ASTM E1404-94(2008)

(Specification)Standard Specification for Laboratory Glass Conical Flasks

Standard Specification for Laboratory Glass Conical Flasks

ABSTRACT

This specification provides standard dimensional requirements for glass conical flasks suitable for general laboratory use. Conical flasks (Erlenmeyer) shall be classified into four types which are divided into classes. Type I is for general purpose with graduated scale and shall be designated into two classes: Class 1 with narrow mouth and heavy duty beaded top and Class 2 with wide mouth and heavy duty beaded top. Type II flasks have tapered ground joint with graduated scale. This type shall be divided into three classes: Class 1 with outer conical, joint without stopper, Class 2 with stopper and Class 3 is used for iodine determination. Flasks of Type III have screw thread finish, with graduated scale. Lastly, Type IV flasks are used for culture and they are differentiated into three classes: Class 1 flask has long neck, plain top, Class 2 has wide base (Fernbach), and Class 3 has also wide base and low form. The flasks shall be made of borosilicate glass.

SCOPE

1.1 This specification provides standard dimensional requirements for glass conical flasks suitable for general laboratory use.

Note 1—For packaging standards, choose the following standards; E 920, E 921, and E 1133.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1404 −94(Reapproved 2008)

Standard Specification for

Laboratory Glass Conical Flasks

This standard is issued under the fixed designation E1404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.2 Class 2—Wide mouth with heavy duty beaded top,

in capacities of 125 mL, 250 mL, 500 mL, 1000 mL, and 2000

1.1 This specification provides standard dimensional re-

mL.

quirements for glass conical flasks suitable for general labora-

3.1.2 Type II—Tapered ground joint, with graduated scale.

tory use.

3.1.2.1 Class 1—Outer Conical, joint without stopper, in

NOTE 1—For packaging standards, choose the following standards;

capacities of 50 mL, 125 mL, 250 mL, 500 mL, 1000 mL, and

E920, E921, and E1133.

2000 mL.

3.1.2.2 Class 2—with stopper, in capacities of 25 mL, 50

2. Referenced Documents

mL, 125 mL, 250 mL, 500 mL, and 1000 mL.

2.1 ASTM Standards:

3.1.2.3 Class 3—For iodine determination, in capacities of

E438 Specification for Glasses in Laboratory Apparatus

125 mL, 250 mL, and 500 mL.

E671 Specification for Maximum Permissible Thermal Re-

3.1.3 Type III—Screw thread finish, with graduated scale, in

sidual Stress in Annealed Glass Laboratory Apparatus

capacities of 50 mL, 125 mL, 250 mL, 500 mL, 1000 mL, and

E675 Specification for Interchangeable Taper-Ground Stop-

2000 mL.

cocks And Stoppers

3.1.4 Type IV—Culture;

E676 Specification for Interchangeable Taper-Ground Joints

3.1.4.1 Class 1—Long neck, plain top, in capacities of 50

E920 Specification for Commercially Packaged Laboratory

mL, 125 mL, 250 mL, 500 mL, 1000 mL, and 2000 mL.

Apparatus

3.1.4.2 Class 2—Wide base (Fernbach), in capacity of 2800

E921 Specification for Export Packaged Laboratory Appa-

mL.

ratus

3.1.4.3 Class3—Wide base, low form, in a capacity of 2500

E1133 Practice for Performance Testing of Packaged Labo-

mL.

ratory Apparatus for United States Government Procure-

NOTE 2—The term milliliter (mL) is commonly used as a special name

ments

for the cubic centimeter (cm ) and similarly the liter (L) for 1000 cubic

E1157 Specification for Sampling and Testing of Reusable

centimeters, in accordance with the International System of Units (SI).

Laboratory Glassware

4. Material and Manufacturing

3. Classification

4.1 Flasks shall be made of borosilicate glass conforming to

3.1 Conical flasks (Erlenmeyer) shall be in in the following

the requirements of Type I, Class A of Specification E438.

types and capacities.

4.2 Maximum residual thermal stress shall be such as to

3.1.1 Type I—general purpose, with graduated scale.

conform to Specification E671.

