ASTM E900-15e1

(Guide)Standard Guide for Predicting Radiation-Induced Transition Temperature Shift in Reactor Vessel Materials

Standard Guide for Predicting Radiation-Induced Transition Temperature Shift in Reactor Vessel Materials

SIGNIFICANCE AND USE

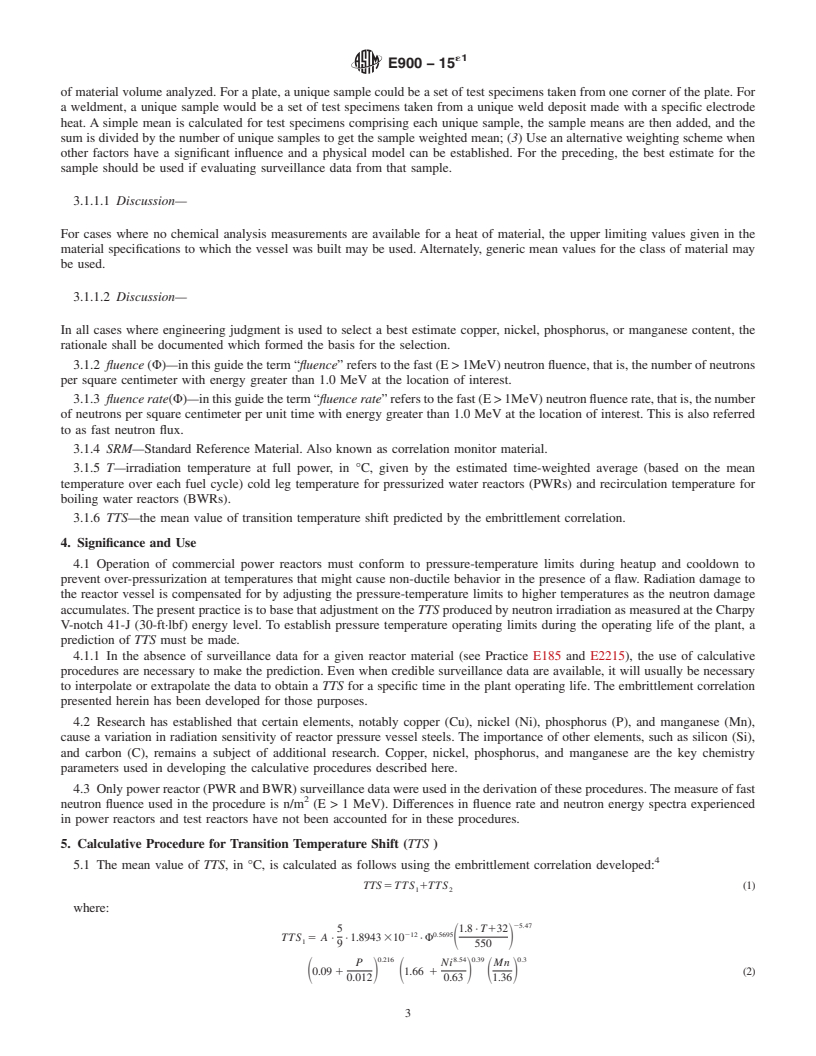

4.1 Operation of commercial power reactors must conform to pressure-temperature limits during heatup and cooldown to prevent over-pressurization at temperatures that might cause non-ductile behavior in the presence of a flaw. Radiation damage to the reactor vessel is compensated for by adjusting the pressure-temperature limits to higher temperatures as the neutron damage accumulates. The present practice is to base that adjustment on the TTS produced by neutron irradiation as measured at the Charpy V-notch 41-J (30-ft·lbf) energy level. To establish pressure temperature operating limits during the operating life of the plant, a prediction of TTS must be made.

4.1.1 In the absence of surveillance data for a given reactor material (see Practice E185 and E2215), the use of calculative procedures are necessary to make the prediction. Even when credible surveillance data are available, it will usually be necessary to interpolate or extrapolate the data to obtain a TTS for a specific time in the plant operating life. The embrittlement correlation presented herein has been developed for those purposes.

4.2 Research has established that certain elements, notably copper (Cu), nickel (Ni), phosphorus (P), and manganese (Mn), cause a variation in radiation sensitivity of reactor pressure vessel steels. The importance of other elements, such as silicon (Si), and carbon (C), remains a subject of additional research. Copper, nickel, phosphorus, and manganese are the key chemistry parameters used in developing the calculative procedures described here.

4.3 Only power reactor (PWR and BWR) surveillance data were used in the derivation of these procedures. The measure of fast neutron fluence used in the procedure is n/m2 (E > 1 MeV). Differences in fluence rate and neutron energy spectra experienced in power reactors and test reactors have not been accounted for in these procedures.

