ASTM F2206-02(2010)

(Specification)Standard Specification for Fabricated Fittings of Butt-Fused Polyethylene (PE) Plastic Pipe, Fittings, Sheet Stock, Plate Stock, or Block Stock

Standard Specification for Fabricated Fittings of Butt-Fused Polyethylene (PE) Plastic Pipe, Fittings, Sheet Stock, Plate Stock, or Block Stock

ABSTRACT

This specification deals with fabricated fittings intended for use with outside-diameter controlled polyethylene pipe and tubing. These fittings are manufactured by heat-fusion joining shape-modified polyethylene components prepared from pipe, molded fittings, sheet, or block. Pressure rating of the fabricated-fitting design is beyond the scope of this standard and shall be established by the fitting manufacturer. This specification includes requirements for both room temperature and elevated temperature pressure-tests to demonstrate a reasonable level of performance of the fabricated-fitting design at the pressure rating established by the fitting manufacturer. Materials shall be tested and shall conform to the requirements for materials, design, workmanship, minimum dimensions, marking, test methods, and quality control.

SCOPE

1.1 This specification establishes requirements for fabricated fittings intended for use with outside-diameter controlled polyethylene pipe and tubing. These fittings are manufactured by heat-fusion joining shape-modified polyethylene components prepared from pipe, molded fittings, sheet, or block. Included are requirements for materials, design, workmanship, minimum dimensions, marking, test methods, and quality control.

1.2 Pressure rating of the fabricated-fitting design is beyond the scope of this standard and shall be established by the fitting manufacturer. This specification includes requirements for both room temperature and elevated temperature pressure-tests to demonstrate a reasonable level of performance of the fabricated-fitting design at the pressure rating established by the fitting manufacturer.

1.3 The pressure-tests requirements are specified by DR. The DR specified is that of the piping system for which the fabricated fitting is intended to be butt-fused.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2206 – 02 (Reapproved 2010)

Standard Specification for

Fabricated Fittings of Butt-Fused Polyethylene (PE) Plastic

Pipe, Fittings, Sheet Stock, Plate Stock, or Block Stock

This standard is issued under the fixed designation F2206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification establishes requirements for fabri- 2.1 ASTM Standards:

cated fittings intended for use with outside-diameter controlled D1598 Test Method for Time-to-Failure of Plastic Pipe

polyethylene pipe and tubing. These fittings are manufactured Under Constant Internal Pressure

by heat-fusion joining shape-modified polyethylene compo- D1600 Terminology for Abbreviated Terms Relating to

nents prepared from pipe, molded fittings, sheet, or block. Plastics

Included are requirements for materials, design, workmanship, D2122 Test Method for Determining Dimensions of Ther-

minimum dimensions, marking, test methods, and quality moplastic Pipe and Fittings

control. D2513 Specification for Polyethylene (PE) Gas Pressure

1.2 Pressure rating of the fabricated-fitting design is beyond Pipe, Tubing, and Fittings

the scope of this standard and shall be established by the fitting D3261 Specification for Butt Heat Fusion Polyethylene

manufacturer.Thisspecificationincludesrequirementsforboth (PE)PlasticFittingsforPolyethylene(PE)PlasticPipeand

room temperature and elevated temperature pressure-tests to Tubing

demonstrate a reasonable level of performance of the D3350 Specification for Polyethylene Plastics Pipe and

fabricated-fitting design at the pressure rating established by Fittings Materials

the fitting manufacturer. F412 Terminology Relating to Plastic Piping Systems

1.3 The pressure-tests requirements are specified by DR. 2.2 Federal Standards:

The DR specified is that of the piping system for which the Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

fabricated fitting is intended to be butt-fused. OPS Part 192 Title 49, Code of Federal Regulations

1.4 The text of this standard references notes and footnotes 2.3 Military Standard:

which provide explanatory material. These notes and footnotes MIL-STD-129 Marking for Shipment and Storage

(excluding those in tables and figures) shall not be considered 2.4 ANSI/NSF Standard:

as requirements of the standard. ANSI/NSF 61 for Drinking Water System Components—

1.5 Units—The values stated in inch-pound units are to be Health Effects

regarded as standard. The values given in parentheses are

3. Terminology

mathematical conversions to SI units which are provided for

information only and are not considered standard. 3.1 Definitions are in accordance with Terminology F412

and abbreviations are in accordance with Terminology D1600,

1.6 The following safety hazards caveat pertains only to the

test methods portion, Section 9, of this specification. This unless otherwise specified.

