ISO 14932:2023

(Main)Rubber compounding ingredients — Organic vulcanizing agents — Determination of organic peroxide content

Rubber compounding ingredients — Organic vulcanizing agents — Determination of organic peroxide content

This document specifies four methods for the determination of the content of the following groups of organic peroxides used as rubber vulcanizing agents. There are three titration methods and one gas-chromatography method. a) titration method A for group a: Peroxyketals: 1,1-Di(tert-butylperoxy)cyclohexane (DTBPC; CAS Registry Number®:3006-86-8) 1,1-Di(tert-butylperoxy)-2-methylcyclohexane (DBPMC; CAS RN 147217‑40‑1); 1,1-Di(tert-butylperoxy)-3,3,5-trimethylcylcohexane (DBPTC; CAS RN 6731‑36‑8); 2,2-Di(tert-butylperoxy)butane (DBPB; CAS RN 2167‑23‑9); Butyl −4,4-di(tert-butylperoxy)valerate (BPV; CAS RN 995‑33‑5); b) titration method B for group b: Diacyl peroxides: Dibenzoyl peroxide (CAS RN 94‑36‑0); Di(2,4-dichlorobenzoyl) peroxide (CAS RN 133‑14‑2); Di(4-methylbenzoyl) peroxide (CAS RN 895‑85‑2); c) titration method C for group c: Diaralkyl and alkyl-aralkyl peroxides: Di(tert-butylperoxyisopropyl)benzene (CAS RN 2212‑81‑9); Dicumyl peroxide (CAS RN 80‑43‑3); tert-Butyl cumyl peroxide (CAS RN 3457‑61‑2); d) gas-chromatography for dialkyl peroxides, using a capillary or packed column. 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane (CAS RN 78‑63‑7)

Ingrédients de mélange du caoutchouc — Agents vulcanisants organiques — Détermination de la teneur en peroxyde organique

Le présent document spécifie quatre méthodes de détermination de la teneur en peroxydes organiques des groupes suivants, utilisés comme agents vulcanisants du caoutchouc. Il y a trois méthodes par titrage et une méthode par chromatographie en phase gazeuse. a) méthode par titrage A pour le groupe a: Peroxycétals: 1,1-Di(tert-butyleperoxy)cyclohexane (DTBPC; CAS Registry Number®3006-86-8) 1,1-Di(tert-butyleperoxy)-2-méthylcyclohexane (DBPMC; CAS RN 147217‑40‑1); 1,1-Di(tert-butyleperoxy)-3,3,5-triméthylcylcohexane (DBPTC; CAS RN 6731‑36‑8); 2,2-Di(tert-butyleperoxy)butane (DBPB; CAS RN 2167‑23‑9); 4,4-di(tert-butyleperoxy)valérate de butyle (BPV; CAS RN 995‑33‑5); b) méthode par titrage B pour le groupe b: Peroxydes de diacyles: Peroxyde de dibenzoyle (CAS RN 94‑36‑0); Peroxyde de Di(2,4-dichlorobenzoyle) (CAS RN 133‑14‑2); Peroxyde de Di(4-méthylbenzoyle) (CAS RN 895‑85‑2); c) méthode par titrage C pour le groupe c: Peroxydes de diaralkyles et peroxydes d'alkyles et d'aralkyles: Di(tert-butyleperoxyisopropyl)benzène (CAS RN 2212‑81‑9); Peroxyde de dicumyle (CAS RN 80‑43‑3); Peroxyde de tert-butyle et de cumyle (CAS RN 3457‑61‑2); d) chromatographie en phase gazeuse pour les peroxydes de dialkyles, sur colonne capillaire ou sur colonne remplie. 2,5-Diméthyl-2,5-di(tert-butyleperoxy)hexane (CAS 78‑63‑7)

