ASTM C1484-10(2018)

(Specification)Standard Specification for Vacuum Insulation Panels

Standard Specification for Vacuum Insulation Panels

ABSTRACT

This specification covers the general requirements for vacuum insulation panels (VIP). These panels have been used wherever high thermal resistance is desired in confined space applications, such as transportation, equipment, and appliances. The panel barrier consists of one or more layers of materials whose primary functions are to control gas diffusion to the core, and to provide mechanical protection. The core shall comprise a system of cells, microspheres, powders, fibers, aerogels, or laminates, whose chemical composition shall be organic, inorganic, or metallic. The physical and mechanical properties of vacuum insulation panels are presented in details. The compressive resistance, panel barrier permeance, and center-of-panel thermal resistivit shall be tested to meet the requirements prescribed. The effective thermal resistance differs significantly from the product of the center-of-panel resistivity and the thickness, and this system characteristic must take into account the details of the overall VIP design as well as its installation. The creep and dimensional stability at service condition shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers the general requirements for Vacuum Insulation Panels (VIP). These panels have been used wherever high thermal resistance is desired in confined space applications, such as transportation, equipment, and appliances.

1.2 Vacuum panels typically exhibit an edge effect due to differences between panel core and panel barrier thermal properties. This specification applies to composite panels whose center-of-panel apparent thermal resistivities (sec. 3.2.3) typically range from 87 to 870 m·K/W at 24°C mean, and whose intended service temperature boundaries range from –70 to 480°C.

1.3 The specification applies to panels encompassing evacuated space with: some means of preventing panel collapse due to atmospheric pressure, some means of reducing radiation heat transfer, and some means of reducing the mean free path of the remaining gas molecules.

1.4 Limitations:

1.4.1 The specification is intended for evacuated planar composites; it does not apply to non-planar evacuated self-supporting structures, such as containers or bottles with evacuated walls.

1.4.2 The specification describes the thermal performance considerations in the use of these insulations. Because this market is still developing, discrete classes of products have not yet been defined and standard performance values are not yet available.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: For specific safety considerations see Annex A1.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1484 −10 (Reapproved 2018)

Standard Specification for

Vacuum Insulation Panels

This standard is issued under the fixed designation C1484; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 1—For specific safety considerations see Annex A1.

1. Scope

1.7 This international standard was developed in accor-

1.1 This specification covers the general requirements for

dance with internationally recognized principles on standard-

Vacuum Insulation Panels (VIP). These panels have been used

ization established in the Decision on Principles for the

wherever high thermal resistance is desired in confined space

Development of International Standards, Guides and Recom-

applications, such as transportation, equipment, and appli-

mendations issued by the World Trade Organization Technical

ances.

Barriers to Trade (TBT) Committee.

1.2 Vacuum panels typically exhibit an edge effect due to

differences between panel core and panel barrier thermal

2. Referenced Documents

properties. This specification applies to composite panels

2.1 ASTM Standards:

whose center-of-panel apparent thermal resistivities (sec.

C165 Test Method for Measuring Compressive Properties of

3.2.3) typically range from 87 to 870 m·K/W at 24°C mean,

Thermal Insulations

andwhoseintendedservicetemperatureboundariesrangefrom

C168 Terminology Relating to Thermal Insulation

–70 to 480°C.

C177 Test Method for Steady-State Heat Flux Measure-

1.3 Thespecificationappliestopanelsencompassingevacu-

ments and Thermal Transmission Properties by Means of

ated space with: some means of preventing panel collapse due

the Guarded-Hot-Plate Apparatus

to atmospheric pressure, some means of reducing radiation

C203 Test Methods for Breaking Load and Flexural Proper-

heat transfer, and some means of reducing the mean free path

ties of Block-Type Thermal Insulation

of the remaining gas molecules.

C390 Practice for Sampling and Acceptance of Thermal

Insulation Lots

1.4 Limitations:

C480 Test Method for Flexure Creep of Sandwich Construc-

1.4.1 The specification is intended for evacuated planar

tions

composites; it does not apply to non-planar evacuated self-

C518 Test Method for Steady-State Thermal Transmission

supporting structures, such as containers or bottles with evacu-

Properties by Means of the Heat Flow Meter Apparatus

ated walls.

