ASTM B779-12

(Specification)Standard Specification for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Steel-Reinforced (ACSR/TW)

Standard Specification for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Steel-Reinforced (ACSR/TW)

ABSTRACT

This specification covers shaped wire compact concentric-lay-stranded aluminum conductor, steel-reinforced (ACSR/TW) and its component wires for use as overhead electrical conductors. Requirements for (1) wire stranding (2) tensile strength and elongation, (3) joints such as electric-butt welds, electric-butt cold-upset welds, or cold-pressure welds, and (4) lay length, diameter, direction, and factor are detailed. The construction requirements include: nominal aluminum cross sectional area, conductor type, nominal number of aluminum wires, number of layers, number and diameter of the steel core wire, mass per unit length, rated strength, and outside diameter of the shaped wire compact. The methods of determining mass per unit length, cross-section, and electrical resistance of the stranded conductor are given. Mechanical and electrical tests shall be performed before stranding.

SCOPE

1.1 This specification covers shaped wire compact concentric-lay-stranded aluminum conductor, steel-reinforced (ACSR/TW) and its component wires for use as overhead electrical conductors (Explanatory Note 1 and Note 2).

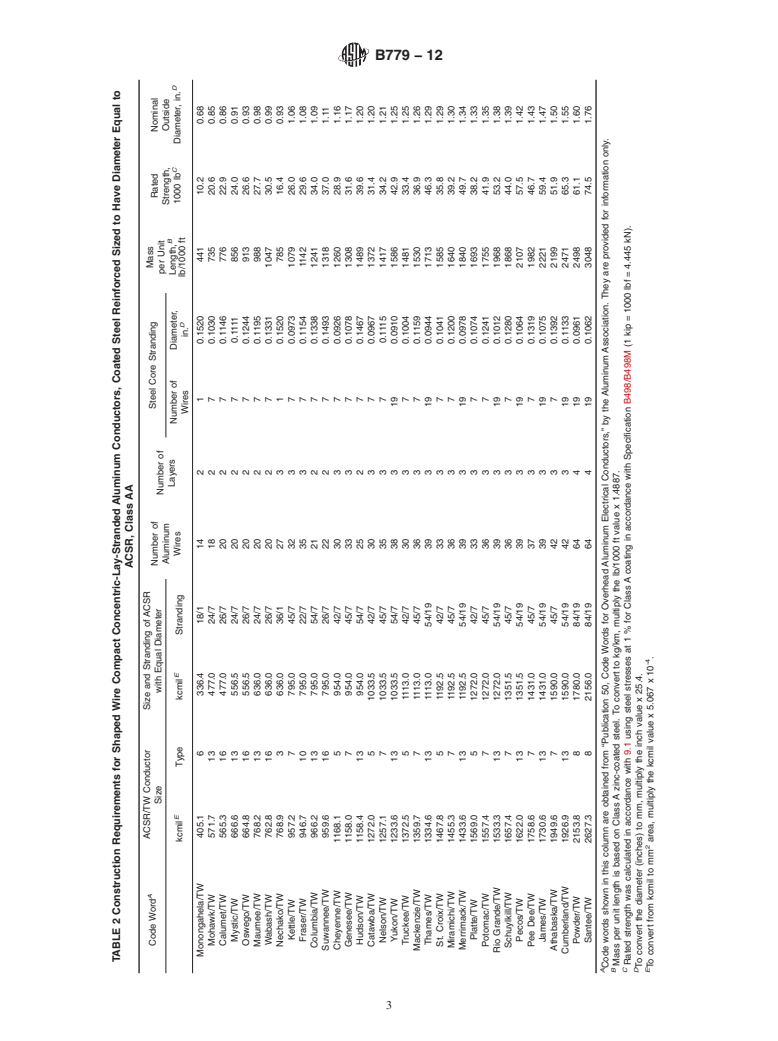

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.Note 1—ACSR/TW is designed to increase the aluminum area for a given diameter of conductor by the use of trapezoidally shaped wires (TW). The conductors consist of a central core of round steel wire(s) surrounded by two or more layers of trapezoidal aluminum 1350-H19 wires. Different strandings of the same size of conductor are identified by type, which is the approximate ratio of steel area to aluminum area expressed in percent (Table 1, Table 2 and Table 3). For the purpose of this specification, the sizes listed in Table 1 and Table 2 are tabulated on the basis of the finished conductor having an area or outside diameter equal to that of specific sizes of standard ACSR so as to facilitate conductor selection.TABLE 1 Construction Requirements for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated Steel Reinforced Size to Have Area Equal to ACSR, Class AA

