ASTM D3103-99

(Test Method)Standard Test Method for Thermal Insulation Quality of Packages

Standard Test Method for Thermal Insulation Quality of Packages

SCOPE

1.1 This test method covers the determination of the thermal insulation quality of a package and its enclosed packaging from temperature differentials between the packaged item and the outside environment. It is suitable for testing packages with and without various internal refrigerants and with or without interior packaging. Representative test conditions covered are indicated by Figs. 1 and 2. Depending upon the type of insulation material used, a water-vaporproof barrier might be used just inside the exterior packages of Fig. 1.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 5.2.3 and 9.2.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3103–99

Standard Test Method for

Thermal Insulation Quality of Packages

This standard is issued under the fixed designation D3103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

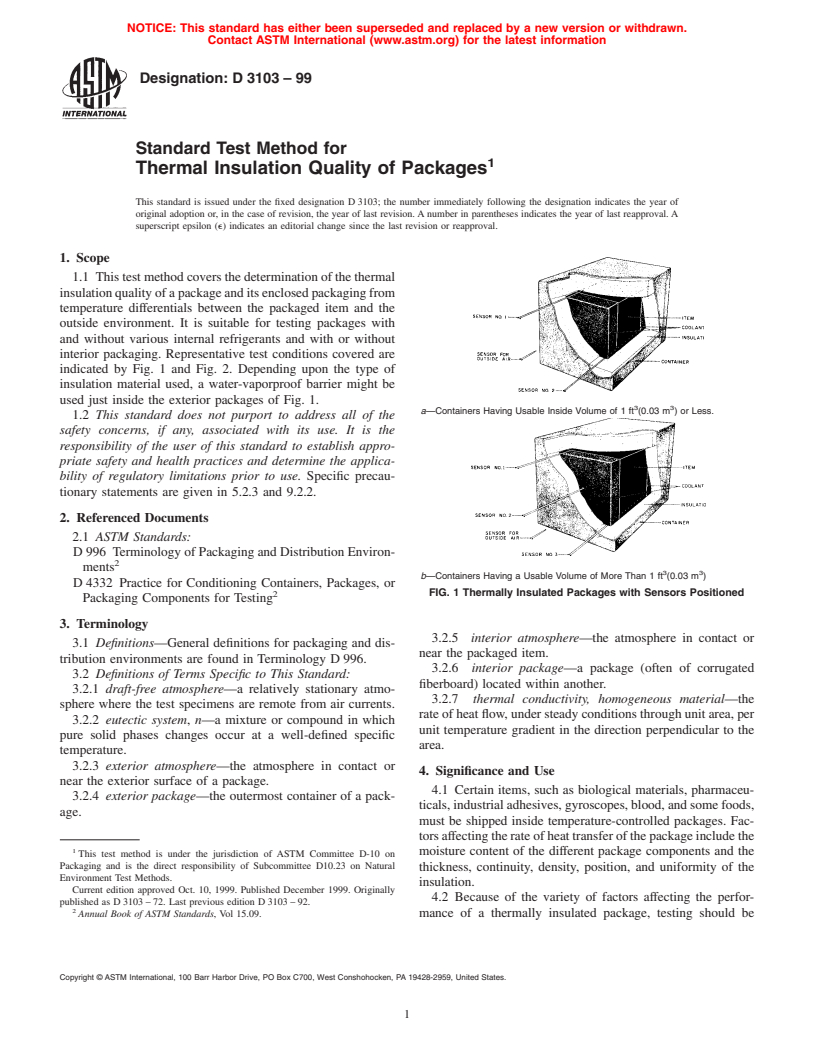

1.1 Thistestmethodcoversthedeterminationofthethermal

insulationqualityofapackageanditsenclosedpackagingfrom

temperature differentials between the packaged item and the

outside environment. It is suitable for testing packages with

and without various internal refrigerants and with or without

interior packaging. Representative test conditions covered are

indicated by Fig. 1 and Fig. 2. Depending upon the type of

insulation material used, a water-vaporproof barrier might be

used just inside the exterior packages of Fig. 1.

3 3

a—Containers Having Usable Inside Volume of 1 ft (0.03 m ) or Less.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in 5.2.3 and 9.2.2.

