ASTM D5875-95(2006)

(Guide)Standard Guide for Use of Cable-Tool Drilling and Sampling Methods for Geoenvironmental Exploration and Installation of Subsurface Water-Quality Monitoring Devices

Standard Guide for Use of Cable-Tool Drilling and Sampling Methods for Geoenvironmental Exploration and Installation of Subsurface Water-Quality Monitoring Devices

SIGNIFICANCE AND USE

Cable-tool rigs (also referred to as churn rigs, water-well drilling rigs, spudders, or percussion rigs) are used in the oil fields and in the water-well industry. The Chinese developed the percussion method some 4000 years ago.

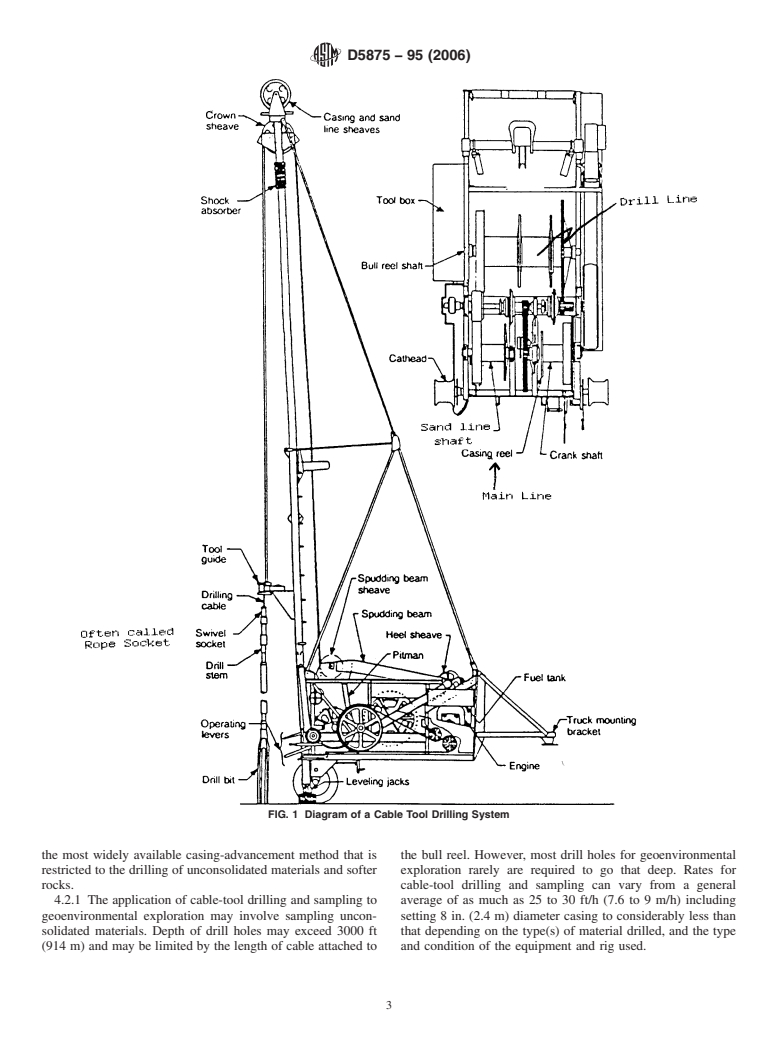

Cable-tool drilling and sampling methods may be used in support of geoenvironmental exploration and for installation of subsurface water-quality monitoring devices in both unconsolidated and consolidated materials. Cable-tool drilling and sampling may be selected over other methods based on its advantages, some of which are its high mobility, low water use, low operating cost, and low maintenance. Cable-tool drilling is the most widely available casing-advancement method that is restricted to the drilling of unconsolidated materials and softer rocks.

The application of cable-tool drilling and sampling to geoenvironmental exploration may involve sampling unconsolidated materials. Depth of drill holes may exceed 3000 ft (914 m) and may be limited by the length of cable attached to the bull reel. However, most drill holes for geoenvironmental exploration rarely are required to go that deep. Rates for cable-tool drilling and sampling can vary from a general average of as much as 25 to 30 ft/h (7.6 to 9 m/h) including setting 8 in. (2.4 m) diameter casing to considerably less than that depending on the type(s) of material drilled, and the type and condition of the equipment and rig used.

Note 2—As a general rule, cable-tool rigs are used to sample the surficial materials, and to set surface casing in order that rotary-core rigs subsequently may be set up on the drill hole to core drill hard rock if coring is required.