ACSR/TW Conductor

Size

Size and Stranding of ACSR with Equal Area

Number of Aluminum Wires

Number of Layers

Steel Core Stranding

Mass per Unit Length,A

lb/1000 ft

Rated

Strength,

1000 lbB

Nominal

Outside

Diameter, in.

kcmil

Type

kcmil

Stranding

Number of Wires

Diameter,

in.

336.4

6

336.4

18/1

14

2

1

0.1367

365

8.6

0.63

477.0

13

477.0

24/7

18

2

7

0.0940

613

17.2

0.78

477.0

16

477.0

26/7

18

2

7

0.1053

655

19.4

0.79

556.5

13

556.5

24/7

18

2

7

0.1015

715

20.0

0.84

556.5

16

556.5

26/7

20

2

7

0.1138

765

22.6

0.85

636.0

3

636.0

36/1

27

3

1

0.1329

646

13.5

0.85

636.0

13

636.0

24/7

18

2

7

0.1085

816

22.9

0.89

636.0

16

636.0

26/7

20

2

7

0.1216

874

25.4

0.91

795.0

7

795.0

45/7

17

2

7

0.0886

892

21.0

0.96

795.0

10

795.0

22/7

18

2

7

0.1108

975

25.9

0.98

795.0

13

795.0

54/7

20

2

7

0.1213

1021

28.2

0.99

795.0

16

795.0

26/7

20

2

7

0.1360

1092

31.8

1.01

954.0

5

954.0

42/7

30

3

7

0.0837

1029

23.7

1.05

954.0

7

954.0

45/7

32

3

7

0.0971

1075

25.9

1.06

954.0

13

954.0

54/7

20

2

7

0.1329

1226

33.5

1.08

1033.5

5

1033.5

42/7

30

3

7

0.0871

1115

25.7

1.09

1033.5

7

...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B779 −12

StandardSpecification for

Shaped Wire Compact Concentric-Lay-Stranded Aluminum

1

Conductors, Steel-Reinforced (ACSR/TW)

This standard is issued under the fixed designation B779; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B498/B498MSpecification for Zinc-Coated (Galvanized)

Steel Core Wire for Use in Overhead Electrical Conduc-

1.1 This specification covers shaped wire compact

tors

concentric-lay-stranded aluminum conductor, steel-reinforced

B500/B500MSpecification for Metallic Coated or Alumi-

(ACSR/TW) and its component wires for use as overhead

num Clad Stranded Steel Core for Use in Overhead

electrical conductors (Explanatory Note 1 and Note 2).

Electrical Conductors

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

B502Specification forAluminum-Clad Steel Core Wire for

as standard. The values given in parentheses are mathematical

Use in Overhead Electrical Aluminum Conductors

conversions to SI units that are provided for information only

B549Specification for Concentric-Lay-Stranded Aluminum

and are not considered standard.

Conductors, Aluminum-Clad Steel Reinforced for Use in

Overhead Electrical Conductors

NOTE 1—ACSR/TW is designed to increase the aluminum area for a

given diameter of conductor by the use of trapezoidally shaped wires B606Specification for High-Strength Zinc-Coated (Galva-

(TW). The conductors consist of a central core of round steel wire(s)

nized) Steel Core Wire for Aluminum and Aluminum-

surrounded by two or more layers of trapezoidal aluminum 1350-H19

Alloy Conductors, Steel Reinforced

wires. Different strandings of the same size of conductor are identified by

B802/B802M Specification for Zinc–5 % Aluminum-

type, which is the approximate ratio of steel area to aluminum area

MischmetalAlloy-Coated Steel Core Wire forAluminum

expressedinpercent(Table1,Table2andTable3).Forthepurposeofthis

specification, the sizes listed in Table 1 and Table 2 are tabulated on the

Conductors, Steel Reinforced (ACSR)

basisofthefinishedconductorhavinganareaoroutsidediameterequalto

B803Specification for High-Strength Zinc–5 %Aluminum-

that of specific sizes of standard ACSR so as to facilitate conductor

Mischmetal Alloy-Coated Steel Core Wire for Use in

selection.