3.2 Definitions:

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user 3.2.1 butt-fusion end(s), n—the butt end(s) of the fabricated

fitting intended for field fusion by the installer.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

tions prior to use. 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction ofASTM Committee F17 on Plastic the ASTM website.

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Current edition approved April 1, 2010. Published May 2010. Originally Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

approved in 2002. Last previous edition approved in 2002 as F2206 – 02. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F2206-02R10. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2206 – 02 (2010)

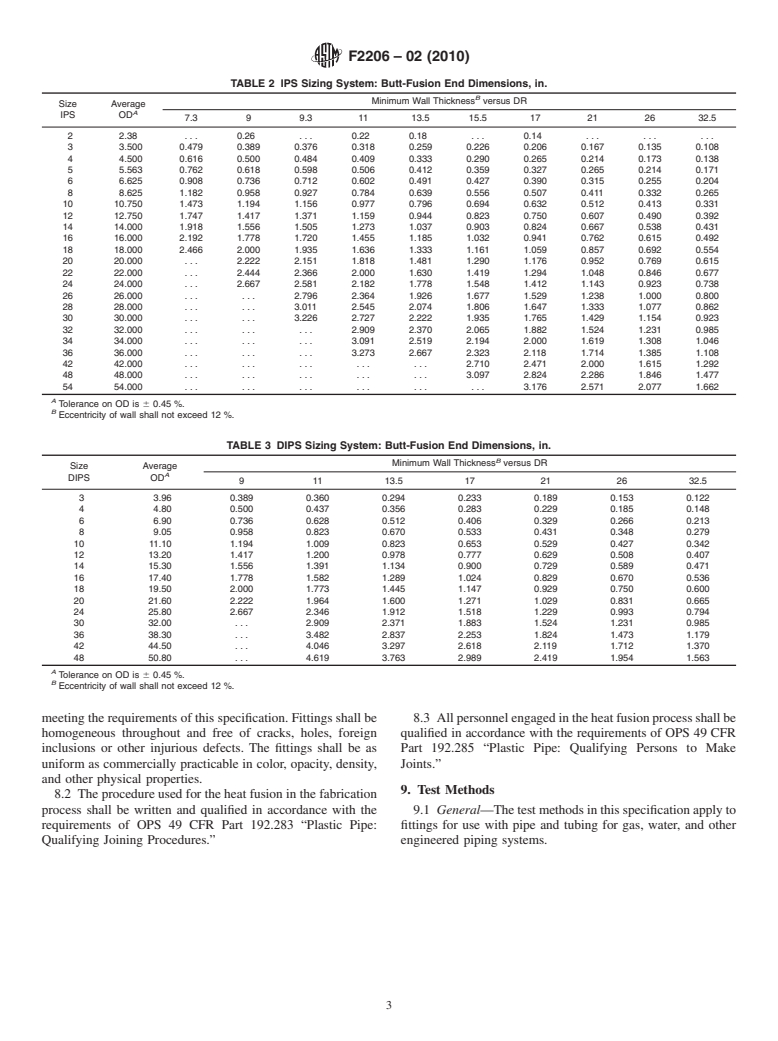

3.2.2 fabricated fitting, n—a fitting constructed from manu- 7.1.1 Diameter—Nominal outside-diameter of the butt-

factured polyethylene components or materials. fusion end shall conform to the IPS or DIPS dimension at area

3.3 Abbreviations: offusion.Outer-diameterdimensionsandtolerancesatthearea

3.3.1 DIPS—ductile iron pipe size. of fusion shall be as shown in Table 2 or Table 3.

3.3.2 DR—dimension ratio. 7.1.2 Wall Thickness—The minimum wall thickness of the

3.3.3 IPS—iron pipe size. butt-fusion end shall be in accordance with Table 2 or Table 3

3.3.4 OD—outside diameter. when measured in accordance with Test Method D2122.

Conditioning to standard temperature but not to standard

4. Classification humidity is required.

7.1.3 Eccentricity—The wall thickness variability of the

4.1 General—This specification establishes requirements

butt-fusion end as measured and calculated in accordance with

for fabricated fittings intended for butt-fusion joining to

Test Method D2122, in any diametrical cross-section of the

polyethylene pipe.

pipe shall not exceed 12 %.

4.1.1 Fabricated fitting components may be machined from

7.1.4 Measurements—These shall be made in accordance

extruded polyethylene or molded polyethylene stock and

with Test Method D2122 for roundable pipe.

heat-fused to form the final part.