3.1.1.1 Class 1—Narrow mouth with heavy duty beaded

top, in capacities of 25 mL, 50 mL, 125 mL, 250 mL, 300 mL,

5. Appearance

500 mL, 1000 mL, 1500 mL, 2000 mL, 4000 mL, and 6000

5.1 The general appearance of the flasks shall be as illus-

mL.

trated in Fig. 1.

6. Design

This specification is under the jurisdiction of ASTM Committee E41 on

6.1 Conical flasks shall have flat bottoms. However, con-

Laboratory Apparatusand is the direct responsibility of Subcommittee E41.01 on

Apparatus.

cavity in the bottom shall be permitted. The flask shall stand

Current edition approved Nov. 1, 2008. Published January 2009. Originally

vertically without rocking or spinning when placed on a level

approvedin1991.Lastpreviouseditionapprovedin2003asE1404–94(2003).DOI:

surface. Bottom heel radius shall be between 15 and 20 % of

10.1520/E1404-94R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or the maximum external diameter.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 Conical sides of the flask shall extend inwardly for the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bottom and shall terminate in a short cylindrical neck.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

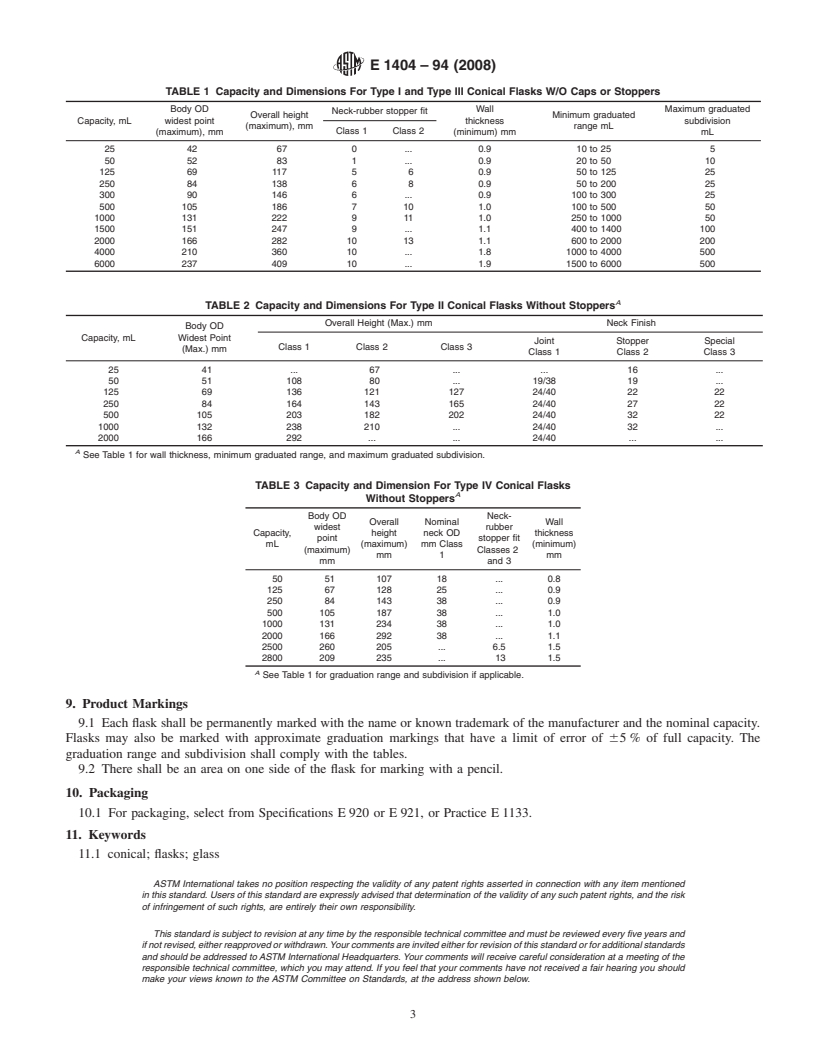

E1404−94 (2008)

FIG. 1 General Appearance of Flasks

6.2.1 Type I and Type IV flasks shall have flask mouth may be modified to have the thread begin near the rim rather

finished with a tooled, heavy duty bead. than approximately 0.55 in. below it.

