ISO/FDIS 24443

(Main)Cosmetics -- Determination of sunscreen UVA photoprotection in vitro

Cosmetics -- Determination of sunscreen UVA photoprotection in vitro

Cosmétiques -- Détermination in vitro de la photoprotection UVA

General Information

RELATIONS

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 24443

ISO/TC 217

Cosmetics — Determination of

Secretariat: INSO

sunscreen UVA photoprotection in

Voting begins on:

20210722 vitro

Voting terminates on:

Cosmétiques — Détermination in vitro de la photoprotection UVA

20210916

ISO/CEN PARALLEL PROCESSING

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/FDIS 24443:2021(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. ISO 2021

---------------------- Page: 1 ----------------------

ISO/FDIS 24443:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 24443:2021(E)

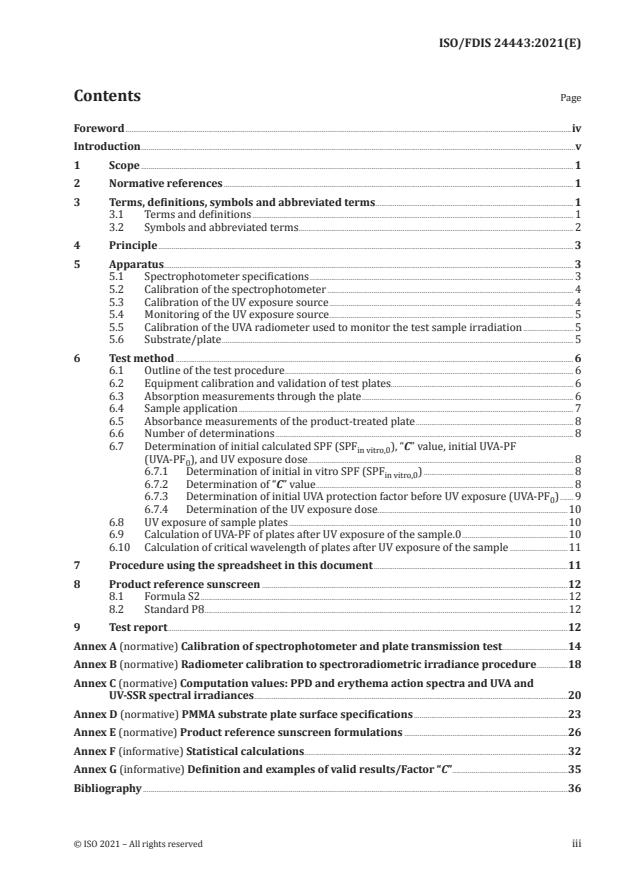

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms, definitions, symbols and abbreviated terms ....................................................................................................... 1

3.1 Terms and definitions ....................................................................................................................................................................... 1

3.2 Symbols and abbreviated terms............................................................................................................................................... 2

4 Principle ........................................................................................................................................................................................................................ 3

5 Apparatus ..................................................................................................................................................................................................................... 3

5.1 Spectrophotometer specifications ......................................................................................................................................... 3

5.2 Calibration of the spectrophotometer ................................................................................................................................ 4

5.3 Calibration of the UV exposure source ............................................................................................................................... 4

5.4 Monitoring of the UV exposure source ............................................................................................................................... 5

5.5 Calibration of the UVA radiometer used to monitor the test sample irradiation .......................... 5

5.6 Substrate/plate ....................................................................................................................................................................................... 5

6 Test method ............................................................................................................................................................................................................... 6

6.1 Outline of the test procedure ...................................................................................................................................................... 6

6.2 Equipment calibration and validation of test plates............................................................................................... 6

6.3 Absorption measurements through the plate .............................................................................................................. 6

6.4 Sample application .............................................................................................................................................................................. 7

6.5 Absorbance measurements of the producttreated plate .................................................................................. 8

6.6 Number of determinations ........................................................................................................................................................... 8

6.7 Determination of initial calculated SPF (SPF ), “C” value, initial UVAPFin vitro,0

(UVAPF ), and UV exposure dose .......................................................................................................................................... 8

6.7.1 Determination of initial in vitro SPF (SPF ) .............................................................................. 8

in vitro,06.7.2 Determination of “C” value ...................................................................................................................................... 8