7.1.5 Laying Lengths—Laying length dimensions shall be

4.1.2 Fabricated fittings intended for use in the distribution

defined by the manufacturer.

of natural gas or other fuel gases shall also meet the require-

7.1.6 Special Sizes—Where existing system conditions or

ments of Specification D2513.

special local requirements make other diameters or dimension

ratios necessary, other sizes or dimension ratios, or both, shall

5. Ordering Information

be acceptable for engineered applications when mutually

5.1 When ordering fittings under this specification include

agreeduponbythecustomerandthemanufacturer,ifthefitting

the following information:

is manufactured from plastic compounds meeting the material

5.1.1 Polyethylene compound (material designation or trade

requirements of this specification, and the fitting performs in

name).

accordance with the requirements in this specification. For

5.1.2 Style of fitting (3 piece tee, 5 segment 90° ell, etc.).

diameters not shown in Table 2 or Table 3, the tolerance shall

5.1.3 Size:

be the same percentage as that shown in the corresponding

5.1.3.1 Nominal size of end connections.

tables for the next smaller listed size. Minimum wall thickness

5.1.3.2 End configurations (for example, IPS or DIPS).

at the butt-fusion end for these special sizes shall not be less

5.1.3.3 System design ratio.

than the minimum wall thickness specified for the pipe the

fitting is designed to be used with.

6. Material

7.2 Physical Requirements—Fabricated fittings using miter

6.1 Material Classification—Polyethylene materials allow-

cut pipe stock shall be manufactured from pipe stock with a

able for use in this specification shall be classified in accor-

wall thickness 25 % greater than that of the pipe to which the

dance with Specification D3350 as shown in Table 1. Consult

fitting is to be joined. (For example: A SDR11 fitting shall be

with the manufacturer for cell classification applicable to their

made using SDR9 pipe stock.)

materials.

7.3 Pressure Test Requirements—One size and DR of each

style fitting manufactured in each of the following size

NOTE 1—Manufacturers should use appropriate quality assurance pro-

cedures to ensure that sheet, block and plate are free from voids, ranges—12 in. (300 mm) and smaller, greater than 12 to less

laminations, foreign inclusions, cracks, and other injurious defects.

than 24 in. (300 to less than 600 mm), and 24 in. (600 mm) and

larger—in each particular material shall be evaluated. The size

7. Requirements

and DR of each style fitting selected shall be tested per 7.3.1

7.1 Dimension and Tolerances—Butt-fusion ends shall be

and7.3.2.Fittingstylesarecharacterizedaselbows,tees,wyes,

produced from fittings or pipe conforming to Specification

crosses, reducing tees, reducing laterals, branch saddles, flange

D3261, or by machining block, sheet, plate, or pipe to the

adapters, mechanical joint adapters, and end caps.

required dimensions.

7.3.1 Sustained Pressure Test—The fitting shall not fail, as

defined in Test Method D1598, when tested at the time,

pressures, and test temperatures per TestAin Table 4. The test

TABLE 1 Specification D3350 Cell Classification Limits for

specimens shall be prepared for testing in the manner pre-

Fitting Materials

scribed in 9.5.1.

Allowable D3350

7.3.2 Elevated Temperature Sustained Pressure Test—The

Cell Classification Units

D3350 Cell Classification Property

fitting shall not fail, as defined in Test Method D1598, when

PE2406 PE3408

testedatthetime,pressures,andtesttemperaturesperTestBor

Density 2 3

TestCin Table 4. The test specimens shall be prepared for

Melt Index 1-2-3-4 3-4-5

testing in the manner prescribed in 9.5.1.

Flexural Modulus 4-5-6 4-5-6

Tensile Strength 2-3 3-4-5

Slow Crack-Growth Resistance 6 6 8. Workmanship, Finish and Appearance

HDB 3 4

8.1 The manufacture of these fittings shall be in accordance

Color/UV Stabilizer C-D-E C-D-E

with good commercial practice so as to produce fittings

F2206 – 02 (2010)

TABLE 2 IPS Sizing System: Butt-Fusion End Dimensions, in.

B

Minimum Wall Thickness versus DR

Size Average

A

IPS OD

7.3 9 9.3 11 13.5 15.5 17 21 26 32.5

2 2.38 . 0.26 . 0.22 0.18 . 0.14 . . .

3 3.500 0.479 0.389 0.376 0.318 0.259 0.226 0.206 0.167 0.135 0.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.