Overhead Electrical Conductors

NOTE 2—The aluminum and temper designations conform to ANSI

Standard H35.1. Aluminum 1350 corresponds to Unified Numbering E29Practice for Using Significant Digits in Test Data to

System (UNS) A91350 in accordance with Practice E527.

Determine Conformance with Specifications

E527Practice for Numbering Metals and Alloys in the

2. Referenced Documents

Unified Numbering System (UNS)

2

2.1 ASTM Standards:

2.2 Other Documents:

B230/B230MSpecification for Aluminum 1350–H19 Wire ANSIH35.1AmericanNationalStandardAlloyandTemper

3

for Electrical Purposes

Designation Systems for Aluminum

B232/B232M Specification for Concentric-Lay-Stranded NBS Handbook 100—Copper Wire Tables of the National

4

Aluminum Conductors, Coated-Steel Reinforced (ACSR)

Bureau of Standards

B263Test Method for Determination of Cross-Sectional

3. Terminology

Area of Stranded Conductors

B354Terminology Relating to Uninsulated Metallic Electri-

3.1 Definitions of Terms Specific to This Standard:

cal Conductors

3.1.1 ACSR/TWcoveredbythisspecificationhasfivetypes

of coated core wire and one type of aluminum-clad core wire

whicharedesignatedbyabbreviationsasfollows(Explanatory

1

This specification is under the jurisdiction of ASTM Committee B01 on

Note 2 and Note 8):

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

3.1.2 ACSR/TW/AW2—ACSR/TW using aluminum-clad

Conductors of Light Metals.

steel wire, normal strength (Specification B502).

Current edition approved June 1, 2012. Published October 2012. Originally

approved in 1987. Last previous edition approved in 2009 as B779–03 (2009).

DOI: 10.1520/B0779-12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.B01

4

Standards volume information, refer to the standard’s Document Summary page on Available from National Technical Information Service (NTIS), 5285 Port

the ASTM website. Royal Rd., Springfield, VA 22161, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B779−12

TABLE 1 Construction Requ

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B779 − 03 (Reapproved 2009) B779 − 12

Standard Specification for

Shaped Wire Compact Concentric-Lay-Stranded Aluminum

1

Conductors, Steel-Reinforced (ACSR/TW)

This standard is issued under the fixed designation B779; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers shaped wire compact concentric-lay-stranded aluminum conductor, steel-reinforced (ACSR/TW)

and its component wires for use as overhead electrical conductors (Explanatory Note 1 and Note 2).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

