ISO/TR 20882:2007

(Main)Footwear — Performance requirements for components for footwear — Lining and insocks

Footwear — Performance requirements for components for footwear — Lining and insocks

ISO/TR 20882:2007 establishes the performance requirements for lining and insock components for footwear (not for finished footwear), irrespective of the material, in order to assess the suitability for the end use and/or fitness for purpose. It also establishes the test methods to be used to evaluate the compliance with the requirements. This Technical Report applies to lining and insocks for various kinds of footwear. ISO/TR 20882:2007 is intended to be used as a reference between the manufacturer and the supplier. It is not intended for third party certification.

Chaussures — Exigences de performance pour les composants des chaussures — Doublures et premières de propreté

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 20882

First edition

2007-02-15

Footwear — Performance requirements

for components for footwear — Lining

and insocks

Chaussures — Exigences de performance pour les composants des

chaussures — Doublures et premières de propreté

Reference number

ISO/TR 20882:2007(E)

©

ISO 2007

---------------------- Page: 1 ----------------------

ISO/TR 20882:2007(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2007 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 20882:2007(E)

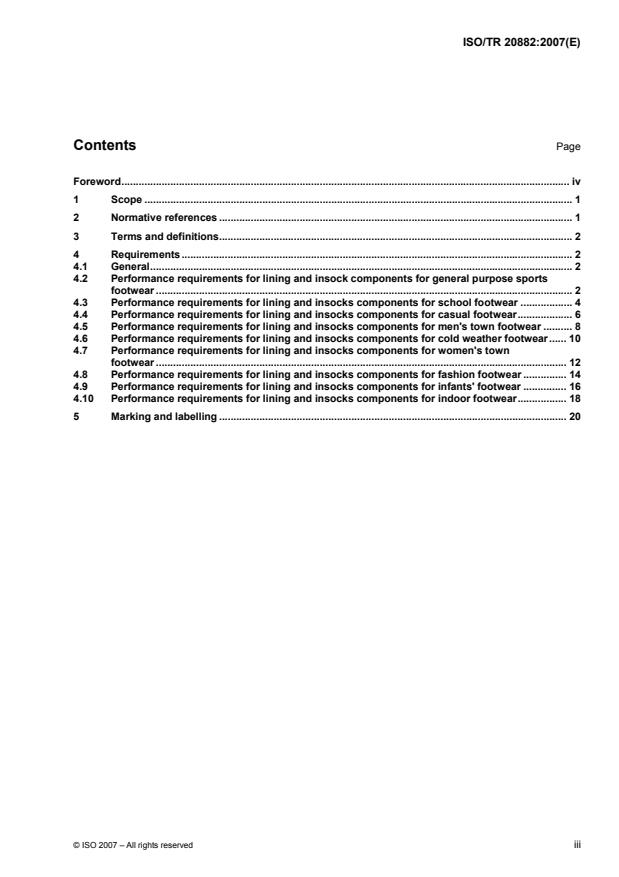

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 2

4 Requirements . 2

4.1 General. 2

4.2 Performance requirements for lining and insock components for general purpose sports

footwear . 2

4.3 Performance requirements for lining and insocks components for school footwear . 4

4.4 Performance requirements for lining and insocks components for casual footwear. 6

4.5 Performance requirements for lining and insocks components for men's town footwear . 8

4.6 Performance requirements for lining and insocks components for cold weather footwear. 10

4.7 Performance requirements for lining and insocks components for women's town

footwear . 12

4.8 Performance requirements for lining and insocks components for fashion footwear . 14

4.9 Performance requirements for lining and insocks components for infants' footwear . 16

4.10 Performance requirements for lining and insocks components for indoor footwear. 18

5 Marking and labelling . 20

© ISO 2007 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 20882:2007(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 20882 was prepared by the European Committee for Standardization (CEN) Technical Committee

CEN/TC 309, Footwear, in collaboration with Technical Committee ISO/TC 216, Footwear, in accordance with

the Agreement on technical cooperation between ISO and CEN (Vienna Agreement).

iv © ISO 2007 – All rights reserved

---------------------- Page: 4 ----------------------

TECHNICAL REPORT ISO/TR 20882:2007(E)

Footwear — Performance requirements for components for

footwear — Lining and insocks

1 Scope

This Technical Report establishes the performance requirements for lining and insock components for

footwear (not for finished footwear), irrespective of the material, in order to assess the suitability for the end

use and/or fitness for purpose. It also establishes the test methods to be used to evaluate the compliance with

the requirements.