6.7.3 Determination of initial UVA protection factor before UV exposure (UVA-PF ) ....... 9

6.7.4 Determination of the UV exposure dose...................................................................................................10

6.8 UV exposure of sample plates .................................................................................................................................................10

6.9 Calculation of UVA-PF of plates after UV exposure of the sample.0 .......................................................10

6.10 Calculation of critical wavelength of plates after UV exposure of the sample ..............................11

7 Procedure using the spreadsheet in this document .....................................................................................................11

8 Product reference sunscreen ...............................................................................................................................................................12

8.1 Formula S2 ...............................................................................................................................................................................................12

8.2 Standard P8 .............................................................................................................................................................................................12

9 Test report ................................................................................................................................................................................................................12

Annex A (normative) Calibration of spectrophotometer and plate transmission test ..................................14

Annex B (normative) Radiometer calibration to spectroradiometric irradiance procedure ................18

Annex C (normative) Computation values: PPD and erythema action spectra and UVA and

UV‑SSR spectral irradiances ...................................................................................................................................................................20

Annex D (normative) PMMA substrate plate surface specifications ................................................................................23

Annex E (normative) Product reference sunscreen formulations .....................................................................................26

Annex F (informative) Statistical calculations .........................................................................................................................................32

Annex G (informative) Definition and examples of valid results/Factor “C” ............................................................35

Bibliography .............................................................................................................................................................................................................................36

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 24443:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and nongovernmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 217 Cosmetics, in collaboration with

the European Committee for Standardization (CEN) Technical Committee CEN/TC 392, Cosmetics, in

accordance with the Agreement on technical cooperation between ISO and CEN (Vienna Agreement).

This second edition cancels and replaces the first edition (ISO 24443:2012), which has been technically

revised.The main changes compared to the previous edition are as follows:

— acceptance of moulded and sandblasted PMMA plates, according to specifications described in

Annex D;— product application fitted to 1,2mg/cm for sandblasted plates;

— description of application gesture according to tested products;

— introduction of a new high UVA PF standard P8;

— introduction of critical wavelength calculation;

— calculation of coefficient "C"accepted from in vivo screening SPF, with specific conditions based on

SEM and percentage of variability, and new range proposed from 0,6 to 1,6;— limitation of UVA irradiation dose to 36 J/cm .

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 24443:2021(E)

Introduction

This document specifies the procedure to determine the ultraviolet protection factor (UVA-PF) of a

sunscreen product using the in vitro UVA-PF according to the principles recommended by the European

Cosmetic and Perfumery Association (COLIPA) in 2011. The outcome of this test method can be used

to determine the UVA classification of topical sunscreen products according to local regulatory

requirements.Topical sunscreen products are primarily rated and labelled according to their ability to protect against

sunburn, using a test method to determine the in vivo sun protection factor (see ISO 24444). This

rating evaluates filtration of sunburn generating radiation across the electromagnetic UV spectrum

(290 nm to 400 nm). However, knowledge of the sun protection factor (SPF) rating does not provide

explicit information on the magnitude of the protection provided specifically in the UVA range of

the spectrum (320 nm to 400 nm), as it is possible to have high SPF products with very modest UVA

protection (e.g. SPF 50 with a UVA-PF of only 3 to 4). There is a demand among medical professionals,

as well as knowledgeable consumers, to have fuller information on the UVA protection provided by

their sunscreen product, in addition to the SPF, in order to make a more informed choice of product,

providing a more balanced and broaderspectrum protection. Moreover, there is also a demand to

prevent UVAinduced darkening of the skin from a cultural point of view even without sunburn. The

UVA-PF value of a product provides information on the magnitude of the protection provided explicitly

in the UVA portion of the spectrum, independent of the SPF values.The test method outlined in this document is derived primarily from the in vitro UVA-PF test method as

developed by COLIPA.© ISO 2021 – All rights reserved v

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 24443:2021(E)

Cosmetics — Determination of sunscreen UVA

photoprotection in vitro

1 Scope

This document specifies an in vitro procedure to characterize the UVA protection of sunscreen

products. Specifications are given to enable determination of the spectral absorbance characteristics of

UVA protection in a reproducible manner.In order to determine relevant UVA protection parameters, the method has been created to provide an

UV spectral absorbance curve from which a number of calculations and evaluations can be undertaken.

