ISO/FDIS 6002

(Main)Standard Details

Industrial valves -- Bolted bonnet steel gate valves

Robinetterie industrielle - Robinets-vannes en acier à chapeau boulonné

General Information

RELATIONS

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 6002

ISO/TC 153

Industrial valves — Bolted bonnet

Secretariat: AFNOR

steel gate valves

Voting begins on:

20201006

Robinetterie industrielle - Robinets-vannes en acier à chapeau

boulonné

Voting terminates on:

20201201

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/FDIS 6002:2020(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. ISO 2020

---------------------- Page: 1 ----------------------

ISO/FDIS 6002:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 6002:2020(E)

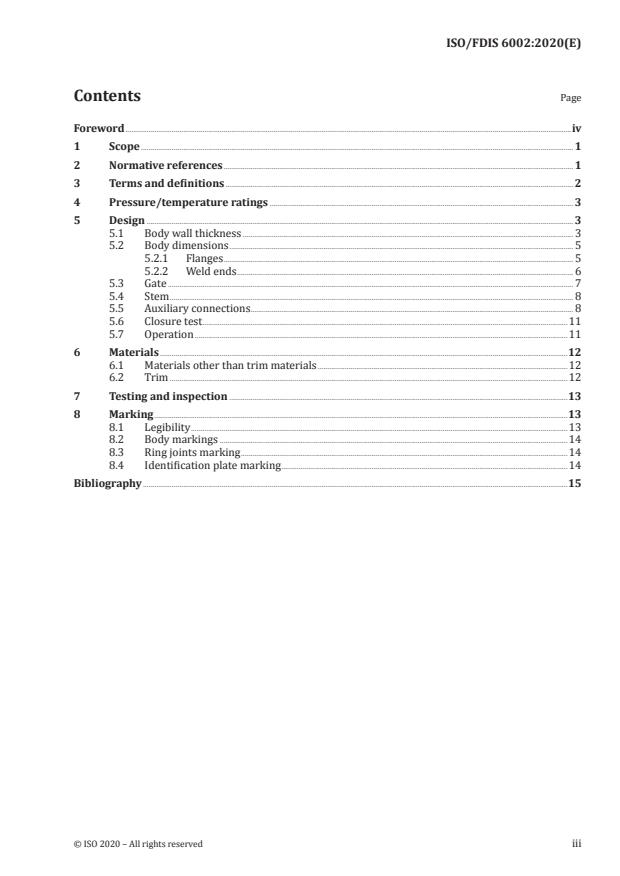

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 2

4 Pressure/temperature ratings .............................................................................................................................................................. 3

5 Design .............................................................................................................................................................................................................................. 3

5.1 Body wall thickness ............................................................................................................................................................................ 3

5.2 Body dimensions ................................................................................................................................................................................... 5

5.2.1 Flanges ...................................................................................................................................................................................... 5

5.2.2 Weld ends ............................................................................................................................................................................... 6

5.3 Gate ................................................................................................................................................................................................................... 7

5.4 Stem .................................................................................................................................................................................................................. 8

5.5 Auxiliary connections ........................................................................................................................................................................ 8

5.6 Closure test ..............................................................................................................................................................................................11

5.7 Operation ..................................................................................................................................................................................................11

6 Materials ....................................................................................................................................................................................................................12

6.1 Materials other than trim materials ..................................................................................................................................12

6.2 Trim ...............................................................................................................................................................................................................12

7 Testing and inspection ................................................................................................................................................................................13

8 Marking .......................................................................................................................................................................................................................13

8.1 Legibility ....................................................................................................................................................................................................13

8.2 Body markings .....................................................................................................................................................................................14

8.3 Ring joints marking ..........................................................................................................................................................................14

8.4 Identification plate marking .....................................................................................................................................................14

Bibliography .............................................................................................................................................................................................................................15

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 6002:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 153, Valves.