2. Referenced Documents

2.1 ASTM Standards:

D996 TerminologyofPackagingandDistributionEnviron-

ments

3 3

b—Containers Having a Usable Volume of More Than 1 ft (0.03 m )

D4332 Practice for Conditioning Containers, Packages, or

2 FIG. 1 Thermally Insulated Packages with Sensors Positioned

Packaging Components for Testing

3. Terminology

3.2.5 interior atmosphere—the atmosphere in contact or

3.1 Definitions—General definitions for packaging and dis-

near the packaged item.

tribution environments are found in Terminology D996.

3.2.6 interior package—a package (often of corrugated

3.2 Definitions of Terms Specific to This Standard:

fiberboard) located within another.

3.2.1 draft-free atmosphere—a relatively stationary atmo-

3.2.7 thermal conductivity, homogeneous material—the

sphere where the test specimens are remote from air currents.

rateofheatflow,understeadyconditionsthroughunitarea,per

3.2.2 eutectic system, n—a mixture or compound in which

unit temperature gradient in the direction perpendicular to the

pure solid phases changes occur at a well-defined specific

area.

temperature.

3.2.3 exterior atmosphere—the atmosphere in contact or

4. Significance and Use

near the exterior surface of a package.

4.1 Certain items, such as biological materials, pharmaceu-

3.2.4 exterior package—the outermost container of a pack-

ticals,industrialadhesives,gyroscopes,blood,andsomefoods,

age.

must be shipped inside temperature-controlled packages. Fac-

torsaffectingtherateofheattransferofthepackageincludethe

moisture content of the different package components and the

This test method is under the jurisdiction of ASTM Committee D-10 on

Packaging and is the direct responsibility of Subcommittee D10.23 on Natural

thickness, continuity, density, position, and uniformity of the

Environment Test Methods.

insulation.

Current edition approved Oct. 10, 1999. Published December 1999. Originally

4.2 Because of the variety of factors affecting the perfor-

published as D3103–72. Last previous edition D3103–92.

Annual Book of ASTM Standards, Vol 15.09. mance of a thermally insulated package, testing should be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3103–99

operating personnel. Usually these refrigerants can be used if provisions

are made to evacuate the built-up gas periodically.

5.3 Temperature Indicators:

5.3.1 Multi-Channel Recorder with Thermocouples—The

recording capability should be as a datalog by thermocouple

number with date and time of reading, that can be presented in

a continuous graph form as a secondary presentation. Resolu-

tion of the device shall be 0.1°C or greater.Accuracy over the

range tested should be 6 1°C. The printer or associated

computer datafile shall be activated by a voltage from an

insulated pair of copper-constantan or other suitable wires 30

AWGB&Sgage(0.255mm)orlessindiameter(notincluding

the thickness of insulation). The recorder and chart shall have

a capability that extends beyond the temperature values en-

countered in the test.

5.3.2 Thermistor-Recorder—A thermistor sensor may be

used, instead of a thermocouple, for sensing interior tempera-

tures of the package. The thermistor may be attached to

recordingequipment,asdescribedin5.3.1,withsupplementary

electrical circuitry as needed, or it may be a wireless, battery

operated, computer programmable unit that stores digital

temperature readings at specified time intervals. Programming

and data downloading of the units is done through a suitable

computer interface with appropriate software. Accuracy over

FIG. 2 Liquid Nitrogen Refrigerator

the range tested should be 6 1°C with resolution to 0.1°C.

Response time over range should be determined prior to use

and suitable for the reading interval of the test.

conducted with the actual package whenever possible. When

simulated packages are used, special care must be exercised so

6. Sampling

that the simulated payload and coolant of the model will be as

6.1 Experimental package designs shall be made in accor-

close as possible to the actual materials in temperature and

dance with the specifications and methods that will be used

other relevant physical properties.

during actual production. When possible, choose the test

packages by random sampling.

