ISO/DIS 19880-2

(Main)Gaseous hydrogen -- Fuelling stations

Gaseous hydrogen -- Fuelling stations

Carburant d'hydrogène gazeux -- Stations-service

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 19880-2

ISO/TC 197 Secretariat: SCC

Voting begins on: Voting terminates on:

2017-06-30 2017-09-21

Gaseous hydrogen — Fueling stations —

Part 2:

Dispensers

Carburant d’hydrogène gazeux — Stations-service —

Partie 2: Titre manque

ICS: 43.060.40; 71.100.20

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 19880-2:2017(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2017

---------------------- Page: 1 ----------------------

ISO/DIS 19880-2:2017(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 19880-2:2017(E)

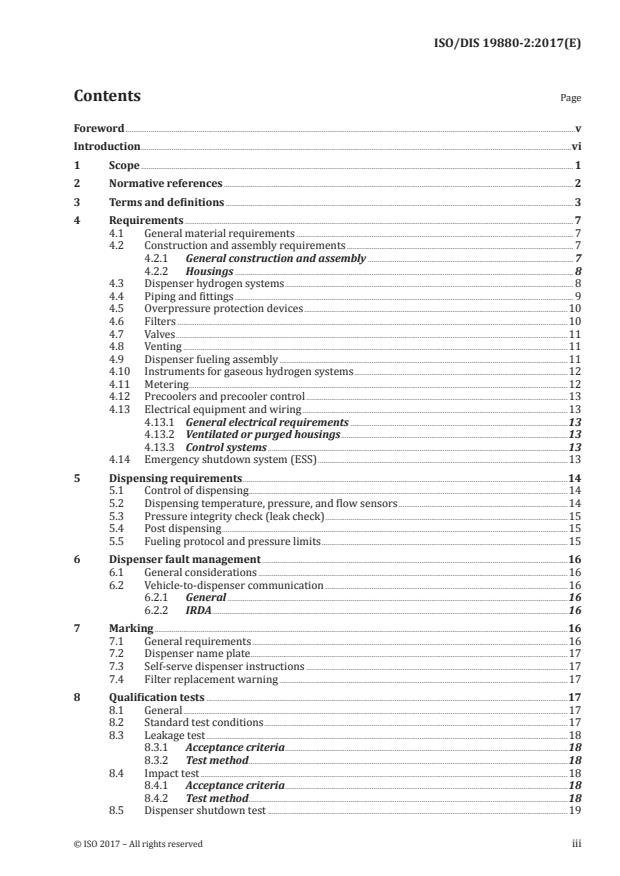

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 2

3 Terms and definitions ..................................................................................................................................................................................... 3

4 Requirements .......................................................................................................................................................................................................... 7

4.1 General material requirements ................................................................................................................................................ 7

4.2 Construction and assembly requirements ...................................................................................................................... 7

4.2.1 General construction and assembly ........................................................................................................... 7

4.2.2 Housings ................................................................................................................................................................................ 8

4.3 Dispenser hydrogen systems ...................................................................................................................................................... 8

4.4 Piping and fittings ................................................................................................................................................................................ 9

4.5 Overpressure protection devices .........................................................................................................................................10

4.6 Filters ...........................................................................................................................................................................................................10

4.7 Valves ............................................................................................................................................................................................................11

4.8 Venting ........................................................................................................................................................................................................11

4.9 Dispenser fueling assembly ......................................................................................................................................................11

4.10 Instruments for gaseous hydrogen systems ...............................................................................................................12

4.11 Metering .....................................................................................................................................................................................................12

4.12 Precoolers and precooler control ........................................................................................................................................13

4.13 Electrical equipment and wiring ..........................................................................................................................................13

4.13.1 General electrical requirements .................................................................................................................13

4.13.2 Ventilated or purged housings ......................................................................................................................13

4.13.3 Control systems ............................................................................................................................................................13

