ASTM F778-88(2001)

(Test Method)Standard Methods for Gas Flow Resistance Testing of Filtration Media

Standard Methods for Gas Flow Resistance Testing of Filtration Media

SCOPE

1.1 The flow resistance of any fabricated filter device will depend on the flow resistance of the media used.

1.2 This standard offers procedures sufficient to determine the gas flow characteristics of flat specimens of media used in the filtration process. The methods are extended to include pleated specimens and bulk media as well.

1.3 In all cases, flow rates through the specimen are determined in accordance with procedures outlined in ASME "Fluid Meters." The test fluid is air.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 778 – 88 (Reapproved 2001)

Standard Methods for

Gas Flow Resistance Testing of Filtration Media

This standard is issued under the fixed designation F 778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope with a Specified Tolerable Error, the Average for a Char-

acteristic of a Lot or Process

1.1 The flow resistance of any fabricated filter device will

2.2 ASME Document:

depend on the flow resistance of the media used.

“Fluid Meters,” Sixth Edition, 1971

1.2 This standard offers procedures sufficient to determine

the gas flow characteristics of flat specimens of media used in

3. Terminology

the filtration process. The methods are extended to include

3.1 Definitions of Terms Specific to This Standard:

pleated specimens and bulk media as well.

3.1.1 air density, r—mass per unit volume.

1.3 In all cases, flow rates through the specimen are

3.1.2 air flow resistance, DP—pressure drop or pressure

determined in accordance with procedures outlined in ASME

differential across a test specimen of filter medium at a

“Fluid Meters.” The test fluid is air.

specified air face velocity or mass flow rate.

1.4 This standard may involve hazardous materials, opera-

3.1.3 constituted bulk media—those types of filter media

tions, and equipment. This standard does not purport to

formed from bonded aggregates or discrete solid materials.

address all of the safety problems associated with its use. It is

3.1.4 edge leakage—air flow that passes into or bypasses

the responsibility of the user of this standard to establish

the test specimen in geometric planes other than those intended

appropriate safety and health practices and determine the

for resistance measurement.

applicability of regulatory limitations prior to use.

3.1.5 face area, A— cross-sectional area perpendicular to

2. Referenced Documents air flow at the specimen test boundary.

2.1 ASTM Standards:

NOTE 1—If specimen inlet and exit face areas are different, “Inlet” or

D 461 Test Methods for Testing Felt “Exit” shall be used to describe the face area in question.

D 585 Practice for Sampling andAccepting a Single Lot of

3.1.6 face velocity, V— volumetric flow rate per unit face

Paper, Paperboard, Fiberboard, and Related Product

area.

D 645 Test for Thickness of Paper and Paperboard

NOTE 2—If specimen inlet and exit face areas are different, “Inlet” or

D 685 Method for Conditioning Paper and Paper Products

“Exit” shall be used to describe the face velocity in question.

for Testing

D 737 Test Method for Air Permeability of Textile Fabrics 3.1.7 mass rate of flow, m˙—mass transport of air per unit

time through the test specimen.

D 1776 Practice for Conditioning Textiles For Testing

D 1777 Method for Measuring Thickness of Textile Mate- 3.1.8 medium area, A —total area of filtration media ex-

m

posed to air flow.

rials

D 2905 Practice for Statements on Number of Specimens

NOTE 3—Medium area may be greater than face area due to pleating,

for Textiles

folding, etc.

D 3574 TestMethodsforFlexibleCellularMaterials—Slab,

3.1.9 medium velocity, V —volumetric flow rate per unit

m

Bonded, and Molded Urethane Foams

medium area.

E 105 Practice for Probability Sampling of Materials

3.1.10 normalized resistance, sDP—product of sigma and

E 122 Practice for Calculating Sample Size to Estimate,

measured air flow resistance.

3.1.11 sigma, s—ratio of air density existing at test condi-

tions to standard air density. Density at standard conditions is

1 3 3

These methods are under the jurisdiction of ASTM Committee D22 on Air

taken to be 0.075 lb/ft (1.201 kg/m ).