5. Test Conditions and Apparatus

7. Test Specimens

5.1 Temperature of Exterior Atmosphere— Draft-free envi-

ronments large enough to accommodate the packages, but not

7.1 A single test specimen shall consist of a package

necessarily the recorder, are required. Usual evaluation of the

enclosingtheactualitemoradummyloadsimulatingtheitem.

packaging materials will involve simple refrigerated or ambi-

The package shall be closed, taped, or sealed in the same

ent exterior atmospheric conditions. These may be established

manner as will be used for actual shipment.

as4 62°C(39 64°F),37.8 62°C(100 64°F),and23 62°C

7.2 The mass, configuration, and location of refrigerant, if

(736 4°F).Additionally, other temperature extremes or cycles

used, must be the same in each pack.

between various temperatures expected during shipment might

7.3 For development or screening evaluation of the overall

be used as an exterior atmosphere.

insulation effectiveness of the container and insulation mate-

5.2 Temperature of Interior Atmosphere of Package—When

rial,theinteriorcavityandpackagewallthicknessshallbekept

no refrigerant is used, interior package temperature may serve

constant (for example, a 12 by 12 by 12-in. (305 by 305 by

as a measure of the thermal insulation quality of the package.

305-mm) interior cavity surrounded by a 1-in. (25-mm) thick-

If it is desired to control the interior temperature of the

ness of insulation and a 14 by 14 by 14-in. (356 by 356 by

atmosphere, use one of the following:

356-mm) container. Test a minimum of three such packages at

5.2.1 Refrigerant Gel, Water Ice, or Other Refrigerant

each exposure listed in 5.1 to obtain an average result and

Source, for internal temperatures above 0°C (32°F),

range of performance.

5.2.2 Solid Carbon Dioxide CO (Dry Ice or Euctectic

7.4 When testing packages having known or previously

Systems), wrapped as used in shipments for maintaining

established performance data, a minimum of three identical

internal temperatures down to−73°C (−108.4°F), or

samples shall be tested to determine reproducibility and

5.2.3 Liquid Nitrogen, for temperatures to − 195°C

repeatability.

(−319°F).

8. Conditioning

NOTE 1—Caution:Gaseous CO and nitrogen are colorless, odorless,

8.1 Condition materials in accordance with Practice D4332

and noncombustible. In well-ventilated uses they present few problems,

or for 24 h at the conditions expected during actual production

butevaporationorsublimationinairtightenclosuresforprolongedperiods

(for example, 12 h) can produce sprung doors and asphyxiation of packing.

D3103–99

9. Procedures inside dimensions are being evaluated, the quantity by mass,

configuration, and total surface area must be constant for the

9.1 Packages Enclosing Solid Refrigerants:

seriesforaccurateevaluationofperformance.Whencrushedor

9.1.1 Verify the calibration of the temperature-monitoring

chopped dry ice is used, the fragments should be of the same

equipment per manufacturer’s directions against an NIS trace-

general size for each package tested and should be free of dry

able standard suitable for the ranges being measured. Battery-

ice dust.

operatedthermistorsrecorderswithorwithoutexternalprobes,

9.1.5 If wires are not ported through the wall of the

should be calibrated by the manufacturer and a certificate of

insulatedcarton,placethecoveronthepackagewiththesensor

NIS traceability of accuracy provided.

wires arranged so that the least possible heat transfer occurs

9.1.2 Place the contents in the conditioned package accord-

through the joint.

ing to the specific configuration to be tested.

9.1.6 Tape or otherwise secure the cover to the package in

9.1.3 Insert the sensors in the package so that they are in

the normal manner.

contact with the item(s) as follows:

9.1.7 Placethepackageinthetestenvironmentonawooden

9.1.3.1 For packages having an inside volume of 1 ft or

platform or shelf in such a manner that no part of the package

less and a single open cavity for both ice and product, place

contacts the chamber walls or floor. If more than one package

one sensor at or near the diagonally opposite corners of the

istestedatonetime,theyshallbeseparatedfromeachotherby

item as shown in Fig. 1a.Additionally, the sensors and at least

1 at least 6 in. (152 mm). Mark the chart with date and time and

⁄2 in. (13 mm) of wire immediately behind them should be in

start the recorder.

contact with the item. Wrapping the wires around the item, if

9.1.7.1 The orientation of the carton should be the same as

practical, is advantageous to mini

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.