ISO 13318-2:2007

(Main)Determination of particle size distribution by centrifugal liquid sedimentation methods — Part 2: Photocentrifuge method

Determination of particle size distribution by centrifugal liquid sedimentation methods — Part 2: Photocentrifuge method

ISO 13318-2:2007 covers methods for determining the particle size distribution of particulate materials by means of centrifugal sedimentation in a liquid. Solids concentrations are determined by the transmission of a light beam. The resulting signal enables conversion to a particle size distribution. The method of determining the particle size distribution described in ISO 13318-2:2007 is applicable to powders that can be dispersed in liquids, powders that are present in slurry form and some emulsions. Typical particle size range for analysis is from about 0,1 µm to 5 µm. The method is applicable to powders in which all particles have the same density and comparable shapes and do not undergo chemical or physical change in the suspension liquid. It is usually necessary that the particles have a density higher than that of the liquid.

Détermination de la distribution granulométrique par les méthodes de sédimentation centrifuge dans un liquide — Partie 2: Méthode photocentrifuge

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13318-2

Second edition

2007-09-15

Determination of particle size distribution

by centrifugal liquid sedimentation

methods —

Part 2:

Photocentrifuge method

Détermination de la distribution granulométrique par les méthodes de

sédimentation centrifuge dans un liquide —

Partie 2: Méthode photocentrifuge

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

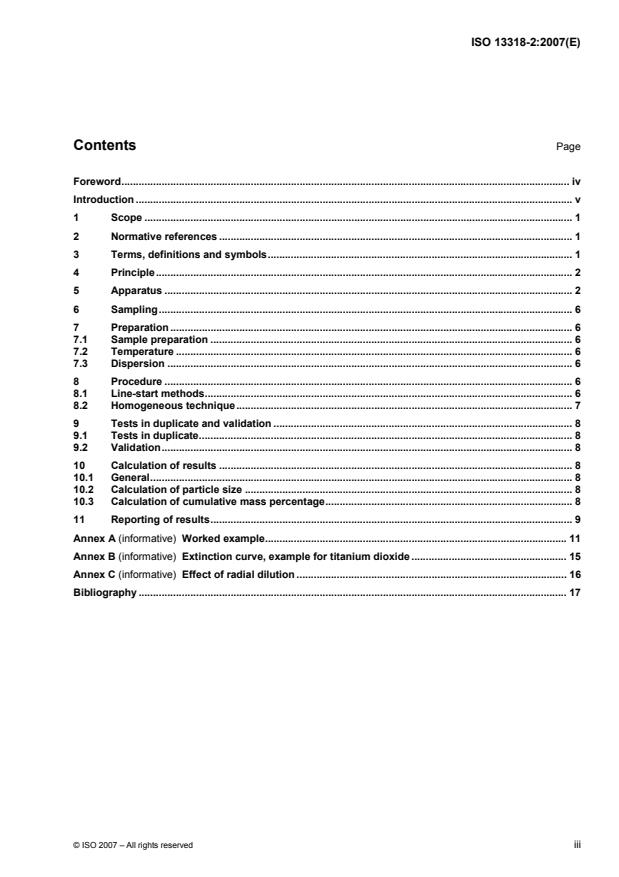

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and symbols. 1

4 Principle. 2

5 Apparatus . 2

6 Sampling. 6

7 Preparation . 6

7.1 Sample preparation . 6

7.2 Temperature . 6

7.3 Dispersion . 6

8 Procedure . 6

8.1 Line-start methods. 6

8.2 Homogeneous technique. 7

9 Tests in duplicate and validation . 8

9.1 Tests in duplicate. 8

9.2 Validation. 8

10 Calculation of results . 8

10.1 General. 8

10.2 Calculation of particle size . 8

10.3 Calculation of cumulative mass percentage. 8

11 Reporting of results. 9

Annex A (informative) Worked example. 11

Annex B (informative) Extinction curve, example for titanium dioxide . 15

Annex C (informative) Effect of radial dilution . 16

Bibliography . 17

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 13318-2 was prepared by Technical Committee ISO/TC 24, Sieves, sieving and other sizing methods,

Subcommittee SC 4, Sizing by methods other than sieving.

This second edition cancels and replaces ISO 13318-2:2001, of which it constitutes a minor revision, due to

the extension of Clause 4 and 5.2, and the addition of Figure 3 and the Bibliography.

ISO 13318 consists of the following parts, under the general title Determination of particle size distribution by

centrifugal liquid sedimentation methods:

⎯ Part 1: General principles and guidelines

⎯ Part 2: Photocentrifuge method

⎯ Part 3: Centrifugal X-ray method

iv © ISO 2007 – All rights reserved

Introduction

The sample suspension in a photocentrifuge may be contained in a cuvette or a disc. Sample concentration is

determined by changes in a light signal monitored at a known radius. The cuvette photocentrifuge can only be

run in the homogeneous mode whereas the disc photocentrifuge may be run in either the homogeneous or the

line-start mode. Some systems permit the coarse end of the distribution to be measured in a gravitational

mode and the fine end in the centrifugal mode. The use of light to determine particle size distribution requires

a calibration factor to be applied as the particle size approaches the wavelength of the light, due to the

inapplicability of the laws of geometric optics.