C740 Guide for Evacuated Reflective Insulation In Cryo-

1.4.2 The specification describes the thermal performance

genic Service

considerations in the use of these insulations. Because this

C1045 Practice for Calculating Thermal Transmission Prop-

market is still developing, discrete classes of products have not

erties Under Steady-State Conditions

yet been defined and standard performance values are not yet

C1055 Guide for Heated System Surface Conditions that

available.

Produce Contact Burn Injuries

1.5 The values stated in SI units are to be regarded as

C1058 Practice for Selecting Temperatures for Evaluating

standard. No other units of measurement are included in this

and Reporting Thermal Properties of Thermal Insulation

standard.

C1114 Test Method for Steady-State Thermal Transmission

1.6 This standard does not purport to address all of the

Properties by Means of the Thin-Heater Apparatus

safety concerns, if any, associated with its use. It is the

C1136 Specification for Flexible, Low Permeance Vapor

responsibility of the user of this standard to establish appro-

Retarders for Thermal Insulation

priate safety, health, and environmental practices and deter-

C1363 Test Method for Thermal Performance of Building

mine the applicability of regulatory limitations prior to use.

Materials and Envelope Assemblies by Means of a Hot

Box Apparatus

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

Organic and Nonhomogeneous Inorganic Thermal Insulations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2018. Published October 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2010 as C1484 – 10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1484-10R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1484−10 (2018)

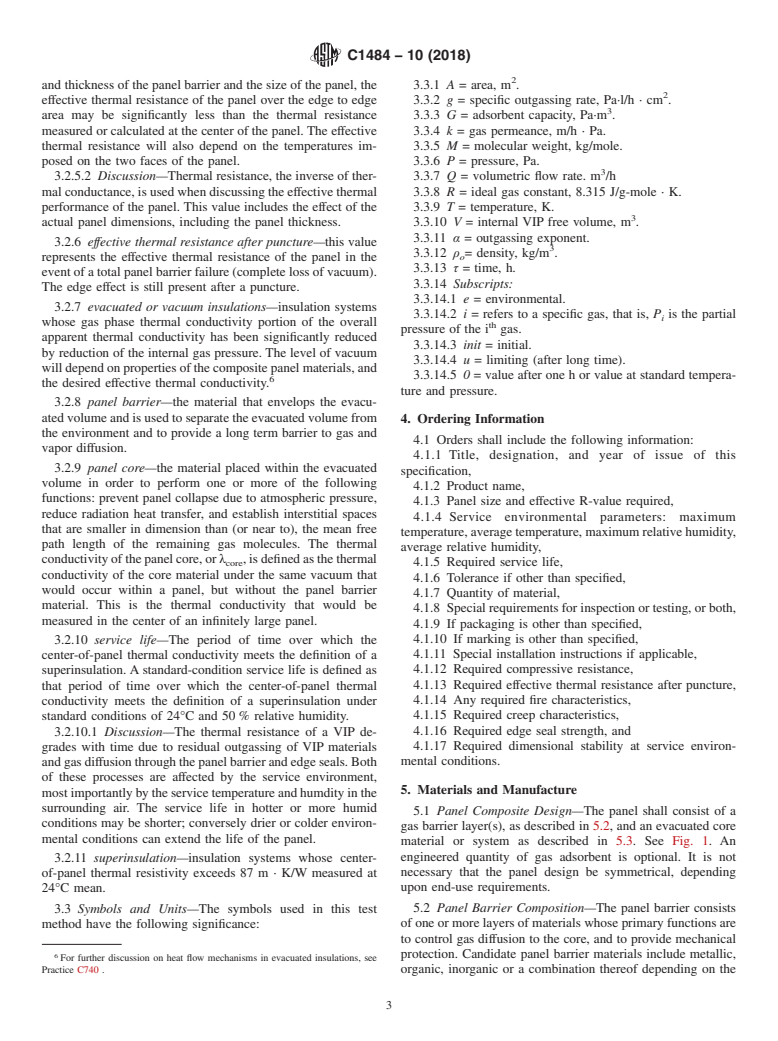

FIG. 1Side View of a Vacuum Insulation Panel Showing Edge Heat Flow and the Center-of-Panel Region

C1667 TestMethodforUsingHeatFlowMeterApparatusto 3. Terminology

Measure the Center-of-Panel Thermal Transmission Prop-

3.1 Definitions—Terminology C168 applies to terms used in

erties of Vacuum Insulation Panels

this specification.

