurement method

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5725-1, ISO 5725-2 and the

following apply.

3.1

analysis of variance

ANOVA

statistical method used to determine the influence of various assignable causes on experimental results

3.2

compressive failure force

CFF

force (in newtons) applied to a particle which results in its failure

3.3

single particle strength

SPS

alternative term for the compressive failure force (CFF) of a particle

1) “DiaTest-SI” is the trade name of a product supplied by Vollstädt-Diamant GmbH, Schlunkendorfer Strasse 21,

14554 Seddiner See, Germany. This information is given for the convenience of users of this Technical Report and does

not constitute an endorsement by ISO of the product named. Equivalent products may be used if they can be shown to

lead to the same results.

© ISO 2006 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/TR 24857:2006(E)

3.4

polycrystalline diamond

PCD

intergrown mass of randomly orientated diamond particles in a metal matrix, synthesized at high temperature

and high pressure

NOTE PCD offers very high hardness, toughness and abrasion resistance.

3.5

US mesh

size of a diamond product determined by the mesh sizes of the sieves used to separate the diamond particles

[1]

NOTE In the US mesh system, a sieve size is defined by the number of lines per inch of that sieve; see ISO 6106

for details.

4 General principles of the single particle strength testing of diamond

Industrial synthetic diamond products may be tested for strength using a variety of techniques. Perhaps the

[2]

most established of these techniques is the friability test (or friatest ), which measures the resistance of a

diamond sample contained within a capsule to multiple impacts by a steel ball. Whilst the friatest may be a

robust technique, being conceptually simple and having a high level of repeatability, it yields only one “figure

of merit” strength value, and cannot be used to describe the distribution of particle strengths within a diamond

sample.

The strength of an individual diamond particle may be measured by subjection to an increasing compressive

force, the threshold force (in newtons) at which the particle “fails” being its recorded strength. This form of

measurement, which is known as single particle strength (SPS), compressive failure force (CFF) or static

strength (as distinct from the dynamic strength of the friatest), is therefore a valuable complementary

technique to the friatest because of the information it provides on the particle strength distribution. At present,

single particle strength testing is most conveniently performed on grit sizes coarser than size D213

(70/80 US mesh).

There are two principal methods for the single particle strength testing of diamond:

[3]

⎯ particles may be either crushed between rotating cylinders , or

⎯ between vertically aligned anvils.

The second of these two methods is substantially more widespread than the first, and is commercially

[4]

available in the form of such systems as the “DiaTest-SI” by the German manufacturer Vollstädt .

In the DiaTest-SI system (and others of a similar design), diamond particles are aligned on an adhesive

“carrier” tape and are subsequently transported between the anvils. An image analysis camera may be

positioned before the anvils in order to measure the size and shape characteristics of the particle. The upper

anvil is attached to a pneumatically (or mechanically) driven piston, whilst the lower anvil is attached to a load

sensor. The anvils may be manufactured from polycrystalline cubic boron nitride (PcBN) or polycrystalline

diamond (PCD), with PCD offering a longer anvil life (this is important, as over-used anvils can have a

significant effect on results).

As the upper anvil is driven downwards, the particle is subjected to a compressive force, and this force is

transmitted through the particle to the lower anvil and the load sensor. Eventually the particle will “fail” in that

some disintegration will occur, and there will be an instantaneous reduction in the force detected by the load

sensor. The nature of this reduction in force is dependent on the defect structure of the particle: a particle with

a high perfection will tend to withstand high compressive forces before disintegrating catastrophically, whilst a

particle with numerous significant defects is more likely to break in several stages. Complex algorithms are

used to examine the force-time characteristics of a crush and to assign an appropriate failure strength value to

the particle.

2 © ISO 2006 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TR 24857:2006(E)

5 Design of the experiments

5.1 General conditions

The Vollstädt “DiaTest-SI” system is capable of measuring the single particle strength distributions of virtually

all common grades of saw grit diamond in the common sizes. Experiments were therefore chosen to evaluate

the performance of the machine over a range of operating conditions in accordance with ISO 5725-1 and

ISO 5725-2.

a) Title: Synthetic industrial diamond grit products — Single-particle compressive failure strength —

“DiaTest-SI” system

b) Name and location of the laboratories:

⎯ Centre 1 Germany

⎯ Centre 2 Ireland

⎯ Centre 3 China

⎯ Centre 4 Germany

⎯ Centre 5 Austria

⎯ Centre 6 Germany

c) Measuring equipment: Vollstädt “DiaTest-SI” system using unified and optimized software

d) Anvil and (pneumatic) piston Each test laboratory received three sets processed from the same PCD

discs:

Abrasive, monocrystalline synthetic diamond macrogrit with the following sizes, properties and sievings:

1) high-strength grade, coarse grit (narrow sieving) 30/35 US-mesh

2) high-strength grade, medium-size grit (broad sieving) 40/50 US-mesh

3) medium-strength grade, medium-size grit (broad sieving) 40/50 US-mesh

4) low-strength grade, fine grit (broad sieving) 60/70 US-mesh

Each test laboratory was provided with three samples each of the particle sizes defined in 1) to 4), each

sample consisting with approximately 500 particles.