6.2.2 Type II, Class 1 shall have taper-ground joint neck

6.3 Necksonallflasksshallbeci

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:E1404–94 (Reapproved 1998) Designation: E 1404 – 94 (Reapproved

2008)

Standard Specification for

Laboratory Glass Conical Flasks

This standard is issued under the fixed designation E 1404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in December 1998.

1. Scope

1.1 This specification provides standard dimensional requirements for glass conical flasks suitable for general laboratory use.

NOTE 1—For packaging standards, choose the following standards; E 920, E 921, and E 1133.

2. Referenced Documents

2.1 ASTM Standards:

E 438 Specification for Glasses in Laboratory Apparatus

E 671 Specification for Maximum Permissible Thermal Residual Stress in Annealed Glass Laboratory Apparatus

E 675 Specification for Interchangeable Taper-Ground Stopcocks andAnd Stoppers

E 676 Specification for Interchangeable Taper-Ground Joints

E 920 Specification for Commercially Packaged Laboratory Apparatus

E 921 Specification for Export Packaged Laboratory Apparatus

E 1133 PerformanceTestingofPackagedLaboratoryApparatusforSpecializedProcurements PracticeforPerformanceTesting

of Packaged Laboratory Apparatus for United States Government Procurements

E 1157 Specification for Sampling and Testing of Reusable Laboratory Glassware

3. Classification

3.1 Conical flasks (Erlenmeyer) shall be in in the following types and capacities.

3.1.1 Type I—general purpose, with graduated scale.

3.1.1.1 Class 1—Narrow mouth with heavy duty beaded top, in capacities of 25 mL, 50 mL, 125 mL, 250 mL, 300 mL, 500

mL, 1000 mL, 1500 mL, 2000 mL, 4000 mL, and 6000 mL.

3.1.1.2 Class 2—Wide mouth with heavy duty beaded top, in capacities of 125 mL, 250 mL, 500 mL, 1000 mL, and 2000 mL.

3.1.2 Type II—Tapered ground joint, with graduated scale.

3.1.2.1 Class 1—Outer Conical, joint without stopper, in capacities of 50 mL, 125 mL, 250 mL, 500 mL, 1000 mL, and 2000

mL.

3.1.2.2 Class 2—with stopper, in capacities of 25 mL, 50 mL, 125 mL, 250 mL, 500 mL, and 1000 mL.

3.1.2.3 Class 3—For iodine determination, in capacities of 125 mL, 250 mL, and 500 mL.

3.1.3 TypeIII—Screwthreadfinish,withgraduatedscale,incapacitiesof50mL,125mL,250mL,500mL,1000mL,and2000

mL.

3.1.4 Type IV—Culture;

3.1.4.1 Class 1—Long neck, plain top, in capacities of 50 mL, 125 mL, 250 mL, 500 mL, 1000 mL, and 2000 mL.

3.1.4.2 Class 2—Wide base (Fernbach), in capacity of 2800 mL.

3.1.4.3 Class 3—Wide base, low form, in a capacity of 2500 mL.

NOTE 2—The term milliliter (mL) is commonly used as a special name for the cubic centimeter (cm ) and similarly the liter (L) for 1000 cubic

centimeters, in accordance with the International System of Units (SI).

This specification is under the jurisdiction of ASTM Committee E-41 on Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on Glass

Apparatus.

Current edition approved Feb. 15, 1994. Published April 1994. Originally published as E1404–91. Last previous edition E1404–91.

This specification is under the jurisdiction of ASTM Committee E41 on Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on Apparatus .

Current edition approved Nov. 1, 2008. Published January 2009. Originally approved in 1991. Last previous edition approved in 2003 as E 1404–94(2003).

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 14.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1404 – 94 (2008)

4. Material and Manufacturing

4.1 Flasks shall be made of borosilicate glass conforming to the requirements of Type I, Class A of Specification E 438.

4.2 Maximum residual thermal stress shall be such as to conform to Specification E 671.

5. Appearance

5.1 The general appearance of the flasks shall be as illustrated in Fig. 1.

6. Design

6.1 Conical flasks shall have flat bottoms. However, concavity in the bottom shall be permitted. The flask shall stand vertically

without rocking or spinning when placed on a level surface. Bottom heel radius shall be between 15 and 20 % of the maximum

external diameter.

6.2 Conical sides of the flask shall extend inwardly

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.