D999 Test Methods for Vibration Testing of Shipping Con-

3.2 Definitions of Terms Specific to This Standard:

tainers

3.2.1 adsorbent—a component of some VIP designs, com-

D1434 TestMethodforDeterminingGasPermeabilityChar-

prising a chemical or physical scavenger for gas molecules.

acteristics of Plastic Film and Sheeting

D2221 Test Method for Creep Properties of Package Cush-

3.2.2 center-of-panel—a small area located at the center of

ioning Materials the largest planar surface of the panel, equidistant from each

D2126 Test Method for Response of Rigid Cellular Plastics

pair of opposite edges of that surface.

to Thermal and Humid Aging

3.2.3 center-of-panel apparent thermal resistivity—the ther-

D3103 Test Method for Thermal Insulation Performance of

mal performance of vacuum panels includes an edge effect due

Distribution Packages

tosomeheatflowthroughthepanelbarrierandthisshuntingof

D3763 Test Method for High Speed Puncture Properties of

heat around the panel becomes more prevalent with greater

Plastics Using Load and Displacement Sensors

panel barrier thermal conductivity, as shown in Fig. 1. For

D4169 Practice for Performance Testing of Shipping Con-

panels larger than a minimum size (as described in 11.4.1), the

tainers and Systems

center-of-panel apparent thermal resistivity is the intrinsic core

E493 Practice for Leaks Using the Mass Spectrometer Leak

thermal resistivity of the VIP. This center-of-panel measure-

Detector in the Inside-Out Testing Mode

mentisusedforqualitycontrol,complianceverification,andto

F88 Test Method for Seal Strength of Flexible Barrier

calculate the effective thermal performance of a panel. The

Materials

effectivethermalperformanceofapanelwillvarywiththesize

2.2 Other Standards:

and shape of the panel.

ISO 8318 Packaging - Complete, Filled Transport Packages

3.2.3.1 Discussion—Apparent thermal resistivity, the in-

- Vibration Tests Using a Sinusoidal Variable Frequency

verse of apparent thermal conductivity, is used when discuss-

IEC68-2-6, Part 2, Test F, Vibration, Basic Environmental

ing the center-of-panel thermal behavior and this value is

Testing Procedures

independent of the panel thickness.

TAPPI T803 Puncture Test of Containerboard

3.2.4 edge seal—any joint between two pieces of panel

barrier material.

Available from International Organization for Standardization (ISO), 1, ch. de

3.2.5 effective thermal resistance (Effective R-value)—this

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch.

value reflects the total panel resistance to heat flow, consider-

Available from International Electrotechnical Commission (IEC), 3 rue de

ing heat flow through the evacuated region and through the

Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

5 panel barrier.

Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org. 3.2.5.1 Discussion—Depending on the thermal conductivity

C1484−10 (2018)

and thickness of the panel barrier and the size of the panel, the 3.3.1 A = area, m .

effective thermal resistance of the panel over the edge to edge 3.3.2 g = specific outgassing rate, Pa·l/h · cm .

area may be significantly less than the thermal resistance 3.3.3 G = adsorbent capacity, Pa·m .

measured or calculated at the center of the panel. The effective 3.3.4 k = gas permeance, m/h · Pa.

thermal resistance will also depend on the temperatures im- 3.3.5 M = molecular weight, kg/mole.

posed on the two faces of the panel. 3.3.6 P = pressure, Pa.

3.2.5.2 Discussion—Thermal resistance, the inverse of ther- 3.3.7 Q = volumetric flow rate. m /h

malconductance,isusedwhendiscussingtheeffectivethermal 3.3.8 R = ideal gas constant, 8.315 J/g-mole · K.

performance of the panel. This value includes the effect of the 3.3.9 T = temperature, K.

actual panel dimensions, including the panel thickness. 3.3.10 V = internal VIP free volume, m .

3.3.11 α = outgassing exponent.

3.2.6 effective thermal resistance after puncture—this value

3.3.12 ρ = density, kg/m .

o

represents the effective thermal resistance of the panel in the

3.3.13 τ = time, h.

eventofatotalpanelbarrierfailure(completelossofvacuum).

3.3.14 Subscripts:

The edge effect is still present after a puncture.

3.3.14.1 e = environmental.

3.2.7 evacuated or vacuum insulations—insulation systems

3.3.14.2 i = refers to a specific gas, that is, P is the partial

i

whose gas phase thermal conductivity portion of the overall

th

pressure of the i gas.

apparent thermal conductivity has been significantly reduced

3.3.14.3 init = initial.

by reduction of the internal gas pressure. The level of vacuum

3.3.14.4 u = limiting (after long time).

willdependonpropertiesofthecompositepanelmaterials,and

3.3.14.5 0 = value after one h or value at standard tempera-

the desired effective thermal conductivity.

ture and pressure.