Quality and are the direct responsibility of Subcommittee D22.03 on Ambient

3.1.12 unconstituted bulk media—those types of filter me-

Atmospheres and Source Emissions.

dia formed from unbonded aggregates or discrete solid mate-

Current edition approved March 10, 1988. Published March 1988. Originally

published as F 788 – 82. Last previous edition F 788 – 82. rials.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers, 345 E. 47th St.,

the ASTM website. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 778 – 88 (2001)

3.1.13 volumetric rate of flow, Q—air volume transport per multiple samples is adequate. However, for design, develop-

unit time through the test specimen. ment, and research, a multiple-point flow regime may be

necessary.

4. Summary of Methods

6. General Requirements

4.1 The testing outlined in this standard consists of measur-

ing air-flow resistance (pressure drop) across a specimen of 6.1 Instrument Accuracy:

6.1.1 Theproceduresofthesemethodsrequiremeasurement

known geometry at one or more air-flow rates. Alternatively,

the flow rate may be measured at one or more values of of pressure drop and either volumetric or mass flow rate.

6.1.2 Pressure drop is a direct measurement. Unless stated

air-flow resistance across the specimen. In either case, test

results are reported as single or multiple data point ordered otherwise in the data report, instrumentation such as manom-

eters shall be selected so as to measure pressure within 63%

pairs of (resistance, face velocity).

4.2 Formanyspecimens,theair-flowresistanceatflowrates of the indicated value. Instruments shall be checked against a

traceable standard.

of interest is of sufficient magnitude that changes in air density

across the specimen may not be ignored, or the airflow 6.1.3 Flow rate is generally a derived quantity obtained

from computations involving a differential pressure type ele-

resistance is not linear with face velocity. In these cases,

ordered pairs of (normalized resistance, mass flow) are re- ment and flowmeter air density. In other cases, flow rate may

be obtained from some kind of direct-reading instrument such

ported rather than ordered pairs of (resistance, face velocity).

as a turbine-type flow meter. Whether read directly or com-

4.3 To provide for quality control application, statistical

puted, flow rate shall be determined to within 63 %, unless

procedures are outlined to guide in the selection of a multiple

stated otherwise in the data report. This value shall be checked

number of specimens.

using a flow prover with traceable accuracy.

4.4 Two test methods involving substantially different test

6.2 Test Apparatus Environment—Effects of environmental

techniques are presented.

conditions on the test air viscosity need to be examined to

4.4.1 Method A—A general method applicable to all filtra-

ensure duplication of test results.

tion media and forms of media: flat, pleated, constituted, and

6.2.1 Temperature—Air viscosity increases as temperature

unconstituted bulk media; small cartridge-type specimens. The

increases at a rate which, at 20°C, is approximately 0.15 %/°C.

test technique consists simply of mounting a specimen in a

Seasonal changes could reflect a temperature differential of

holder and applying air flow.

30°C and result in the apparent flow resistance error of 4.5 %.

4.4.2 Method B—Alimited method applying particularly to

Temperature control must be provided.

nondestructive testing of sheets of material that either edge

6.2.2 Pressure—The American Institute of Physics Hand-

leak or substantially deform when using the simple clamping

book, 2nd Edition, gives the pressure increment of air viscosity

approaches of MethodA.The technique for Method B is based

at 20°C and 1 atm as 0.1224 µp or a possible 0.67 % error per

on the “guarded cylinder” principle and requires a concentric

atmosphere. No precaution is necessary.