4.14 Emergency shutdown system (ESS) ..................................................................................................................................13

5 Dispensing requirements .........................................................................................................................................................................14

5.1 Control of dispensing......................................................................................................................................................................14

5.2 Dispensing temperature, pressure, and flow sensors ........................................................................................14

5.3 Pressure integrity check (leak check) ..............................................................................................................................15

5.4 Post dispensing ....................................................................................................................................................................................15

5.5 Fueling protocol and pressure limits ................................................................................................................................15

6 Dispenser fault management ...............................................................................................................................................................16

6.1 General considerations .................................................................................................................................................................16

6.2 Vehicle-to-dispenser communication ..............................................................................................................................16

6.2.1 General .................................................................................................................................................................................16

6.2.2 IRDA .........................................................................................................................................................................................16

7 Marking .......................................................................................................................................................................................................................16

7.1 General requirements ....................................................................................................................................................................16

7.2 Dispenser name plate .....................................................................................................................................................................17

7.3 Self-serve dispenser instructions ........................................................................................................................................17

7.4 Filter replacement warning ......................................................................................................................................................17

8 Qualification tests ............................................................................................................................................................................................17

8.1 General ........................................................................................................................................................................................................17

8.2 Standard test conditions ..............................................................................................................................................................17

8.3 Leakage test ............................................................................................................................................................................................18

8.3.1 Acceptance criteria ...................................................................................................................................................18

8.3.2 Test method ...................................................................... ................................................................................................18

8.4 Impact test ...............................................................................................................................................................................................18

8.4.1 Acceptance criteria ...................................................................................................................................................18

8.4.2 Test method ...................................................................... ................................................................................................18

8.5 Dispenser shutdown test ............................................................................................................................................................19

© ISO 2017 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 19880-2:2017(E)

8.5.1 Acceptance criteria ...................................................................................................................................................19

8.5.2 Test method ...................................................................... ................................................................................................19

8.6 Post dispensing ....................................................................................................................................................................................19

8.6.1 Acceptance criteria ...................................................................................................................................................19

8.6.2 Test method ...................................................................... ................................................................................................19

8.7 Hose breakaway test .......................................................................................................................................................................20

8.7.1 Acceptance criterial .................................................................................................................................................20

8.7.2 Test method ...................................................................... ................................................................................................20

8.8 Vehicle-dispenser interface test ............................................................................................................................................20

8.8.1 Acceptance criterial .................................................................................................................................................20

8.8.2 Test method ...................................................................... ................................................................................................21

8.9 Dispenser ground continuity test ........................................................................................................................................21

8.9.1 Acceptance criterial .................................................................................................................................................21

8.9.2 Test method ...................................................................... ................................................................................................21

8.10 Dielectric voltage-withstand test .........................................................................................................................................21

8.10.1 Acceptance criterial .................................................................................................................................................21

8.10.2 Test method ...................................................................... ................................................................................................21

8.11 Rain test .....................................................................................................................................................................................................22

8.11.1 Acceptance criterial .................................................................................................................................................22

8.11.2 Test method ...................................................................... ................................................................................................22

8.12 Marking material adhesion and legibility test ..........................................................................................................22

8.12.1 Acceptance criterial .................................................................................................................................................22

8.12.2 Test method ...................................................................... ................................................................................................22

9 Routine tests ..........................................................................................................................................................................................................23

9.1 Leakage test ............................................................................................................................................................................................23

9.2 Dielectric voltage-withstand test .........................................................................................................................................23

10 Product literature .............................................................................................................................................................................................23

10.1 General ........................................................................................................................................................................................................23

10.2 Installation ...............................................................................................................................................................................................23

10.3 Maintenance and service .............................................................................................................................................................23

10.4 Operation ..................................................................................................................................................................................................24

Annex A (informative) Marking class requirements .........................................................................................................................25

Bibliography .............................................................................................................................................................................................................................27

iv © ISO 2017 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 19880-2:2017(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: w w w . i s o .org/ iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 197, Hydrogen technologies.