5.2 Additional conditions

A second phase of the study was performed in the same manner, with each laboratory receiving a further

three sets of PCD anvils and a further three sets of each of the four diamond samples.

For all tests to be carried out, the test laboratories appointed a measuring instrument operator.

The respective three sets of anvils (anvil and piston) were employed in such a manner that one set of anvils

was used for high-strength grade in size 30/35, and another set of anvils was used for the high-strength grade

in size 40/50. The third set of anvils was used to test both the medium-strength grade in size 40/50 and the

low-strength grade in size 60/70.

These test series were designed to evaluate the accuracy of the Vollstädt measuring equipment in terms of

the correctness and precision of strength measurements. The parameter to be tested was the so-called CFF

value (compressive failure force, in newtons).

© ISO 2006 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/TR 24857:2006(E)

5.3 Results

The following values were determined.

a) Mean strength, S

mean

F

∑ take out

S =

mean

n

b) Median strength, S

med

SF=

med take out, med

where

F is the compressive failure force (CFF), in newtons, remaining after all unquantifiable

take out

particle crushes (given the arbitrary strength value 9,999 N by the DiaTest-SI system)

have been removed from the data set;

F is the middle value of F when sorted in ascending order;

take out, med take out

n is the number of particles (quantifiably) tested.

NOTE If the number of F values is even, the median strength is the average of the middle pair of F

take out take out

values.

Four grades of saw grit diamond were used for the study:

• HS601: a high-strength grade, in size D601 (30/35 US mesh)

• HS427: the same high-strength grade, in size D427 (40/50 US mesh)

• MS427: a medium-strength grade, in size D427 (40/50 US mesh)

• LS251: a low-strength grade, in size D251 (60/70 US mesh)

In all four diamond grades, the particle sizing and particle strength distributions were typical of those found in

standard industrial diamond products.

For each grade, the many samples sent to the various centres were extracted from a single larger “batch”.

Each sample consisted of around 500 particles, and the sample extraction process was performed using well-

established proprietary random-splitting equipment. It is therefore believed that the best possible measures

were taken to ensure that individual samples were the same, and representative of the larger batch.

Furthermore, test centres were instructed to test all particles in a sample, rather than a fixed number, to

remove associated sample selection variations.

Six samples of each grade were analysed by each of the six centres — three samples were tested in the first

phase of the study, and the remaining three samples were tested in a subsequent second phase.

Particular efforts were made to minimise the effect of anvil variation on single particle strength results.

Polycrystalline diamond discs were carefully chosen to ensure homogeneity, processed into anvils, and

distributed to the test centres for use with specific diamond samples.

For the first phase of the study a particular disc was processed into anvils for use with the 18 samples of

HS601 (three samples for each centre), a second disc produced anvils for use with the 18 samples of HS427,

and a third disc produced anvils for the 18 samples of MS427 and the three samples of LS251. This approach

ensured that possible disc-to-disc structural variations did not affect the results either within a test centre or

4 © ISO 2006 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TR 24857:2006(E)

between test centres for a particular diamond grade. Regrettably the limited size of such polycrystalline discs

necessitated the processing of new discs for the second phase of the study. However, the same method was

used for the distribution of anvils in the second phase.

6 Assignable causes of variations in single particle strength

The results of the many tests (144 in total) were analysed with the aim of determining the general variation in

[5]

the single particle strength measurement and the “assignable causes” of the variation . Assignable causes

of variation in a measurement system may be summarized in the mnemonic:

• Man: the effect of different machine operators

• Machine: different units giving different results

• Materials: differences or inhomogeneities in the materials used in the test

• Method: differences in the measurement procedure

Some of these assignable causes were investigated by the statistical analyses of the results, whilst other

assignable causes were minimized in their effect by judicious experimental design.

The contributions to test variability of man and machine were combined by ensuring that each test centre used

only one person, operating only one “DiaTest-SI” unit, for the entire study.

The category materials should perhaps be separated into two components: the test saw grit diamond samples

and the polycrystalline diamond anvils. The contributions to test variability of the test diamond samples took

the form of systematic differences in strength between different grades, and random variations in the strength

from different samples of the same grade. The contributions to test variability of the polycrystalline diamond

anvils took the form of variations in compressive strength (or other behaviour under loading) of different anvils

from the same disc, and variations in strength between discs. As mentioned earlier, the effects of between-

disc variations were eradicated within each of the two phases of the study by the use of specific discs with

specific diamond types, and the effects of within-disc variations on results from different samples of the same

diamond type were minimized by careful selection of polycrystalline diamond discs according to their structural

homogeneity.

Finally, variations in the method were addressed by each test centre using the same, strictly defined,

measurement procedure.

7 Statistical analyses of the results

[6]

A common statistical technique for analysing an experiment such as this is analysis of variance (ANOVA) .