cylinder specimen holder, plus provision for two individually

6.2.3 Humidity—TheASHRAEHandbookofFundamentals

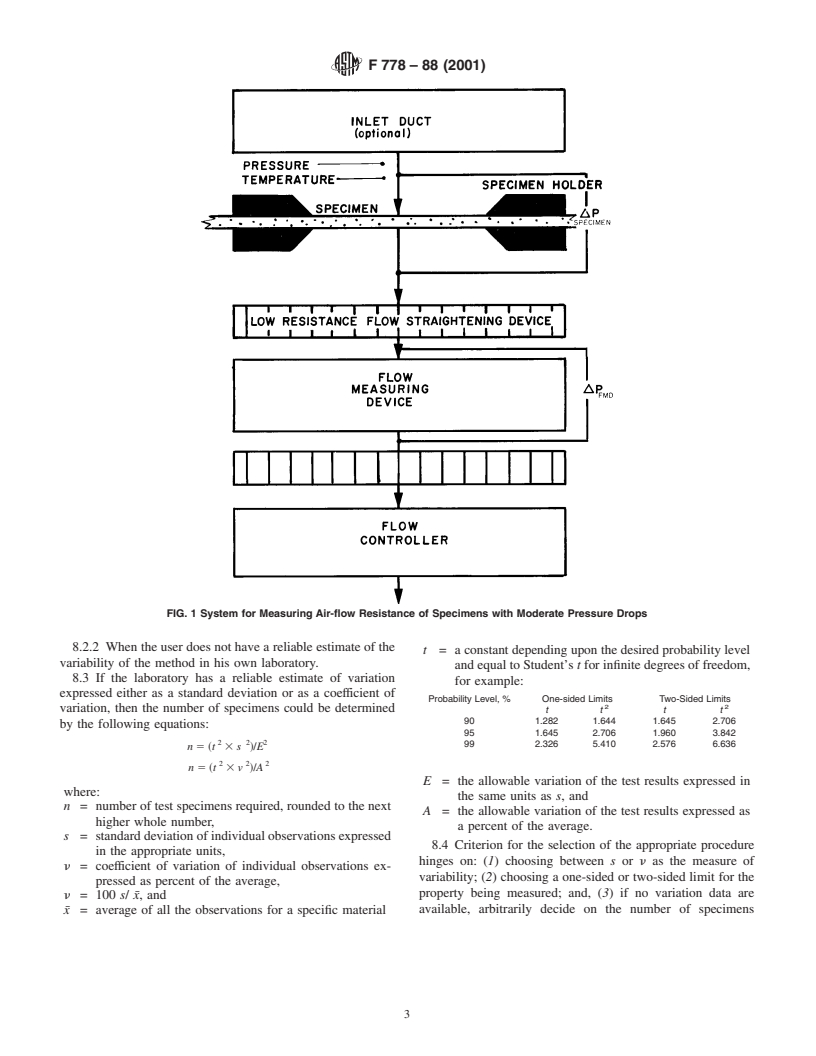

adjustable air flows (See Section 15 and Fig. 1.) In the

in the chapter on Psychrometrics reveals that even for the

implementation of Method B, a parallel, evenly distributed air

extreme case of saturated air at 100°F there is not a significant

flowisperpendicularlydirectedthroughaspecimensubdivided

viscosity difference from that of dry air. No precaution is

into concentric guard and measuring area sections. The two

necessary. However, humidity control is required in specimen

areas have separate downstream air chambers. To obtain a

preparation. See Section 10.

(resistance, face velocity) data point, the appropriate volumet-

ric flow rate is established through the measuring area. The

7. Sampling

guard area volumetric flow rate is then established so that the

differential pressure between guard and measuring area cham-

7.1 The sample to be tested as a flat media, pleated media,

bers is zero on the downstream side of the specimen. Pressure

or bulk media should be obtained under the guidance of the

drop is then read for flow through the specimen measuring

particular standard or specification covering the generic mate-

area. Guard area flow rate need not be determined.

rial or as agreed upon between the purchaser and seller.

5. Significance and Use

8. Number of Specimens

5.1 The air-flow resistance (pressure drop) of a filter is an

8.1 Practice D 2905 covers six recommendations for deter-

important parameter that can assist in characterizing the

mining the number of specimens necessary to elucidate the

physical make-up as well as the utility of a filter.

average quality of a material under various conditions. The

5.2 Therefore, flow characteristics of clean filter media can

choice of the six recommendations to be used in a specific

be used for quality control, product development, and basic method will depend on the purpose of the test and the available

research. It may be used by the producer of filter media to

information.

illustrate media type or to meet product specification and can 8.2 The recommendations in Practice D 2905 describe two

be used by the consumer as a criterion for media selection.

conditions:

5.3 These methods may also be used for acceptance testing. 8.2.1 The procedure to follow when the user has a reliable

5.4 For purposes of quality control, meeting product speci- estimate of the variability of the method in his own laboratory;

fication, or acceptance testing, a single-point flow regime on and,

F 778 – 88 (2001)

FIG. 1 System for Measuring Air-flow Resistance of Specimens with Moderate Pressure Drops

8.2.2 When the user does not have a reliable estimate of the

t = a constant depending upon the desired probability level

variability of the method in his own laboratory.

and equal to Student’s t for infinite degrees of freedom,

8.3 If the laboratory has a reliable estimate of variation

for example:

expressed either as a standard deviation or as a coefficient of

Probability Level, % One-sided Limits Two-Sided Limits

2 2

variation, then the number of specimens could be determined tt tt

90 1.282 1.644 1.645 2.706

by the following equations:

95 1.645 2.706 1.960 3.842

2 2 2

99 2.326 5.410 2.576 6.636

n 5 ~t 3 s !/E

2 2 2

n 5 ~t 3 v !/A

E = the allowable variation of the test results expressed in

where:

the same units as s, and

n = number of test specimens required, rounded to the next

A = the allowable variation of the test results expressed as

higher whole number,

a percent of the average.

s = standard deviation of individual observations expressed

8.4 Criterion for the selection of the appropriate procedure

in the appropriate units,

hinges on: (1) choosing between s or n as the measure of

n = coefficient of variation of individual observations ex-

variability; (2) choosing a one-sided or two-sided limit for the

pressed as percent of the average,

property being measured; and, (3) if no variation data are

n = 100 s/ x¯, and

available, arbitrarily decide on the number of specimens

x¯ = average of all the observations for a specific material

F 778 – 88 (2001)

dictated by the type and character of the material. For more 11.1.2 Flat Media—For flat filtration media in particular, it

details, refer to Section 5 of Practice D 2905. is desirable to use simple clamping techniques such as sug-

gested in Annex A1 instead of more elaborate specimen

9. Conditioning of Test Specimens

preparation.Absence of edge leakage or clamping deformation

effects for simple clamping or both, shall be demonstrated for

9.1 Because many of the materials used in filter media

each new combination of material and clamping method used.

undergo physical changes with changes in temperature and

To do this, the new combination of material and simple

moisture, it is usually desirable to expose the test specimen to

clamping method shall be tested; then the same specimen shall

a standard conditioned atmosphere for a period of time before

be retested with edge sealing and spacer bar of equivalent

testing is initiated.

thickness to the test specimen. No change in resistance shall be

9.2 Those materials which are considered to be textiles or

noted.

textile-like (woven, knitted, or nonwoven fabrics; fiber batts or

mats; or coated fabrics) should be conditioned as specified by 11.1.3 Pleated Specimens—Positive end sealing of pleats is

Practice D 1776.The standard atmosphere for this Practice is a required. Three suggested mounting schemes are delineated in

relative humidity of 65 6 2 % and a temperature of 21 6 1°C Annex A2.

(70 6 2°F). When international testing is involved, a relative

11.1.4 Bulk Media—Air-flow resistance of bulk media is

humidity of 65 6 2 % and a temperature of 20 6 2°C may be

materially affected by the packing method used. It is a

used.

requirement that the packing procedure be fully documented in

9.3 Those materials which are considered to be paper or

any test of these materials (see Section 18).

paper-like should be conditioned as specified by Method

11.2 SpecimenArea—Specimensizeshallbedictatedbythe

D 685. The standard atmosphere for this Practice is a relative

prevailing practice for the class of materials under test.

2 2

humidity of 50 6 2 % and a temperature of 23 6 1°C (73.4 6

Examples are 5.94 in. (38.32 cm ) for papers and paperlike

2 2

1.8°F).

materials and 15.5 in. (100 cm ) for blanket-like materials. In

9.4 The time duration required for conditioning should be

no case shall test specimen size for flat media be less than 5.94

2 2

that necessary for the test specimen to attain equilibrium with

in. (38.32 cm ). Specimens may be rectangular or round;

the conditioning atmosphe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.