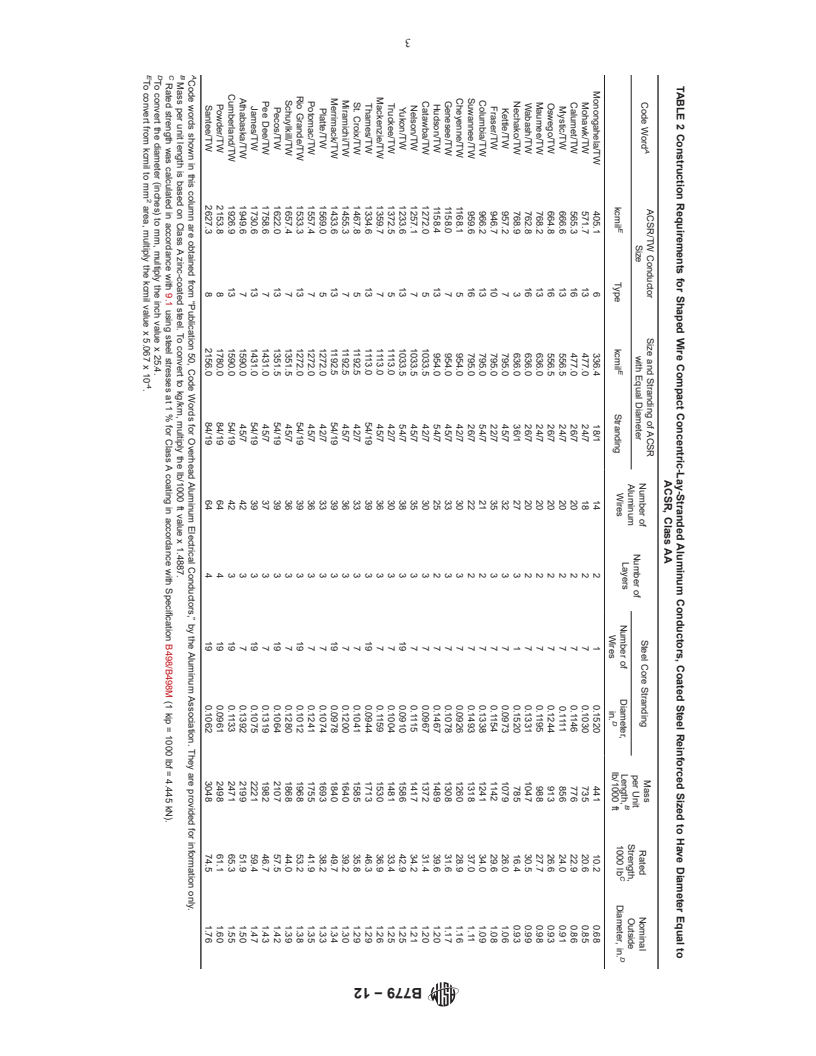

NOTE 1—ACSR/TW is designed to increase the aluminum area for a given diameter of conductor by the use of trapezoidally shaped wires (TW). The

conductors consist of a central core of round steel wire(s) surrounded by two or more layers of trapezoidal aluminum 1350-H19 wires. Different strandings

of the same size of conductor are identified by type, which is the approximate ratio of steel area to aluminum area expressed in percent (Table 1, Table

2 and Table 3). For the purpose of this specification, the sizes listed in Table 1 and Table 2 are tabulated on the basis of the finished conductor having

an area or outside diameter equal to that of specific sizes of standard ACSR so as to facilitate conductor selection.

NOTE 2—The aluminum and temper designations conform to ANSI Standard H 35.1. Aluminum 1350 corresponds to Unified Numbering System

(UNS) A91350 in accordance with Practice E527.

2. Referenced Documents

2

2.1 ASTM Standards:

B230/B230M Specification for Aluminum 1350–H19 Wire for Electrical Purposes

B232/B232M Specification for Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced (ACSR)

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B341/B341M Specification for Aluminum-Coated (Aluminized) Steel Core Wire for Aluminum Conductors, Steel Reinforced

3

(ACSR/AZ) (Withdrawn 2007)

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

B498/B498M Specification for Zinc-Coated (Galvanized) Steel Core Wire for Use in Overhead Electrical Conductors

B500/B500M Specification for Metallic Coated or Aluminum Clad Stranded Steel Core for Use in Overhead Electrical

Conductors

B502 Specification for Aluminum-Clad Steel Core Wire for Use in Overhead Electrical Aluminum Conductors

B549 Specification for Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Clad Steel Reinforced for Use in Overhead

Electrical Conductors

B606 Specification for High-Strength Zinc-Coated (Galvanized) Steel Core Wire for Aluminum and Aluminum-Alloy

Conductors, Steel Reinforced

B802/B802M Specification for Zinc–5 % Aluminum-Mischmetal Alloy-Coated Steel Core Wire for Aluminum Conductors,

Steel Reinforced (ACSR)

B803 Specification for High-Strength Zinc–5 % Aluminum-Mischmetal Alloy-Coated Steel Core Wire for Use in Overhead

Electrical Conductors

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved April 1, 2009June 1, 2012. Published May 2009October 2012. Originally approved in 1987. Last previous edition approved in 20032009 as

B779 – 03.B779 – 03 (2009). DOI: 10.1520/B0779-03R09.10.1520/B0779-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B779 − 12

TABLE 1 Construction Requirements for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated Steel

Reinforced Size to Have Area Equal to ACSR, Class AA

ACSR/TW Conductor Size and Stranding of ACSR

Mass per

Steel Core Stranding

Number of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.