ISO 11794:2017

(Main)Copper, lead, zinc and nickel concentrates — Sampling of slurries

Copper, lead, zinc and nickel concentrates — Sampling of slurries

ISO 11794:2017 sets out the basic methods for sampling particulate material that is mixed with a liquid, usually water, to form a slurry. In industry and in the mining and mineral processing literature, slurry is also referred to as pulp, but this term is not used in ISO 11794:2017. At very high ratios of fine particulate solids to liquids where material assumes a soft plastic form, the mixture is correctly termed as a paste. Sampling of pastes is not covered in ISO 11794:2017. The procedures described in ISO 11794:2017 apply to sampling of particulate materials that are transported in moving streams as slurries, but not pressurized slurries. These streams may fall freely or be confined in pipes, launders, flumes, sluices, spirals or similar channels. Sampling of slurries in stationary situations, such as a settled or even a well-stirred slurry in a holding vessel or dam, is not recommended and is not covered in ISO 11794:2017. ISO 11794:2017 describes procedures that are designed to provide samples representative of the slurry solids and particle-size distribution of the slurry under examination. After draining the slurry sample of fluid and measuring the fluid volume, damp samples of the contained particulate material in the slurry are available for drying (if required) and measurement of one or more characteristics in an unbiased manner and with a known degree of precision. The characteristics are measured by chemical analysis, physical testing or both. The sampling methods described are applicable to slurries that require inspection to verify compliance with product specifications, determination of the value of a characteristic as a basis for settlement between trading partners or estimation of a set of average characteristics and variances that describes a system or procedure. Provided that flow rates are not too high, the reference method against which other sampling procedures are compared is one where the entire stream is diverted into a vessel for a specified time or volume interval. This method corresponds to the stopped-belt method described in ISO 12743.

Concentrés de cuivre, de plomb, de zinc et de nickel — Échantillonnage des schlamms

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11794

Second edition

2017-06

Copper, lead, zinc and nickel

concentrates — Sampling of slurries

Concentrés de cuivre, de plomb, de zinc et de nickel —

Échantillonnage des schlamms

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

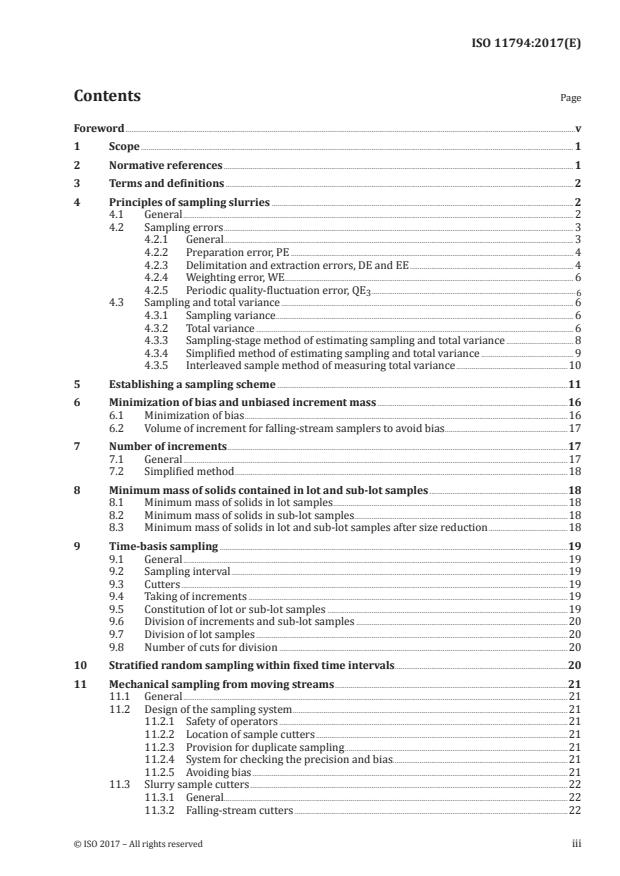

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Principles of sampling slurries . 2

4.1 General . 2

4.2 Sampling errors . 3

4.2.1 General. 3

4.2.2 Preparation error, PE . 4

4.2.3 Delimitation and extraction errors, DE and EE . 4

4.2.4 Weighting error, WE . 6

4.2.5 Periodic quality-fluctuation error, QE .

3 6

4.3 Sampling and total variance . 6

4.3.1 Sampling variance. 6

4.3.2 Total variance . 6

4.3.3 Sampling-stage method of estimating sampling and total variance . 8

4.3.4 Simplified method of estimating sampling and total variance . 9

4.3.5 Interleaved sample method of measuring total variance .10

5 Establishing a sampling scheme .11

6 Minimization of bias and unbiased increment mass .16

6.1 Minimization of bias .16

6.2 Volume of increment for falling-stream samplers to avoid bias.17

7 Number of increments .17

7.1 General .17

7.2 Simplified method .18

8 Minimum mass of solids contained in lot and sub-lot samples .18

8.1 Minimum mass of solids in lot samples .18

8.2 Minimum mass of solids in sub-lot samples .18

8.3 Minimum mass of solids in lot and sub-lot samples after size reduction .18

9 Time-basis sampling .19

9.1 General .19

9.2 Sampling interval .19

9.3 Cutters .19

9.4 Taking of increments .19

9.5 Constitution of lot or sub-lot samples .19

9.6 Division of increments and sub-lot samples .20

9.7 Division of lot samples .20

9.8 Number of cuts for division .20

10 Stratified random sampling within fixed time intervals.20

11 Mechanical sampling from moving streams .21

11.1 General .21

11.2 Design of the sampling system .21

11.2.1 Safety of operators .21

11.2.2 Location of sample cutters .21

11.2.3 Provision for duplicate sampling .21

11.2.4 System for checking the precision and bias.21

11.2.5 Avoiding bias .21

11.3 Slurry sample cutters .22

11.3.1 General.22

11.3.2 Falling-stream cutters .22

11.3.3 Cutter velocities .23

11.4 Mass of solids in increments .23

11.5 Number of primary increments .23

11.6 Routine checking .23

12 Manual sampling from moving streams .23

12.1 General .23

12.2 Choosing the sampling location .24

12.3 Sampling implements .24

12.4 Mass of solids in increments .25

12.5 Number of primary increments .25

12.6 Sampling procedures .25

13 Sampling of stationary slurries .25

14 Sample preparation .25

14.1 General .25

14.2 Sample division.25

14.3 Sample grinding .26

14.4 Chemical analysis samples . .26

14.5 Physical test samples .26

15 Packing and marking of samples .26

Annex A (normative) Sampling-stage method for estimating sampling and total variance .27

Annex B (informative) Examples of correct slurry sampling devices .34

Annex C (informative) Examples of incorrect slurry sampling devices .37

Annex D (normative) Manual sampling implements .41

Bibliography .42

iv © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO tec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.