These include calculation of the UltravioletA protection factor (UVAPF) [correlating with in vivo

UVAPF from the persistent pigment darkening (PPD) testing procedure], critical wavelength and UVA

absorbance proportionality. These computations are optional and relate to local sunscreen product

labelling requirements. This method relies on the use of static in vivo SPF results for scaling the UV

absorbance curve.This document is not applicable to powder products such as pressed powder and loose powder products.

2 Normative referencesThere are no normative references in this document.

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1.1

ultraviolet radiation

electromagnetic radiation in the range of 290 nm to 400 nm

3.1.2

UVB

ultraviolet B

electromagnetic radiation in the range of 290 nm to 320 nm

3.1.3

UVA

ultraviolet A

electromagnetic radiation in the range of 320 nm to 400 nm

Note 1 to entry: UVA II = 320 nm to 340 nm; UVA I = 340 nm to 400 nm.

© ISO 2021 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/FDIS 24443:2021(E)

3.1.4

spectral absorbance

ai(λ)

logarithm to base 10 of the reciprocal of the spectral internal transmittance, ai(λ)=−log10 τi(λ)

Note 1 to entry: In the context of this standard the absorption or transmission of sunscreen is used.

3.1.5irradiance

fluence rate per unit area, expressed in W/m , for a defined range of wavelengths

Note 1 to entry: From 290 nm to 400 nm for UVA + UV-B irradiance; from 320 nm to 400 nm for UVA irradiance.

3.1.6spectral irradiance

I(λ)

irradiance (3.1.5) per unit wavelength, I(λ), expressed in W/m /nm

Note 1 to entry: Spectral irradiance can refer to PPD testing or SPF testing.

3.1.7

spectrophotometer

equipment for measuring the reflection or transmission properties of a material as a function of

wavelength limited to ultraviolet, visible and short infrared ranges in this document

3.1.8spectroradiometer

device designed to measure the spectral density of illuminants

3.1.9

radiometer

device for measuring the radiant flux (power) of electromagnetic radiation

3.1.10

product reference sunscreen

reference sunscreen product used to validate the testing procedure

3.1.11

solar simulator

equipment used to simulate the solar irradiance and spectrum

3.1.12

plate

substrate

material to which the test product is to be applied

3.2 Symbols and abbreviated terms

3.2.1

UVA-PF

in vitro ultraviolet A protection factor

in vitro UVA protection factor of a sun protection product against UVA radiation, which can be derived

mathematically with in vitro spectral modelling3.2.2

SPF

in vitro

in vitro sun protection factor

in vitro protection factor of a sun protection product against erythema-inducing radiation calculated

with spectral modelling2 © ISO 2021 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 24443:2021(E)

3.2.3

critical wavelength

CWL

wavelength at which the area under the absorbance curve represents 90 % of the total area under the

curve in the UV regionNote 1 to entry: Calculated from spectral data.

3.2.4

erythema action spectrum

E(λ)

relative effects of individual spectral bands of an exposure source for an erythema response

3.2.5PPD action spectrum

P(λ)

relative effects of individual spectral bands of an exposure source for a persistent pigment response

4 PrincipleThe test is based on the assessment of UV-transmittance through a thin film of sunscreen sample spread

on a roughened substrate, before and after exposure to a controlled dose of radiation from a defined UV

exposure source.Because of several variables that cannot be controlled with typical thin film spectroscopic techniques,

each set of sunscreen transmission data is mathematically adjusted so that the in vitro SPF data yield

the same measured in vivo SPF value that was determined by in vivo testing. As in vivo method can

raise ethical consideration, any alternative SPF method, published as an ISO method, may be used.