The cable-tool rig may be used to facilitate the installation of a subsurface water-quality monitoring device(s) including in-situ testing devices. The monitoring device(s) may be installed through the casing as the casing is removed from the borehole. The sand line can be used to raise, lower, or set in-situ testing devic...

SCOPE

1.1 This guide covers cable-tool drilling and sampling procedures used for geoenvironmental exploration and installation of subsurface water-quality monitoring devices.

1.2 Several sampling methods exist for obtaining samples from drill holes for geoenvironmental purposes and subsequent laboratory testing. Selection of a particular drilling procedure should be made on the basis of sample types needed and geohydrologic conditions observed at the study site.

1.3 Drilling procedures for geoenvironmental exploration often will involve safety planning, administration and documentation. This guide does not purport to specifically address exploration and site safety.

Note 1—This guide does not include considerations for geotechnical site characterizations that are addressed in a separate guide.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through the ASTM consensus process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5875 − 95(Reapproved 2006)

Standard Guide for

Use of Cable-Tool Drilling and Sampling Methods for

Geoenvironmental Exploration and Installation of

Subsurface Water-Quality Monitoring Devices

This standard is issued under the fixed designation D5875; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope document means only that the document has been approved

through the ASTM consensus process.

1.1 This guide covers cable-tool drilling and sampling

procedures used for geoenvironmental exploration and instal-

2. Referenced Documents

lation of subsurface water-quality monitoring devices.

2.1 ASTM Standards:

1.2 Several sampling methods exist for obtaining samples

D653 Terminology Relating to Soil, Rock, and Contained

fromdrillholesforgeoenvironmentalpurposesandsubsequent

Fluids

laboratory testing. Selection of a particular drilling procedure

D1452 Practice for Soil Exploration and Sampling byAuger

should be made on the basis of sample types needed and

Borings

geohydrologic conditions observed at the study site.

D1586 Test Method for Penetration Test (SPT) and Split-

1.3 Drilling procedures for geoenvironmental exploration

Barrel Sampling of Soils

often will involve safety planning, administration and docu-

D1587 Practice for Thin-Walled Tube Sampling of Soils for

mentation. This guide does not purport to specifically address

Geotechnical Purposes

exploration and site safety.

D3550 Practice for Thick Wall, Ring-Lined, Split Barrel,

Drive Sampling of Soils

NOTE 1—This guide does not include considerations for geotechnical

D4428/D4428M Test Methods for Crosshole Seismic Test-

site characterizations that are addressed in a separate guide.

ing

1.4 The values stated in inch-pound units are to be regarded

D5088 Practice for Decontamination of Field Equipment

as the standard. The SI units given in parentheses are for

Used at Waste Sites

information only.

1.5 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Terminology used within this guide is in accordance

responsibility of the user of this standard to establish appro-

with Terminology D653 with the addition of the following:

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 bailer—a long, narrow bucket, made from a piece of

1.6 This guide offers an organized collection of information

or a series of options and does not recommend a specific large-diameter pipe with a dart valve in the bottom, used to

remove cuttings from the borehole.

course of action. This document cannot replace education or

experience and should be used in conjunction with professional

3.2.2 bentonite—the common name for drilling-fluid addi-

judgment. Not all aspects of this guide may be applicable in all

tives and well-construction products consisting mostly of

circumstances. This ASTM standard is not intended to repre-

naturally occurring montmorillonite. Some bentonite products

sent or replace the standard of care by which the adequacy of

have chemical additives which may affect water-quality analy-

a given professional service must be judged, nor should this

ses.

document be applied without consideration of a project’s many

3.2.3 bentonite granules and chips—irregularly-shaped par-

unique aspects. The word “Standard” in the title of this

ticles of bentonite (free from additives) that have been dried

and separated into a specific size range.

This guide is under the jurisdiction of ASTM Committee D18 on Soil and

Rockand is the direct responsibility of Subcommittee D18.21 on Groundwater and

Vadose Zone Investigations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2006. Published July 2006. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1995. Last previous edition approved in 2000 as D5875 – 95 (2000). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5875-95R06. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5875 − 95 (2006)

3.2.4 bentonite pellets—roughly spherical- or disc-shaped 3.2.16 intermittent sampling devices—usually barrel-type

units of compressed bentonite powder (some pellet manufac- samplers that are driven below the bottom of a borehole with

turers coat the bentonite with chemicals that may affect the drill rods or with a wireline system to lower, drive, and retrieve

water-quality analysis). the sampler following completion of an increment of drilling.