This Technical Report applies to lining and insocks for all kinds of footwear as defined in Clause 3.

This Technical Report is intended to be used as a reference between the manufacturer and the supplier. It is

not intended for third party certification.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 31-0, Quantities and units — Part 0: General principles

ISO 17694, Footwear — Test methods for uppers and lining — Flex resistance

ISO 17696, Footwear — Test methods for uppers, lining and insocks — Tear strength

ISO 17697, Footwear — Test methods for uppers, lining and insocks — Seam strength

ISO 17699, Footwear — Test methods for uppers and lining — Water permeability and absorption

EN ISO 17700, Footwear — Test methods for uppers, linings and insocks — Colour fastness to rubbing

ISO 17704, Footwear — Test methods for uppers, lining and insocks — Abrasion resistance

ISO 17705, Footwear — Test methods for uppers, lining and insocks — Thermal insulation

ISO 17709, Footwear — Sampling location, preparation and duration of conditioning of samples and test

pieces

EN ISO 19952, Footwear — Vocabulary

ISO 20869, Footwear — Test methods for outsoles, insoles, lining and insocks — Water soluble content

ISO 22649, Footwear — Test methods for insoles and insocks — Water absorption and desorption

ISO 22652, Footwear — Test methods for insoles, lining and insocks — Perspiration resistance

ISO 22653, Footwear — Test methods for lining and insocks — Static friction

© ISO 2007 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/TR 20882:2007(E)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 19952 apply.

4 Requirements

4.1 General

This Technical Report establishes two different types of performance requirement.

The essential requirements shall all be taken into account. The additional ones can be additionally agreed by

the component supplier and the footwear manufacturer as indicated in 4.2 to 4.10.

The results of each single analytical determination, as well as the average values, shall be rounded off in

accordance with ISO 31-0.

When taken from finished footwear, samples shall be prepared in accordance with ISO 17709.

4.2 Performance requirements for lining and insock components for general purpose

sports footwear

4.2.1 Essential requirements (lining)

These essential requirements shall be fulfilled in all cases. See Table 1.

Table 1 — Test methods and properties for general sports footwear — Essential requirements

for linings

Test method Property Requirement

ISO 17696 Tear strength lining W 15 N

reinforcing lining W 20 N (if it applies)

ISO 17697 Lining seam method A W 4,0 N/mm

strength

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution

ISO 17704 Abrasion 25 600 cycles dry without hole through the thickness of the material

resístance component

12 800 cycles wet

2 © ISO 2007 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/TR 20882:2007(E)

4.2.2 Essential requirements (insocks)

These essential requirements shall be fulfilled in all cases. See Table 2.

Table 2 — Test methods and properties for general sports footwear — Essential requirements

for insocks

Test method Property Requirement

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution

ISO 17704 Abrasion 25 600 cycles dry

resístance

12 800 cycles wet

2

ISO 22649 Insocks water (method B) absorption W 70 mg/cm

absorption and

desorption W 60 %

desorption

4.2.3 Additional requirements (lining)

These additional requirements should be agreed by both component supplier and footwear manufacturer.

See Table 3.

Table 3 — Test methods and properties for general sports footwear — Additional requirements

for linings

Subclause Test method Property Requirement

2

4.2.3.1 ISO 17699 Lining water vapour WVP W 2,0 mg/cm .h

permeability and

2

if WVP of upper < 0,8 mg/cm .h then

absorption

2

WVA of lining W 8,0 mg/cm

4.2.3.2 ISO 20869 Water soluble u 1,5 % sulfated ashed water soluble (SAWS)

substances content

u 16 % total water soluble (TWS)

a

(testing not necessary to certain lining materials)

4.2.3.3 ISO 22652 Perspiration resistance After five cycles the component shall not develop any cracks

when bent, and must keep 80 % tear resistance

a

(testing not necessary to certain lining materials)

4.2.3.4 ISO 22653 Static friction W 0,7

4.2.3.5 ISO 17694 Flex resistance dry 15 000 cycles without visible damage

a

This requirement is considered essential for leather.