SCOPE

1.1 This guide presents a method for predicting values of reference transition temperature shift (TTS) for irradiated pressure vessel materials. The method is based on the TTS exhibited by Charpy V-notch data at 41-J (30-ft·lbf) obtained from surveillance programs conducted in several countries for commercial pressurized (PWR) and boiling (BWR) light-water cooled (LWR) power reactors. An embrittlement correlation has been developed from a statistical analysis of the large surveillance database consisting of radiation-induced TTS and related information compiled and analyzed by Subcommittee E10.02. The details of the database and analysis are described in a separate report (ADJE090015-EA).2,3 This embrittlement correlation was developed using the variables copper, nickel, phosphorus, manganese, irradiation temperature, neutron fluence, and product form. Data ranges and conditions for these variables are listed in 1.1.1. Section 1.1.2 lists the materials included in the database and the domains of exposure variables that may influence TTS but are not used in the embrittlement correlation.

1.1.1 The range of material and irradiation conditions in the database for variables used in the embrittlement correlation:

1.1.1.1 Copper content up to 0.4 %.

1.1.1.2 Nickel content up to 1.7 %.

1.1.1.3 Phosphorus content up to 0.03 %.

1.1.1.4 Manganese content within the range from 0.55 to 2.0 %.

1.1.1.5 Irradiation temperature within the range from 255 to 300°C (491 to 572°F).

1.1.1.6 Neutron fluence within the range from 1 × 1021 n/m2 to 2 × 1024 n/m2 (E> 1 MeV).

1.1.1.7 A categorical variable describing the product form (that is, weld, plate, forging).

1.1.2 The range of material and irradiation conditions in the database for variables not included in the embrittlement correlation:

1.1.2.1 A533 Type B Class 1 and 2, A302 Grade B, A302 Grade B (modified), and A508 Class 2 and 3. Also, European and Japanese steel grades that are equivalent to these ASTM Grades.

1.1.2.2 Submerged arc welds, shielded a...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E900 − 15

Standard Guide for

Predicting Radiation-Induced Transition Temperature Shift

1

in Reactor Vessel Materials

This standard is issued under the fixed designation E900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Old Ref 1 was editorially removed and the adjunct information was updated and added to Section 2, Refer-

enced Documents, in April 2017.

1. Scope 1.1.1 The range of material and irradiation conditions in

the database for variables used in the embrittlement correla-

1.1 This guide presents a method for predicting values of

tion:

reference transition temperature shift (TTS) for irradiated

1.1.1.1 Copper content up to 0.4 %.

pressure vessel materials. The method is based on the TTS

1.1.1.2 Nickel content up to 1.7 %.

exhibited by Charpy V-notch data at 41-J (30-ft·lbf) obtained

1.1.1.3 Phosphorus content up to 0.03 %.

from surveillance programs conducted in several countries for

1.1.1.4 Manganesecontentwithintherangefrom0.55to2.0

commercialpressurized(PWR)andboiling(BWR)light-water

%.

cooled (LWR) power reactors. An embrittlement correlation

1.1.1.5 Irradiationtemperaturewithintherangefrom255to

has been developed from a statistical analysis of the large

300°C (491 to 572°F).

21 2

surveillance database consisting of radiation-induced TTS and

1.1.1.6 Neutronfluencewithintherangefrom1×10 n/m

24 2

related information compiled and analyzed by Subcommittee to2×10 n/m (E> 1 MeV).

E10.02. The details of the database and analysis are described 1.1.1.7 A categorical variable describing the product form

2,3

(that is, weld, plate, forging).

in a separate report (ADJE090015-EA). This embrittlement

1.1.2 The range of material and irradiation conditions in

correlation was developed using the variables copper, nickel,

the database for variables not included in the embrittlement

phosphorus, manganese, irradiation temperature, neutron

correlation:

fluence,andproductform.Datarangesandconditionsforthese

1.1.2.1 A533 Type B Class 1 and 2, A302 Grade B, A302

variables are listed in 1.1.1. Section 1.1.2 lists the materials

Grade B (modified), and A508 Class 2 and 3. Also, European

includedinthedatabaseandthedomainsofexposurevariables

and Japanese steel grades that are equivalent to these ASTM

that may influence TTS but are not used in the embrittlement

Grades.

correlation.

1.1.2.2 Submerged arc welds, shielded arc welds, and elec-

troslag welds having compositions consistent with those of the

welds used to join the base materials described in 1.1.2.1.

1

12

This guide is under the jurisdiction of ASTM Committee E10 on Nuclear

1.1.2.3 Neutron fluence rate within the range from3×10

Technology and Applications and is the direct responsibility of Subcommittee

2 16 2

n/m/sto5×10 n/m /s (E > 1 MeV).

E10.02 on Behavior and Use of Nuclear Structural Materials.

1.1.2.4 Neutron energy spectra within the range expected at

Current edition approved Feb. 1, 2015. Published April 2015. Originally

approvedin1983.Lastpreviouseditionapprovedin2007asE900–02(2007).DOI:

the reactor vessel region adjacent to the core of commercial

10.1520/E0900-15E01.

PWRs and BWRs (greater than approximately 500MW elec-

2

Available from ASTM International Headquarters. Order Adjunct No.

tric).

ADJE090015-EA.

3

To inform the TTS prediction of Section 5 of this guide, the E10.02

1.1.2.5 Irradiation exposure times of up to 25 years in

Subcommittee decided to limit the data considered to Charpy shift values (∆T )

41J

boiling water reactors and 31 years in pressurized water

measured from irradiations conducted in PWRs and BWRs. A database of 1,878

reactors.