The user is referred to the following standards relating to

3.2.5 coeffıcient of uniformity— C (D), the ratio D /D ,

u 60 10

suggested sampling methods and procedures: Practice D1452,

where D is the particle diameter corresponding to 60 % finer

Test Method D1586, Practice D3550, and Practice D1587.

on the cumulative particle-size distribution curve, and D is

the particle diameter corresponding to 10 % finer on the 3.2.17 in-situ testing devices—sensors or probes, used to

obtain mechanical- or chemical-test data, that are typically

cumulative particle-size distribution curve.

pushed, rotated or driven below the bottom of a borehole

3.2.6 collar—the section of a drill tool between the wrench

following completion of an increment of drilling. However,

square and the pin or box joint.

some in-situ testing devices (such as electronic pressure

3.2.7 dart valve—atypeofvalveusedonabailer,thatopens

transducers, gas-lift samplers, tensiometers, and so forth) may

when the bailer drops through the cuttings at the bottom of the

require lowering and setting of the device(s) in pre-existing

borehole.

boreholes by means of a suspension line or a string of lowering

3.2.8 drill bit—the steel tool on the lower end of the string rods or pipes. Centralizers may be required to correctly

position the device(s) in the borehole.

of tools which does the actual drilling; shaped to perform the

operations of penetration, reaming, crushing, and mixing.

3.2.18 jars—a tool composed of two connected links or

reins with vertical play between them (see Fig. 1 (4)). Drilling

3.2.9 drill hole—a cylindrical hole advanced into the sub-

jars have a stroke of 9- to 18-in. whereas, fishing jars have a

surface by mechanical means. Also known as a borehole or

stroke of 18- to 36-in. (7 mm). Jars permit a sudden upward

boring.

load or shock to loosen a string of tools stuck in the borehole.

3.2.10 drill stem—a steel tool composed of a round bar of

3.2.19 sand pump—bailer made of tubing with a hinge-flap

steelwithapinjointatitsupperendandaboxjointatitslower

valve and a plunger that works inside the barrel. It is used in

end that is placed below the jars in a string of drilling tools to

sand and gravel where the dart-valve bailer will not pick up the

furnish the necessary weight to the tool string.

materials adequately.

3.2.11 drill string—the complete cable-tool drilling assem-

3.2.20 spear—a fishing tool used when the drilling line or

bly including bit, drill rods and connector assemblies (subs).

sand line breaks leaving the drilling tools or bailer in the hole

The total length of this assembly is used to determine drilling

with the line on top of the lost tools.

depth by referencing the position of the top of the string to a

datum near the ground surface.

3.2.21 swivel socket—a socket that permits the tool string to

spin or turn during the drilling action (sometimes referred to as

3.2.12 drive shoe—a forged- or machined-steel collar either

a rope socket).

a threaded- or drop-type attached to the upper joint of casing to

3.2.22 subsurface water-quality monitoring device— an in-

protect the casing threads during driving operations.

strument placed below ground surface to obtain a sample for

3.2.13 filter pack—also known as a gravel pack or primary

analysis of the chemical, biological or radiological character-

filter pack in the practice of monitoring-well installations. The

istics of subsurface pore water or to make in-situ measure-

gravel pack is usually granular material, having specified

ments.

grain-size characteristics, that is placed between a monitoring

3.2.23 wrench square—a square section on any drilling tool

device and the borehole wall. The basic purpose of the filter

by which the joints are set up or broken.

pack or gravel envelope is to act as a non-clogging filter when

the aquifer is not suited to natural development or a formation

stabilizer when the aquifer is suitable for natural development. 4. Significance and Use

3.2.13.1 Discussion—Under most circumstances a clean,

4.1 Cable-toolrigs(alsoreferredtoaschurnrigs,water-well

quartz sand or gravel should be used. In some cases a

drilling rigs, spudders, or percussion rigs) are used in the oil

pre-packed screen may be used.

fields and in the water-well industry. The Chinese developed

the percussion method some 4000 years ago.

3.2.14 grout shoe—a drillable plug containing a check valve

that is positioned within the lowermost section of a casing

4.2 Cable-tool drilling and sampling methods may be used

column. Grout is injected through the check valve to fill the

in support of geoenvironmental exploration and for installation

annular space between the casing and the borehole wall or

of subsurface water-quality monitoring devices in both uncon-

another casing.

solidated and consolidated materials. Cable-tool drilling and

3.2.14.1 Discussion—The composition (or mix) of the drill-

sampling may be selected over other methods based on its

able plug should be known and documented. A grout shoe

advantages,someofwhichareitshighmobility,lowwateruse,

would probably only be installed in a cable-tool drilled hole if

low operating cost, and low maintenance. Cable-tool drilling is

the hole was to be continued on by a rotary-type drilling rig.