© ISO 2007 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/TR 20882:2007(E)

4.2.4 Additional requirements (insocks)

These additional requirements should be agreed by both component supplier and footwear manufacturer.

See Table 4.

Table 4 — Test methods and properties for general sports footwear — Additional requirements

for insocks

Subclause Test method Property Requirement

4.2.4.1 ISO 20869 Water soluble u 1,5 % sulfated ashed water soluble (SAWS)

substances content

u 16 % total water solubles (TWS)

a

(testing not necessary to certain insocks materials)

4.2.4.2 ISO 22652 Perspiration resistance After five cycles the component shall not develop any cracks

when bent, and must keep 80 % tear resistance

(testing not necessary to certain insocks materials)

4.2.4.3 ISO 22653 Static friction W 0,7

4.2.4.4 ISO 17694 Flex resistance dry 15 kc without visible damage

4.2.4.5 ISO 17696 Tear strength insocks W 15 N

a

This requirement is considered essential for leather.

4.3 Performance requirements for lining and insocks components for school footwear

4.3.1 Essential requirements (lining)

These essential requirements shall be fulfilled in all cases. See Table 5.

Table 5 — Test methods and properties for school footwear — Essential requirements for linings

Test method Property Requirement

ISO 17696 Tear strength lining W 15 N

reinforcing lining W 20 N (if it applies)

ISO 17697 Lining seam method A W 3,5 N/mm

strength

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution

ISO 17704 Abrasion 25 600 cycles dry without hole through the thickness of the

resístance material component

12 800 cycles wet

4 © ISO 2007 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TR 20882:2007(E)

4.3.2 Essential requirements (insocks)

These essential requirements shall be fulfilled in all cases. See Table 6.

Table 6 — Test methods and properties for school footwear — Essential requirements for insocks

Test method Property Requirement

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution

ISO 17704 Abrasion resistance 25 600 cycles dry

12 800 cycles wet

2

ISO 22649 Insocks water (method B) absorption W 70 mg/cm

absorption

desorption W 60 %

and desorption

4.3.3 Additional requirements (lining)

These additional requirements should be agreed by both component supplier and footwear manufacturer.

See Table 7.

Table 7 — Test methods and properties for school footwear — Additional requirements for linings

Subclause Test method Property Requirement

2

4.3.3.1 ISO 17699 Lining water vapour WVP W 2,0 mg/cm .h

permeability and

2

if WVP of upper < 0,8 mg/cm .h then

absorption

2

WVA of lining W 8,0 mg/cm

4.3.3.2 ISO 20869 Water soluble u 1,5 % sulfated ashed water soluble (SAWS)

substances content

u 16 % total water soluble, (TWS)

a

(testing not necessary to certain lining materials)

4.3.3.3 ISO 22652 Perspiration resistance After three cycles the component shall not develop any

cracks when bent, and must keep 80 % tear resistance

(testing not necessary to certain lining materials)

4.3.3.4 ISO 22653 Static friction W 0,7

4.3.3.5 ISO 17694 Flex resistance dry 15 000 cycles without visible damage

a

This requirement is considered essential for leather.

© ISO 2007 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO/TR 20882:2007(E)

4.3.4 Additional requirements (insocks)

These additional requirements should be agreed by both component supplier and footwear manufacturer.

See Table 8.

Table 8 — Test methods and properties for school footwear — Additional requirements for insocks

Subclause Test method Property Requirement

4.3.4.1 ISO 20869 Water soluble u 1,5 % sulfated ashed water soluble (SAWS)

substances content

u 16 % total water soluble (TWS)

a

(testing not necessary to certain insocks materials)

4.3.4.2 ISO 22652 Perspiration resistance After three cycles the component shall not develop any

cracks when bent, and must keep 80 % tear resistance

(testing not necessary to certain insocks materials)

4.3.4.3 ISO 22653 Static friction W 0,7

4.3.4.4 ISO 17694 Flex resistance dry 15 000 cycles without visible damage

4.3.4.5 ISO 17696 Tear strength insocks W 15 N

a

This requirement is considered essential for leather.