ANOVA evaluates differences in results in terms of the various assignable causes – if there is simply one

factor that is changed between tests (e.g. machine) then one-factor ANOVA may be employed, whilst for

changes in several factors (e.g. machine, material) multi-factor ANOVA should be employed.

In the single particle strength experiment reported here, there were three factors that changed between tests:

test centre, diamond type and run (“repeat”).

However, a fundamental requirement of ANOVA that prohibits its use for this experiment is that the random

variations within each test be normally distributed. Here, these random variations correspond to variations in

strength of the particles in each “repeat”. As will be apparent, single particle strength distributions of diamond

products are not necessarily normal (Gaussian) in form, and so the form of the basic data captured in this

study invalidates the assumptions of ANOVA. Therefore, a different statistical approach was required in order

to obtain an ANOVA-type evaluation of the important factors that contribute towards variation in single particle

strength.

© ISO 2006 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/TR 24857:2006(E)

Non-normal single particle strength distributions are best described by non-parametric statistics, and so the

median was chosen as the descriptor of distribution location, and non-parametric significance tests were used

to determine the statistical significance of differences between distributions. An introduction to distribution

statistics and an exercise to prove the appropriateness of non-parametric statistics are presented in Annex A.

Recalling Clause 6, it is expected that the assignable cause that will have the most significant effect on

strength measurements (other than the systematic differences deriving from the different diamond types) is

man/machine – other assignable causes have been hopefully minimized by careful experimental design.

Two fundamental measurement characteristics of each test centre's man/machine are precision and bias. If a

man/machine has the ability to perform repeated measurements with little variation in results, it has high

precision. If a man/machine is able to obtain a measurement result that does not differ much from the “true”

result, it has low bias. (In this study it is difficult to know the “true” strength distribution of a diamond type, so it

is taken to be the average of the distributions from all the test centres.)

The statistical analyses performed here fall into two basic categories: analyses of between-centre variations

and analyses of within-centre variations.

Between-centre variations derive from differences in strength measurement between machines of different

test centres, and so are informative of the bias of the machines. These variations were assessed by

comparing results across test centres, having firstly combined within each test centre the results from its

repeats.

Within-centre variations derive from a single machine's ability to measure results consistently, and so are

informative of the precision of the machine. These variations were assessed by considering the six repeats for

each diamond type individually, calculating the “scatter” in their results.

Further details of the analytical approaches are given in Clause 8, together with the results and discussion.

8 Results and discussion

8.1 Between-centre variation: all diamond types combined

The effect of the factor test centre (i.e. the assignable cause man/machine) was evaluated by combining all

tests performed within each test centre. Each test centre performed 24 tests (6 repeats on each of 4 diamond

types) and, when combined with equal weighting, these formed a “master” single particle strength distribution

for the test centre with a median that can be called the overall centre median.

By comparing the six overall centre medians (both in terms of simple percentage differences, and by statistical

[7]

significance tests such as the Mann-Whitney U test , described in Annex B), an appreciation of the

fundamental differences in the results from each test centre (i.e. the underlying bias in the test centre's

man/machine) was obtained. For ease of reference, all figures associated with between-centre variations are

found in Annex C.

Table C.1 shows that the “master” distributions from each of the six centres were quite similar in terms of their

th

principal statistics (in this table and others of a similar format, “P10” is used as an abbreviation of “10

percentile”, and so on). The medians of these distributions, the six overall centre medians, all lay within

approximately ±2 % of the average overall centre median (found in the right column of the table).

Mann-Whitney U tests were performed to determine which overall centre medians were statistically

significantly different from each other. The results are presented in Table C.6. As Annex B explains, a p value

of less than 0,05 indicates a statistically significant difference (at the 95 % confidence level) between the two

medians being compared.

Here, it was found that in 5 (out of the possible 15) comparisons the two medians were statistically

significantly different. Whilst this initially seemed a surprisingly high number (given the apparent similarities

between the distributions), it was most probably due to the high number (many thousands) of strength values

6 © ISO 2006 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TR 24857:2006(E)

in each “master” distribution — as the sample size increases so does the confidence in the results, and hence

even minor differences can become statistically significant.

th th th

In summary, perhaps the only notable case of bias in a test centre was that of Centre 1: the 10 , 25 and 90

percentiles of Centre 1 were higher than those of the other centres, and 4 of the 5 statistically significant

differences between medians involved the median of Centre 1.

8.2 Between-centre variation: individual diamond types

Similar analyses were performed on individual diamond types — within each test centre the six repeats on a

particular diamond type were combined to form a larger data set. By comparing the data sets from the six test

centres, the bias of each test centre as a function of diamond type was examined. In other words, perhaps a

particular test centre had a man/machine that showed systematic bias when measuring a particular diamond

type. The equivalent study in ANOVA would be the interaction between test centre and diamond type.

Tables C.2 and C.7 show the distribution statistics and Mann-Whitney U test p values respectively for the

diamond type HS601. The differences between the medi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.