3.2.15 grout packer—a reusable inflatable or expandable

annular plug that is attached to a tremie pipe, usually posi-

The boldface numbers given in parentheses refer to a list of references at the

tioned immediately above the discharge end of the pipe. end of the text.

D5875 − 95 (2006)

FIG. 1 Diagram of a Cable Tool Drilling System

the most widely available casing-advancement method that is the bull reel. However, most drill holes for geoenvironmental

restricted to the drilling of unconsolidated materials and softer exploration rarely are required to go that deep. Rates for

rocks. cable-tool drilling and sampling can vary from a general

4.2.1 The application of cable-tool drilling and sampling to average of as much as 25 to 30 ft/h (7.6 to 9 m/h) including

geoenvironmental exploration may involve sampling uncon- setting 8 in. (2.4 m) diameter casing to considerably less than

solidated materials. Depth of drill holes may exceed 3000 ft that depending on the type(s) of material drilled, and the type

(914 m) and may be limited by the length of cable attached to and condition of the equipment and rig used.

D5875 − 95 (2006)

NOTE 2—As a general rule, cable-tool rigs are used to sample the

equipment consists of drill bit (see Fig. 1 (2)—bit used for

surficial materials, and to set surface casing in order that rotary-core rigs

all-around general drilling and, (3)—bit used for chopping and

subsequently may be set up on the drill hole to core drill hard rock if

breaking hard materials and rock), drilling jars (optional), and

coring is required.

a drill stem (see Fig. 1 (1)), with a swivel socket (see Fig. 2)

4.2.2 The cable-tool rig may be used to facilitate the

connected by a wire rope fastened to a drum called a bull reel

installation of a subsurface water-quality monitoring device(s)

that raises and lowers the drilling tools and permits percussion

includingin-situtestingdevices.Themonitoringdevice(s)may

drilling either by crushing the material or by drive sampling.

be installed through the casing as the casing is removed from

The spudding beam, commonly referred to as the walking

the borehole. The sand line can be used to raise, lower, or set

beam, that is driven by the pitman and crank, imparts a

in-situ testing device(s), or all of these. If necessary, the casing

reciprocating motion to the drilling line (see Fig. 3 (6)).

may also be left in the borehole as part of the device.

NOTE 4—All cable-tool rigs have the capacity to lift and drop heavy

NOTE 3—The user may install a monitoring device within the same

drive clamps for installing large-diameter casing in unconsolidated mate-

borehole wherein sampling, in-situ, or pore-fluid testing, or coring was

rials.

performed.

5.2 Water-well drilling rigs have been converted (for the

5. Apparatus

purpose of geoenvironmental-engineering explorations) by

5.1 Cable-tool rigs have a string of drill tools with a drive replacing the jars and stem, and replacing the chopping bit (see

Fig. 1 (3)) with a drive barrel, (see Fig. 4) that is used for

clamp(seeFig.1 (6))onthedrillstringconnectedbywirerope

that periodically can be hoisted and allowed to “fall” for sampling purposes. If the bit becomes stuck in the borehole it

percussion drilling in unconsolidated and consolidated materi-

cannormallybefreedbyupwardblowsofthedrillingjars(jars

als and for driving/retrieving casing. The full string of drilling can also be used in the same mode to extract casing). The

FIG. 2 A Full String of Cable Tools Consists of Five Components That are Necessary for Drilling

D5875 − 95 (2006)

FIG. 3 Drilling Tools

primary function of the drilling jars is to transmit the energy result.Theelementsofthetoolstringarecoupledtogetherwith

from the bull wheel to the drill stem and the sample barrel.The right-hand threaded tool joints of standard API (American

stroke of the drilling jars is 9 to 18 in. (0.23 to 0.46 m) and Petroleum Institute) design and dimension (7).

distinguishes them from fishing jars that have a stroke 18 to 36

5.4 The wire cable that carries and rotates the drilling tool is

in. (0.46 to 0.91 m). Jars are often not used when hard-rock

called the drill line. It is a ⁄8-in. (16-mm) to 1-in. (25-mm)

drilling (6, 7).

left-hand lay cable that twists the tool joint on each upward

5.3 The swivel socket connects the drill string to the cable stroke to prevent it from unscrewing. The drill line is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.