INTERNATIONAL STANDARD ISO 13318-2:2007(E)

Determination of particle size distribution by centrifugal liquid

sedimentation methods —

Part 2:

Photocentrifuge method

WARNING — This part of ISO 13318 may involve hazardous materials, operations and equipment. This

part of ISO 13318 does not purport to address all of the safety problems associated with its use. It is

the responsibility of the user of this part of ISO 13318 to establish appropriate safety and health

practices and determine the applicability of the regulatory limitations prior to its use.

1 Scope

This part of ISO 13318 covers methods for determining the particle size distribution of particulate materials by

means of centrifugal sedimentation in a liquid. Solids concentrations are determined by the transmission of a

light beam. The resulting signal enables conversion to a particle size distribution.

The method of determining the particle size distribution described in this part of ISO 13318 is applicable to

powders that can be dispersed in liquids, powders that are present in slurry form and some emulsions. Typical

particle size range for analysis is from about 0,1 µm to 5 µm. The method is applicable to powders in which all

particles have the same density and comparable shapes and do not undergo chemical or physical change in

the suspension liquid. It is usually necessary that the particles have a density higher than that of the liquid.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 13318-1, Determination of particle size distribution by centrifugal liquid sedimentation methods — Part 1:

General principles and guidelines

ISO 14887, Sample preparation — Dispersing procedures for powders in liquids

3 Terms, definitions and symbols

For the purposes of this document, the terms, definitions and symbols given in ISO 13318-1, and the following

symbols, apply.

D optical density

E extinction coefficient for a particle of diameter x

i i

F(surface) frequency undersize by surface

G constant dependent upon the geometry of the system, the dimensions of the light beam and on

the shape of the particles

l transmission of the emergent light beam, at the time t, after the start of sedimentation

l transmission of the emergent light beam when no particles are present

M distance from rotation axis to measurement zone (mm)

n number of particles of diameter x in the beam

i i

R distance from rotation axis to centrifuge wall, inner disc radius (mm)

S distance from rotation axis to liquid/air interface of sample (mm)

x diameter of the smallest particle in the light beam (µm)

x diameter of the largest particle in the light beam, i.e. the Stokes diameter (µm)

St

4 Principle

A stable, finely collimated beam of light passes through a spinning disc or cuvette and sedimenting sample

and is detected at a known radius. Light rays, typically from either a white light source (e.g. incandescent bulb)

or a monochromatic coherent source (e.g. laser), pass through the suspension and are detected by a

photodiode or photomultiplier. The disc photocentrifuge can be operated in the line-start or homogeneous

mode whereas the cuvette photocentrifuge can be operated only in the homogeneous mode. The signal of the

light beam is monitored over the analysis time. The mass percentage of sample present in the beam is

determined by calculating the ratio of the light transmission signal, by use of a clear dispersing liquid, to the

light transmission signal with the sample present.

In the line-start mode the disc initially contains clear fill liquid to give maximum light transmission. Then the

sample is injected as a thin layer on top of the spinning fill liquid and begins to settle outward radially. When

the largest particles present reach the light beam the light transmission decreases, returning to the original

transmission value when the smallest particle present passes through the beam. A buffer layer is usually

injected over the fill liquid to prevent suspension breaking through the interface in a phenomenon known as

“streaming”.

In an alternative configuration, the determination of the particle size distribution by centrifugal liquid

sedimentation method can also be accomplished using a photocentrifuge containing a line light source and a

line sensor detector system aligned with the sample cell. In this configuration, light intensity/extinction

alterations during centrifugation are measured simultaneously over the whole sedimentation zone as a

function of both time and of position. From these data, the particle size distribution may be calculated either

from the time course of the extinction at a freely selectable position within the sample [numerical integration,

ISO 13318-1:2001, Equation (11) in 4.3.3.3] or from the extinction profile along the sample at a freely

selectable time (analytical integration, for details see Reference [1]).

5 Apparatus

5.1 Disc photocentrifuge, with a chamber consisting of a hollow disc with an entry port coaxial with the

axis of rotation (see Figure 1). Typically this is mounted vertically, or at a small angle to the vertical, on to the

−1 −1

shaft of an electric motor with a digitally variable speed typically between 500 r⋅min and 15 000 r⋅min . A

white light source and detector assembly measures transmittance through the suspension as a function of

time. The instrument can be used in either a line-start or homogeneous mode. Extinction coefficient

corrections need to be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.