Samples are exposed to a specific measured dose of UV radiation to account for the photostability

characteristics of the test product.The resulting spectral absorbance data have been shown to be a useful representation of both the

width and height of the UVA protection characteristics of the sunscreen product being tested. The

mathematical modelling procedure has been empirically derived to correlate with human in vivo

(persistent pigment darkening) test results.5 Apparatus

5.1 Spectrophotometer specifications

The spectrophotometer wavelength range shall span the primary waveband of 290 nm to 400 nm. The

wavelength increment step shall be 1 nm.A spectrophotometer that does not have a monochromator after the test sample should employ a

fluorescence rejection filter.The spectrophotometer input optics should be designed for diffuse illumination and/or diffuse

collection of the transmitted irradiance through the roughened polymethylmethacrylate (PMMA)

substrate, with and without the sunscreen layer spread on its surface.The size of the diameter of the entrance port of the spectrophotometer probe shall be smaller than the

size of the light spot to be measured at the sample level (in order to account for stray light).

The area of each reading site should be at least 0,5 cm in order to reduce the variability between

readings and to compensate for the lack of uniformity in the product layer.© ISO 2021 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/FDIS 24443:2021(E)

The wavelength should be accurate to within 1 nm, as checked using a holmium-doped filter (see

Annex A). The ability of an instrument to accurately measure absorbance is limited by the sensitivity of

the instrument. The minimum required dynamic range for this methodology is 2,2 absorbance units as

determined according to Annex A.The maximum measured absorbance should be within the dynamic range of the device used. If

the test measurements yield absorbance curves that exceed the determined upper limit of the

spectrophotometer, the product should be re-tested using an instrument with increased sensitivity and

dynamic range.The lamp in the spectrophotometer that is used to measure the transmittance shall emit continuous

radiation over the range of 290 nm to 400 nm, and the level of irradiance should be sufficiently low, so

that the photostability of the product is not unduly challenged (a xenon lamp is a convenient solution).

Therefore, the UV dose during one measurement cycle should not exceed 0,2 J/cm .NOTE A spectrophotometer is used to measure the absorbance properties of the sunscreen on the test

plates. A spectroradiometer is used to measure the spectral energy distribution and intensity of the UV exposure

source or the spectrophotometer during the absorbance measurement of the sunscreen on the test plate.

Coupled with an UV source, the spectroradiometer can give similar results to a spectrophotometer.

5.2 Calibration of the spectrophotometerThe spectrophotometer shall be validated every month by measurements of reference materials.

A three-fold test is required, as described in Annex A:— dynamic range of the spectrophotometer;

— linearity test of the spectrophotometer;

— wavelength accuracy test.

5.3 Calibration of the UV exposure source

The spectral irradiance at the exposure plane of the UV exposure source that is used for irradiation

(to take into account any photoinstability) shall be as similar as possible to the irradiance at ground

[1] [2]level under a standard zenith sun. As defined by COLIPA, the reference standard sun has a total

2 2irradiance of 51,4 W/m to 63,7 W/m and a UVA to UVB irradiance ratio of 16,9 to 17,5.

Therefore, the UV irradiance shall be within the following acceptance limits (measured at sample

distance).Table 1 — UV exposure source specifications

UV exposure source specifications as measured with a spectroradiometer

2 2

Total UV irradiance (290 nm to 400 nm) 40 W/m to 200 W/m

a b

Irradiance ratio of UVA to UVB 1122

320 nm to 400 nm.

290 nm to 320 nm.

In broadbeam UVsources, spectra from different locations under the beam shall be recorded over at

least 5 different locations (a location is defined for each plate) in order to account for uniformity.

4 © ISO 2021 – All rights reserved---------------------- Page: 9 ----------------------

ISO/FDIS 24443:2021(E)

The uniformity shall be ≥ 90 % as calculated by Formula (1):

U = (1-(max-min)/(X̅)) (1)

where

U is the uniformity in percentage;

X̅ is the average.

If the uniformity is less than 90 %, then optical components should be adjusted or appropriate

compensation for different irradiance shall be made in the exposure time on each plate.

The UV exposure source device should have the ability to maintain samples within the range of

27 °C (±2 °C) to 32 °C (±2 °C). It is important that the temperature of the sample itself on the plate

shall be measured and not just the surrounding air temperature. Therefore, the measurement of the

temperature shall be on plate level.To maintain samples at required temperature, a filter system that particularly reduces infrared

radiation shall be used to achieve the specified temperature range. Cooling trays for the sample plates

or ventilators shall be used to maintain a temperature lower than 32 °C (±2 °C) and warming devices to

maintain samples at or above 27 °C (±2 °C).Measurement should be made using a sensor that is traceable to a national or an international

calibration standard, within the range of use.5.4 Monitoring of the UV exposure source