Charpy TTSmeasurementswascompiledfromsurveillancereportsonoperatingand

decommissioned light water reactors of Western design from 13 countries (Brazil,

1.2 It is the responsibility of the user to show that the

Belgium, France, Germany, Italy, Japan, Mexico, The Netherlands, South Korea,

conditions of interest in their application of this guide are

Sweden, Switzlerland, Taiwan, and the United States), and from the technical

addressed adequately by the technical information on which

literature. For each data record, the following information had to be available:

fluence, fluence rate, irradiation temperature, and % content of Cu, Ni, P, and Mn.

the guide is based. It should be noted that the conditions

Reports and technical papers documenting the results of research programs

quantified by the database are not distributed evenly over the

conductedinmaterialtestreactorswerealsoreviewed.Datafromthesesourceswas

range of materials and irradiation conditions described in 1.1,

includedinthe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E900 − 15 E900 − 15

Standard Guide for

Predicting Radiation-Induced Transition Temperature Shift

1

in Reactor Vessel Materials

This standard is issued under the fixed designation E900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Old Ref 1 was editorially removed and the adjunct information was updated and added to Section 2, Refer-

enced Documents, in April 2017.

1. Scope

1.1 This guide presents a method for predicting values of reference transition temperature shift (TTS) for irradiated pressure

vessel materials. The method is based on the TTS exhibited by Charpy V-notch data at 41-J (30-ft·lbf) obtained from surveillance

programs conducted in several countries for commercial pressurized (PWR) and boiling (BWR) light-water cooled (LWR) power

reactors. An embrittlement correlation has been developed from a statistical analysis of the large surveillance database consisting

of radiation-induced TTS and related information compiled and analyzed by Subcommittee E10.02. The details of the database and

2,3,

analysis are described in a separate report ((ADJE090015-EA).1). This embrittlement correlation was developed using the

variables copper, nickel, phosphorus, manganese, irradiation temperature, neutron fluence, and product form. Data ranges and

conditions for these variables are listed in 1.1.1. Section 1.1.2 lists the materials included in the database and the domains of

exposure variables that may influence TTS but are not used in the embrittlement correlation.

1.1.1 The range of material and irradiation conditions in the database for variables used in the embrittlement correlation:

1.1.1.1 Copper content up to 0.4 %.

1.1.1.2 Nickel content up to 1.7 %.

1.1.1.3 Phosphorus content up to 0.03 %.

1.1.1.4 Manganese content within the range from 0.55 to 2.0 %.

1.1.1.5 Irradiation temperature within the range from 255 to 300°C (491 to 572°F).

21 2 24 2

1.1.1.6 Neutron fluence within the range from 1 × 10 n/m to 2 × 10 n/m (E> 1 MeV).

1.1.1.7 A categorical variable describing the product form (that is, weld, plate, forging).

1.1.2 The range of material and irradiation conditions in the database for variables not included in the embrittlement

correlation:

1.1.2.1 A533 Type B Class 1 and 2, A302 Grade B, A302 Grade B (modified), and A508 Class 2 and 3. Also, European and

Japanese steel grades that are equivalent to these ASTM Grades.

1.1.2.2 Submerged arc welds, shielded arc welds, and electroslag welds having compositions consistent with those of the welds

used to join the base materials described in 1.1.2.1.

12 2 16 2

1.1.2.3 Neutron fluence rate within the range from 3 × 10 n/m /s to 5 × 10 n/m /s (E > 1 MeV).

1.1.2.4 Neutron energy spectra within the range expected at the reactor vessel region adjacent to the core of commercial PWRs

and BWRs (greater than approximately 500MW electric).

1.1.2.5 Irradiation exposure times of up to 25 years in boiling water reactors and 31 years in pressurized water reactors.

1.2 It is the responsibility of the user to show that the conditions of interest in their application of this guide are addressed

adequately by the technical information on which the guide is based. It should be noted that the conditions quantified by the

1

This guide is under the jurisdiction of ASTM Committee E10 on Nuclear Technology and Applications and is the direct responsibility of Subcommittee E10.02 on

Behavior and Use of Nuclear Structural Materials.

Current edition approved Feb. 1, 2015. Published April 2015. Originally approved in 1983. Last previous edition approved in 2007 as E900 – 02(2007). DOI:

10.1520/E0900-15.10.1520/E0900-15E01.

2

The boldface numbers in parentheses refer to aAvailable from ASTM International Headquarters. Order Adjunct No. ADJE090015-EAlist of references at the end of this

standard.

3

To inform the TTS prediction of Section 5 of this guide, the E10.02 Subcommittee decided to limit the data considered to Charpy shift values (ΔT ) measured from

41J

irradiations conducted in PWRs and BWRs. A database of 1,878 Charpy TTS measurements was compiled from surveillance reports on operating and decommissioned light

water reactors of Western design from 13 countries (Brazil, Belgium, France, Germany, Italy, Japan, Mexico, The Netherlands, South Korea, Sweden, Switzlerland, Taiwa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.