4.4 Performance requirements for lining and insocks components for casual footwear

4.4.1 Essential requirements (lining)

These essential requirements shall be fulfilled in all cases. See Table 9.

Table 9 — Test methods and properties for casual footwear — Essential requirements for linings

Test method Property Requirement

ISO 17696 Tear strength lining W 15 N

reinforcing lining W 20 N (if it applies)

ISO 17697 Lining seam method A W 4,0 N/mm

strength

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution.

ISO 17704 Abrasion 25 600 cycles dry without hole through the thickness of the

resístance material component

12 800 cycles wet

6 © ISO 2007 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TR 20882:2007(E)

4.4.2 Essential requirements (insocks)

These essential requirements shall be fulfilled in all cases. See Table 10.

Table 10 — Test methods and properties for casual footwear — Essential requirements for insocks

Test method Property Requirement

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution.

ISO 17704 Abrasion resistance 25 600 cycles dry

12 800 cycles wet

2

ISO 22649 Insocks water (method B) absorption W 70 mg/cm

absorption

desorption W 60 %

and desorption

4.4.3 Additional requirements (lining)

These additional requirements should be agreed by both component supplier and footwear manufacturer.

See Table 11.

Table 11 — Test methods and properties for casual footwear — Additional requirements for linings

Subclause Test method Property Requirement

2

4.4.3.1 ISO 17699 Lining water vapour WVP W 2,0 mg/cm .h

permeability and

2

if WVP of upper < 0,8 mg/cm .h then

absorption

2

WVA of lining W 8,0 mg/cm

4.4.3.2 ISO 20869 Water soluble u 1,5 % sulfated ashed water soluble (SAWS)

substances content

u 16 % total water soluble (TWS)

a

(testing not necessary to certain lining materials)

4.4.3.3 ISO 22652 Perspiration resistance After five cycles the component shall not develop any cracks

when bent, and must keep 80 % tear resistance

(testing not necessary to certain lining materials)

4.4.3.4 ISO 22653 Static friction W 0,7

4.4.3.5 ISO 17694 Flex resistance dry 15 000 cycles without visible damage

a

This requirement is considered essential for leather.

© ISO 2007 – All rights reserved 7

---------------------- Page: 11 ----------------------

ISO/TR 20882:2007(E)

4.4.4 Additional requirements (insocks)

These additional requirements should be agreed by both component supplier and footwear manufacturer.

See Table 12.

Table 12 — Test methods and properties for casual footwear — Additional requirements for insocks

Subclause Test method Property Requirement

4.4.4.1 ISO 20869 Water soluble u 1,5 % sulfated ashed water soluble (SAWS)

substances content

u 16 % total water soluble (TWS)

a

(testing not necessary to certain insocks materials)

4.4.4.2 ISO 22652 Perspiration resistance After five cycles the component shall not develop any cracks

when bent, and must keep 80 % tear resistance

(testing not necessary to certain insocks materials)

4.4.4.3 ISO 22653 Static friction W 0,7

4.4.4.4 ISO 17694 Flex resistance dry 15 000 cycles without visible damage

4.4.4.5 ISO 17696 Tear strength insocks W 15 N

a

This requirement is considered essential for leather.

4.5 Performance requirements for lining and insocks components for men's town footwear

4.5.1 Essential requirements (lining)

These essential requirements shall be fulfilled in all cases. See Table 13.

Table 13 — Test methods and properties for men's town footwear — Essential requirements for linings

Test method Property Requirement

ISO 17696 Tear strength lining W 10 N

reinforcing lining W 20 N (if it applies)

ISO 17697 Lining seam method A W 3,5 N/mm

strength

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution

ISO 17704 Abrasion resistance 25 600 cycles dry without hole through the thickness of the

material component

6 400 cycles wet

8 © ISO 2007 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/TR 20882:2007(E)

4.5.2 Essential requirements (insocks)

These essential requirements shall be fulfilled in all cases. See Table 14.

Table 14 — Test methods and properties for men's town footwear — Essential requirements

for insocks

Test method Property Requirement

EN ISO 17700 Colour fastness method A staining

W 3 (grey scale) after 50 cycles with perspiration solution

ISO 17704 Abrasion resistance 25 600 cycles dry

6 400 cycles wet

2

ISO 22649 Insoc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.