The emission of the UV exposure source used for exposure shall be checked for compliance with the

given acceptance limits by a suitably qualified expert (at least) every 12 months, or 2 500 h of lamp

running time. The inspection should be conducted with a spectroradiometer that has been calibrated

against a standard lamp that is traceable to a national or an international calibration standard. In

addition to the spectroradiometric inspection, the intensity of the UV exposure source used for

exposure shall be checked prior to each use.This can be done using either a spectroradiometer or a radiometer with sensitivity in the UVA,

calibrated for the same UV exposure source spectrum used for the exposure step of the procedure,

applying the coefficient of calibration to adjust for variance between the UVA radiometer and the

reference spectroradiometer.5.5 Calibration of the UVA radiometer used to monitor the test sample irradiation

If a UVA radiometer is used, this device shall be suitably calibrated. This requires that it is calibrated

with the UVA irradiance measurement results of the spectroradiometer used to measure the exposure

source (as during annual solar simulator calibration).Calibration shall be conducted in terms of UVA irradiance (320 nm to 400 nm) in accordance with

Annex B and shall be at the same level at which the test plates are exposed. Once calibrated with the

spectroradiometer, the UVA radiometer may be used to determine the UV doses to be used during the

exposure procedure on a day-to-day basis.5.6 Substrate/plate

The substrate/plate is the material to which the test product is to be applied. For this method, PMMA

plates with one rough side of the substrate shall be used and are commercially available. The size of the

substrate should be chosen such that the application area is not less than 16 cm .

[9][18]The specifications and preparation of this type of plate are described in Annex D.

© ISO 2021 – All rights reserved 5---------------------- Page: 10 ----------------------

ISO/FDIS 24443:2021(E)

6 Test method

6.1 Outline of the test procedure

6.1.1 Conduct the calibration and validation of the test equipment, including the spectrophotometer

used for transmission/absorbance measurements and the UVA radiometer (or spectroradiometer)

used to measure the UV exposure source. Verify the transmission properties of the test plates batch as

described in Annex D.6.1.2 Conduct blank measurements of a glycerin-treated or Vaseline treated plate for the reference

“blank”, which will be used in the subsequent absorbance measurements.6.1.3 Conduct in vitro absorbance measurements of the sunscreen product spread on a PMMA plate,

prior to any UV irradiation. Acquire the initial mAF spectrum with A0(λ) data, where mAF (=10^A)

6.1.4 Conduct the mathematical adjustment of the initial UV absorbance spectrum using coefficient “C”

[see formula (2) the calculation in 6.7.2] to achieve an in vitro SPF (no UV dose) equal to the measured

static in vivo SPF. Initial UVAPF is calculated using A (λ) and C. A single UV exposure dose, D, is

0 0calculated, equal to 1,2 × UVA-PF in J/cm , for each plate.

6.1.5 Conduct UV exposure of the same sample as in 6.1.3, according to the calculated UV exposure

dose D.6.1.6 Measure the in vitro absorbance of the sunscreen product after UV exposure. Acquire the second

UV spectrum with A(λ) data.6.1.7 Conduct the mathematical adjustment of the second mAF spectrum (following UV exposure) by

multiplying with the same coefficient “C”, previously determined in 6.1.4. The resulting absorbance curve

is the final adjusted absorbance values.6.2 Equipment calibration and validation of test plates

Test procedures as described in Annex A are to be completed to validate the wavelength accuracy,

linearity and absorbance limits of the spectrophotometer/spectroradiometer to be used for the test

procedure. Validation of the UV properties of the test PMMA plates batch shall also be conducted as

described in Annex D.6.3 Absorption measurements through the plate

It is necessary to first determine the absorbance of UV radiation through a “blank” PMMA plate.

Prepare a “blank” plate by spreading a few microlitres of glycerin/Vaseline on the roughened side

of the plate. Choose the amount of glycerine/vaseline such that the entire surface is just completely

covered (approximately 15 μl for a 50 mm × 50 mm plate).Any excess of glycerine/vaseline should be avoided. Measure the absorbance through this “blank”

plate and use this as the baseline measurement for subsequent absorbance measurements.

Measurements shall be performed on same type of p...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.