ISO 19617:2018

(Main)Traditional Chinese medicine — General requirements for the manufacturing process of natural products

Traditional Chinese medicine — General requirements for the manufacturing process of natural products

ISO 19617:2018 specifies the general requirements for manufacturing processes to ensure the quality of finished products used in traditional Chinese medicine (TCM). This document covers premises, documentation, personnel, training, manufacturing control and quality control. This document applies to the manufacturing of natural products used in and as TCM. ISO 19617:2018 does not conflict with general pharmaceutical good manufacturing practices (GMPs). ISO 19617:2018 applies to all materials of natural origin: medicinal plants, medicinal animals, medicinal minerals, crude drugs or crude drug preparations.

Médecine traditionnelle chinoise — Exigences générales relatives au procédé de fabrication des produits naturels

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19617

First edition

2018-04

Traditional Chinese medicine —

General requirements for the

manufacturing process of natural

products

Médecine traditionnelle chinoise — Exigences générales relatives au

procédé de fabrication des produits naturels

Reference number

ISO 19617:2018(E)

©

ISO 2018

---------------------- Page: 1 ----------------------

ISO 19617:2018(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 19617:2018(E)

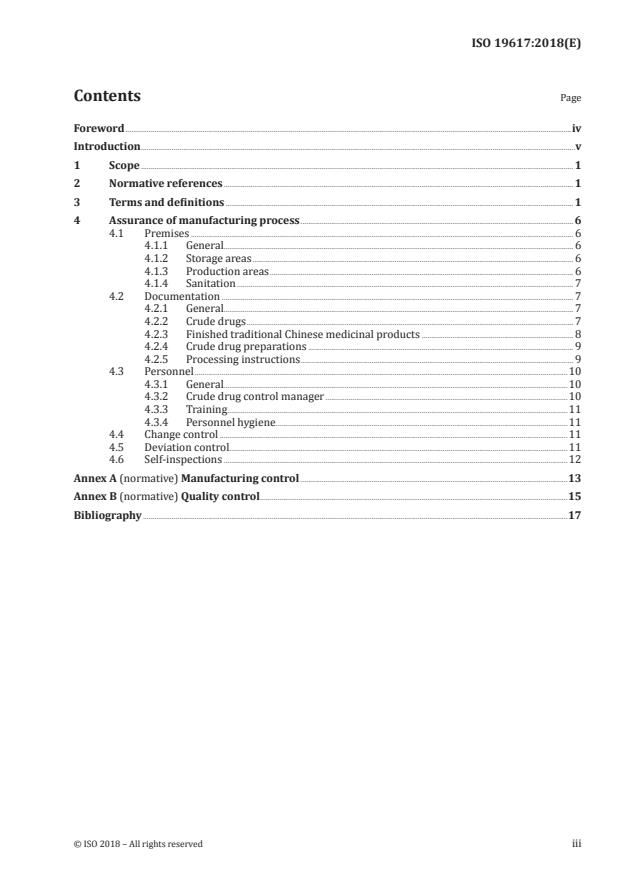

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Assurance of manufacturing process . 6

4.1 Premises . 6

4.1.1 General. 6

4.1.2 Storage areas . 6

4.1.3 Production areas . 6

4.1.4 Sanitation . 7

4.2 Documentation . 7

4.2.1 General. 7

4.2.2 Crude drugs . 7

4.2.3 Finished traditional Chinese medicinal products . 8

4.2.4 Crude drug preparations . 9

4.2.5 Processing instructions . 9

4.3 Personnel .10

4.3.1 General.10

4.3.2 Crude

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.