3.2.8 panel barrier—the material that envelops the evacu-

atedvolumeandisusedtoseparatetheevacuatedvolumefrom

4. Ordering Information

the environment and to provide a long term barrier to gas and

4.1 Orders shall include the following information:

vapor diffusion.

4.1.1 Title, designation, and year of issue of this

3.2.9 panel core—the material placed within the evacuated

specification,

volume in order to perform one or more of the following

4.1.2 Product name,

functions: prevent panel collapse due to atmospheric pressure,

4.1.3 Panel size and effective R-value required,

reduce radiation heat transfer, and establish interstitial spaces

4.1.4 Service environmental parameters: maximum

that are smaller in dimension than (or near to), the mean free

temperature,averagetemperature,maximumrelativehumidity,

path length of the remaining gas molecules. The thermal

average relative humidity,

conductivityofthepanelcore,orλ ,isdefinedasthethermal

core 4.1.5 Required service life,

conductivity of the core material under the same vacuum that

4.1.6 Tolerance if other than specified,

would occur within a panel, but without the panel barrier

4.1.7 Quantity of material,

material. This is the thermal conductivity that would be

4.1.8 Special requirements for inspection or testing, or both,

measured in the center of an infinitely large panel.

4.1.9 If packaging is other than specified,

4.1.10 If marking is other than specified,

3.2.10 service life—The period of time over which the

center-of-panel thermal conductivity meets the definition of a 4.1.11 Special installation instructions if applicable,

4.1.12 Required compressive resistance,

superinsulation. A standard-condition service life is defined as

that period of time over which the center-of-panel thermal 4.1.13 Required effective thermal resistance after puncture,

4.1.14 Any required fire characteristics,

conductivity meets the definition of a superinsulation under

standard conditions of 24°C and 50 % relative humidity. 4.1.15 Required creep characteristics,

4.1.16 Required edge seal strength, and

3.2.10.1 Discussion—The thermal resistance of a VIP de-

grades with time due to residual outgassing of VIP materials 4.1.17 Required dimensional stability at service environ-

mental conditions.

andgasdiffusionthroughthepanelbarrierandedgeseals.Both

of these processes are affected by the service environment,

5. Materials and Manufacture

mostimportantlybytheservicetemperatureandhumdityinthe

surrounding air. The service life in hotter or more humid

5.1 Panel Composite Design—The panel shall consist of a

conditions may be shorter; conversely drier or colder environ-

gas barrier layer(s), as described in 5.2, and an evacuated core

mental conditions can extend the life of the panel.

material or system as described in 5.3. See Fig. 1.An

engineered quantity of gas adsorbent is optional. It is not

3.2.11 superinsulation—insulation systems whose center-

necessary that the panel design be symmetrical, depending

of-panel thermal resistivity exceeds 87 m · K/W measured at

upon end-use requirements.

24°C mean.

5.2 Panel Barrier Composition—The panel barrier consists

3.3 Symbols and Units—The symbols used in this test

method have the following significance: of one or more layers of materials whose primary functions are

to control gas diffusion to the core, and to provide mechanical

protection. Candidate panel barrier materials include metallic,

For further discussion on heat flow mechanisms in evacuated insulations, see

Practice C740 . organic, inorganic or a combination thereof depending on the

C1484−10 (2018)

level of vacuum required, the desired service life, and the 6.6 Panel Barrier Permeance—The panel barrier per-

intended service temperature regimes. Panel barrier materials meance is required for the VIP Service Life calculations. The

are selected to prevent outgassing, or at least to give off only panel barrier permeance shall be measured and reported for

those gases or vapors which can be conveniently adsorbed. individual gases of interest.

5.3 Panel Core Composition—The core shall comprise a

NOTE 4—The panel barrier permeance may also be affected by the

service environment.

system of cells, microspheres, powders, fibers, aerogels, or

laminates, whose chemical composition shall be organic,

6.7 Dimensional Stability at Service Conditions—Themaxi-

inorganic, or metallic. Within the reticular portion of the core,

mum allowable change in panel dimensions caused by the

subsystems such as honeycomb or integral wall systems are

change from ambient to service environmental conditio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.