This document was developed using the CSA Standards mentioned in the Bibliography under a

Copyright License Agreement between CSA Group and ISO.A list of all parts in the ISO 19880- series can be found on the ISO website.

© ISO 2017 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 19880-2:2017(E)

Introduction

The purpose of this International Standard is to promote the implementation of hydrogen powered land

vehicles through the creation of performance based safety and testing requirements for compressed

hydrogen fuel dispensers. The successful commercialization of hydrogen land vehicle technologies

requires codes and standards pertaining to fueling stations, vehicle fuel system components and the

global homologation of standards requirements for technologies with the same end use. This will allow

manufacturers to achieve economies of scale in production through the ability to manufacture one

product for global use.This International Standard is a part of the series of ISO standards for hydrogen fueling stations with

its scope limited to compressed hydrogen dispensers for land vehicles that use hydrogen as fuel.

Dispensers are a major component of hydrogen fueling stations, without which hydrogen vehicles

will not become a significant element of mobility in the future. This Standard includes requirements

for manufacture, commissioning and routine maintenance of dispensers in order to assure the safe

operation of dispensing hydrogen to vehicles.vi © ISO 2017 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 19880-2:2017(E)

Gaseous hydrogen — Fueling stations —

Part 2:

Dispensers

1 Scope

This standard provides the safety requirements and test methods for complete compressed hydrogen

dispensers with dispensing pressures up to the H70 pressure class designation. A typical hydrogen

dispenser is illustrated in Figure 1 as installed and fueling a vehicle.Figure1 — Typical compressed hydrogen dispenser

The process diagram in Figure 2 shows components in the dispenser typically required to meet the

dispensing functionality and safety requirements. The actual process configuration and equipment

selections may be different, but ultimately the requirements defined by this document need to be

met by the dispensing system. Additionally, not all equipment has to be physically housed within the

enclosure-at the dispensing area as long as the specification of component design or type and location

are adequate to ensure that the overall process meets requirements in this standard.

© ISO 2017 – All rights reserved 1---------------------- Page: 7 ----------------------

ISO/DIS 19880-2:2017(E)

Figure 2 — Example of a dispenser system

This document provides the requirements for hydrogen dispensers and may provide specific references

to other standards for individual components included in the hydrogen dispenser such as valves

(ISO 19880-3) and hoses (ISO 19880-3).This document addresses the general requirements of the fueling protocol and directs the user to

ISO 19880-1 for additional requirements and the test methods required to verify proper fueling

protocol implementation.This document does not address the accuracy of flow meters that may be used to meter dispensed fuel.

2 Normative referencesThe following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

IEC 61511-1, Functional safety — Safety instrumented systems for the process industry sector — Part 1:

Framework, definitions, system, hardware and software requirementsISO 13849, Safety of machinery — Safety-related parts of control systems

IEC 60204-1, Safety of machinery — Electrical equipment of machines — Part 1: General Requirements

IEC 60364, Electrical installations for buildingsIEC 60079, Explosive atmospheres

ISO 13849-2:2012, Safety of machinery — Safety-related parts of control systems — Part 2: Validation

ISO 14687-2, Hydrogen fuel — Product specification — Part 2: Proton exchange membrane (PEM) fuel cell

applications for road vehiclesISO 15649, Petroleum and natural gas industries — Piping

ISO 17268, Gaseous hydrogen land vehicle refueling connection devices

2 © ISO 2017 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 19880-2:2017(E)

ISO 19880-1 , Gaseous hydrogen — Fueling stations — Part 1: General requirements

ISO 19880-3 , Gaseous hydrogen — Fueling stations — Part 3: Valves

ISO 19880-5 , Gaseous hydrogen — Fueling stations — Part 5: Fueling station hoses

ISO 19880-6, Gaseous hydrogen — Fueling stations — Part: 6 FittingsSAE J2601 , Fueling Protocols for Light Duty Gaseous Hydrogen Surface Vehicles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

automatic valve

valve that is self-actuated or remotely actuated by a control device

3.2

breakaway device

component installed upstream of the nozzle to shut off gas flow in the event of vehicle driving away

while still connected to the dispenser3.3

component pressure rating

maximum allowable pressure at which it is permissible to operate a component as specified by the

manufacturer at a specified temperatureNote 1 to entry: Components designed to the Maximum Allowable Pressure under the European Pressure

Equipment Directive have their component ratings by the manufacturer indicated by the value of “PS”.