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14932

Second edition

2023-08

Rubber compounding ingredients —

Organic vulcanizing agents —

Determination of organic peroxide

content

Ingrédients de mélange du caoutchouc — Agents vulcanisants

organiques — Détermination de la teneur en peroxyde organique

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

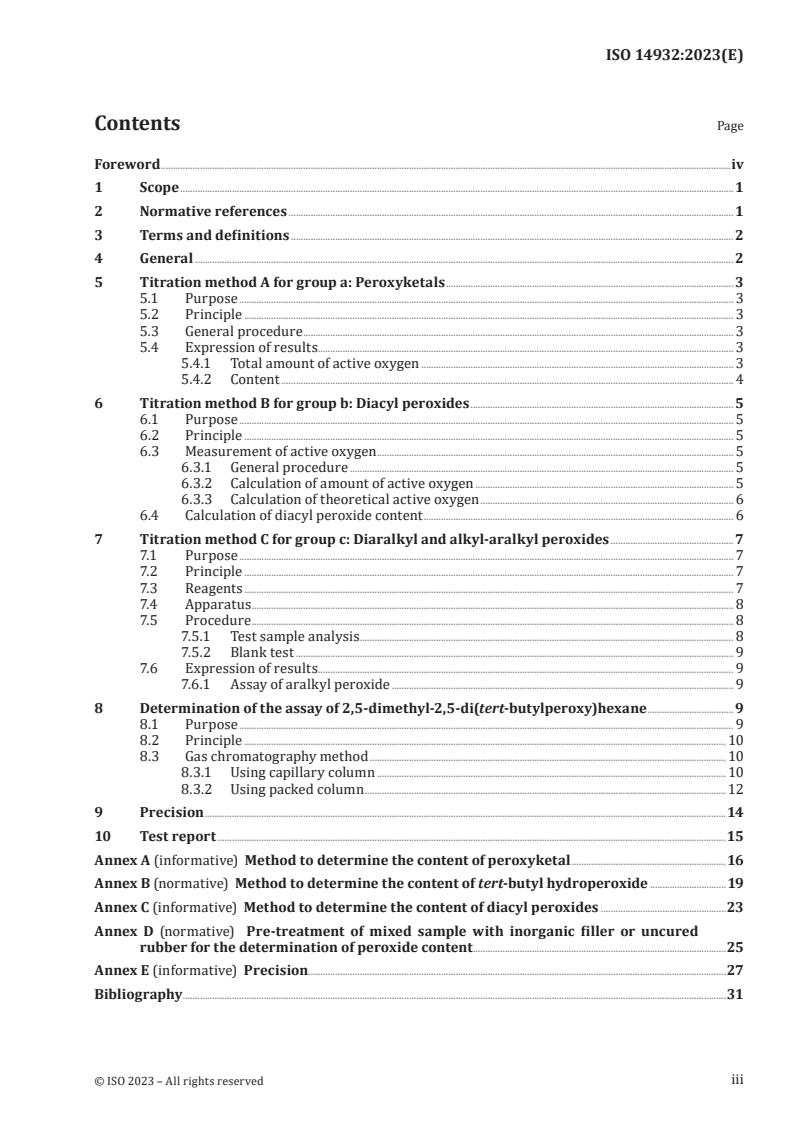

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 General . 2

5 Titration method A for group a: Peroxyketals . 3

5.1 Purpose . 3

5.2 Principle . 3

5.3 General procedure . 3

5.4 Expression of results . . 3

5.4.1 Total amount of active oxygen . 3

5.4.2 Content . 4

6 Titration method B for group b: Diacyl peroxides . 5

6.1 Purpose . 5

6.2 Principle . 5

6.3 Measurement of active oxygen . 5

6.3.1 General procedure . 5

6.3.2 Calculation of amount of active oxygen . 5

6.3.3 Calculation of theoretical active oxygen . 6

6.4 Calculation of diacyl peroxide content . 6

7 Titration method C for group c: Diaralkyl and alkyl-aralkyl peroxides .7

7.1 Purpose . 7

7.2 Principle . 7

7.3 Reagents . 7

7.4 Apparatus . 8

7.5 Procedure . 8

7.5.1 Test sample analysis . 8

7.5.2 Blank test . 9

7.6 Expression of results . 9

7.6.1 Assay of aralkyl peroxide . 9

8 Determination of the assay of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane .9

8.1 Purpose . 9

8.2 Principle . 10

8.3 Gas chromatography method . 10

8.3.1 Using capillary column . 10

8.3.2 Using packed column .12

9 Precision .14

10 Test report .15

Annex A (informative) Method to determine the content of peroxyketal .16

Annex B (normative) Method to determine the content of tert-butyl hydroperoxide .19

Annex C (informative) Method to determine the content of diacyl peroxides .23

Annex D (normative) Pre-treatment of mixed sample with inorganic filler or uncured

rubber for the determination of peroxide content .25

Annex E (informative) Precision.27

Bibliography .31

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 3, Raw materials (including latex) for use in the rubber industry.

This second edition cancels and replaces the first edition (ISO 14932:2012), which has been technically

revised.

The main changes are as follows:

— gas chromatography using packed column has been added in 8.3;

— the solvent has been changed from chloroform to toluene and isopropyl alcohol;

— tetrahydrofuran has been removed due to toxicity;

— CAS Registry Numbers (CAS RN) have been added;

— Annex D and the former Annex E have been merged as Annex D;

— Formula (D.1) has been corrected.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

INTERNATIONAL STANDARD ISO 14932:2023(E)

Rubber compounding ingredients — Organic vulcanizing

agents — Determination of organic peroxide content

WARNING — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all the safety problems, if any, associated with its

use. It is the responsibility of the user to establish appropriate safety and health practices and to

determine the applicability of any other restrictions.

1 Scope

This document specifies four methods for the determination of the content of the following groups of

organic peroxides used as rubber vulcanizing agents. There are three titration methods and one gas-

chromatography method.

a) titration method A for group a: Peroxyketals:

®1)

1,1-Di(tert-butylperoxy)cyclohexane (DTBPC; CAS Registry Number :3006-86-8)

1,1-Di(tert-butylperoxy)-2-methylcyclohexane (DBPMC; CAS RN 147217-40-1);

1,1-Di(tert-butylperoxy)-3,3,5-trimethylcylcohexane (DBPTC; CAS RN 6731-36-8);

2,2-Di(tert-butylperoxy)butane (DBPB; CAS RN 2167-23-9);

Butyl −4,4-di(tert-butylperoxy)valerate (BPV; CAS RN 995-33-5);

b) titration method B for group b: Diacyl peroxides:

Dibenzoyl peroxide (CAS RN 94-36-0);

Di(2,4-dichlorobenzoyl) peroxide (CAS RN 133-14-2);

Di(4-methylbenzoyl) peroxide (CAS RN 895-85-2);

c) titration method C for group c: Diaralkyl and alkyl-aralkyl peroxides:

Di(tert-butylperoxyisopropyl)benzene (CAS RN 2212-81-9);

Dicumyl peroxide (CAS RN 80-43-3);

tert-Butyl cumyl peroxide (CAS RN 3457-61-2);

d) gas-chromatography for dialkyl peroxides, using a capillary or packed column.

2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane (CAS RN 78-63-7)

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 385, Laboratory glassware — Burettes ®

1) Chemical Abstracts Service (CAS) Registry Number is a trademark of the American Chemical Society (ACS).

This information is given

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.