This second edition cancels and replaces the first edition (ISO 6002:1992), which has been technically

revised.The main changes compared to the previous edition are as follows:

— in the whole text, deletion of PN 20 and PN 50, addition of PN 63 and inclusion of nominal pipe sizes

NPS and Class designations;— update of the normative references in Clause 2;

— addition of definitions for DN, NPS, PN and Class;

— revision of Figure 1 identifying valves terms and Figure 6 for butt-welding for auxiliary connections;

— addition of requirements for gate in 5.3 and stem in 5.4;— addition of requirements for closure test in 5.6;

— deletion of former Table 1 on body wall thickness, deletion of former Table 3 on endtoend

dimensions for buttweld end valves and deletion of former 5.4 on envelope dimensions;

— revision of Table 1 on body end port inside diameter, and Table 8 on component materials;

— update of Clause 7 on testing and inspection and Clause 8 on marking.Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 6002:2020(E)

Industrial valves — Bolted bonnet steel gate valves

1 Scope

This document specifies the requirements for bolted bonnet steel gate vales having the following

features:— bolted bonnet;

— outside screw and yoke;

— inside screw (alternative for PN 10, PN 16, Class 150, PN 25 and PN 40 only);

— single or double obturator;

— wedge or parallel seating;

— with or without nonmetallic obturator or seat seals;

— flanged or butt-welding ends.

It covers valves of the nominal sizes DN:

— 10; 15; 20; 25; 32; 40; 50; 65; 80; 100; 125; 150; 200; 250; 300; 350; 400; 450; 500; 600; 700; 800;

900; 1 000;corresponding to nominal pipe sizes NPS:

— ⅜; ½; ¾; 1; 1 ¼; 1 ½; 2; 2 ½; 3; 4; 5; 6; 8; 10; 12; 14; 16; 18; 20; 24; 28; 32; 36; 40;

and applies to valves of the following pressure designations:— PN 10; 16; 25; 40; 63; 100;

— Class 150; 300; 600.

This document applies to bolted bonnet steel gate valves used for all industrial applications.

Additional requirements given in the relevant application standards can apply to bolted bonnet

steel gate valves used for more specific applications (e.g. for the water industry, the chemical and

petrochemical process industry, the oil and gas industry).2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4991, Steel castings for pressure purposesISO 5208, Industrial valves — Pressure testing of metallic valves

ISO 5210, Industrial valves — Multi-turn valve actuator attachments

ISO 5752, Metal valves for use in flanged pipe systems — Face-to-face and centre-to-face dimensions

ISO 9327 (all parts), Steel forgings and rolled or forged bars for pressure purposes — Technical delivery

conditions© ISO 2020 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/FDIS 6002:2020(E)

ISO 93281, Steel flat products for pressure purposes — Technical delivery conditions — Part 1: General

requirementsISO 93282, Steel flat products for pressure purposes — Technical delivery conditions — Part 2: Non-alloy

and alloy steels with specified elevated temperature propertiesISO 93283, Steel flat products for pressure purposes — Technical delivery conditions — Part 3: Weldable

fine grain steels, normalizedISO 93284, Steel flat products for pressure purposes — Technical delivery conditions — Part 4: Nickel-

alloy steels with specified low temperature propertiesISO 93285, Steel flat products for pressure purposes — Technical delivery conditions — Part 5: Weldable

fine grain steels, thermomechanically rolledISO 14737, Carbon and low alloy cast steels for general applications

EN 10921, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 1: Steel flangesEN 12982, Industrial valves — End-to-end and centre-to-end dimensions for butt welding end valves

EN 125161, Industrial valves — Shell design strength — Part 1: Tabulation method for steel valve shells

EN 125162, Industrial valves — Shell design strength — Part 2: Calculation method for steel valve shells

ASME B16.10, Face-to-Face and End-to-End Dimensions of ValvesASME B16.34, Valves Flanged, Threaded, and Welding End

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

nominal size

NPS

alphanumeric designation of size for components of a pipework system, which is used for reference

purposes, comprising the letters DN or NPS followed by a dimensionless number indirectly related to

the physical size, in millimetres, of the bore or outside diameter of the end connections

Note 1 to entry: The number following the letters DN or NPS does not represent a measurable value and is not

used for calculation purposes except where specified in the relevant standard.Note 2 to entry: See ISO 6708 and ASME B16.34.