Note 2 to entry: Further guidance on dispenser pressure terminology and design rating is included in 19880-1.

3.4control system

system which responds to input signals from the process and/or from an operator and generates output

signals causing the process to operate in the desired manner3.5

Cv value (flow coefficient)

coefficient to represent the flow rate of fluid that a valve is capable of handling

Note 1 to entry: Cv is the flow coefficient of a valve with the fluid at 15,56 °C under a pressure difference of

703 kg/m .Note 2 to entry: There are different types of flow coefficients including Cv, Kv and Av.

1) Under preparation. (Stage at the time of publication ISO/XXX 19880-1.)2) Under preparation. (Stage at the time of publication ISO/XXX 19880-3.)

3) Under preparation. (Stage at the time of publication ISO/XXX 19880-5.)

4) Under preparation. (Stage at the time of publication ISO/XXX 19880-6.)

© ISO 2017 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/DIS 19880-2:2017(E)

3.6

dispenser

parts of the pressurized-gas fueling station via which the pressurized gas is dispensed to vehicles

Note 1 to entry: As an example, the dispenser may include a dispenser housing, gas flow meter, a fueling hose and

fueling nozzle attachments.3.7

dispensing system

system, downstream of the hydrogen storage, comprising all equipment necessary to carry out the

vehicle fueling and protect against dispensing faults3.8

emergency shutdown system (ESS)

system which responds to automatic and/or manually activated emergency shutdown devices to stop

hazardous movements and operations such as the flow of hydrogen gas to the dispenser and vehicle

3.0E-Stop

device for manually activating the ESS

3.10

enclosure

protective housing that may enclose, or partially enclose, equipment such as compressors, valve

manifolds, compressed hydrogen storage systems in order to protect equipment from the environment,

provide noise attenuation, or provide safety barrier to the areas surrounding the equipment

Note 1 to entry: In this standard the enclosure of the dispenser is defined as a “housing.”

Note 2 to entry: Some hydrogen station manufacturers may build an all-in-one fueling station where the dispenser

components are built into one side or end of the equipment enclosure without using a separate dispenser housing.

3.11fitting

connector used in joining piping, tubing, or components for internal fluid transfer

3.12fueling assembly

part of the dispenser providing the interface between the hydrogen fueling station and the vehicle -

an assembly consisting of a breakaway device, a hose(s), a nozzle and connectors between these

components3.13

fueling station

facility for the dispensing of compressed hydrogen, which includes all stationary equipment that

supplies, compresses, stores, and dispenses gaseous hydrogen to fuel a land vehicle

3.14fueling hose

flexible conduit used for dispensing gaseous hydrogen to vehicles through a fueling nozzle

3.15housing

protective structure that encloses process piping and may also enclose measurement, control and

ancillary dispenser equipment including point of sale and user authorization interface

Note 1 to entry: Housing may be synonymous with: enclosure, cabinet, or frame.4 © ISO 2017 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/DIS 19880-2:2017(E)

3.16

hydrogen service level (HSL)

pressure level in MPa used to characterize the hydrogen service of the dispenser based on the NWP

rating of the vehicleNote 1 to entry: The numerical value of HSL also matches the number after the “H” in Pressure Class. See the

definition of Pressure Class for further discussion.3.17

manufacturer

person or organization responsible for the design and fabrication of the equipment and comp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.