2 © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/FDIS 6002:2020(E)

3.2

Class

alphanumeric designation for pressuretemperature rating that is common for components used

in a piping system, used for reference purposes, comprising the letters "PN" or "Class" followed

by a dimensionless number indirectly related to the pressure retaining capability as a function of

temperature of the componentNote 1 to entry: The number following the letters PN or Class does not represent a measurable value and is not

used for calculation purposes except where specified in the relevant standard. There is no definitive correlation

that links PN designations to Class designations.Note 2 to entry: See ISO 7268 and ASME B16.34.

4 Pressure/temperature ratings

4.1 The pressure/temperature ratings shall be in accordance with EN 125161 for PNdesignated

valves and in accordance with ASME B16.34 for Classdesignated valves.4.2 The temperature shown for a corresponding pressure rating is the temperature of the pressure

containing shell of the valve. In general, this temperature is the same as that of the contained fluid. The

use of a pressure rating corresponding to a temperature other than that of the contained fluid is the

responsibility of the user.4.3 For temperatures below the lowest temperature listed in the pressure/temperature rating tables,

the working pressure shall not be greater than the pressure stated for the lowest listed temperature. The

use of valves at lower temperatures is the responsibility of the user. Consideration should be given to the

loss of ductility and impact strength of many materials at low temperature.5 Design

5.1 Body wall thickness

5.1.1 The terms used in 5.1 are illustrated in Figure 1. d is the minimum inside diameter given in

Table 1.5.1.2 The minimum body wall thickness, T , at the time of manufacture, shall be in accordance with:

— EN 125161 or EN 125162 for PNdesignated valves,— ASME B16.34 or EN 125161 for Classdesignated valves.

Exceptions are given in 5.1.3 to 5.1.5.

Additional metal thickness needed for assembly stresses, closing stresses, stress concentrations and

shapes other than circular shall be determined by the manufacturers, since these factors vary widely.

5.1.3 The weld preparation in buttwelding end valves (see 5.2.2.2) shall not reduce the body wall

thickness to less than the values specified in 5.1.2 within a region closer to the outside surface of the

body neck than T measured along the run direction.The transition to the weld preparation shall be gradual and the section shall be essentially circular

through the entire length of the transition. Sharp discontinuities or abrupt changes in section in areas

that infringe into the transition shall be avoided, except that test collars or bands, either welded or

integral, are allowed.© ISO 2020 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/FDIS 6002:2020(E)

In no case shall the thickness be less than 0,77 T at a distance of 2 T from the weld end.

m m5.1.4 The valve body neck shall maintain the minimum body wall thickness T as specified in 5.1.2

within the distance 1,1 dT measured from the outside of the body run along the neck direction, where

d is the inside diameter as defined in 5.2.1.3.Beyond the distance 1,1 dT from the outside of the body run, straight circular sections of body necks

with inside diameter d' shall be provided with a minimum local wall thickness of T' where T' is

determined, by interpolation if necessary, as the...

DRAFT INTERNATIONAL STANDARD

ISO/DIS 6002

ISO/TC 153 Secretariat: AFNOR

Voting begins on: Voting terminates on:

2020-01-29 2020-04-22

Industrial valves - Bolted bonnet steel gate valves

Robinetterie industrielle - Robinets-vannes en acier à chapeau boulonné

ICS: 23.060.30

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 6002:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 6002:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 6002:2020(E)

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 2

4 Pressure/temperature ratings .............................................................................................................................................................. 3

5 Design .............................................................................................................................................................................................................................. 3

5.1 Body wall thickness ............................................................................................................................................................................ 3

5.2 Body dimensions ................................................................................................................................................................................... 4

5.2.1 Flanges ...................................................................................................................................................................................... 4

5.2.2 Weld ends ............................................................................................................................................................................... 5

5.3 Gate ................................................................................................................................................................................................................... 6

5.4 Stem .................................................................................................................................................................................................................. 8

5.5 Auxiliary connections ........................................................................................................................................................................ 8

5.6 Closure test ..............................................................................................................................................................................................11

5.7 Operation ..................................................................................................................................................................................................12

6 Materials ....................................................................................................................................................................................................................12

6.1 Materials other than trim materials ..................................................................................................................................12

6.2 Trim ...............................................................................................................................................................................................................13

7 Testing and inspection ................................................................................................................................................................................13

8 Marking .......................................................................................................................................................................................................................14

8.1 Legibility ....................................................................................................................................................................................................14

8.2 Body markings .....................................................................................................................................................................................14

8.3 Ring joints marking ..........................................................................................................................................................................14

8.4 Identification plate marking .....................................................................................................................................................14

Bibliography .............................................................................................................................................................................................................................15

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 6002:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 153, Valves.

This second edition cancels and replaces the first edition (ISO 6002:1992), which has been technically

revised.The main changes compared to the previous edition are as follows:

— in the whole text, deletion of PN 20 and PN 50, addition of PN 63 and inclusion of nominal pipe sizes

NPS and Class designations;— update of the normative references in Clause 2;

— addition of definitions for DN, NPS, PN and Class;

— revision of Figure 1 identifying valves terms and Figure 6 for butt-welding for auxiliary connections;

— addition of requirements for gate in 5.3 and stem in 5.4;— addition of requirements for closure test in 5.6;

— deletion of former Table 1 on body wall thickness, deletion of former Table 3 on end-to-end

dimensions for butt-weld end valves and deletion of former 5.4 on envelope dimensions;

— revision of Table 8 on component materials;— update of Clause 7 on testing and inspection and Clause 8 on marking.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 6002:2020(E)

Introduction

The purpose of this document is the establishment of the basic requirements and recommendations for

flanged or butt-weld end steel gate valves of bolted bonnet construction.It is not the purpose to replace ISO 10434 or any other international Standard.

© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 6002:2020(E)

Industrial valves - Bolted bonnet steel gate valves

1 Scope

This document specifies the requirements for bolted bonnet steel gate vales having the following

features:— bolted bonnet;

— outside screw and yoke;

— inside screw(alternative for PN 10, PN 16, PN 25 and PN 40 only);

— single or double obturator;

— wedge or parallel seating;

— with or without non-metallic obturator or seat seals;

— flanged or butt-welding ends.

It covers valves of the nominal sizes DN:

— 10; 15; 20; 25; 32; 40; 50; 65; 80; 100; 125; 150; 200; 250; 300; 350; 400; 450; 500; 600; 700; 800;

900; 1 000;corresponding to nominal pipe sizes NPS:

— 3/8; 1/2; 3/4; 1; 1 1/4; 1 1/2; 2; 2 1/2; 3; 4; 5; 6; 8; 10; 12; 14; 16; 18; 20; 24; 28; 32; 36; 40;

and applies to valves of the following pressure designations:— PN 10; 16; 25; 40; 63; 100;

— Class 150; 300; 600.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4991, Steel castings for pressure purposesISO 5208, Industrial valves — Pressure testing of metallic valves

ISO 5210, Industrial valves — Multi-turn valve actuator attachments

ISO 5752:1982, Metal valves for use in flanged pipe systems — Face-to-face and centre-to-face dimensions

ISO 7005-1, Pipe flanges — Part 1: Steel flanges for industrial and general service piping systems

ISO 9327 (series), Steel forgings and rolled or forged bars for pressure purposes

ISO 9328-1, Steel flat products for pressure purposes — Technical delivery conditions — Part 1: General

requirementsISO 9328-2, Steel flat products for pressure purposes — Technical delivery conditions — Part 2: Non-alloy

and alloy steels with specified elevated temperature properties© ISO 2020 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 6002:2020(E)

ISO 9328-3, Steel flat products for pressure purposes — Technical delivery conditions — Part 3: Weldable

fine grain steels, normalizedISO 9328-4, Steel flat products for pressure purposes — Technical delivery conditions — Part 4: Nickel-

alloy steels with specified low temperature propertiesISO 9328-5, Steel flat products for pressure purposes — Technical delivery conditions — Part 5: Weldable

fine grain steels, thermomechanically rolledISO 14737, Carbon and low alloy cast steels for general applications

EN 1092-1, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 1: Steel flangesEN 12982, Industrial valves — End-to-end and centre-to-end dimensions for butt welding end valves

EN 12516-1, Industrial valves — Shell design strength — Part 1: Tabulation method for steel valve shells

EN 12516-2, Industrial valves — Shell design strength — Part 2: Calculation method for steel valve shells

ASME B16.5, Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

ASME B16.10, Face-to-Face and End-to-End Dimensions of ValvesASME B16.34, Valves Flanged, Threaded, and Welding End

ASME B16.47, Large Diameter Steel Flanges: NPS 26 through NPS 60 Metric/Inch Standard

3 Terms and definitionsFor the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

nominal size

DN or NPS

alphanumeric designation of size for components of a pipework system, which is used for reference

purposes, comprising the letters DN or NPS followed by a dimensionless number indirectly related to

the physical size, in millimetres, of the bore or outside diameter of the end connections

Note 1 to entry: The number following the letters DN or NPS does not represent a measurable value and is not

used for calculation purposes except where specified in the relevant standard.Note 2 to entry: See ISO 6708 and ASME B16.34.

3.2

PN or Class

alphanumeric designation for pressure-temperature rating that is common for components used

in a piping system, used for reference purposes, comprising the letters "PN" or "Class" followed

by a dimensionless number indirectly related to the pressure retaining capability as a function of

temperature of the componentNote 1 to entry: The number following the letters PN or Class does not represent a measurable value and is not

used for calculation purposes except where specified in the relevant standard. There is no definitive correlation

that links PN designations to Class designations.Note 2 to entry: See ISO 7268 and ASME B16.34.

2 © ISO 2020 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 6002:2020(E)

4 Pressure/temperature ratings

4.1 The pressure/temperature ratings shall be in accordance with EN 12516-1 for PN-designated

valves and in accordance with ASME B16.34 for Class-designated valves.4.2 The temperature shown for a corresponding pressure rating is the temperature of the pressure-

containing shell of the valve. In general, this temperature is the same as that of the contained fluid. The

use of a pressure rating corresponding to a temperature other than that of the contained fluid is the

responsibility of the user.4.3 For temperatures below the lowest temperature listed in the pressure/temperature rating tables,

the working pressure shall be no greater than the lowest listed temperature. The use of valves at lower

temperatures is the responsibility of the user. Consideration should be given to the loss of ductility and

impact strength of many materials at low temperature.5 Design

5.1 Body wall thickness

5.1.1 The terms used in 5.1 are illustrated in Figure 1. d is the inside diameter given in Table 1.

5.1.2 The minimum body wall thickness, t , at the time of manufacture, shall be in accordance with:

— EN 12516-1 or EN 12516-2 for PN-designated valves,— ASME B16.34 or EN 12516-1 for Class-designated valves.

Exceptions are given in 5.1.3 to 5.1.5.

Additional metal thickness needed for assembly stresses, closing stresses, stress concentrations and

shapes other than circular shall be determined by the manufacturers, since these factors vary widely.

5.1.3 The weld preparation in butt-welding end valves (see 5.2.2.2) shall not reduce the body wall

thickness to less than the values specified in 5.1.2 within a region closer to the outside surface of the

body neck than t measured along the run direction.The transition to the weld preparation shall be gradual and the section shall be essentially circular

through the entire length of the transition. Sharp discontinuities or abrupt changes in section in areas

that infringe into the transition shall be avoided, except that test collars or bands, either welded or

integral, are allowed.In no case shall the thickness be less than

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.